KOMET® – Solid Drilling - komet group

KOMET® – Solid Drilling - komet group

KOMET® – Solid Drilling - komet group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

101<br />

<strong>KOMET®</strong> <strong>–</strong> <strong>Solid</strong> <strong>Drilling</strong> 4<br />

Index 5<br />

Programme Summary <strong>–</strong> <strong>Solid</strong> <strong>Drilling</strong> 6<br />

Adaptors 6<br />

Tools for <strong>Solid</strong> <strong>Drilling</strong>, Trepanning and Flat Bottoming<br />

Programme Summary <strong>–</strong> <strong>Solid</strong> <strong>Drilling</strong> 7<br />

7<br />

<strong>KOMET®</strong> Tool Selection 8<br />

Help Table for <strong>Solid</strong> <strong>Drilling</strong> 8<br />

<strong>KOMET®</strong> Tool Selection 9<br />

Help Table for <strong>Solid</strong> <strong>Drilling</strong> 9<br />

KOMET KUB® Drillmax 10<br />

High-Performance <strong>Solid</strong> Carbide Drill 10<br />

KOMET KUB® Drillmax 11<br />

KOMET KUB® Drillmax 12<br />

High-Performance <strong>Solid</strong> Carbide Drill with Cylindrical Shank DIN 6535 HA / HE, R.H. cutting 12<br />

X 3,0 <strong>–</strong> 16,0 mm 12<br />

5×D 13<br />

High-Performance <strong>Solid</strong> Carbide Drill with Cylindrical Shank DIN 6535 HA / HE, R.H. cutting 13<br />

KOMET KUB® Drillmax 13<br />

KOMET KUB® Drillmax 14<br />

High-Performance <strong>Solid</strong> Carbide Drill with Cylindrical Shank DIN 6535 HA / HE, R.H. cutting 14<br />

X 3,0 <strong>–</strong> 16,0 mm 14<br />

7 <strong>–</strong> 8×D 15<br />

High-Performance <strong>Solid</strong> Carbide Drill with Cylindrical Shank DIN 6535 HA / HE, R.H. cutting 15<br />

KOMET KUB® Drillmax 15<br />

KOMET KUB® Drillmax XL 16<br />

High-Performance <strong>Solid</strong> Carbide Drill with Cylindrical Shank DIN 6535 HA, R.H. cutting 16<br />

X 3,0 <strong>–</strong> 10,0 mm · 20×D 16<br />

X 3,0 <strong>–</strong> 8,0 mm · 30×D 17<br />

High-Performance <strong>Solid</strong> Carbide Drill with Cylindrical Shank DIN 6535 HA, R.H. cutting 17<br />

KOMET KUB® Drillmax XL 17<br />

KOMET KUB® Drillmax, KOMET KUB® Drillmax XL 18<br />

Technical Notes 18<br />

KOMET KUB® Drillmax, KOMET KUB® Drillmax XL 19<br />

Technical Notes 19<br />

KOMET KUB® Drillmax XL 20<br />

5×D / 7<strong>–</strong>8×D 21<br />

Technical Informations 21<br />

KOMET KUB® Drillmax 21<br />

JEL® PCD High-performance Drill<br />

JEL® Drill Reamer 22<br />

Drillcut · Drillmax · Dreammax 23<br />

22<br />

JEL® Drillcut 24 24<br />

PCD High-Performance Drill with Cylindrical Shank DIN 6535 HA, R.H. cutting 24<br />

X 5,0 <strong>–</strong> 12,0 mm · 5×D 24<br />

X 6,0 <strong>–</strong> 10,0 mm · 5×D 25<br />

PCD High-Performance Drill with Cylindrical Shank DIN 6535 HA, R.H. cutting<br />

JEL® Drillmax 22 25<br />

JEL® Dreammax 26<br />

25<br />

Drill Reamer with Cylindrical Shank DIN 6535 HA, R.H. cutting 26<br />

X 6,0 <strong>–</strong> 12,0 mm · 4×D 26<br />

JEL® Drillcut 24 / Drillmax 22 / Dreammax 27<br />

Technical Notes<br />

KOMET KUB K2® 28<br />

27<br />

Replaceable Head Drill for Tiny Diameters 28<br />

KOMET KUB K2®<br />

KOMET KUB K2® 30<br />

29<br />

Replaceable Head Drill with Cylindrical Shank ISO 9766, R.H. cutting<br />

X 10,0 <strong>–</strong> 12,9 mm 30<br />

30<br />

3×D / 5×D / 7×D 31<br />

Replaceable Head Drill with Cylindrical Shank ISO 9766, R.H. cutting<br />

KOMET KUB K2® 31<br />

KOMET KUB K2® 32<br />

31<br />

Replaceable Head Drill with Cylindrical Shank ISO 9766, R.H. cutting<br />

X 13,0 <strong>–</strong> 16,9 mm 32<br />

32<br />

3×D / 5×D / 7×D 33<br />

Replaceable Head Drill with Cylindrical Shank ISO 9766, R.H. cutting<br />

KOMET KUB K2® 33<br />

KOMET KUB K2® 34<br />

33<br />

Replaceable Head Drill with Cylindrical Shank ISO 9766, R.H. cutting<br />

X 17,0 <strong>–</strong> 20,5 mm 34<br />

34<br />

3×D / 5×D 35<br />

Replaceable Head Drill with Cylindrical Shank ISO 9766, R.H. cutting<br />

KOMET KUB K2® 35<br />

KOMET KUB K2® 36<br />

35<br />

Technical Notes<br />

X 10,0 <strong>–</strong> 20,5 mm 36<br />

36<br />

3×D / 5×D / 7×D 37<br />

KOMET KUB K2® 37<br />

Technical Informations 37<br />

KOMET KUB Quatron® 38<br />

Continuous <strong>Drilling</strong> to 3×D 38<br />

KOMET KUB Quatron® 39<br />

KOMET KUB Quatron® 40<br />

Insert Drill with ABS® Connection, R.H. cutting 40<br />

X 14 <strong>–</strong> 33 mm 40<br />

2×D / 3×D 41<br />

Insert Drill with ABS® Connection, R.H. cutting 41<br />

KOMET KUB Quatron® 41<br />

KOMET KUB Quatron® 42<br />

Insert Drill with ABS® Connection, R.H. cutting 42<br />

X 34 <strong>–</strong> 65 mm 42<br />

2×D / 3×D 43<br />

Insert Drill with ABS® Connection, R.H. cutting 43<br />

KOMET KUB Quatron® 43<br />

KOMET KUB Quatron® concept 44 in tool design.<br />

Insert Drill with Cylindrical Shank (Combination Shank), R.H. cutting 44<br />

X 14 <strong>–</strong> 33 mm 44<br />

2×D / 3×D 45<br />

Insert Drill with Cylindrical Shank (Combination Shank), R.H. cutting 45<br />

KOMET KUB Quatron® 45<br />

KOMET KUB Quatron® 46<br />

Insert Drill with Cylindrical Shank (Combination Shank), R.H. cutting 46<br />

X 34 <strong>–</strong> 44 mm 46<br />

2×D / 3×D 47<br />

Insert Drill with Cylindrical Shank (Combination Shank), R.H. cutting 47<br />

KOMET KUB Quatron® 47<br />

KOMET KUB Quatron® 48<br />

Technical Notes 48<br />

X 14 <strong>–</strong> 65 mm 48<br />

2×D / 3×D 49<br />

KOMET KUB Quatron® 49<br />

Technical Notes 49<br />

KOMET KUB Quatron® 50<br />

Technical Informations 50<br />

2×D 50<br />

3×D 51<br />

<strong>KOMET®</strong> <strong>–</strong> <strong>Solid</strong> <strong>Drilling</strong><br />

