The magazine - Lafarge

The magazine - Lafarge

The magazine - Lafarge

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

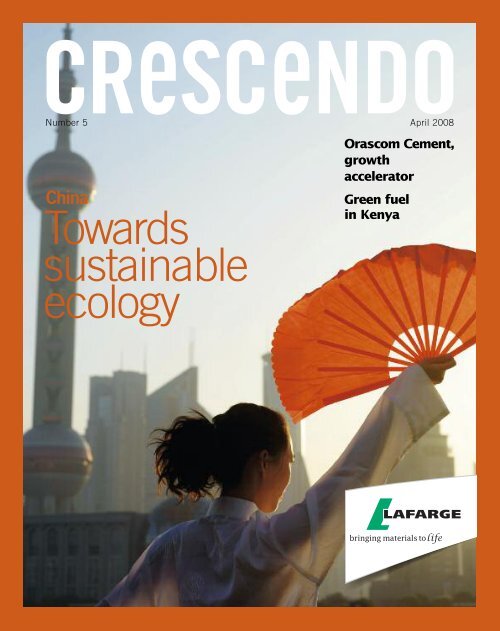

Number 5 April 2008<br />

China<br />

Towards<br />

sustainable<br />

ecology<br />

Orascom Cement,<br />

growth<br />

accelerator<br />

Green fuel<br />

in Kenya

© Photolibrary<br />

EXPLORING<br />

A WORLD ON THE MOVE<br />

06 China, towards sustainable ecology<br />

12 <strong>The</strong> sky’s the limit for today’s towers<br />

16 <strong>The</strong> structural revolution of Villa Navarra<br />

MOVING FORWARD<br />

IN OUR BUSINESSES<br />

20 Orascom Cement, a growth accelerator<br />

26 Human Resources: the challenge of internal growth<br />

30 Health & Safety: forging ahead<br />

CONTRIBUTING<br />

TO A SUSTAINABLE WORLD<br />

36 Objective: “zero net energy”<br />

38 Rebuilding a community<br />

40 Renovated Romanian heritage<br />

42 Bees provide a buzz for biodiversity<br />

44 Green fuel in Kenya<br />

STRIVING<br />

TO ATTAIN OUR FULL POTENTIAL<br />

48 Highlights<br />

BRUNO LAFONT<br />

Chairman and<br />

CEO of <strong>Lafarge</strong> ©<br />

questioning bias, thinking out of the box, progressing every day… Proving<br />

by our initiatives that <strong>Lafarge</strong>’s leadership in sustainable development,<br />

controlled growth and local development is not just empty words… <strong>The</strong>se<br />

are the topics covered in this issue of Crescendo, which focuses on the<br />

international arena, as does our Group. <strong>The</strong> Middle East is our first<br />

destination, increasingly central to <strong>Lafarge</strong>’s strategy since the acquisition<br />

of Orascom Cement. We then head for China, a key growth vector,<br />

representing alone half of the worldwide cement market. Contributing to<br />

growth in China also means supporting this country in achieving its<br />

environmental goals. In this area in particular, the Chinese authorities<br />

recently demonstrated a first-rate, can-do approach to reducing energy<br />

consumption.<br />

Building professionals have a tendency to overestimate the cost of<br />

sustainable buildings. <strong>Lafarge</strong>’s<br />

leading role in the EEB (Energy<br />

Efficiency in Building) initiative<br />

to reduce energy consumption<br />

in buildings aims to contribute to changing this. Finally, Crescendo aims<br />

to show that healthy and dynamic economic growth can go hand-in-hand<br />

with social development and support for local communities. <strong>The</strong> “biofuel”<br />

project in Kenya, the exemplary renovation of a former quarry in Spain,<br />

or the massive mobilization to help people affected by the forest fires in<br />

Greece all demonstrate that our values have meaning and that they are<br />

central to our commitment to excellence.<br />

Progressing every day<br />

BRUNO LAFONT<br />

C R E S C E N D O | L A FA R G E | A P R I L 2 0 0 8 | P A G E 0 3<br />

Jacques Grison

a world on the move<br />

© Photothèque <strong>Lafarge</strong> exploring

EXPLORING A WORLD ON THE MOVE<br />

<strong>The</strong> growth of emerging markets is a cause for concern in light<br />

of the increasing risks from global warming. And China in<br />

particular with its 1.3 billion inhabitants. Criticized for the rise<br />

in greenhouse gas emissions directly caused by<br />

its development, the Middle Kingdom is countering the criticisms<br />

of industrialized nations and putting the spotlight on its can-do<br />

approach to protecting the environment.<br />

China, towards<br />

sustainable ecology<br />

<strong>The</strong> port<br />

of Chongqing,<br />

in Yunnan Province,<br />

second most<br />

industrialized city<br />

in China.<br />

western nations have always been fascinated by China, which houses<br />

a fifth of the world’s population, and this fascination has grown since it<br />

entered the global development arena. China’s economic “miracle” with<br />

high levels of growth (11.4% in 2007) has inspired awe in industrialized<br />

nations. Over the last ten years, China’s GDP to date has grown at a rate<br />

of over 200% according to the International Monetary Fund. Particularly<br />

evident in the building sector, China’s dynamic economy now absorbs<br />

half of the world production of cement. About 30 cities have crossed the<br />

2-million inhabitant mark and population levels in towns developing on the<br />

outskirts can be counted in tens of millions. To meet industrial and<br />

residential energy needs, China is increasing its electrical production<br />

capacity by 50 gigawatts a year, which is like building two new power<br />

stations a week!<br />

<strong>The</strong> soaring economy is affecting China’s population and indirectly<br />

impacting the world economy. But public opinion in the most developed<br />

countries is also voicing its concern. Indeed, people are fearful of global<br />

warming and this exploding economic development is perceived as a<br />

threat for the environment. <strong>The</strong> media and environmental groups were<br />

quick to pinpoint China as the world’s highest producer of CO2 in 2007.<br />

However, two key factors shall be taken in account. First, while China did<br />

actually produce more CO2 than any other country, its rate of emission •••<br />

P A G E 0 6 | L A FA R G E | O C T O B R E 2 0 0 7 | C R E S C E N D O C R E S C E N D O | L A FA R G E | A P R I L 2 0 0 8 | P A G E 0 7<br />

