leonardo - Probat

leonardo - Probat

leonardo - Probat

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Roasting Procedures<br />

PROBAT offers the following roasting procedures:<br />

• Drum roaster (type L, G and R)<br />

• Centrifugal roaster (type RZ)<br />

• Tangential roaster (type RT, RN, Gothot)<br />

• Continuous roaster (type RC)<br />

• ThermaTwo 1200<br />

Units<br />

But you usually need more than roasting machines for professional<br />

coffee refinement. For this reason PROBAT provides<br />

solutions starting with the small-scale gourmet roaster and<br />

ending with plant components required by the large companies<br />

of the coffee industry and aligned with their needs.<br />

Such components include various conveyor systems like<br />

conveyor belts and bucket elevators as well as pneumatic<br />

solutions such as high-suction conveyors, suction-impulse<br />

conveying units and high-pressure conveyor units. On the<br />

side circular sieve cleaners, air cleaners and metal separators<br />

provide for a thorough cleansing of green coffee.<br />

For green coffee blends undertaken on the basis of „blending<br />

before roasting“, a blending scale component is available.<br />

Further expedient components such as briquette and pellet<br />

presses for compacting the chaffs ensuing during roasting,<br />

stone separators, conveyor systems and roasted coffee silo<br />

units are available for post-roasting processes. Roasted coffee<br />

scales serve to compose roasted coffee blends („blending<br />

after roasting“) as well as for documenting silo inventories.<br />

Finally, there are ground coffee silos for a pure-grade<br />

storage of the ground coffee.<br />

Controls<br />

PROBAT offers controls for roasters, mills, and whole roasting<br />

units which can be combined to an overall solution. The<br />

existing computer control was redeveloped and sets new<br />

standards in terms of operator convenience and user interface.<br />

Mills<br />

Roll mills range from about 50 up to 5,000 kg per hour. Rolls<br />

are standard equipped with special fluting; depending on the<br />

model, supplementary equipment such as infinitely variable<br />

roll adjustment for attaining any degree of grinding, watercooled<br />

grinding rolls, integrated permanent magnet and turbo<br />

mixer is available.<br />

Products and Technology 06 | 07<br />

Service and Training<br />

PROBAT’s service programme extends beyond assembly,<br />

maintenance, repairs and the fitting of spare parts. PROBAT<br />

also carries out in-house training. This could be a product<br />

training or a training imparting coffee knowledge. Moreover,<br />

individual on-location training at the customer’s roasting<br />

unit is possible at any time.<br />

Spare Parts<br />

Spare parts for PROBAT’s units, roasting machines or grinders<br />

can often be provided even for equipment that is older<br />

than 50 years. On request and as far as possible they can be<br />

tailored to the individual needs of customers.<br />

Environment<br />

Of course, all PROBAT units conform to the respective stringent<br />

laws and environmental regulations. Depending on the market,<br />

different requirements for the treatment of exhaust gas<br />

apply. Besides the prevalent systems such as afterburners or<br />

catalytic converters, PROBAT offers a technology called Proforte<br />

that cleans exhaust gases using a non-flame and regenerative<br />

thermal oxidation process and thus no longer requires<br />

an additional blower burner – which means saving energy.<br />

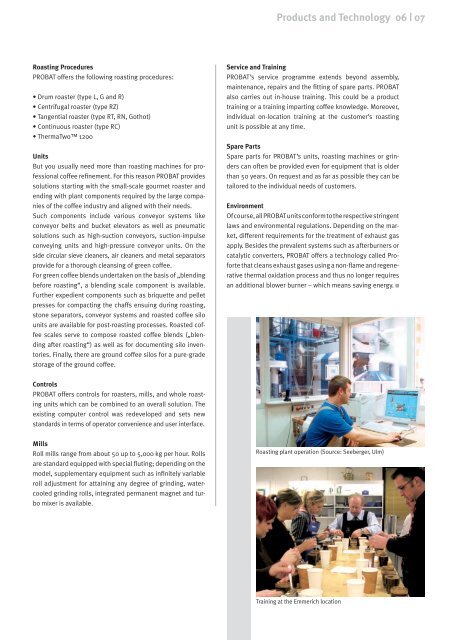

Roasting plant operation (Source: Seeberger, Ulm)<br />

Training at the Emmerich location