4<br />

KOMET KUB Quatron® 51<br />

Technical Informations 51<br />

KOMET KUB Quatron® 52<br />

Alternative Inserts 52<br />

2×D / 3×D 52<br />

Problems � Possible causes � Solutions 53<br />

KOMET KUB Quatron® 53<br />

KOMET KUB Pentron® 54<br />

Continuous <strong>Drilling</strong> to 5×D 54<br />

KOMET KUB Pentron® 55<br />

KOMET KUB Pentron® 56<br />

Insert Drill with ABS® Connection, R.H. cutting<br />

X 14,0 <strong>–</strong> 26,0 mm 56<br />

56<br />

4×D / 5×D 57<br />

Insert Drill with ABS® Connection, R.H. cutting 57<br />

KOMET KUB Pentron® 57<br />

KOMET KUB Pentron® 58<br />

Insert Drill with ABS® Connection, R.H. cutting<br />

X 26,2 <strong>–</strong> 37,0 mm 58<br />

58<br />

4×D / 5×D 59<br />

Insert Drill with ABS® Connection, R.H. cutting 59<br />

KOMET KUB Pentron® 59<br />

KOMET KUB Pentron® 60<br />

Insert Drill with ABS® Connection, R.H. cutting<br />

X 37,3 <strong>–</strong> 46,0 mm 60<br />

60<br />

4×D / 5×D 61<br />

Insert Drill with ABS® Connection, R.H. cutting 61<br />

KOMET KUB Pentron® 61<br />

KOMET KUB Pentron® 62<br />

Insert Drill with Cylindrical Shank ISO 9766, R.H. cutting<br />

X 14,0 <strong>–</strong> 26,0 mm 62<br />

62<br />

4×D / 5×D 63<br />

Insert Drill with Cylindrical Shank ISO 9766, R.H. cutting 63<br />

KOMET KUB Pentron® 63<br />

KOMET KUB Pentron® 64<br />

Insert Drill with Cylindrical Shank ISO 9766, R.H. cutting<br />

X 26,2 <strong>–</strong> 37,0 mm 64<br />

64<br />

4×D / 5×D 65<br />

Insert Drill with Cylindrical Shank ISO 9766, R.H. cutting 65<br />

KOMET KUB Pentron® 65<br />

KOMET KUB Pentron® 66<br />

Insert Drill with Cylindrical Shank ISO 9766, R.H. cutting<br />

X 37,3 <strong>–</strong> 46,0 mm 66<br />

66<br />

4×D / 5×D 67<br />

Insert Drill with Cylindrical Shank ISO 9766, R.H. cutting 67<br />

KOMET KUB Pentron® 67<br />

KOMET KUB Pentron® 68<br />

Technical Notes<br />

X 14,0 <strong>–</strong> 46,0 mm 68<br />

68<br />

4×D 69<br />

Technical Notes 69<br />

KOMET KUB Pentron® 69<br />

KOMET KUB Pentron® 70<br />

Technical Notes<br />

X 14,0 <strong>–</strong> 46,0 mm 70<br />

70<br />

5×D 71<br />

Technical Notes 71<br />

KOMET KUB Pentron® 71<br />

KOMET KUB Pentron® 72<br />

Technical Informations 72<br />

4×D / 5×D 72<br />

Alternative Inserts 73<br />

KOMET KUB Pentron® 73<br />

KOMET KUB Trigon® / KUB® Drill 74<br />

Continuous <strong>Drilling</strong> to 4×D 74<br />

KOMET KUB Trigon®<br />

KOMET KUB® 75<br />

75<br />

KOMET KUB Trigon® 76<br />

Insert Drill with ABS® Connection, R.H. cutting 76<br />

X 14 <strong>–</strong> 44 mm 76<br />

2×D / 3×D / 4×D 77<br />

Insert Drill with ABS® Connection, R.H. cutting 77<br />

KOMET KUB Trigon® 77<br />

KOMET KUB Trigon® 78<br />

Insert Drill with ABS® Connection, R.H. cutting 78<br />

X 14 <strong>–</strong> 44 mm 78<br />

2×D / 3×D / 4×D 79<br />

KOMET KUB Trigon® 79<br />

Technical Notes 79<br />

KOMET KUB Trigon® 80<br />

Insert Drill with Cylindrical Shank (Combination Shank), R.H. cutting 80<br />

X 12 <strong>–</strong> 19,5 mm 80<br />

2×D / 3×D / 4×D 81<br />

Insert Drill with Cylindrical Shank (Combination Shank), R.H. cutting 81<br />

KOMET KUB Trigon® 81<br />

KOMET KUB Trigon® 82<br />

Insert Drill with Cylindrical Shank (Combination Shank), R.H. cutting 82<br />

X 20 <strong>–</strong> 29,5 mm 82<br />

2×D / 3×D / 4×D 83<br />

Insert Drill with Cylindrical Shank (Combination Shank), R.H. cutting 83<br />

KOMET KUB Trigon® 83<br />

KOMET KUB Trigon® 84<br />

Insert Drill with Cylindrical Shank (Combination Shank), R.H. cutting 84<br />

X 30 <strong>–</strong> 44 mm 84<br />

2×D / 3×D / 4×D 85<br />

level of quality.<br />

Insert Drill with Cylindrical Shank (Combination Shank), R.H. cutting 85<br />

KOMET KUB Trigon® 85<br />

KOMET KUB Trigon® 86<br />

Insert Drill with Cylindrical Shank (Combination Shank), R.H. cutting 86<br />

X 12 <strong>–</strong> 44 mm 86<br />

2×D / 3×D / 4×D 87<br />

KOMET KUB Trigon® 87<br />

Technical Notes 87<br />

KOMET KUB Trigon® 88<br />

Insert Drill with Cylindrical Shank (parallel clamping surface), R.H. cutting 88<br />

X 14 <strong>–</strong> 19,5 mm 88<br />

3×D / 4×D 89<br />

Insert Drill with Cylindrical Shank (parallel clamping surface), R.H. cutting 89<br />

KOMET KUB Trigon® 89<br />

KOMET KUB Trigon® 90<br />

Insert Drill with Cylindrical Shank (parallel clamping surface), R.H. cutting 90<br />

X 20 <strong>–</strong> 29,5 mm 90<br />

3×D / 4×D 91<br />

Insert Drill with Cylindrical Shank (parallel clamping surface), R.H. cutting 91<br />

KOMET KUB Trigon® 91<br />

KOMET KUB Trigon® 92<br />

Insert Drill with Cylindrical Shank (parallel clamping surface), R.H. cutting 92<br />

X 30 <strong>–</strong> 54 mm 92<br />

3×D / 4×D 93<br />

Insert Drill with Cylindrical Shank (parallel clamping surface), R.H. cutting 93<br />

KOMET KUB Trigon® 93<br />

KOMET KUB Trigon® 94<br />

Insert Drill with Cylindrical Shank (parallel clamping surface), R.H. cutting 94<br />

X 14 <strong>–</strong> 54 mm, 3×D / 4×D 94<br />

2×D / 3×D / 4×D 95<br />

KOMET KUB Trigon® 95<br />

Alternative Inserts 95<br />

KOMET KUB Trigon® 96<br />

Insert Drill with ABS® Connection, L.H. cutting 96<br />

X 14 <strong>–</strong> 44 mm 96<br />

2×D / 3×D 97<br />

Insert Drill with ABS® Connection, L.H. cutting 97<br />

KOMET KUB Trigon® 97<br />

KOMET KUB Trigon® 98<br />

Insert Drill with ABS® Connection, L.H. cutting 98<br />

X 14 <strong>–</strong> 44 mm 98<br />

2×D / 3×D 99<br />

KOMET KUB Trigon® 99<br />

Alternative Inserts 99<br />

KOMET KUB Trigon® 100<br />

Insert Drill with Cylindrical Shank (parallel clamping surface), L.H. cutting 100<br />

X 14 <strong>–</strong> 54 mm 100<br />

3×D 101<br />

Insert Drill with Cylindrical Shank (parallel clamping surface), L.H. cutting 101<br />

KOMET KUB Trigon® 101<br />

KOMET KUB Trigon® 102<br />

Insert Drill with Cylindrical Shank (parallel clamping surface), L.H. cutting 102<br />

X 14 <strong>–</strong> 54 mm 102<br />

3×D 103<br />

KOMET KUB Trigon® 103<br />

Alternative Inserts 103<br />

KOMET KUB® 104<br />

Insert Drill with ABS® Connection, R.H. cutting 104<br />

X 38,5 <strong>–</strong> 82 mm 104<br />

3×D 105<br />

Insert Drill with ABS® Connection, R.H. cutting 105<br />

KOMET KUB® 105<br />

KOMET KUB® 106<br />

Insert Drill with ABS® Connection, R.H. cutting 106<br />

X 38,5 <strong>–</strong> 82 mm 106<br />

3×D 107<br />

Alternative Inserts 107<br />

KOMET KUB® 107<br />

KOMET KUB® 108<br />

Insert Drill with ABS® Connection, R.H. cutting 108<br />

X 45 <strong>–</strong> 82 mm 108<br />

2×D / 3×D 109<br />

Insert Drill with ABS® Connection, R.H. cutting 109<br />

KOMET KUB® 109<br />

KOMET KUB® 110<br />

Insert Drill with ABS® Connection, R.H. cutting 110<br />

X 45 <strong>–</strong> 82 mm 110<br />

2×D / 3×D 111<br />

Alternative Inserts 111<br />

KOMET KUB® 111<br />

KOMET KUB® / KUB Trigon® 112<br />

Technical Informations 112<br />

2×D 112<br />

3×D 113<br />

KOMET KUB® / KUB Trigon® 113<br />

Technical Informations 113<br />

KOMET KUB Trigon® 114<br />

Technical Notes 114<br />

4×D 114<br />

Problems � Possible causes � Solutions 115<br />

KOMET KUB® / KUB Trigon® 115<br />

KOMET KUB Duon® 116<br />

Continuous <strong>Drilling</strong> to 5×D 116<br />

KOMET KUB Duon® 117<br />

KOMET KUB Duon® 118<br />

Twin Cutting Drill with ABS® Connection and Cylindrical Shank, R.H. cutting<br />

118<br />

X 17,3 <strong>–</strong> 20,7 mm 118<br />

5×D 119<br />

Twin Cutting Drill with ABS® Connection and Cylindrical Shank, R.H. cutting<br />

119<br />

KOMET KUB Duon® 119<br />

KOMET KUB Duon® 120<br />

Twin Cutting Drill with ABS® Connection and Cylindrical Shank, R.H. cutting<br />

120<br />

X 20,8 <strong>–</strong> 24,2 mm 120<br />

5×D 121<br />

Twin Cutting Drill with ABS® Connection and Cylindrical Shank, R.H. cutting<br />

121<br />

KOMET KUB Duon® 121<br />

KOMET KUB Duon® 122<br />

Twin Cutting Drill with ABS® Connection and Cylindrical Shank, R.H. cutting<br />

122<br />

X 24,3 <strong>–</strong> 27,7 mm 122<br />

5×D 123<br />

Twin Cutting Drill with ABS® Connection and Cylindrical Shank, R.H. cutting<br />

123<br />

KOMET KUB Duon® 123<br />

KOMET KUB Duon® 124<br />

Twin Cutting Drill with ABS® Connection and Cylindrical Shank, R.H. cutting<br />

124<br />

X 27,8 <strong>–</strong> 31,2 mm 124<br />

5×D 125<br />

Twin Cutting Drill with ABS® Connection and Cylindrical Shank, R.H. cutting<br />

125<br />

KOMET KUB Duon® 125<br />

KOMET KUB Duon® 126<br />

Twin Cutting Drill with ABS® Connection and Cylindrical Shank, R.H. cutting<br />

126<br />

X 31,3 <strong>–</strong> 34,7 mm 126<br />

5×D 127<br />

Twin Cutting Drill with ABS® Connection and Cylindrical Shank, R.H. cutting<br />

127<br />

KOMET KUB Duon® 127<br />

KOMET KUB Duon® 128<br />

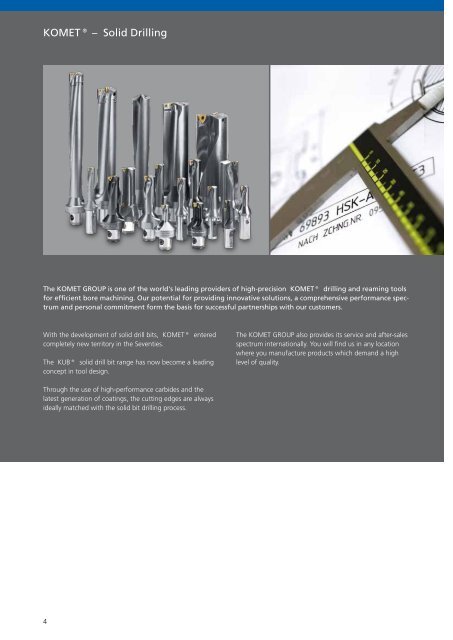

The KOMET GROUP is one of the world's leading providers of high-precision <strong>KOMET®</strong> drilling and reaming tools<br />

for efficient bore machining. Our potential for providing innovative solutions, a comprehensive performance spectrum<br />

and personal commitment form the basis for successful partnerships with our customers.<br />

With the development of solid drill bits, <strong>KOMET®</strong> entered<br />

completely new territory in the Seventies.<br />

The KUB® solid drill bit range has now become a leading<br />

Through the use of high-performance carbides and the<br />

latest generation of coatings, the cutting edges are always<br />

ideally matched with the solid bit drilling process.<br />

The KOMET GROUP also provides its service and after-sales<br />

spectrum internationally. You will find us in any location<br />

where you manufacture products which demand a high

Twin Cutting Drill with ABS® Connection and Cylindrical Shank, R.H. cutting 128<br />

X 34,8 <strong>–</strong> 38,2 mm 128<br />

5×D 129<br />

Twin Cutting Drill with ABS® Connection and Cylindrical Shank, R.H. cutting 129<br />

KOMET KUB Duon® 129<br />

KOMET KUB Duon® 130<br />

Twin Cutting Drill with ABS® Connection, R.H. cutting 130<br />

X 38,3 <strong>–</strong> 41,7 mm 130<br />

5×D 131<br />

Twin Cutting Drill with ABS® Connection, R.H. cutting 131<br />

KOMET KUB Duon® 131<br />

KOMET KUB Duon® 132<br />

Twin Cutting Drill with ABS® Connection, R.H. cutting 132<br />

X 41,8 <strong>–</strong> 44,2 mm 132<br />

5×D 133<br />

Twin Cutting Drill with ABS® Connection, R.H. cutting 133<br />

KOMET KUB Duon® 133<br />

KOMET KUB Duon® 134<br />

Twin Cutting Drill with ABS® Connection and Cylindrical Shank, R.H. cutting 134<br />

X 17,3 <strong>–</strong> 44,2 mm 134<br />

5×D 135<br />

Twin Cutting Drill with ABS® Connection and Cylindrical Shank, R.H. cutting 135<br />

KOMET KUB Duon® 135<br />

for pre-centering from drilling depth > 5×D 135<br />

KOMET KUB Duon® 136<br />

Technical Notes 136<br />

5×D 136<br />

Problems � Possible causes � Solutions 137<br />

KOMET KUB Duon® 137<br />

KOMET KUB Centron® 138<br />

Continuous <strong>Drilling</strong> to 9×D 138<br />

KOMET KUB Centron® 139<br />

KOMET KUB® V464 139<br />

KOMET KUB Centron® 140<br />

Insert Drill (drill head/basic element) with ABS® Connection, R.H. cutting 140<br />