© Photononstop

“ <strong>The</strong> five-year plan intends<br />

to cut energy<br />

consumption by 4% a year.”<br />

••• per inhabitant is still considerably lower than in the United States,<br />

Europe or Japan. Second, focused can-do policies have recently been<br />

put into practice by the authorities to reconcile economic growth with<br />

environmental protection.<br />

<strong>The</strong> first signs of a responsible industry<br />

<strong>The</strong> Chinese authorities have expressed their annoyance at this criticism.<br />

Like the governments of other emerging nations, they dislike being<br />

lectured by countries that based their economic growth on the consumption<br />

of fossil fuels (the main cause of current CO 2 concentration levels in<br />

the atmosphere) for two centuries. <strong>The</strong>y have retorted that they have<br />

absolutely no intention of curbing their growth when their standard of<br />

living is still well below that of more developed countries. Even so, China<br />

is aware of the risks involved in uncontrolled economic development<br />

and the central government has embarked on a new policy focusing on<br />

energy efficiency and reducing pollution.<br />

Pan Yue, Vice-Minister of the Environmental Protection Administration,<br />

described the government’s position in an interview for the Nanfang Zhoumo<br />

<strong>magazine</strong>: “In 2007, we included the need to cut energy consumption<br />

by 4% and to reduce polluting emissions by 2% a year in our eleventh<br />

P A G E 0 8 | L A FA R G E | A P R I L 2 0 0 8 | C R E S C E N D O<br />

PAN YUE<br />

Vice-Minister of the State Environmental<br />

Protection Administration<br />

© Photononstop<br />

Shanghai by night…<br />

Consumption of<br />

electricity is rising by a<br />

colossal 50 GW a year.<br />

five-year plan. Far from falling, in 2006, emissions of the main pollutants<br />

rose, there was an ecological accident every two days on average, and<br />

complaints by the population concerning the environment rose by 30%.”<br />

<strong>The</strong> year 2007 saw a reversal of the trend and energy consumption in<br />

terms of GDP fell by 3.27%. This is encouraging, but still considered<br />

under par by Prime Minister Wen Jiabao in view of the country’s commitments<br />

for 2010. So in another show of willingness, the government took<br />

drastic action, which includes restrictions on new industrial projects if<br />

regions do not comply with environmental regulations. Going beyond<br />

the commitments made by many Western countries, the government<br />

has set the State Environmental Protection Administration, now a fullyfledged<br />

ministry, the goal of producing 15% of renewable energy by<br />

2015 and 30% by 2030.<br />

Three per cent of GDP: the weight of pollution<br />

For the government, the priority is now to reconcile economic development<br />

with respect for the environment. Indeed, China knows that one is<br />

not possible without the other in the 21st century. <strong>The</strong> China Green<br />

National Accounting Study Report thus estimated that pollution cost the<br />

country 512 billion yuan (about 50 billion euros) in 2004, equal to 3% of<br />

© REA<br />

LAFARGE IN CHINA<br />

“In compliance with <strong>Lafarge</strong>’s pledges in the Sustainability Ambitions<br />

2012 programme, we have voluntarily set ourselves objectives that go<br />

beyond local regulations,” explains Marie Fan Xiaohong, Environment<br />

Manager of <strong>Lafarge</strong> Shui On Cement in China. We intend to dramatically<br />

cut our CO2 emissions and to reduce dust emissions, SO2 (sulfur dioxide)<br />

and NOx. Present on the Chinese market since 1994, the Group has<br />

become a leader in the cement business in the south-west of the country<br />

following a joint-venture with a local firm in November 2005. Its twenty<br />

production units offload 24 million tons of cement and employ 10,000<br />

people. Several ultra-modern, highly energy-efficient plants are currently<br />

being built to coincide with market growth. <strong>Lafarge</strong> also produces<br />

plasterboard in Shanghai, Chongqing or Chengdu and is preparing its<br />

rollout on the aggregates and concrete markets. ■<br />

EXPLORING A WORLD ON THE MOVE<br />

GDP. This was an unacceptable situation for the authorities who pledged<br />

new, much more restrictive standards in the National Programme on<br />

Climate Change launched in June 2007.<br />

Against this backdrop, some ambitious projects are under way, including<br />

the eco-city of Dongtan on the island of Chongming, an hour’s boat ride<br />

from Shanghai. This new city should by ready by 2010, coinciding with<br />

the Universal Exhibition in Shanghai. It will be fully self-sufficient, powered<br />

by electricity from wind turbines and solar panels, with local organic food<br />

production and a public transport system comprising a hydrogen bus<br />

and river taxis. <strong>The</strong> new city should be able to house 50,000 people.<br />

This new vision probably fuelled ambition to develop Chongqing, a<br />

30-million-inhabitant megalopolis in south-west China, and where Bruno<br />

Lafont, Chairman and CEO of <strong>Lafarge</strong>, was appointed advisor to the<br />

