Program Information Mobile Hydraulics, Mobile ... - ERGOVIAL

Program Information Mobile Hydraulics, Mobile ... - ERGOVIAL

Program Information Mobile Hydraulics, Mobile ... - ERGOVIAL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

82 <strong>Mobile</strong> Electronics<br />

6<br />

Interfaces for <strong>Mobile</strong> Electronics<br />

U Pumps, motors and valves<br />

with proportional or switched<br />

electrohydraulic control can be<br />

controlled directly from the<br />

outputs of the mobile electronic<br />

units<br />

U Integrated electronic units in<br />

hydraulic components are<br />

preferably controlled via the<br />

CAN bus or analog voltages<br />

U Such input devices as joysticks<br />

and foot pedals deliver setpoints<br />

in the form of input<br />

signals which are processed<br />

by control units, amplifiers or<br />

integrated electronic units.<br />

<strong>Hydraulics</strong><br />

Electronics<br />

Here too, major advantages are<br />

obtained by using the CAN bus<br />

instead of analog voltages, such<br />

as the reduced wiring effort<br />

and extended diagnostic capabilities<br />

U Other input signals for control<br />

units or amplifiers are delivered<br />

by a whole variety of sensors.<br />

Signal transmission with<br />

analog voltages or currents<br />

frequently yields the advantage<br />

of unlimited speed for real-time<br />

control functions, although<br />

the CAN bus can also be used<br />

occasionally<br />

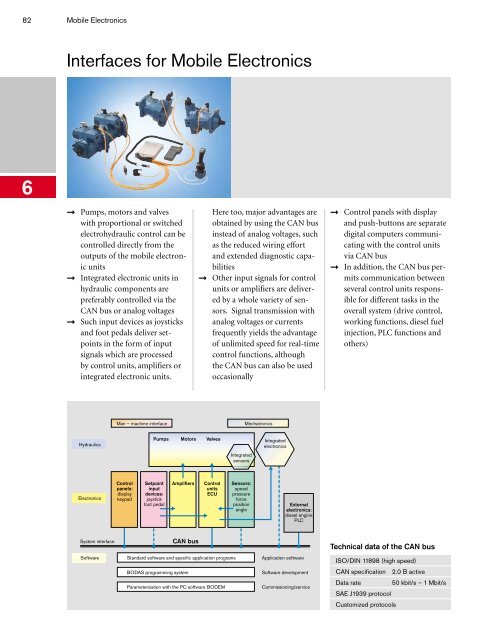

Man – machine interface Mechatronics<br />

Control<br />

panels:<br />

display<br />

keypad<br />

Pumps Motors Valves Integrated<br />

electronics<br />

Integrated<br />

sensors<br />

Setpoint<br />

input<br />

devices:<br />

joystick<br />

foot pedal<br />

Amplifiers Control<br />

units<br />

ECU<br />

System interface CAN bus<br />

Sensors:<br />

speed<br />

pressure<br />

force<br />

position<br />

angle<br />

External<br />

electronics:<br />

diesel engine<br />

PLC<br />

Software Standard software and specific application programs<br />

Application software<br />

BODAS programming system<br />

Parameterization with the PC software BODEM<br />

Software development<br />

Commissioning/service<br />

U Control panels with display<br />

and push-buttons are separate<br />

digital computers communicating<br />

with the control units<br />

via CAN bus<br />

U In addition, the CAN bus permits<br />

communication between<br />

several control units responsible<br />

for different tasks in the<br />

overall system (drive control,<br />

working functions, diesel fuel<br />

injection, PLC functions and<br />

others)<br />

Technical data of the CAN bus<br />

ISO/DIN 11898 (high speed)<br />

CAN specification 2.0 B active<br />

Data rate 50 kbit/s – 1 Mbit/s<br />

SAE J1939 protocol<br />

Customized protocols