X 20 <strong>–</strong> 54 mm 140<br />

4×D <strong>–</strong> 9×D 141<br />

Insert Drill (drill head/basic element) with ABS® Connection, R.H. cutting 141<br />

KOMET KUB Centron® 141<br />

KOMET KUB Centron® 142<br />

Insert Drill (drill head/basic element) with ABS® Connection, R.H. cutting 142<br />

X 55 <strong>–</strong> 81 mm 142<br />

4×D <strong>–</strong> 9×D 143<br />

Insert Drill (drill head/basic element) with ABS® Connection, R.H. cutting 143<br />

KOMET KUB Centron® 143<br />

KOMET KUB Centron® 144<br />

Technical Notes 144<br />

X 20 <strong>–</strong> 81 mm 144<br />

4×D <strong>–</strong> 9×D 145<br />

Alternative Inserts 145<br />

KOMET KUB Centron® 145<br />

KOMET KUB Centron® 146<br />

Assembly Parts / Accessories 146<br />

X 20 <strong>–</strong> 64 mm 146<br />

X 65 <strong>–</strong> 81 mm 147<br />

Assembly Parts / Accessories 147<br />

KOMET KUB Centron® 147<br />

KOMET KUB Centron® 148<br />

Technical Notes 148<br />

9×D 148<br />

Problems � Possible causes � Solutions 149<br />

KOMET KUB Centron® 149<br />

KOMET KUB Centron® 150<br />

Mounting Instructions 150<br />

X 20 <strong>–</strong> 64 mm 150<br />

X 65 <strong>–</strong> 81 mm 151<br />

Mounting Instructions 151<br />

KOMET KUB Centron® 151<br />

KOMET KUB® V464 152<br />

Insert Drill (drill head) with ABS® T Connection, R.H. cutting 152<br />

X 80 <strong>–</strong> 155 mm 152<br />

6×D 153<br />

Assembly Parts / Accessories 153<br />

KOMET KUB® V464 153<br />

KOMET KUB® V464 154<br />

Technical Notes 154<br />

X 80 <strong>–</strong> 155 mm 154<br />

6×D 155<br />

Alternative Inserts 155<br />

KOMET KUB® V464 155<br />

KOMET KUB® V50 156<br />

Drill Head with ABS® Connection, Taper or VDI Shank, R.H. cutting 156<br />

X 83 <strong>–</strong> 128 mm 156<br />

4×D 157<br />

Drill Head with ABS® Connection, Taper or VDI Shank, R.H. cutting 157<br />

KOMET KUB® V50 157<br />

<strong>KOMET®</strong> V71 158<br />

Flat Bottoming Tool with ABS® Connection, R.H. cutting 158<br />

X 37 <strong>–</strong> 64 mm 158<br />

3×D 159<br />

Flat Bottoming Tool with ABS® Connection, R.H. cutting 159<br />

<strong>KOMET®</strong> V71 159<br />

<strong>KOMET®</strong> 160<br />

Trepannning tool with ABS® connection, taper or VDI shank, R.H. cutting 160<br />

X 83 <strong>–</strong> 198 mm 160<br />

X 14 <strong>–</strong> 82 mm 161<br />

Stacked Plate Tool with ABS® connection, R.H. cutting 161<br />

<strong>KOMET®</strong> 161<br />

Index Page<br />

Programme summary<br />

Tool selection<br />

<strong>Solid</strong> drilling tools<br />

KUB® Drillmax / KUB® Drillmax XL<br />

JEL® Drillcut 24<br />

JEL® Drillmax 22<br />

JEL® Dreammax<br />

KUB K2®<br />

KUB Quatron®<br />

KUB Pentron®<br />

KUB Trigon®<br />

KUB® drill<br />

KUB Duon®<br />

KUB Centron®<br />

KUB® V464<br />

KUB® drill head<br />

Flat-bottoming tool<br />

Trepannning tool<br />

Packet drill<br />

Easy Special<br />

6 <strong>–</strong> 7<br />

8 <strong>–</strong> 9<br />

10 <strong>–</strong> 21<br />

22 <strong>–</strong> 24<br />

25<br />

26 <strong>–</strong> 27<br />

28 <strong>–</strong> 37<br />

38 <strong>–</strong> 53<br />

54 <strong>–</strong> 73<br />

74 <strong>–</strong> 103<br />

104 <strong>–</strong> 115<br />

116 <strong>–</strong> 137<br />

138 <strong>–</strong> 151<br />

152 <strong>–</strong> 155<br />

156 <strong>–</strong> 157<br />

158 <strong>–</strong> 159<br />

160<br />

161<br />

Chapter 4<br />

5<br />

1

1<br />

Programme Summary <strong>–</strong> <strong>Solid</strong> <strong>Drilling</strong><br />

6<br />

5<br />

Adaptors<br />

HSK-A Adaptors<br />

with ABS® connection<br />

E 400<br />

HSK-A 50<br />

HSK-A 63<br />

HSK-A100<br />

HSK-A 50<br />

HSK-A 63<br />

HSK-A 80<br />

HSK-A100<br />

HSK-A 50<br />

HSK-A 63<br />

HSK-A100<br />

Eccentric adjusting device with ABS® connection<br />

E 402<br />

HSK-A 63<br />

HSK-A100<br />

SK 40<br />

SK 45<br />

SK 50<br />

Expanding chuck<br />

E 448<br />

SK 40<br />

ABS 50<br />

ABS 63<br />

ABS 80<br />

ABS 100<br />

Thermal expansion chuck<br />

E 490 x 6<br />

x 6<br />

x 8<br />

x 10<br />

x 12<br />

x 14<br />

x 16<br />

ABS 50<br />

ABS 63<br />

x 12<br />

x 16<br />

Adaptor sleeve Weldon / cylindrical shank (combination shank)<br />

E 447 / 444<br />

SK 40<br />

SK 50<br />

Eccentric adjusting device with ABS® connection<br />

E 434<br />

SK 40<br />

SK 50<br />

SK 40<br />

SK 50<br />

x 20<br />

x 25<br />

x 32<br />

Thermal expansion chuck<br />

E 496 x 6<br />

SK 40<br />

SK 50<br />

HSK-A 32<br />

HSK-A 40<br />

HSK-A 50<br />

HSK-A 63<br />

HSK-A100<br />

Expanding chuck<br />

E 410<br />

Adaptor sleeve Weldon<br />

E 406<br />

Taper shanks DIN 69871<br />

with ABS® connection<br />

E 430<br />

x 8<br />

x 10<br />

x 12<br />

x 14<br />

x 16<br />

ABS 50<br />

ABS 63<br />

ABS 80<br />

ABS 100<br />

x 8<br />

x 10<br />

x 12<br />

x 14<br />

x 16<br />

x 20<br />

x 25<br />

x 32<br />

x 40<br />

ABS 50<br />

ABS 63<br />

Torsional dampener with ABS® connection<br />

E 435<br />

ABS 50<br />

ABS 63<br />

ABS 80<br />

x 6<br />

x 8<br />

x 10<br />

ABS® Adaptors<br />

Extension / Reducer<br />

E 466 / 464<br />

ABS 50<br />

ABS 63<br />

ABS 80<br />

ABS 100<br />

with ABS®<br />

connection<br />

E 458<br />

NC 3020<br />

NC 4020<br />

NC 5020<br />

NC 6020<br />

ABS 63<br />

ABS 80<br />

ABS 100<br />

ABS 125<br />

Adjustment device<br />

E 461<br />

ABS 50<br />

ABS 63<br />

Eccentric adjusting device<br />

E 462<br />

ABS 50<br />

ABS 63<br />

Expanding chuck<br />

E 482<br />

ABS 40<br />

ABS 50<br />

ABS 63<br />

Thermal expansion chuck<br />

E 502<br />

ABS 32<br />

ABS 40<br />

ABS 50<br />

ABS 63<br />

Adaptor sleeve Weldon<br />

E 474<br />

ABS 50<br />

ABS 63<br />

ABS 80<br />

Adaptor sleeve Whistle Notch<br />

E 472<br />

ABS 50<br />

ABS 63<br />

ABS 80<br />

Spindle adaptor flange<br />

DIN 2079<br />

ISO 30<br />

ISO 40<br />

ISO 50<br />

VDI Adaptor<br />

with ABS® connection<br />

E 456<br />

ABS 50<br />

ABS 63<br />

ABS 50<br />

ABS 63<br />

x 6<br />

x 8<br />

x 10<br />

x 12<br />

x 14<br />

x 16<br />

x 20<br />

x 25<br />

x 32<br />

x 20<br />

x 25<br />

x 32<br />

ABS 50<br />

ABS 63<br />

ABS 80<br />

ABS 100<br />

ABS 50<br />

ABS 63<br />

ABS 80<br />

ABS 100<br />

PSC Adaptors ISO 26623<br />

Capto* interface with ABS® connection<br />

E 460<br />

*Capto is a SANDVIK<br />

brand name<br />

C5<br />

C6<br />

C8<br />

ABS 50<br />

ABS 63<br />

ABS 80<br />

ABS 50<br />

ABS 63<br />

ABS 80<br />

ABS 100<br />

x 6<br />

x 8<br />

x 10<br />

x 12<br />

x 14<br />

x 16<br />

Further adaptors see chapter 5.

1<br />

ABS 50<br />

ABS 63<br />

ABS 80<br />

ABS 50<br />

ABS 63<br />

ABS 50<br />

ABS 50<br />

ABS 63<br />

ABS 80<br />

ABS 50<br />

ABS 63<br />

ABS 50<br />

ABS 63<br />

ABS 80<br />

ABS 100<br />

ABS 50<br />

ABS 63<br />

ABS 80<br />

ABS 50<br />

ABS 63<br />

ABS 80<br />

ABS 50<br />

ABS 63<br />

ABS 80<br />

ABS 50<br />

Tools for <strong>Solid</strong> <strong>Drilling</strong>, Trepanning and Flat Bottoming<br />

with ABS® connection<br />

KUB Quatron®<br />

x 14 <strong>–</strong> 65 mm<br />

E 40 <strong>–</strong> 43<br />

KUB Pentron®<br />

x 14 <strong>–</strong> 46 mm<br />

E 56 <strong>–</strong> 61<br />

KUB Trigon®<br />

x 14 <strong>–</strong> 44 mm<br />

E 76 <strong>–</strong> 77<br />

KUB® drill<br />

x 38,5 <strong>–</strong> 82 mm<br />

E 104 <strong>–</strong> 105<br />

KUB Duon®<br />

x 17,3 <strong>–</strong> 44,2 mm<br />

E 118 <strong>–</strong> 133<br />

KUB Centron®<br />

x 20 <strong>–</strong> 81 mm<br />

E 140 <strong>–</strong> 143<br />

KUB® V464<br />

x 80 <strong>–</strong> 155 mm<br />

E 154<br />

Flat-bottoming tool<br />

x 37 <strong>–</strong> 64 mm<br />

E 158<br />

Packet drill<br />

x 14 <strong>–</strong> 82 mm<br />

E 161<br />

Easy Special<br />

x 14 <strong>–</strong> 44 mm<br />

E Chapter 4<br />

Programme Summary <strong>–</strong> <strong>Solid</strong> <strong>Drilling</strong><br />