mayor. “We have set ourselves some very ambitious objectives,” states<br />

Wang Hongju, the city’s mayor. “First, we are planning to double the •••<br />

C R E S C E N D O | L A FA R G E | A P R I L 2 0 0 8 | P A G E 0 9

© DR<br />

CLAUDE MANDIL<br />

Engineer from the École des<br />

Mines, and a graduate of the<br />

École Polytechnique. Former<br />

Director General of Energy and<br />

Raw Materials at the Ministry<br />

of Industry and chairman of the<br />

French Oil Institute.<br />

Executive Director of the<br />

International Energy Agency<br />

from February 2003 to<br />

September 2007.<br />

Claude Mandil<br />

“<strong>The</strong> Chinese authorities<br />

are aware of the threats”<br />

P A G E 1 0 | L A FA R G E | A P R I L 2 0 0 8 | C R E S C E N D O<br />

Claude Mandil, former executive director of the International<br />

Energy Agency (IEA).<br />

Is China the world’s top polluter?<br />

Claude Mandil : In 2007, it was the highest<br />

emitter of CO2 in the world just ahead of the<br />

United States. But if we compare emissions<br />

(5 billion tons of CO2 a year) to population<br />

(1.3 billion inhabitants), China contributes<br />

to CO2 pollution four times less than<br />

Americans or Europeans. Even so, growth<br />

rates in China and other emerging countries<br />

indicate a potentially massive increase in<br />

greenhouse gas emissions.<br />

What are your projections for 2050?<br />

C. M. : It all depends on policies. If nothing<br />

is done, we will probably have been burned<br />

alive before then anyway! If the Kyoto<br />

commitments are respected, we should be<br />

able to bring CO2 emissions back to their<br />

present level. But scientists aren’t happy with<br />

this objective. <strong>The</strong>y defend a scenario based<br />

on a peak in 2015, which should then<br />

be halved by 2050. This is an extraordinary<br />

challenge. It will require an intense<br />

mobilization of opinions, deep changes<br />

in our behavior, and key policies to promote<br />

renewable energy, nuclear energy and<br />

above all technologies for capturing<br />

and confining CO2. What is China’s position with respect<br />

to these scenarios?<br />

C. M. : <strong>The</strong> authorities are aware of the<br />

environmental threats to the planet.<br />

<strong>The</strong>y’re ready to take action as long as<br />

this doesn’t curb their growth.<br />

<strong>The</strong>y’re involved in international<br />

discussions under the UN’s umbrella.<br />

<strong>The</strong> Chinese government insists it has<br />

already considerably stepped up its<br />

efforts. Is this really the case?<br />

C. M. : <strong>The</strong> eleventh five-year plan contains<br />

some very ambitious objectives for cutting<br />

energy consumption per unit of GDP: 20% by<br />

2010. This is much higher than Europe which<br />

is at about 1% a year. But China publicly<br />

announced that it cannot meet this goal at<br />

present. Moreover, emission standards for<br />

new cars, based on those of the European<br />

Union, have been implemented. A policy to<br />

actively promote renewable energy and<br />

nuclear energy is also under way, although<br />

this is a drop in the ocean compared to coal.<br />

Finally, concerning coal, half of their new<br />

facilities are next-generation power stations,<br />

thus more energy-efficient and less polluting.<br />

Can companies play a role in this<br />

mobilization?<br />

C. M. : Pending the implementation<br />

of a post-Kyoto system which covers the<br />

whole world, they can impose the idea<br />

of sector-based agreements between key<br />

industries. Concerning cement firms, <strong>Lafarge</strong><br />

proposes limit thresholds for emissions.<br />

As it produces 50% of worldwide cement,<br />

China must be involved in these agreements,<br />

particularly as a number of its cement works<br />

are recent and more energy-efficient. ■<br />

© Arup.com<br />

•••<br />

economic weight of the city in five years. Secondly, we have embarked<br />

on a can-do policy to cut energy consumption and emissions, introduce<br />

a sustainable development approach and improve our citizens’ living<br />

standards.” <strong>The</strong> city unveiled a five-point plan to achieve these objectives<br />

in 2008. Some of the features include the creation of hi-tech industrial<br />

activities; the closure of several former steelworks, cement works or<br />

polluting facilities; the development of renewable energy; and a system for<br />

controlling waste and pollution.<br />

Other local public-private initiatives are also a solution to economic development<br />

that respects the environment. In this context, the province of<br />

Yunnan has embarked on a key project with a twofold objective. First,<br />

they want to meet considerable local demand for construction materials;<br />

second, they want to modernize this key sector in the provincial economy,<br />

by encouraging energy-saving policies, developing the use of waste as a<br />

fuel alternative or developing new quality products. <strong>The</strong>se measures<br />

resulted in the conclusion of a milestone agreement between <strong>Lafarge</strong><br />

and Chongqing City, covering accelerating development of all the Group’s<br />

activities. It is difficult to know yet whether these new policies will allow<br />

China to achieve an “ecological” miracle this time round, but the development<br />

of an industry able to reconcile economic drive with respect for the<br />

environment could eventually serve as a model for all emerging markets. ■<br />

EXPLORING A WORLD ON THE MOVE<br />

With the policy to cut polluting<br />

emissions, renewable energy<br />

production projects are flourishing.<br />

Here, the project for the eco-city<br />

of Dongtan.<br />

DID YOU KNOW ?<br />

THE GOVERNMENT IS COMMITTED TO ITS<br />

ENVIRONMENTAL POLICY<br />

In a further show of its commitment to sustainable development, China<br />

created a fully-fledged Environment Ministry on March 15, 2008.<br />

This decision will add weight and resources to the former State<br />

Environmental Protection Administration, which worked to combat<br />

pollution and energy waste.<br />

In December 2008, <strong>Lafarge</strong> became a member of the Chinese Cement<br />

