8 6 Helmut Gutenberger and Wojciech Pastuszczyn on ... - Messer

8 6 Helmut Gutenberger and Wojciech Pastuszczyn on ... - Messer

8 6 Helmut Gutenberger and Wojciech Pastuszczyn on ... - Messer

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

C<strong>on</strong>trolled system for a natural<br />

gas/oxygen burner<br />

ciency is achieved with pure oxygen since the waste<br />

gas heat losses are minimised by the removal of the<br />

79% of n<strong>on</strong>-reactive nitrogen ballast that exists in air.<br />

Furthermore, the less nitrogen, the less envir<strong>on</strong>mental<br />

polluti<strong>on</strong> through nitrous oxides (NOx).<br />

A large number of lead works in Europe are already<br />

benefiting from <strong>Messer</strong>’s know-how <str<strong>on</strong>g>and</str<strong>on</strong>g> industrial<br />

gases for lead refining in order to maximise the efficiency<br />

of the melting process with Oxijet® lance<br />

systems or the tailor-made burners of the Oxipyr®<br />

family (see table).<br />

Dr. Martin Demuth, <strong>Messer</strong> Austria<br />

THE MAIN ADVANTAGES OF<br />

USING OXYGEN ARE:<br />

+ Greater flexibility due to higher melting efficiency<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> shorter load times<br />

+ Reducti<strong>on</strong> in specific energy c<strong>on</strong>sumpti<strong>on</strong><br />

+ Decrease in amount of waste gas<br />

+ Less envir<strong>on</strong>mental polluti<strong>on</strong> from emissi<strong>on</strong>s<br />

+ Less dust discharge due to lower flow rates<br />

+ Lower investment costs due to smaller<br />

filtrati<strong>on</strong> systems<br />

+ No air preheating necessary<br />

+ Integrated afterburning possible<br />

<strong>on</strong> air 09 · 2008<br />

Lead bulli<strong>on</strong> before further processing: Today the heavy metal is<br />

mainly used for lead accumulators<br />

Cover story : 11<br />

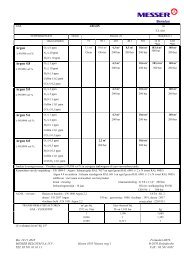

Possible applicati<strong>on</strong>s of oxygen in lead producti<strong>on</strong><br />

Oxygen Pure <strong>Messer</strong><br />

enrichment oxygen process<br />

Primary producti<strong>on</strong><br />

Sinter plant (agglomerati<strong>on</strong>) x Oxijet®<br />

Pb shaft furnace x Oxijet®, Pulsox<br />

Pb-Zn shaft furnace (I.M. furnace) x Oxijet®, Pulsox<br />

Rotary furnace x x Oxipyr®<br />

TBRC/Kaldo x x Oxipyr®<br />

QSL x<br />

Kivcet x<br />

Isasmelt x x Oxijet®<br />

Ausmelt x x Oxijet®<br />

Flash smelter x Oxijet®<br />

Recycling/Sec<strong>on</strong>dary producti<strong>on</strong><br />

Scrap cutting x<br />

Rotary furnace x x Oxipyr®<br />

TBRC/Kaldo x Oxipyr®<br />

Isasmelt x Oxijet®<br />

Ausmelt<br />

Refining<br />

x Oxijet®<br />

Removal of Sb, Sn <str<strong>on</strong>g>and</str<strong>on</strong>g> As<br />

Selective oxidati<strong>on</strong><br />

x x Oxijet®<br />

of Sb, Sn <str<strong>on</strong>g>and</str<strong>on</strong>g> As<br />

Envir<strong>on</strong>ment<br />

x x Oxipot<br />

Sulphur recovery x<br />

Afterburning x x Oxipyr®, Oxijet®