with cylindrical shank<br />

x 6<br />

x 8<br />

x 10<br />

x 12<br />

x 14<br />

x 16<br />

x 6<br />

x 8<br />

x 10<br />

x 12<br />

x 6<br />

x 8<br />

x 10<br />

x 6<br />

x 8<br />

x 10<br />

x 12<br />

x 16<br />

x 20<br />

x 25<br />

x 32<br />

x 40<br />

x 20<br />

x 25<br />

x 32<br />

x 40<br />

x 20<br />

x 25<br />

x 32<br />

x 20<br />

x 25<br />

x 32<br />

x 40<br />

x 25<br />

x 32<br />

x 40<br />

x 20<br />

x 25<br />

x 32<br />

x 40<br />

Key<br />

ABS® connection<br />

ABS® connection<br />

Cylindrical connection<br />

Whistle Notch connection<br />

Weldon connection<br />

Shrink connection<br />

KUB® drill head<br />

larger sizes on request<br />

Trepannning tool<br />

on request<br />

KUB® Drillmax<br />

x 3 <strong>–</strong> 16 mm<br />

E 12 <strong>–</strong> 17<br />

JEL® Drillcut 24<br />

x 5 <strong>–</strong> 12 mm<br />

E 24<br />

JEL® Drillmax 22<br />

x 6 <strong>–</strong> 10 mm<br />

E 25<br />

JEL® Dreammax<br />

x 6 <strong>–</strong> 12 mm<br />

E 26<br />

KUB K2®<br />

x 10 <strong>–</strong> 20,5 mm<br />

E 30 <strong>–</strong> 35<br />

KUB Quatron®<br />

x 14 <strong>–</strong> 44 mm<br />

E 44 <strong>–</strong> 47<br />

KUB Pentron®<br />

x 14 <strong>–</strong> 46 mm<br />

E 62 <strong>–</strong> 67<br />

KUB Trigon®<br />

x 12 <strong>–</strong> 44 mm<br />

E 80 <strong>–</strong> 85<br />

KUB Trigon®<br />

x 14 <strong>–</strong> 54 mm<br />

E 88 <strong>–</strong> 93<br />

KUB Duon®<br />

x 17,3 <strong>–</strong> 44,2 mm<br />

E 118 <strong>–</strong> 129<br />

Easy Special<br />

x 14 <strong>–</strong> 44 mm<br />

E Chapter 4<br />

x 83 <strong>–</strong> 128 mm<br />

E 156<br />

x 83 <strong>–</strong> 198 mm<br />

E 160<br />

7<br />

1

1<br />

<strong>KOMET®</strong> Tool Selection<br />

Help Table for <strong>Solid</strong> <strong>Drilling</strong><br />

8<br />

X (mm) L / D<br />

Machining<br />

3,0 <strong>–</strong> 16,0<br />

3,0 <strong>–</strong> 10,0<br />

5×D<br />

7-8×D<br />

20×D<br />

30×D<br />

§ § $ & & & & $ &<br />

§ § $ & & & & &<br />

5,0 <strong>–</strong> 12,0 5×D § § & & & & & &<br />

6,0 <strong>–</strong> 10,0 5×D § § & & & & & &<br />

6,0 <strong>–</strong> 12,0 4×D § § & & & & & & &<br />

10,0 <strong>–</strong> 20,5 +0,05<br />

14,0 <strong>–</strong> 65,0 ±0,2<br />

3 <strong>–</strong><br />

7×D<br />

§ § & & § §<br />

2×D § § § § § § § § § $ $<br />

3×D § § § § § § § § § $ $<br />

14,0 <strong>–</strong> 46,0 +0,3<br />

<strong>–</strong>0,1 4×D § § $ $ $ $ $ & $ $<br />

14,0 <strong>–</strong> 46,0 +0,35<br />

<strong>–</strong>0,1 5×D § § $ $ $ $ $ $ $<br />

12,0 <strong>–</strong> 44,0 ±0,1 2×D § § § § § § $ § $ §<br />

12,0 <strong>–</strong> 54,0 ±0,1 3×D § § $ $ $ $ $ $ & §<br />

14,0 <strong>–</strong> 44,0 ±0,1 4×D § § & & & & & & $<br />

38,5 <strong>–</strong> 82,0 +1,0<br />

<strong>–</strong>0,5 3×D § § & & & & & & & $<br />

45,0 <strong>–</strong> 82,0 ±0,2<br />

2×D § § § § § $ $ § $ $<br />

3×D § § § $ $ $ $ $ $<br />

17,3 <strong>–</strong> 44,2 ±0,1 5×D § § $ & $ $ & $ § &<br />

20,0 <strong>–</strong> 81,0 ±0,1 9×D § § $ & & & & &<br />

80,0 <strong>–</strong> 155,0 6×D § § $ & & & & & §<br />

83,0 <strong>–</strong> 128,0 ±0,4 4×D § § $ & & & & &<br />

83,0 <strong>–</strong> 198,0 ±0,5 3×D § $ $ $ $ § §<br />

37,0 <strong>–</strong> 64,0 ±0,5 3×D $ § §<br />

14,0 <strong>–</strong> 82,0<br />

14,0 <strong>–</strong> 44,0<br />

Length/<br />

diameter<br />

ratio<br />

2×D $ $ $ & $ $ $ $ § & &<br />

3×D $ $ $ & $ $ $ $ § & &<br />

1,5 -<br />

4×D<br />

solid<br />

drilling<br />

blind<br />

hole<br />

forge/<br />

casting skin,<br />

interface<br />

angled start<br />

and drilling<br />

out, interrupted<br />

cut<br />

convex cross bore centering<br />

bore,<br />

seam<br />

chamber stack plate<br />

drilling<br />

rough<br />

boring<br />

adjustable<br />

§ § § $ $ $ $ $ §<br />

§ very good $ good & possible: see technical notes

§ $ § $ $<br />

§ $ § $ $<br />

P M K N S H<br />

E 12 <strong>–</strong> 17<br />

§<br />

JEL® Drillcut 24 PCD<br />

cylindrical shank DIN 6535 HA<br />

E 24<br />

§<br />

JEL® Drillmax 22 PCD<br />

cylindrical shank DIN 6535 HA<br />

E 25<br />

§ §<br />

JEL® Dreammax<br />

cylindrical shank DIN 6535 HA<br />

E 26<br />

§ $ § $ §<br />

KUB K2®<br />

cylindrical shank ISO 9766<br />

E 30 <strong>–</strong> 35<br />

§ $ § $ § § § § § §<br />

§ $ § $ § § § § § §<br />

§ $ $ § § § § $<br />

§ $ $ § § § § $<br />

§ $ § $ § § § § § §<br />

§ $ § & § § § § §<br />

§ & § & § § § §<br />

E 40 <strong>–</strong> 47<br />

E 56 <strong>–</strong> 67<br />

E 76 <strong>–</strong> 93<br />

E 96 <strong>–</strong> 101<br />

KUB® drill adjustable<br />

§ & $ & § § § § E 104 <strong>–</strong> 105<br />

ABS® connection<br />

§ $ $ $ § § § § § §<br />

§ & $ & § § § § §<br />

E 108 <strong>–</strong> 109<br />

§ & § & § § § §<br />

KUB Duon®<br />

ABS® connection<br />

cylindrical shank (combination shank)<br />

E 118 <strong>–</strong> 133<br />

KUB Centron®<br />

§ & § § § § E 138 <strong>–</strong> 141<br />

ABS® connection<br />

KUB® V464 drill head<br />

§ & § § § § E 154<br />

ABS® T connection<br />

§ & $ & § § § § KUB® drill head<br />

E 156<br />

§ & $ & § § § § Trepannning tool<br />

E 160<br />

Flat-bottoming tool<br />

§ $ $ & § § § § E 158<br />

ABS® connection<br />

§ $ $ & § $ § $<br />

§ & $ & § $ § $<br />

§ $ $ & § § § § § Easy Special<br />

L.H. cutting<br />

<strong>KOMET®</strong> Tool Selection<br />

Help Table for <strong>Solid</strong> <strong>Drilling</strong><br />

Coolant Material Tool Page<br />

Emulsion MQL<br />

internal<br />

external<br />

internal<br />

external<br />

MQL only with<br />

cylindrical shank<br />

Mild steel/<br />

tool steel<br />

Stainless and acidresistant<br />

steel<br />

Grey cast iron,<br />

spheroidal cast iron<br />

Non-ferrous<br />

metals<br />

Heat-resistant<br />

steels<br />

Hardened tool<br />

steel<br />

KUB® Drillmax<br />

cylindrical shank DIN 6535 HA<br />

cylindrical shank DIN 6535 HE<br />

KUB Quatron®<br />

ABS® connection<br />

cylindrical shank (combination shank)<br />

KUB Pentron®<br />

ABS® Verbindung<br />

cylindrical shank ISO 9766<br />

KUB Trigon®<br />

ABS® connection<br />

cylindrical shank (combination shank)<br />

VDI kompatibel<br />

KUB® drill<br />

ABS® connection<br />

Packet drill<br />

E 161<br />

Chapter 4<br />

9<br />

1

1<br />

KOMET KUB® Drillmax High-Performance <strong>Solid</strong> Carbide Drill<br />

KUB® Drillmax<br />

High-performance drill for small diameters<br />

The KUB® Drillmax high-performance solid carbide drills<br />

complete our range for drill diameters of 3 to 16 mm and<br />

length/diameter ratios of 5×D and 7-8×D.<br />

Optimised, special flutes are ideal for removing chips and<br />

for highly productive machining.<br />

Variant:<br />

- Drill diameter: 3.00 <strong>–</strong> 16.00 mm<br />

- Hole tolerance: IT9 (achievable)<br />

- <strong>Drilling</strong> depth: 5×D, 7-8×D<br />

- Shank shape: HA and HE (DIN 6535)<br />

- Coating: TiAlN<br />

- Point angle: 140°<br />

- Helix angle: 30°<br />

- Internal coolant supply<br />

KUB® Drillmax XL<br />

High-performance drill for deep holes<br />

With the KOMET KUB® Drillmax XL, the expertise gained<br />

from developing many special solutions has been transferred<br />

to a standard tool range, which is available from stock for<br />

20×D in diameters of 3.0 to 10.0 mm and for 30×D in<br />

diameters of 3.0 to 8.0 mm.<br />

The spiral-fluted deep-hole drills have four guide chamfers,<br />

ensuring good guidance.<br />

Variant:<br />

- 4 x guide chamfers<br />

- Drill diameter: for 20×D: 3.00 <strong>–</strong> 10.0 mm<br />

for 30×D: 3.00 <strong>–</strong> 8.00 mm<br />

- Shank: DIN 6535 HA<br />

- Coating: TiAlN<br />

- Point angle: 140°<br />

- Helix angle: 30°<br />

- Internal coolant supply<br />

10<br />

BENEFITS for you:<br />

Excellent hole tolerances<br />

Optimum chip removal thanks to special flutes<br />

Optimum machining result thanks to good<br />

coordination of carbide and coating with drill<br />

geometry<br />

Long tool edge life thanks to effective coating<br />

BENEFITS for you:<br />

M 4 x chamfers for high drilling and alignment<br />

precision<br />

Ideal chip removal thanks to optimised, special<br />

flutes<br />

Reliable drilling up to 30×D, with no pecking<br />

Significantly reduced production times due to<br />

extremely high feed rates and cutting speeds<br />

Note:<br />

Pilot hole required, depth: 2 <strong>–</strong> 3×D<br />

KOMET KUB® Drillmax 5×D standard drills with the same<br />

diameter can be used.