Association. It is for us another opportunity to contribute to upgrading<br />

environmental and safety standards of the industry and to embark other<br />

players in a common goal towards sustainability.<br />

<strong>Lafarge</strong> was hailed as one of the ten most influential international brands<br />

at a forum on construction and energy efficiency organized by the Chinese<br />

construction ministry. It received the accolade for being the only company<br />

able to provide an internal plasterboard-based heat insulation system<br />

combining both reliability and energy-efficiency.<br />

C R E S C E N D O | L A FA R G E | A P R I L 2 0 0 8 | P A G E 1 1

<strong>The</strong> sky’s the limit<br />

for today’s towers<br />

P A G E 1 2 | L A FA R G E | A P R I L 2 0 0 8 | C R E S C E N D O<br />

Faced with demographic growth, urban development, and global<br />

warming, many specialists are advocating energy-efficient<br />

and dense modern cities, spreading upwards. Architects are now<br />

inventing comfortable and pleasant sustainable or eco-towers<br />

with the potential offered by groundbreaking techniques and<br />

materials. And the towers are getting taller.<br />

all worldwide population figures are on the rise. <strong>The</strong> number of people<br />

on the planet is increasing and will reach 7.9 billion by 2025, compared<br />

to 6.4 billion today. More than two out of three inhabitants will live in<br />

the world’s cities. China alone will have to build over 400 new cities by<br />

then to absorb its soaring rural exodus. Space is limited and land is<br />

expensive. Most large cities, from São Paulo to Sydney, including Dubai,<br />

Shanghai or Bangkok, are looking upwards. With more than 7,000<br />

buildings higher than 152 meters, Hong Kong held the record for the<br />

city with the most skyscrapers in the world in 2005, ahead of New York<br />

or Tokyo. For many urban planners, high-density development is the<br />

key to countering the threat of global warming and declining natural<br />

resources and this involves building new, even taller towers. Because<br />

these towers use up less land, green and agricultural areas can be<br />

maintained, thus promoting biodiversity; permeable soil areas can also<br />

be spared and traffic congestion can be better controlled. In the new<br />

part of the Russian city of Yekaterinburg, for example, building upwards<br />

has helped to preserve surrounding forest areas and even bring the<br />

forest into the city. With very energy-efficient design, these new<br />

skyscrapers can also significantly reduce greenhouse gas emissions.<br />

In Paris’s La Défense business district, the Generali Tower, to be<br />

completed by 2012, will boast half-opaque, half-transparent façades<br />

to better control heat input, as well as natural ventilation, solar •••<br />

<strong>The</strong> One Exchange Square<br />

in Hong Kong is a group<br />

of three, 52-storey<br />

buildings interlinked<br />

by gardens.<br />

© Getty Images<br />

EXPLORING A WORLD ON THE MOVE

© DR © DR<br />

ALAIN SARFATI<br />

> Architect of the French<br />

Embassy in Beijing, China, and<br />

the Panache Tower project at<br />

Paris’s La Défense, Alain Sarfati<br />

runs Area, a multidisciplinary<br />

agency instrumental in the<br />

construction of several new<br />

towns in the 1970s. Area was<br />

behind the building of the<br />

National Archive Centre for the<br />

World of Work in Roubaix<br />

(1993), the National <strong>The</strong>atre in<br />

Toulouse’s city centre (1998)<br />

and the Bel Air area in Saint-<br />

Germain-en-Laye.<br />

THOM MAYNE<br />

> Winner of the Pritzker<br />

Architecture Prize in 2005,<br />

Thom Mayne created<br />

the Morphosis agency and the<br />

Southern California Institute<br />

of Architecture. Designer<br />

of the head office of BMW<br />

in Munich, he is currently<br />

building the Lighthouse Tower<br />

in Paris’s La Défense and<br />

working on other projects such<br />

as the Design Center in Taipei,<br />

China, the Sun Tower in South<br />

Korea and the Olympic Village<br />

in New York.<br />

P A G E 1 4 | L A FA R G E | A P R I L 2 0 0 8 | C R E S C E N D O<br />

Alain Sarfati’s<br />

project for the<br />

Emperor Tower.<br />

La Défense’s future<br />

Lighthouse Tower<br />

designed by<br />

Thom Mayne.<br />

© S. Area / Sarfati<br />

© SIPA<br />

••• sensors, wind turbines on the roof, and outside gardens on each<br />

floor. Its neighbouring “Phare” or Lighthouse Tower will be equipped<br />

with a “double skin” on the south side and a transparent façade on the<br />

north side to maximize energy efficiency, in addition to a rainwater<br />

recovery system.<br />

Progress from all sides<br />

Engineering has progressed so much over the last few years that some<br />

real technical feats are now possible. Some of these include development<br />

of interlacing outside frames; load-bearing lattices; super corner<br />

columns or reinforced concrete pillars; the use of pendulum-like<br />

counterweights to reduce building oscillation; and groupings of thin<br />

high-rise buildngs. New materials have also been developed, including<br />

light-sensitive glass or ultra-high performance concretes. “<strong>The</strong>y offer<br />

unprecedented curving potential,” comments architect Alain Sarfati,<br />

designer of the curvy Panache Tower project in La Défense. <strong>The</strong>se<br />

developments are wings allowing architects to fly even higher. Like giant<br />

minarets, dominating Kuala Lumpur’s skyline, the 452-meter Petronas<br />

Twin Towers used to be the highest buildings on record. <strong>The</strong>n last<br />

February, they were outdone by Burj Dubai in the United Arab Emirates,<br />

standing at a colossal 604.9 meters. But this is only the tip of the<br />

tower… Indeed, the developers hope to build it up to 800 meters. But<br />

this is a mere trifle compared to the Bionic Tower project, a 1,228-meter<br />

“rocket”, basking in artificial lakes and gardens, in Shanghai, or the<br />

2,000-meter-high set of 55 stacked pyramids, brainchild of architect<br />

Shimizu in Tokyo.<br />

Fascinating or off-putting?<br />

As fascinating as they may be, these buildings are not to everyone’s<br />

taste. While the Financial Center in Taipei or the pagoda-shaped Jin<br />

Mao Tower in Shanghai fit naturally into the local backdrop, other<br />

designs have been less convincing. Symbols of power, tower blocks<br />

were not really intended to be well-designed urban furniture for<br />

everyone’s benefit. “<strong>The</strong> upshot is that the isolated blocks are more<br />

costly, with higher charges and do not address high-density objectives.<br />

EXPLORING A WORLD ON THE MOVE<br />

<strong>The</strong> land use coefficient is only 1.5 at La Défense, but three for Paris<br />

and eight for Chicago!” comments Alain Sarfati. He goes on to explain<br />

that the 19th century left us two major, but incompatible revolutions:<br />

“Horizontal speed, by train and car, which promoted urban sprawl, and<br />

vertical speed in elevators, a factor which contributed to the development<br />

of high-rise buildings. In some large cities, the problem is that no<br />

choice was made between the two phenomena,” he said. “So many<br />

people opted to live on the outskirts of cities in poorly situated tower<br />

blocks, with insufficient service networks, ultimately leading to the rejection<br />

of this type of building. Towns to live in are needed, welcoming all<br />

members of society, with powerful public transport networks and<br />

spacious gardens. In short, a real social project.” But positive changes<br />

are also afoot in this area. Thom Mayne’s “Phare” Building at La<br />

Défense is designed to blend in with its environment. “Rather than an<br />

isolated and independent building, we sought to develop a hybrid structure<br />

generating smooth transit through underground areas... up to<br />

horizontal public areas which then become vertical, thus offering a<br />

wealth of cultural and commercial experiences,” the architect explains.<br />

By revisiting the functional mix of offices, accommodation, shops and<br />

leisure and better designing the buildings, they should also offer a<br />

higher quality of life. <strong>The</strong> colossal Burj Dubai and the Shimizu Pyramid<br />

are cities in a tower. Accommodation, offices, shops, hotels, hospitals…<br />

<strong>The</strong> entire urban fabric can be contained in a vertical structure,<br />

with roads replaced by floors to create space and interactions on<br />

several levels. ■<br />

C R E S C E N D O | L A FA R G E | A P R I L 2 0 0 8 | P A G E 1 5

EXPLORING A WORLD ON THE MOVE<br />

La Villa Navarra opens a new era in materials. Its roof in<br />

Ductal® concrete is a world first, the hybrid fruit of the<br />

boldness and expertise of Rudy Ricciotti*, architect and<br />

laureate of the National Architecture Grand Prix 2006,<br />

Romain Ricciotti, structural engineer, and Mouloud Behloul,<br />

<strong>Lafarge</strong> concrete engineer. <strong>The</strong>y meet up for a round table to<br />