KOMET KUB® Drillmax<br />

Cylindrical Shank DIN 6535 HA / HE<br />

x 3 <strong>–</strong> 16 mm, R.H. cutting<br />

<strong>Drilling</strong> depth 5×D<br />

<strong>Drilling</strong> depth 7-8×D<br />

Cylindrical Shank DIN 6535 HA<br />

x 3 <strong>–</strong> 10 mm, R.H. cutting<br />

<strong>Drilling</strong> depth 20×D<br />

x 3 <strong>–</strong> 8 mm, R.H. cutting<br />

<strong>Drilling</strong> depth 30×D<br />

Technical Notes<br />

Guideline values for solid drilling<br />

Technical Informations<br />

Page<br />

12 <strong>–</strong> 13<br />

14 <strong>–</strong> 15<br />

16<br />

17<br />

18 <strong>–</strong> 19<br />

21<br />

11<br />

1

1<br />

KOMET KUB® Drillmax<br />

12<br />

X 3,0 <strong>–</strong> 16,0 mm<br />

High-Performance <strong>Solid</strong> Carbide Drill with Cylindrical Shank DIN 6535 HA / HE, R.H. cutting<br />

L / D solid drilling blind hole forge/casting<br />

skin, interface<br />

5×D § § $ & & & & X $ & X<br />

§ very good $ good & possible: see technical notes, page 21 X not possible<br />

x d<br />

angled convex cross bore centering<br />

bore<br />

l N<br />

L<br />

chamber stack plate<br />

drilling<br />

5 × D<br />

for<br />

workpiece material<br />

X D X d × l<br />

DIN 6535 HA DIN 6535 HE<br />

L N P M K N S H<br />

Order No. Order No.<br />

p<br />

3,0 6 × 36 V03 03000.112730 V03 03000.212730 66 24 0,016<br />

3,1 6 × 36 V03 03100.112730 V03 03100.212730 66 24 0,016<br />

3,2 6 × 36 V03 03200.112730 V03 03200.212730 66 24 0,017<br />

3,3<br />

3,4<br />

6 × 36<br />

6 × 36<br />

V03 03300.112730<br />

V03 03400.112730<br />

V03 03300.212730<br />

V03 03400.212730<br />

66<br />

66<br />

24<br />

24<br />

0,017<br />

0,017<br />

§ $ $<br />

3,5 6 × 36 V03 03500.112730 V03 03500.212730 66 24 0,018<br />

3,6 6 × 36 V03 03600.112730 V03 03600.212730 66 24 0,018<br />

3,7 6 × 36 V03 03700.112730 V03 03700.212730 66 24 0,018<br />

3,8 6 × 36 V03 03800.112730 V03 03800.212730 74 30 0,018<br />

3,9 6 × 36 V03 03900.112730 V03 03900.212730 74 30 0,018<br />

4,0 6 × 36 V03 04000.112730 V03 04000.212730 74 30 0,018<br />

4,1 6 × 36 V03 04100.112730 V03 04100.212730 74 30 0,019<br />

4,2<br />

4,3<br />

6 × 36<br />

6 × 36<br />

V03 04200.112730<br />

V03 04300.112730<br />

V03 04200.212730<br />

V03 04300.212730<br />

74<br />

74<br />

30<br />

30<br />

0,019<br />

0,019<br />

§ $ $<br />

4,4 6 × 36 V03 04400.112730 V03 04400.212730 74 30 0,019<br />

4,5 6 × 36 V03 04500.112730 V03 04500.212730 74 30 0,019<br />

4,6 6 × 36 V03 04600.112730 V03 04600.212730 74 30 0,019<br />

4,7 6 × 36 V03 04700.112730 V03 04700.212730 74 30 0,019<br />

4,8 6 × 36 V03 04800.112730 V03 04800.212730 82 35 0,020<br />

4,9 6 × 36 V03 04900.112730 V03 04900.212730 82 35 0,020<br />

5,0 6 × 36 V03 05000.112730 V03 05000.212730 82 35 0,020<br />

5,1 6 × 36 V03 05100.112730 V03 05100.212730 82 35 0,021<br />

5,2 6 × 36 V03 05200.112730 V03 05200.212730 82 35 0,021<br />

5,3 6 × 36 V03 05300.112730 V03 05300.212730 82 35 0,022<br />

5,4<br />

5,5<br />

6 × 36<br />

6 × 36<br />

V03 05400.112730<br />

V03 05500.112730<br />

V03 05400.212730<br />

V03 05500.212730<br />

82<br />

82<br />

35<br />

35<br />

0,022<br />

0,023<br />

§ $ $<br />

5,54 6 × 36 V03 05540.112730 V03 05540.212730 82 35 0,023<br />

5,6 6 × 36 V03 05600.112730 V03 05600.212730 82 35 0,023<br />

5,7 6 × 36 V03 05700.112730 V03 05700.212730 82 35 0,024<br />

5,8 6 × 36 V03 05800.112730 V03 05800.212730 82 35 0,024<br />

5,9 6 × 36 V03 05900.112730 V03 05900.212730 82 35 0,025<br />

6,0 6 × 36 V03 06000.112730 V03 06000.212730 82 35 0,025<br />

6,1 8 × 36 V03 06100.112730 V03 06100.212730 91 43 0,027<br />

6,2 8 × 36 V03 06200.112730 V03 06200.212730 91 43 0,027<br />

6,3 8 × 36 V03 06300.112730 V03 06300.212730 91 43 0,030<br />

6,4 8 × 36 V03 06400.112730 V03 06400.212730 91 43 0,030<br />

6,5 8 × 36 V03 06500.112730 V03 06500.212730 91 43 0,032 § $ $<br />

6,6 8 × 36 V03 06600.112730 V03 06600.212730 91 43 0,032<br />

6,7 8 × 36 V03 06700.112730 V03 06700.212730 91 43 0,032<br />

6,8 8 × 36 V03 06800.112730 V03 06800.212730 91 43 0,035<br />

6,9 8 × 36 V03 06900.112730 V03 06900.212730 91 43 0,035<br />

x D<br />

140°<br />

rough boring adjustable<br />

Note: with whistle notch clamping surface conforming to DIN 6535 HE. Delivery time 1 week (minimum purchase: 3 pieces)

5×D<br />

KOMET KUB® Drillmax<br />

High-Performance <strong>Solid</strong> Carbide Drill with Cylindrical Shank DIN 6535 HA / HE, R.H. cutting<br />

5 × D<br />

for<br />

workpiece material<br />

X D X d × l<br />

DIN 6535 HA DIN 6535 HE<br />

L N P M K N S H<br />

Order No. Order No.<br />

p<br />

7,0 8 × 36 V03 07000.112730 V03 07000.212730 91 43 0,037<br />

7,1 8 × 36 V03 07100.112730 V03 07100.212730 91 43 0,037<br />

7,2 8 × 36 V03 07200.112730 V03 07200.212730 91 43 0,039<br />

7,3 8 × 36 V03 07300.112730 V03 07300.212730 91 43 0,039<br />

7,4 8 × 36 V03 07400.112730 V03 07400.212730 91 43 0,040<br />

7,43<br />

7,5<br />

8 × 36<br />

8 × 36<br />

V03 07430.112730<br />

V03 07500.112730<br />

V03 07430.212730<br />

V03 07500.212730<br />

91<br />

91<br />

43<br />

43<br />

0,040<br />

0,040 § $ $<br />

7,6 8 × 36 V03 07600.112730 V03 07600.212730 91 43 0,041<br />

7,7 8 × 36 V03 07700.112730 V03 07700.212730 91 43 0,041<br />

7,8 8 × 36 V03 07800.112730 V03 07800.212730 91 43 0,043<br />

7,9 8 × 36 V03 07900.112730 V03 07900.212730 91 43 0,043<br />

8,0 8 × 36 V03 08000.112730 V03 08000.212730 91 43 0,044<br />

8,1 10 × 40 V03 08100.112730 V03 08100.212730 103 49 0,045<br />

8,2 10 × 40 V03 08200.112730 V03 08200.212730 103 49 0,045<br />

8,3 10 × 40 V03 08300.112730 V03 08300.212730 103 49 0,047<br />

8,4 10 × 40 V03 08400.112730 V03 08400.212730 103 49 0,047<br />

8,5 10 × 40 V03 08500.112730 V03 08500.212730 103 49 0,050<br />

8,6 10 × 40 V03 08600.112730 V03 08600.212730 103 49 0,050<br />

8,7 10 × 40 V03 08700.112730 V03 08700.212730 103 49 0,052<br />

8,8 10 × 40 V03 08800.112730 V03 08800.212730 103 49 0,052<br />

8,9 10 × 40 V03 08900.112730 V03 08900.212730 103 49 0,055<br />

9,0 10 × 40 V03 09000.112730 V03 09000.212730 103 49 0,055<br />

9,1 10 × 40 V03 09100.112730 V03 09100.212730 103 49 0,057 § $ $<br />

9,2 10 × 40 V03 09200.112730 V03 09200.212730 103 49 0,057<br />

9,3 10 × 40 V03 09300.112730 V03 09300.212730 103 49 0,062<br />

9,4 10 × 40 V03 09400.112730 V03 09400.212730 103 49 0,062<br />

9,5 10 × 40 V03 09500.112730 V03 09500.212730 103 49 0,067<br />

9,54 10 × 40 V03 09540.112730 V03 09540.212730 103 49 0,067<br />

9,6 10 × 40 V03 09600.112730 V03 09600.212730 103 49 0,067<br />

9,7 10 × 40 V03 09700.112730 V03 09700.212730 103 49 0,072<br />

9,8 10 × 40 V03 09800.112730 V03 09800.212730 103 49 0,072<br />

9,9 10 × 40 V03 09900.112730 V03 09900.212730 103 49 0,077<br />

10,0 10 × 40 V03 10000.112730 V03 10000.212730 103 49 0,077<br />

10,1 12 × 45 V03 10100.112730 V03 10100.212730 118 56 0,080<br />

10,2 12 × 45 V03 10200.112730 V03 10200.212730 118 56 0,085<br />

10,3 12 × 45 V03 10300.112730 V03 10300.212730 118 56 0,090<br />

10,4 12 × 45 V03 10400.112730 V03 10400.212730 118 56 0,094<br />

10,5 12 × 45 V03 10500.112730 V03 10500.212730 118 56 0,097<br />

10,6 12 × 45 V03 10600.112730 V03 10600.212730 118 56 0,100<br />

10,7 12 × 45 V03 10700.112730 V03 10700.212730 118 56 0,102<br />

10,8 12 × 45 V03 10800.112730 V03 10800.212730 118 56 0,105<br />

10,9 12 × 45 V03 10900.112730 V03 10900.212730 118 56 0,107<br />

11,0 12 × 45 V03 11000.112730 V03 11000.212730 118 56 0,110<br />

11,1 12 × 45 V03 11100.112730 V03 11100.212730 118 56 0,112 § $ $<br />

11,2 12 × 45 V03 11200.112730 V03 11200.212730 118 56 0,115<br />

11,3 12 × 45 V03 11300.112730 V03 11300.212730 118 56 0,117<br />

11,4 12 × 45 V03 11400.112730 V03 11400.212730 118 56 0,120<br />

11,5 12 × 45 V03 11500.112730 V03 11500.212730 118 56 0,122<br />

11,54 12 × 45 V03 11540.112730 V03 11540.212730 118 56 0,122<br />

11,6 12 × 45 V03 11600.112730 V03 11600.212730 118 56 0,125<br />

11,7 12 × 45 V03 11700.112730 V03 11700.212730 118 56 0,127<br />

11,8 12 × 45 V03 11800.112730 V03 11800.212730 118 56 0,130<br />

11,9 12 × 45 V03 11900.112730 V03 11900.212730 118 56 0,132<br />

12,0 12 × 45 V03 12000.112730 V03 12000.212730 118 56 0,135<br />

12,5 14 × 45 V03 12500.112730 V03 12500.212730 124 60 0,180<br />

12,8 14 × 45 V03 12800.112730 V03 12800.212730 124 60 0,180<br />

13,0 14 × 45 V03 13000.112730 V03 13000.212730 124 60 0,182<br />

13,3 14 × 45 V03 13300.112730 V03 13300.212730 124 60 0,182 § $ $<br />

13,5 14 × 45 V03 13500.112730 V03 13500.212730 124 60 0,185<br />

13,8 14 × 45 V03 13800.112730 V03 13800.212730 124 60 0,185<br />

14,0 14 × 45 V03 14000.112730 V03 14000.212730 124 60 0,188<br />

14,5 16 × 48 V03 14500.112730 V03 14500.212730 133 63 0,240<br />

14,8 16 × 48 V03 14800.112730 V03 14800.212730 133 63 0,240<br />

15,0<br />

15,5<br />

16 × 48<br />

16 × 48<br />

V03 15000.112730<br />

V03 15500.112730<br />

V03 15000.212730<br />

V03 15500.212730<br />

133<br />

133<br />

63<br />

63<br />

0,250<br />

0,270 § $ $<br />

15,8 16 × 48 V03 15800.112730 V03 15800.212730 133 63 0,270<br />

16,0 16 × 48 V03 16000.112730 V03 16000.212730 133 63 0,282<br />

Other diameters on request.<br />

Guideline values for solid drilling: page 18-19.<br />

13<br />

1

1<br />

KOMET KUB® Drillmax<br />

14<br />

x d<br />

l N<br />

L<br />

X 3,0 <strong>–</strong> 16,0 mm<br />

High-Performance <strong>Solid</strong> Carbide Drill with Cylindrical Shank DIN 6535 HA / HE, R.H. cutting<br />

L / D solid drilling blind hole forge/casting<br />

skin, interface<br />

7-8×D § § $ & & & & X $ & X<br />

§ very good $ good & possible: see technical notes, page 21 X not possible<br />

angled convex cross bore centering<br />

bore<br />

chamber stack plate<br />

drilling<br />

rough boring adjustable<br />

7 <strong>–</strong> 8 × D<br />

for<br />

workpiece material<br />

X D X d × l<br />

DIN 6535 HA DIN 6535 HE<br />

L N P M K N S H<br />

Order No. Order No.<br />

p<br />

3,0 6 × 36 V04 03000.112730 V04 03000.212730 70 28 0,017<br />

3,1 6 × 36 V04 03100.112730 V04 03100.212730 70 28 0,017<br />

3,2 6 × 36 V04 03200.112730 V04 03200.212730 70 28 0,017<br />

3,3<br />

3,4<br />

6 × 36<br />

6 × 36<br />

V04 03300.112730<br />

V04 03400.112730<br />

V04 03300.212730<br />

V04 03400.212730<br />

70<br />

70<br />

28<br />

28<br />

0,017<br />

0,018<br />

§ $ $<br />

3,5 6 × 36 V04 03500.112730 V04 03500.212730 70 28 0,018<br />

3,6 6 × 36 V04 03600.112730 V04 03600.212730 70 28 0,018<br />

3,7 6 × 36 V04 03700.112730 V04 03700.212730 70 28 0,018<br />

3,8 6 × 36 V04 03800.112730 V04 03800.212730 80 36 0,019<br />

3,9 6 × 36 V04 03900.112730 V04 03900.212730 80 36 0,019<br />

4,0 6 × 36 V04 04000.112730 V04 04000.212730 80 36 0,019<br />

4,1 6 × 36 V04 04100.112730 V04 04100.212730 80 36 0,020<br />

4,2<br />

4,3<br />

6 × 36<br />

6 × 36<br />

V04 04200.112730<br />

V04 04300.112730<br />

V04 04200.212730<br />

V04 04300.212730<br />

80<br />

80<br />

36<br />

36<br />

0,020<br />

0,020<br />

§ $ $<br />

4,4 6 × 36 V04 04400.112730 V04 04400.212730 80 36 0,021<br />

4,5 6 × 36 V04 04500.112730 V04 04500.212730 80 36 0,021<br />

4,6 6 × 36 V04 04600.112730 V04 04600.212730 80 36 0,021<br />

4,7 6 × 36 V04 04700.112730 V04 04700.212730 80 36 0,021<br />

4,8 6 × 36 V04 04800.112730 V04 04800.212730 92 45 0,023<br />

4,9 6 × 36 V04 04900.112730 V04 04900.212730 92 45 0,023<br />

5,0 6 × 36 V04 05000.112730 V04 05000.212730 92 45 0,024<br />

5,1 6 × 36 V04 05100.112730 V04 05100.212730 92 45 0,025<br />

5,2 6 × 36 V04 05200.112730 V04 05200.212730 92 45 0,025<br />

5,3 6 × 36 V04 05300.112730 V04 05300.212730 92 45 0,026<br />

5,4<br />

5,5<br />

6 × 36<br />

6 × 36<br />

V04 05400.112730<br />

V04 05500.112730<br />

V04 05400.212730<br />

V04 05500.212730<br />

92<br />

92<br />

45<br />

45<br />

0,027<br />

0,027<br />

§ $ $<br />

5,54 6 × 36 V04 05540.112730 V04 05540.212730 92 45 0,027<br />

5,6 6 × 36 V04 05600.112730 V04 05600.212730 92 45 0,028<br />

5,7 6 × 36 V04 05700.112730 V04 05700.212730 92 45 0,029<br />

5,8 6 × 36 V04 05800.112730 V04 05800.212730 92 45 0,030<br />

5,9 6 × 36 V04 05900.112730 V04 05900.212730 92 45 0,030<br />

6,0 6 × 36 V04 06000.112730 V04 06000.212730 92 45 0,031<br />

6,1 8 × 36 V04 06100.112730 V04 06100.212730 100 52 0,032<br />

6,2 8 × 36 V04 06200.112730 V04 06200.212730 100 52 0,034<br />

6,3 8 × 36 V04 06300.112730 V04 06300.212730 100 52 0,036<br />

6,4<br />

6,5<br />

8 × 36<br />

8 × 36<br />

V04 06400.112730<br />

V04 06500.112730<br />

V04 06400.212730<br />

V04 06500.212730<br />

100<br />

100<br />

52<br />

52<br />

0,038<br />

0,039<br />

§ $ $<br />

6,6 8 × 36 V04 06600.112730 V04 06600.212730 100 52 0,040<br />

6,7 8 × 36 V04 06700.112730 V04 06700.212730 100 52 0,041<br />

6,8 8 × 36 V04 06800.112730 V04 06800.212730 100 52 0,043<br />

Note: with whistle notch clamping surface conforming to DIN 6535 HE. Delivery time 1 week (minimum purchase: 3 pieces)<br />

x D<br />

140°

7 <strong>–</strong> 8×D<br />

KOMET KUB® Drillmax<br />

High-Performance <strong>Solid</strong> Carbide Drill with Cylindrical Shank DIN 6535 HA / HE, R.H. cutting<br />