talk about this building.<br />

<strong>The</strong> structural<br />

revolution<br />

of Villa Navarra<br />

a<br />

P A G E 1 6 | L A FA R G E | A P R I L 2 0 0 8 | C R E S C E N D O<br />

n exceptional work, both aesthetically and for<br />

its technical complexity, Villa Navarra looks like<br />

a long, furtive silhouette set on the very rock,<br />

simply laid bare. And it is around this notion<br />

of “minimal aesthetics”, so dear to Rudy<br />

Ricciotti, that the discussion begins.<br />

Rudy Ricciotti : Our intention was to limit<br />

the villa’s impact on the site by blending it into<br />

the slope, without backfill, following a logic<br />

of unobtrusiveness. <strong>The</strong> outcome of this logic<br />

is its ultra-thin Ductal® roof. Can you remind<br />

us of size, Romain?<br />

Romain Ricciotti : 40 meters long,<br />

with a 7.86-meter cantilever and edges<br />

3 centimeters thick.<br />

Mouloud Behloul : In terms of concrete,<br />

that’s a sheet of paper! Ductal® is an ultrahigh<br />

performance fibre concrete, which allows<br />

us to break away from passive structures.<br />

It opens the way to a huge reduction in<br />

material and great creative freedom in forms,<br />

which, in this case, are curved, feminine.<br />

Romain Ricciotti : <strong>The</strong>se forms were<br />

dictated by external restrictions, such as the<br />

© Philippe Ruault<br />

width of the trucks used to transport materials.<br />

But also by the resolute demand for optimum<br />

mechanical yield, similar to that of steel<br />

structures. This structural roof only works in<br />

flexion, with a warp of 4 millimeters as a result<br />

of temperature variations, which is completely<br />

new. It has no incorporated waterproofing or<br />

insulation.<br />

Mouloud Behloul : Here, the material<br />

is used in its purest expression. Its specific<br />

nature – neither metal, nor wood, nor glass,<br />

and not really concrete – forced us to re-ask<br />

all those questions that “reinforced concrete”<br />

engineers hardly ever ask these days and to<br />

re-invent design and manufacturing methods.<br />

So, at the pouring stage, we had to calculate<br />

and check the direction of the fibres,<br />

because these change the mechanical<br />

properties of the concrete.<br />

Rudy Ricciotti : What we are talking about<br />

here is the very core of our work, which, in my<br />

opinion, is all about a choreography of efforts:<br />

an exceptional material, used in nuclear power<br />

stations, poured in aluminum moulds similar<br />

to the moulds used in the aeronautics industry,<br />

but employed with the traditional, even<br />

archaic, skills of craftsmen.<br />

Romain Ricciotti : You mention<br />

a “choreography of efforts”… It’s worth<br />

pointing out that the successive revolutions<br />

initiated by concrete have always come<br />

about through “committed” collaboration<br />

between architects and engineers.<br />

Mouloud Behloul : As I see it, the Navarra<br />

project is the fruit of reflection on the structural<br />

properties of Ductal® concrete. It probably<br />

marks the beginning of new beliefs and new<br />

practices concerning structures.<br />

Rudy Ricciotti : And I’m fairly optimistic<br />

about the chances of seeing the use<br />

of this exceptional material becoming very<br />

widespread.<br />

RUDY RICCIOTTI<br />

ROMAIN RICCIOTTI<br />

MOULOUD BEHLOUL<br />

A HOUSE-GALLERY<br />

> Enrico Navarra’s name is widely<br />

associated with Jean-Michel<br />

Basquiat, since he acted as one<br />

of his art dealers in the 1880s.<br />

He has just closed his Parisian<br />

art gallery down. He intends<br />

to make the Villa Navarra and<br />

its exceptional site into an<br />

enigmatic gallery, accessible only<br />

via a virtual visit.<br />

> Ductal® is ultra-high<br />

performance concrete made<br />

by <strong>Lafarge</strong>: its resistance is six to<br />

eight times greater than that<br />

of conventional concrete<br />

and it contains metallic fibers<br />

that make it ductile.<br />

While it enables a level of finesse<br />

never before seen in classic<br />

concrete works, it is also<br />

resistant to bending.<br />

It can undergo major<br />

transformations (pressure<br />

or dilation, for example), without<br />

breaking and it is resistant<br />

to hostile external conditions,<br />

such as abrasion, pollution, bad<br />

weather and scratches.<br />

C R E S C E N D O | L A FA R G E | A P R I L 2 0 0 8 | P A G E 1 7<br />

© Élise Sévère © Agence Ricciotti<br />

© Agence Ricciotti

© Ignus Gerbermoving<br />

forward<br />

in our businesses

P A G E 2 0 | L A FA R G E | A P R I L 2 0 0 8 | C R E S C E N D O<br />

With the recent acquisition of Orascom Cement,<br />

the Middle East’s leading cement producer, <strong>Lafarge</strong> has<br />

seized the opportunity to firmly establish its presence<br />

in emerging markets promising brisk growth. This is<br />

another advantage that widens the Group’s development.<br />

Orascom Cement,<br />

a growth accelerator<br />

o<br />

rascom Cement is one of the major players on the world scene of<br />

growing markets. <strong>The</strong> company founded by Egypt’s Sawiris family in<br />

the Middle East is ranked number one in its field. Orascom Cement<br />

occupies a leading position in Egypt, Algeria, the United Arab Emirates<br />

and the north of Iraq. It is also very well-placed in many markets offering<br />

high potential (Saudi Arabia, Syria and Turkey, but also Nigeria, Pakistan<br />

and North Korea). What is the key to its success? A smart equation<br />

associating quality industrial assets, excellent positioning in booming<br />

markets, and low production costs.<br />

An Egyptian success story spanning 30 years<br />

Founded by Onsi Sawiris in the 1970s, Orascom Construction Industries<br />

went on, in over two short decades, to become one of Egypt’s<br />

leading construction companies. It built its reputation with varied and<br />

complex construction projects: luxury hotels, railways, office and<br />

commercial buildings, and even wastewater treatment plants. At the<br />

turn of the 1990s, Onsi Sawiris passed on control of the company to his<br />

son, Nassef Sawiris. He embarked on an ambitious diversification<br />

programme, investing in cement. After remarkable success in Egypt,<br />

Nassef Sawiris launched the internationalization of his group, starting •••<br />

In the United Arab<br />

Emirates, the new town<br />

of Dubai Marina,<br />

an ambitious project,<br />

should provide housing<br />

for 120,000 inhabitants.<br />

© John Lamb<br />

MOVING FORWARD IN OUR BUSINESSES

MOVING FORWARD IN OUR BUSINESSES<br />

© Alain Le Breton<br />

NASSEF SAWIRIS<br />

> After joining the Orascom<br />

group in 1992, Nassef Sawiris<br />

became CEO of Orascom<br />

Construction Industries in 1998,<br />

ahead of an initial public<br />

offering completed in 1999.<br />

His strategy, based on<br />

geographic expansion and<br />

investment in complementary<br />

activities, such as cement,<br />

has helped him transform<br />

the company into an<br />

international level group.<br />

P A G E 2 2 | L A FA R G E | A P R I L 2 0 0 8 | C R E S C E N D O<br />

••• in Algeria. In a few years, Orascom Cement made strong progress,<br />

both in terms of growth and profitability. Today, Orascom Cement has<br />

a cement production capacity of 35 million tons, which should grow<br />

to 45 million tons by 2010, with an operating margin of over 40%.<br />

<strong>The</strong> factories, all new or recent, are already organized to meet steep<br />

rises in production.<br />

Today, the Middle East’s leading cement producer has entered a<br />

new phase through its merger with the world leader, <strong>Lafarge</strong>. <strong>The</strong><br />

acquisition of Orascom Cement is completely in line with <strong>Lafarge</strong>’s<br />

growth strategy in the emerging markets. By acquiring a leading<br />

position in a region offering high potential growth and profitability,<br />

<strong>Lafarge</strong> has made a long term strategic operation.<br />

A major urban growth phenomenon<br />

<strong>The</strong> Middle East enjoys a number of advantages in terms of economic<br />

growth, demography and urbanization. <strong>The</strong> infrastructure needs are huge<br />

and demand for cement is constantly growing in the region. <strong>The</strong> dynamic<br />

state of the construction sector in the Middle East is far from running out<br />

of steam. <strong>The</strong> phenomenon of urbanization affecting most of the countries<br />

in the zone implies steadily growing needs in housing and infrastructure<br />

C R E S C E N D O | L A FA R G E | A P R I L 2 0 0 8 | P A G E 2 3<br />

© DR Médiathèque <strong>Lafarge</strong><br />

Orascom’s production<br />

sites complement<br />

<strong>Lafarge</strong>’s installations,<br />

creating dense,<br />

coherent coverage<br />

of a zone where<br />

demand is high.<br />

equipment. Thanks to a solid, steadily growing economy fed by oil and gas<br />

revenue, the upper-middle classes enjoy increased purchasing power<br />

and they are turning towards new real estate products. And the States have<br />

embarked on multiple major projects. <strong>The</strong> projects of the United Arab<br />