7 <strong>–</strong> 8 × D<br />

for<br />

workpiece material<br />

X D X d × l<br />

DIN 6535 HA DIN 6535 HE<br />

L N P M K N S H<br />

Order No. Order No.<br />

p<br />

6,9 8 × 36 V04 06900.112730 V04 06900.212730 108 60 0,045<br />

7,0 8 × 36 V04 07000.112730 V04 07000.212730 108 60 0,045<br />

7,1 8 × 36 V04 07100.112730 V04 07100.212730 108 60 0,046<br />

7,2 8 × 36 V04 07200.112730 V04 07200.212730 108 60 0,047<br />

7,3 8 × 36 V04 07300.112730 V04 07300.212730 108 60 0,047<br />

7,4 8 × 36 V04 07400.112730 V04 07400.212730 108 60 0,048<br />

7,43 8 × 36 V04 07430.112730 V04 07430.212730 108 60 0,048 § $ $<br />

7,5 8 × 36 V04 07500.112730 V04 07500.212730 108 60 0,049<br />

7,6 8 × 36 V04 07600.112730 V04 07600.212730 108 60 0,050<br />

7,7 8 × 36 V04 07700.112730 V04 07700.212730 108 60 0,050<br />

7,8 8 × 36 V04 07800.112730 V04 07800.212730 108 60 0,051<br />

7,9 8 × 36 V04 07900.112730 V04 07900.212730 108 60 0,052<br />

8,0 8 × 36 V04 08000.112730 V04 08000.212730 108 60 0,053<br />

8,1 10 × 40 V04 08100.112730 V04 08100.212730 122 68 0,055<br />

8,2 10 × 40 V04 08200.112730 V04 08200.212730 122 68 0,057<br />

8,3 10 × 40 V04 08300.112730 V04 08300.212730 122 68 0,060<br />

8,4 10 × 40 V04 08400.112730 V04 08400.212730 122 68 0,062<br />

8,5 10 × 40 V04 08500.112730 V04 08500.212730 122 68 0,065<br />

8,6 10 × 40 V04 08600.112730 V04 08600.212730 122 68 0,067<br />

8,7 10 × 40 V04 08700.112730 V04 08700.212730 122 68 0,070<br />

8,8 10 × 40 V04 08800.112730 V04 08800.212730 122 68 0,072<br />

8,9 10 × 40 V04 08900.112730 V04 08900.212730 122 68 0,075<br />

9,0 10 × 40 V04 09000.112730 V04 09000.212730 122 68 0,077<br />

9,1 10 × 40 V04 09100.112730 V04 09100.212730 130 76 0,080 § $ $<br />

9,2 10 × 40 V04 09200.112730 V04 09200.212730 130 76 0,082<br />

9,3 10 × 40 V04 09300.112730 V04 09300.212730 130 76 0,085<br />

9,4 10 × 40 V04 09400.112730 V04 09400.212730 130 76 0,087<br />

9,5 10 × 40 V04 09500.112730 V04 09500.212730 130 76 0,090<br />

9,54 10 × 40 V04 09540.112730 V04 09540.212730 130 76 0,090<br />

9,6 10 × 40 V04 09600.112730 V04 09600.212730 130 76 0,090<br />

9,7 10 × 40 V04 09700.112730 V04 09700.212730 130 76 0,092<br />

9,8 10 × 40 V04 09800.112730 V04 09800.212730 130 76 0,095<br />

9,9 10 × 40 V04 09900.112730 V04 09900.212730 130 76 0,097<br />

10,0 10 × 40 V04 10000.112730 V04 10000.212730 130 76 0,099<br />

10,1 12 × 45 V04 10100.112730 V04 10100.212730 152 90 0,102<br />

10,2 12 × 45 V04 10200.112730 V04 10200.212730 152 90 0,105<br />

10,3 12 × 45 V04 10300.112730 V04 10300.212730 152 90 0,110<br />

10,4 12 × 45 V04 10400.112730 V04 10400.212730 152 90 0,112<br />

10,5 12 × 45 V04 10500.112730 V04 10500.212730 152 90 0,115<br />

10,6 12 × 45 V04 10600.112730 V04 10600.212730 152 90 0,117<br />

10,7 12 × 45 V04 10700.112730 V04 10700.212730 152 90 0,120<br />

10,8 12 × 45 V04 10800.112730 V04 10800.212730 152 90 0,122<br />

10,9 12 × 45 V04 10900.112730 V04 10900.212730 152 90 0,125<br />

11,0 12 × 45 V04 11000.112730 V04 11000.212730 152 90 0,127<br />

11,1 12 × 45 V04 11100.112730 V04 11100.212730 152 90 0,130 § $ $<br />

11,2 12 × 45 V04 11200.112730 V04 11200.212730 152 90 0,132<br />

11,3 12 × 45 V04 11300.112730 V04 11300.212730 152 90 0,135<br />

11,4 12 × 45 V04 11400.112730 V04 11400.212730 152 90 0,137<br />

11,5 12 × 45 V04 11500.112730 V04 11500.212730 152 90 0,140<br />

11,54 12 × 45 V04 11540.112730 V04 11540.212730 152 90 0,140<br />

11,6 12 × 45 V04 11600.112730 V04 11600.212730 152 90 0,145<br />

11,7 12 × 45 V04 11700.112730 V04 11700.212730 152 90 0,150<br />

11,8 12 × 45 V04 11800.112730 V04 11800.212730 152 90 0,155<br />

11,9 12 × 45 V04 11900.112730 V04 11900.212730 152 90 0,160<br />

12,0 12 × 45 V04 12000.112730 V04 12000.212730 152 90 0,168<br />

12,5 14 × 45 V04 12500.112730 V04 12500.212730 170 106 0,198<br />

12,8 14 × 45 V04 12800.112730 V04 12800.212730 170 106 0,200<br />

13,0 14 × 45 V04 13000.112730 V04 13000.212730 170 106 0,210<br />

13,3 14 × 45 V04 13300.112730 V04 13300.212730 170 106 0,220 § $ $<br />

13,5 14 × 45 V04 13500.112730 V04 13500.212730 170 106 0,230<br />

13,8 14 × 45 V04 13800.112730 V04 13800.212730 170 106 0,240<br />

14,0 14 × 45 V04 14000.112730 V04 14000.212730 170 106 0,246<br />

14,5 16 × 48 V04 14500.112730 V04 14500.212730 192 122 0,315<br />

14,8 16 × 48 V04 14800.112730 V04 14800.212730 192 122 0,317<br />

15,0<br />

15,5<br />

16 × 48<br />

16 × 48<br />

V04 15000.112730<br />

V04 15500.112730<br />

V04 15000.212730<br />

V04 15500.212730<br />

192<br />

192<br />

122<br />

122<br />

0,320<br />

0,340 § $ $<br />

15,8 16 × 48 V04 15800.112730 V04 15800.212730 192 122 0,350<br />

16,0 16 × 48 V04 16000.112730 V04 16000.212730 192 122 0,360<br />

Other diameters on request.<br />

Guideline values for solid drilling: page 18-19.<br />

15<br />

1

1<br />

KOMET KUB® Drillmax XL<br />

16<br />

x d<br />

l N<br />

20 × D<br />

for<br />

workpiece material<br />

X D X d × l<br />

DIN 6535 HA<br />

L N P M K N S H<br />

Order No.<br />

p<br />

3,0 6 × 36 V05 03000.117830 108 62<br />

4,0 6 × 36 V05 04000.117830 132 82<br />

4,5 6 × 36 V05 04500.117830 144 95<br />

5,0 6 × 36 V05 05000.117830 156 103<br />

5,5 6 × 36 V05 05500.117830 168 113<br />

6,0 6 × 36 V05 06000.117830 178 123<br />

6,5 8 × 36 V05 06500.117830 192 133<br />

8,0 8 × 36 V05 08000.117830 222 164<br />

8,5 10 × 40 V05 08500.117830 244 174<br />

9,0 10 × 40 V05 09000.117830 256 184<br />

10,0 10 × 40 V05 10000.117830 270 205<br />

L<br />

X 3,0 <strong>–</strong> 10,0 mm · 20×D<br />

High-Performance <strong>Solid</strong> Carbide Drill with Cylindrical Shank DIN 6535 HA, R.H. cutting<br />

Warning! A pilot hole must always be drilled. Direct spot drilling is not possible, even on a machined spot-drill surface.<br />

Angled surfaces or unmachined spot-drill surfaces must also be faced or spot faced for the pilot drilling tool (page 20).<br />

K 4 x guide chamfers<br />

K coating: TiAlN<br />

K with coolant channels<br />

Other diameters on request.<br />

x D<br />

140°<br />

§ §<br />

§ §<br />

§ §

X 3,0 <strong>–</strong> 8,0 mm · 30×D KOMET KUB® Drillmax XL<br />

High-Performance <strong>Solid</strong> Carbide Drill with Cylindrical Shank DIN 6535 HA, R.H. cutting<br />

x d<br />

Warning! A pilot hole must always be drilled. Direct spot drilling is not possible, even on a machined spot-drill surface.<br />

Angled surfaces or unmachined spot-drill surfaces must also be faced or spot faced for the pilot drilling tool (page 20).<br />

l N<br />

L<br />

30 × D<br />

for<br />

workpiece material<br />

X D X d × l<br />

DIN 6535 HA<br />

L N P M K N S H<br />

Order No.<br />

p<br />

3,0 6 × 36 V06 03000.117830 138 92<br />

4,0 6 × 36 V06 04000.117830 172 122<br />

4,5 6 × 36 V06 04500.117830 189 137<br />

5,0 6 × 36 V06 05000.117830 206 153<br />

5,5 6 × 36 V06 05500.117830 223 168<br />

6,0 6 × 36 V06 06000.117830 238 183<br />

6,5 8 × 36 V06 06500.117830 257 198<br />

8,0 8 × 36 V06 08000.117830 302 244<br />

Other diameters on request.<br />

Guideline values for solid drilling: page 19.<br />

4 x guide chamfers K<br />

coating: TiAlN K<br />

with coolant channels K<br />

§ §<br />

§ §<br />

x D<br />

140°<br />

17<br />

1

1<br />

KOMET KUB® Drillmax, KOMET KUB® Drillmax XL<br />

Technical Notes<br />

Material <strong>group</strong><br />

P<br />

S<br />

1.0<br />

2.0<br />

2.1<br />

3.0<br />

4.0<br />

4.1<br />

5.0<br />

5.1<br />

6.0<br />

M<br />

6.1<br />

7.0<br />

8.0<br />

8.1<br />

9.0<br />

K<br />

9.1<br />

10.0<br />

10.1<br />

10.2<br />

N<br />

13.0<br />

H<br />

18<br />

12.0<br />

12.1<br />

13.1<br />

14.0<br />

15.0<br />

16,0<br />

Strength Rm (N/mm²)<br />

# 500<br />

500-<br />

900<br />

St37-2 / 1.0037;<br />

9SMn28 / 1.0715;<br />

St44-2 / 1.0044<br />

St52-2 / 1.0050,<br />

C55 / 1.0525,<br />

16MnCr5 / 1.7131<br />

< 500 lead alloys<br />

9SMnPb28 / 1.0718<br />

> 900 -<br />

1200<br />

> 1200<br />

250<br />

42CrMo4 / 1.7225,<br />

CK60 / 1.1221<br />

X6CrMo4 / 1.2341,<br />

X165CrMoV12 / 1.2601<br />

Inconel 718 / 2.4668,<br />

special alloys: Inconel, Hastelloy, Nimonic, stc.<br />

Nimonic 80A / 2.4631<br />

titanium,<br />

400 TiAl5Sn2 / 3.7114<br />

titanium alloys<br />

# 600<br />

< 900<br />

> 900<br />

180<br />

X2CrNi189 / 1.4306,<br />

X5CrNiMo1810 / 1.4401<br />

X8CrNb17 / 1.4511,<br />

X10CrNiMoTi1810 / 1.4571<br />

X10CrAl7 / 1.4713,<br />

X8CrS-38-18 / 1.4862<br />

GG-25 / 0.6025,<br />

GG-35 / 0.6035<br />

250 alloy gray cast iron<br />

GG-NiCr202 / 0.6660<br />

# 600 130 spheroidal graphite cast iron, ferritic GGG-40 / 0.7040<br />

230<br />

> 600 250<br />

1400<br />

1800<br />

Guideline values for solid drilling<br />

Hardness HB<br />

GGG-50 / 0.7050<br />

GGG-55 / 0.7055<br />

GTW-55 / 0.8055<br />

GGG-60 / 0.7060<br />

GTS-65 / 0.8165<br />

alloyed spheroidal<br />

200 GGG-NiCr20-2 / 0.7661<br />

graphite cast iron<br />

300<br />

90<br />

100<br />

60<br />

75<br />

Material<br />

non-alloy steels<br />

non-alloy /<br />

low alloy steels<br />

low alloy steels: heat resistant structural,<br />

heat treated, nitride and tools steels<br />

high alloy steels<br />

HSS<br />

stainless steels<br />

stainless steels<br />

stainless /<br />

fireproof steels<br />

gray cast iron<br />

spheroidal graphite cast iron, ferritic/perlitic<br />

spheroidal graphite cast iron,<br />

perlitic malleable iron<br />

vermicular cast iron<br />

copper alloy, brass,<br />

lead-alloy bronze, lead bronze:<br />

good cut<br />

copper alloy, brass,<br />

bronze:<br />

average cut<br />

wrought<br />

aluminium alloys<br />

cast alum. alloy:<br />

Si-content 0,2<br />

CuZn36Pb3 / 2.1182,<br />

G-CuPb15Sn / 2.1182<br />

CuZn40Al1 / 2.0550,<br />

E-Cu57 / 2.0060<br />

AlMg1 / 3.3315,<br />

AlMnCu / 3.0517<br />

G-AlMg5 / 3.3561,<br />

G-AlSi9Mg / 3.2373<br />

cast alum.alloy:<br />

100 G-AlSi10Mg / 3.2381<br />

Si-content >10%<br />

hardened steels<br />

< 45 HRC<br />

hardened steels<br />

> 45 HRC<br />

Cutting speed<br />

v c (m/min)<br />

Cutting values shown are relating to the basic recommendations for cutting materials given.<br />

5×D / 7-8×D<br />

Feed f (mm/rev)<br />

x 3,0-5,0 x 5,1-8,0<br />

min opt. max min opt. max min opt. max<br />

95 115 135 0,08 0,14 0,20 0,15 0,20 0,25<br />

70 85 100 0,06 0,12 0,18 0,12 0,17 0,22<br />

70 85 100 0,06 0,12 0,18 0,10 0,18 0,25<br />

70 75 80 0,05 0,10 0,15 0,10 0,15 0,20<br />

45 60 75 0,05 0,09 0,13 0,10 0,14 0,18<br />

40 55 70 0,06 0,12 0,18 0,12 0,17 0,22<br />

25 45 65 0,05 0,08 0,10 0,09 0,15 0,20<br />

15 30 40 0,05 0,08 0,10 0,06 0,10 0,14<br />

90 115 140 0,10 0,18 0,25 0,15 0,23 0,30<br />

70 95 120 0,10 0,18 0,25 0,15 0,23 0,30<br />

100 120 140 0,08 0,14 0,20 0,15 0,20 0,25<br />

80 100 120 0,06 0,12 0,18 0,10 0,15 0,20<br />

70 90 110 0,06 0,12 0,18 0,10 0,15 0,20<br />

60 70 80 0,06 0,12 0,18 0,10 0,15 0,20<br />

60 70 80 0,06 0,12 0,18 0,10 0,15 0,20

5×D / 7-8×D 20×D / 30×D<br />

Feed f (mm/rev)<br />

KOMET KUB® Drillmax, KOMET KUB® Drillmax XL<br />

x 8,1-10,0 x 10,1-12,0 x 12,1-14,0 x 14,1-16,0<br />

Cutting speed<br />

vc (m/min)<br />

x 3,0-4,0 x 4,1-6,0 x 6,1-10,0<br />

min opt. max min opt. max min opt. max min opt. max min opt. max min opt. max min opt. max min opt. max<br />