Emirates offer a glimpse of boom years ahead for the sector. <strong>The</strong> construction<br />

of ten museums has already been announced, including a Guggenheim<br />

Foundation by architect Frank Gehry and the Louvre Universal<br />

Museum in Abu Dhabi, designed by Jean Nouvel, 2008 laureate of<br />

the Pritzker architecture prize for his work. Also in the works is a huge<br />

Islamic Arts museum in Qatar, designed by Ieoh Ming Pei and •••

MOVING FORWARD IN OUR BUSINESSES<br />

••• Jean-Michel Wilmotte, the French-American duo of architects of the<br />

Grand Louvre in Paris. Even the Bahrain archipelago has hired the services<br />

of star architects, including Anglo-Irakian Zaha Hadid, Japan’s Tadao<br />

Ando and France’s Architecture Studio. Similarly, Saudi Arabia intends to<br />

construct an immense tower 1,609 meters high at Djebbah, on the Red<br />

Sea. This is a record, compared to the 800 meters of the Burj Dubai or<br />

the 1,001 meters of the future Kuwait Tower.<br />

Boosting our presence and know-how<br />

This merger also brings <strong>Lafarge</strong> a rich source of human resources.<br />

<strong>Lafarge</strong> will benefit from the know-how of qualified teams and a development<br />

culture forged in the emerging markets. This also makes a<br />

springboard for the development of the Group’s Aggregates<br />

& Concrete Business in the region.<br />

P A G E 2 4 | L A FA R G E | A P R I L 2 0 0 8 | C R E S C E N D O<br />

With the acquisition of Orascom Cement, many<br />

teams with diversified skills and competences now<br />

enrich the Group’s potential.<br />

By combining the internal development programme currently under<br />

way within its Cement Business with this acquisition, the Group’s total<br />

annual production capacity should grow by 50% between 2007 and<br />

2010, to reach 260 million tons of cement.<br />

Altogether, this is a strategic operation that, singles out <strong>Lafarge</strong> as<br />

the best-performing company in its sector and the leader in the highgrowth<br />

emerging markets. ■<br />

© Ignus Gerber<br />

© DR<br />

ÉRIC VERDEIL<br />

Researcher at the CNRS, deputy<br />

director of <strong>magazine</strong><br />

Géocarrefour and the author<br />

of several works.<br />

Éric Verdeil<br />

<strong>The</strong> Middle East, a region<br />

with huge potential<br />

Éric Verdeil, a researcher at the CNRS, University of Lyon,<br />

is specialized in urbanism in the Middle East.<br />

What can you tell us about today’s<br />

demographic situation of the Middle<br />

Eastern countries?<br />

Éric Verdeil : Globally, the whole Middle<br />

East region maintains annual demographic<br />

growth of close to 2%, noticeably higher<br />

than all the other developing regions. Egypt,<br />

for example, has a high fertility rate.<br />

Generally speaking, and in comparison with<br />

other regions of the planet, such as South<br />

Asia, the Middle East is experiencing<br />

significant demographic growth.<br />

What trends in urbanization<br />

can we see in the Middle East?<br />

É. V. : In this region, there is a considerable<br />

movement towards urbanization.<br />

We observe a still strong trend towards<br />

and around the capitals. However, there is<br />

another major phenomenon to underline,<br />

which is the transfer of population towards<br />

secondary towns. This is urbanization<br />

developing around small and medium-sized<br />

conurbations. This is a major trend,<br />

because these towns have great needs<br />

in infrastructure and equipment. Because<br />

of this, many places have to make<br />

consequent efforts to catch up with the<br />

level of the larger cities.<br />

<strong>The</strong> rate of growth in GDP in the developing<br />

countries in the Middle East increased<br />

steeply in 2007. What are the principal<br />

factors behind this rise?<br />

É. V. : <strong>The</strong> revenue coming from<br />

hydrocarbons makes a decisive contribution<br />

to supporting the growth of the Middle East<br />

countries. <strong>The</strong> Maghreb region also benefits<br />

from financial fallout. <strong>The</strong> capitals of the<br />

Gulf export their capital derived from oil to<br />

the services sector, real estate investment,<br />

hotel projects, etc. Indeed, we observe clear<br />

progress in the rate of growth of GDP.<br />

In particular, this benefits the better-off<br />

middle classes with high potential<br />

purchasing power. In the real estate sector,<br />

this is reflected in the research into new<br />

products. This is certainly a restricted<br />

market in terms of housing, but one that<br />

represents a segment enjoying very<br />

high growth. <strong>The</strong>se upper-middle classes<br />

have links abroad and seek their inspiration<br />

in other styles of living. For example, they<br />

tend to turn towards the urban periphery to<br />

design new living spaces. ■<br />

C R E S C E N D O | L A FA R G E | A P R I L 2 0 0 8 | P A G E 2 5

P A G E 2 6 | L A FA R G E | M A Y 2 0 0 8 | C R E S C E N D O<br />

Staff levels need to be adapted to achieve the Group’s objectives<br />

in terms of bolstering production capacity.<br />

Forecasting needs require new means of recruitment in regions<br />

where competition to find qualified staff is tight.<br />

Human Resources:<br />

the challenge of internal<br />

growth<br />

t<br />

o meet growing demand in the building sector, <strong>Lafarge</strong> decided to<br />

increase its production capacity by 45 million tons of cement between<br />

2006 and 2010. This is an ambitious challenge, particularly now that<br />

the Group’s growth pools are far from its bases, in China, India, Southeast<br />

Asia, Central Europe, Africa, and the Middle East. All regions<br />

where technical skills are required to meet the huge growth of the<br />

building sector. And every new plant means 200 to 300 new<br />

employees, engineers, supervisors, operators and foremen need to<br />

be recruited and trained.<br />

“<strong>The</strong> acceleration of our growth has led us to review the way we were<br />

organized, in order to anticipate our needs upstream, to increase our<br />

recruitments and to train new teams,” states Pascal Rousseaux, in<br />

charge of human resources for the Cement technical teams. In its<br />

Cement Business, <strong>Lafarge</strong> recruited 585 engineers in 2007, compared<br />