0,15 0,23 0,30 0,20 0,28 0,35 0,25 0,33 0,40 0,30 0,38 0,45 40 85 100 0,06 0,10 0,15 0,10 0,20 0,30 0,15 0,25 0,35<br />

0,15 0,20 0,25 0,18 0,24 0,30 0,20 0,28 0,35 0,30 0,44 0,48 40 75 100 0,06 0,09 0,12 0,10 0,17 0,25 0,15 0,20 0,25<br />

0,20 0,28 0,35 0,25 0,33 0,40 0,30 0,38 0,45 0,35 0,44 0,52 40 85 100 0,06 0,10 0,15 0,15 0,25 0,30 0,15 0,25 0,35<br />

0,12 0,19 0,25 0,15 0,23 0,30 0,20 0,28 0,35 0,25 0,33 0,40 35 60 80 0,06 0,09 0,12 0,10 0,15 0,20 0,15 0,20 0,25<br />

0,12 0,18 0,23 0,15 0,22 0,28 0,18 0,25 0,32 0,20 0,28 0,35<br />

0,15 0,20 0,25 0,18 0,24 0,30 0,20 0,28 0,35 0,22 0,31 0,40<br />

0,11 0,17 0,22 0,14 0,20 0,25 0,16 0,23 0,30 0,20 0,28 0,35<br />

0,08 0,13 0,18 0,12 0,17 0,22 0,14 0,20 0,26 0,16 0,23 0,30<br />

0,20 0,30 0,40 0,25 0,33 0,40 0,25 0,35 0,45 0,30 0,40 0,50 40 70 85 0,07 0,11 0,15 0,18 0,24 0,30 0,20 0,25 0,35<br />

0,20 0,30 0,40 0,25 0,33 0,40 0,25 0,35 0,45 0,30 0,40 0,50 40 70 85 0,07 0,11 0,15 0,18 0,24 0,30 0,20 0,25 0,35<br />

0,15 0,23 0,30 0,20 0,28 0,35 0,25 0,33 0,40 0,30 0,38 0,45 35 65 80 0,06 0,10 0,15 0,15 0,20 0,25 0,15 0,25 0,30<br />

0,14 0,20 0,25 0,18 0,24 0,30 0,20 0,28 0,35 0,25 0,33 0,40 35 65 80 0,06 0,10 0,15 0,15 0,20 0,25 0,15 0,25 0,30<br />

0,14 0,20 0,25 0,18 0,24 0,30 0,20 0,28 0,35 0,25 0,33 0,40 35 65 80 0,06 0,10 0,15 0,15 0,20 0,25 0,15 0,25 0,30<br />

0,14 0,20 0,25 0,18 0,24 0,30 0,20 0,28 0,35 0,25 0,33 0,40<br />

0,14 0,20 0,25 0,18 0,24 0,30 0,20 0,28 0,35 0,25 0,33 0,40 35 65 80 0,06 0,09 0,12 0,15 0,20 0,25 0,15 0,25 0,30<br />

Cutting values shown are relating to the basic recommendations for cutting materials given.<br />

Important: See chapter 8 for more application details and safety notes!<br />

Feed f (mm/rev)<br />

Technical Notes<br />

19<br />

1

1<br />

KOMET KUB® Drillmax XL<br />

20<br />

From experience:<br />

1. Pilot hole<br />

<strong>Drilling</strong> depth 2 <strong>–</strong> 3 × D<br />

2. Start with deep-hole drill<br />

Enter the pilot hole at a reduced cutting speed<br />

vc = 20-30 m/min at the working feed rate.<br />

Just before reaching the bottom of the pilot hole, stop the<br />

feed and increase the speed to the cycle speed steplessly.<br />

3. Increase the deep-hole drilling<br />

Feed rate to the cycle speed. Drill to the required hole depth without pecking. When drilling a through<br />

hole, reduce the feed rate by 50 % when the drill tip exits at through holes <strong>–</strong> risk of chipping.<br />

4. Back out of the hole<br />

Once the final drilling depth is reached, withdraw the tool 2-3 mm, then reduce the cutting speed<br />

to vc = 20-30 m/min and withdraw at vf = 3000 mm/min until the pilot hole depth. Then back out<br />

from the hole at n = 300 rpm vf = 3000 mm/min.<br />

Important: See chapter 8 for more application details and safety notes!

5×D / 7<strong>–</strong>8×D KOMET KUB® Drillmax<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

8.<br />

9.<br />

10.<br />

11.<br />

� �<br />

�<br />

Starting on uneven surfaces (cast surfaces)<br />

• depending on the quality of the surface or when spot drilling, reduce the feed<br />

Starting on angled surfaces<br />

• spot face surface before starting bore<br />

Angled bore exit<br />

• reduce feed by 50 % in the exit area<br />

Starting on cambered surfaces<br />

• drilling on centre with reduced feed is possible<br />

• spot facing is required if the bore start point is outside the radius centre<br />

<strong>Drilling</strong> through a cross bore<br />

• half feed rate at interruption<br />

Starting on a groove or large centering bore<br />

• end-face the seam or centre beforehand where applicable<br />

(diameter min. 0.1 mm greater than drill diameter)<br />

• possible under certain conditions. Reduce feed where necessary<br />

<strong>Drilling</strong> a chamfer<br />

• not possible<br />

Starting on an edge<br />

• not possible (start point must be flat)<br />

Starting on a welded seam<br />

• spot face surface before starting bore<br />

<strong>Drilling</strong> through stacked plates<br />

• possible in principle<br />

• good workpiece clamping required<br />

• avoid large spaces between elements<br />

Roughing<br />

• 5×D and 7-8×D possible<br />

• 20×D and 30×D not possible<br />

Warning! A pilot hole must always be drilled. Direct spot drilling is not possible, even on a machined spot-drill surface.<br />

Angled surfaces or unmachined spot-drill surfaces must also be faced or spot faced for the pilot drilling tool.<br />

Technical Informations<br />

21<br />

1

1<br />

JEL® PCD High-performance Drill<br />

22<br />

JEL® Drillcut 24 JEL® Drillmax 22<br />

Modern PCD cutting material<br />

Due to high hardness and resistance to abrasion,<br />

polycrystalline diamond (PCD) cutting materials have<br />

achieved significant importance in machining aluminium<br />

alloys.<br />

JEL® Drill Reamer<br />

JEL® Dreammax<br />

With our PCD tipped cutting tools we will take your<br />

machine to its full potential at maximum productivity.<br />

Depending on the application there is almost unlimited<br />

cutting speed possible. It is no longer the tool which<br />

determines the cutting data but the efficiency of your<br />

machine.<br />

<strong>Drilling</strong> to precise tolerances in one operation, thereby<br />

reducing the tools required and saving costs<br />

Hole tolerance IT 7 achievable<br />

Main application area:<br />

Grey cast iron<br />

Spheroidal graphite cast iron<br />

Aluminium

BENEFITS for you:<br />

For maximum cutting speeds<br />

and tool life<br />

For cutting lightweight<br />

structural materials such as<br />

aluminium, magnesium and<br />

fibre-reinforced plastics<br />

Drillcut · Drillmax · Dreammax<br />

PCD High-performance Drill Drillcut 24<br />

x 5 <strong>–</strong> 12 mm, R.H. cutting<br />

<strong>Drilling</strong> depth 5×D<br />

PCD High-performance Drill Drillmax 22<br />

x 6 <strong>–</strong> 10 mm, R.H. cutting<br />

<strong>Drilling</strong> depth 5×D<br />

Drill Reamer Dreammax<br />

x 6 <strong>–</strong> 12 mm, R.H. cutting<br />

<strong>Drilling</strong> depth 4×D<br />

Technical Notes<br />

Guidelines<br />

Page<br />

24<br />

25<br />

26<br />

27<br />

23<br />

1

1<br />

JEL® Drillcut 24<br />

24<br />

L / D solid drilling blind hole forge/casting<br />

skin, interface<br />

x d<br />

angled convex cross bore centering<br />

bore<br />

l N<br />

5 × D<br />

for<br />

workpiece material<br />

X d1 for thread<br />

X d × l<br />

DIN 6535 HA<br />

L N P M K N S H<br />

Order No.<br />

p<br />

5,00 M6 6 × 36 38588082000500 82 35 0,023<br />

5,50 M6 roll formed + M6×0,5 6 × 36 38588082000550 82 35 0,025<br />

6,00 6 × 36 38588082000600 82 35 0,027<br />

6,80 M8 8 × 36 38588091000680 91 43 0,045<br />

7,40 M8 roll formed<br />

8 × 36 38588091000740 91 43 0,047<br />

8,00 8 × 36 38588091000800 91 43 0,050<br />

8,50 M10 10 × 40 38588003000850 103 49 0,060<br />

9,30 M10×1,25 roll formed<br />

10 × 40 38588003000930 103 49 0,075<br />

10,00 10 × 40 38588003001000 103 49 0,090<br />

10,20 M12 12 × 45 38588018001020 118 56 0,116<br />

11,20 M12×1,5 roll formed<br />

12 × 45 38588018001120 118 56 0,122<br />

12,00 M14 12 × 45 38588018001200 118 56 0,142<br />

L<br />

X 5,0 <strong>–</strong> 12,0 mm · 5×D<br />

PCD High-Performance Drill with Cylindrical Shank DIN 6535 HA, R.H. cutting<br />

chamber stack plate<br />

drilling<br />

5×D § § & & & & & X & X X<br />

§ very good $ good & possible X not possible<br />

K with solid carbide shank<br />

K 2 cutting edges and 4 guides<br />

K straight fluted<br />

K with coolant channels<br />

K cutting material: PCD sandwich<br />

x d1<br />

rough boring adjustable<br />

130°<br />

§<br />

§<br />

§<br />

§

X 6,0 <strong>–</strong> 10,0 mm · 5×D JEL® Drillmax 22<br />

x d<br />

PCD High-Performance Drill with Cylindrical Shank DIN 6535 HA, R.H. cutting<br />

L / D solid drilling blind hole forge/casting<br />

skin, interface<br />

5×D § § & & & & & X & X X<br />

§ very good $ good & possible X not possible<br />

l N<br />

5 × D<br />

for<br />

workpiece material<br />

X d1 X d × l<br />

DIN 6535 HA<br />

L N P M K N S H<br />

Order No.<br />

p<br />

6,00 6 × 36 38405002000600 82 30 0,038 §<br />

8,00 8 × 36 38405002000800 91 42 0,047 §<br />

10,00 10 × 40 38405002001000 103 50 0,083 §<br />

Guideline values for solid drilling: page 27.<br />

angled convex cross bore centering<br />

bore<br />

L<br />

chamber stack plate<br />

drilling<br />

x d1<br />

rough boring adjustable<br />

with solid carbide shank K<br />

2 cutting edges and 4 guides K<br />

spiral fluted K<br />

with coolant channels K<br />

cutting material: PCD sandwich K<br />

130°<br />

25<br />

1

1<br />

JEL® Dreammax<br />

Drill Reamer with Cylindrical Shank DIN 6535 HA, R.H. cutting<br />

26<br />

L / D solid drilling blind hole forge/casting<br />

skin, interface<br />

x d<br />

l N<br />

L<br />

X 6,0 <strong>–</strong> 12,0 mm · 4×D<br />

4×D § § & & & & & X & & X<br />

§ very good $ good & possible X not possible<br />

K for bore tolerance H7<br />

K 2 cutting edges<br />

K straight fluted<br />

K with coolant channels<br />