to 350 in 2006. This year, the company is planning to take on 800<br />

employees, and recruitment should top the thousand mark by 2009.<br />

This is not even counting the four technical centres across the world,<br />

which also boosted their headcount by an additional 130 to 140<br />

engineers in 2008. “We started with an in-house strategy, promoting<br />

our best talents to management positions,” recounts Keith Deighton,<br />

in charge of organization and human resources in the Cement •••<br />

Planned production capacity<br />

increases mean that<br />

recruitment of skilled staff is<br />

now central to Group strategy<br />

on a worldwide level.<br />

© Jacques Grison<br />

MOVING FORWARD IN OUR BUSINESSES

PROMISING GATEWAYS BETWEEN<br />

INDIA AND NORTH AMERICA<br />

This is the first talent partnership of its kind<br />

in <strong>Lafarge</strong> wherein two units. <strong>Lafarge</strong> in India<br />

and in North America have entered into a formal<br />

partnership to source talent that benefits both<br />

operations. With a year’s partnership, <strong>Lafarge</strong><br />

in North America has been able to gain access to<br />

deep technical cement experience. As the<br />

programme applies to existing talent as much as<br />

it does new recruits, it also helps <strong>Lafarge</strong> in India<br />

with retention efforts in a hot marketplace.<br />

“<strong>The</strong>se motivating career prospects for<br />

candidates have helped us to improve our image<br />

as an employer, enabling us to recruit more<br />

easily,” explains Reva Prakash, human resources<br />

manager for the Cement Business in India. About<br />

thirty engineers are currently on the programme,<br />

some are already working in Canada, with others<br />

on the course at the <strong>Lafarge</strong> plants in India,<br />

Malaysia and Indonesia, which recently joined<br />

the programme. “<strong>The</strong> prospects are very<br />

promising,” says David Cheney, in charge<br />

of human resources in the Cement Business in<br />

the United States and Canada; “We can cover<br />

20% of our human resources needs by recruiting<br />

about thirty engineers and technicians in India<br />

every year.” While this project continues<br />

to expand its territories breaking geographical<br />

barriers, the journey is already a win-win success.<br />

As Raji Ramanan Project Leader for this<br />

partnership says, “Managing the cultural<br />

transition and development of these talented<br />

professionals to fit the new work environment<br />

were the biggest challenges that we had to face<br />

in this project and while we work as a team across<br />

countries we see the efforts pay already.” ■<br />

P A G E 2 8 | L A FA R G E | M A Y 2 0 0 8 | C R E S C E N D O<br />

© DR Médiathèque <strong>Lafarge</strong><br />

For many, incentive for joining<br />

the Group lies in the interesting<br />

career prospects it offers.<br />

“I CAME TO DRINK AT<br />

THE SOURCE”<br />

Marc Sinclair Mamiah,<br />

a young engineer from<br />

Cameroon thus<br />

summarizes his move<br />

to the TCEA (Technical<br />

Center Europe - Africa)<br />

in France, in the process<br />

and quality department<br />

(DPQ). This expatriation<br />

is part of his career plan:<br />

he believes it is an<br />

opportunity to progress<br />

and occupy positions<br />

with more responsibilities<br />

when he goes back to his<br />

original unit in Cameroon.<br />

••• Division. “But this method, principally used in China, is not enough<br />

given our rate of growth and the number of positions to be filled.” As<br />

a matter of fact, <strong>Lafarge</strong> plans to recruit 1,000 employees a year in<br />

China, to accompany its growth.<br />

Attracting employees and keeping them<br />

In addition to numbers, the quality of these employees is also a primary<br />

concern. But to attract the best talent, the Group has to deal with<br />

competition and local players. Not to mention oil and mining companies.<br />

"Our growth prospects leds us to rethink our strategy,” continues Keith<br />

Deighton. “We adopted a new, more forward-looking approach to anticipate<br />

our human resources needs. <strong>The</strong>n we started to recruit preproject<br />

to give ourselves time to find the right employees and train<br />

them.” This strategy resulted in the Spoutnik project in Russia and<br />

the former Soviet block and satellite states in 2007. A unit comprising<br />

a human resource project manager, two headhunters and a careers<br />

manager joined the local HR teams. A real war machine! <strong>The</strong> model<br />

was so successful that it was adapted for China, India and Africa.<br />

“Spoutnik made us completely rethink our operating procedures,”<br />

comments Pascal Rousseaux. “<strong>The</strong> business units now view the industrial<br />

challenges of growth and their human resources issues from a<br />

more global standpoint.”<br />

Another brand-new initiative is that <strong>Lafarge</strong>’s human resources<br />

managers in North America are now working hand-in-hand with their<br />

Indian counterparts. <strong>The</strong> goal is to recruit engineers or technicians in<br />

India to offset the lack of available labour in the United States and<br />

Canada (see box). Similarly, the Group recruits young high-flyers by<br />

MOVING FORWARD IN OUR BUSINESSES<br />

setting up partnerships with engineering schools. “Finding them is<br />

one thing, keeping them is another,” emphasizes Deighton. “Money is<br />

not enough of an incentive. Our strong advantage is that we offer<br />

motivating professional careers and prospects of rapid promotion. Our<br />

values and our Principals of action are strong assets in this environment.”<br />

Indeed, Group structure, based on a smaller business unit<br />

organization, offers potentially fast promotion to high management<br />

positions. This prospect should appeal to many young graduates<br />

destined to become the top managers of tomorrow. ■<br />

PLANTS BECOME SCHOOLS<br />

Appearances may be deceptive, but these are not run-of-the-mill plants.<br />

<strong>The</strong> school plants are a concept designed by <strong>Lafarge</strong> in 2007 to allow<br />

employees from all backgrounds to do training courses in real working<br />

conditions. This system teaches the industrial skills required to become<br />

a control room operator, maintenance inspector or process technician.<br />

Special sessions are organized for the engineers. <strong>The</strong> programme allows<br />

new recruits and units joining the Group following a takeover to quickly<br />

take the <strong>Lafarge</strong> culture and work methods on board. Dedicated teams<br />

monitor and teach trainees throughout their course. Five school plants<br />

are already up and running: two in China, one in Kenya for sub-Saharan<br />

Africa, one in Mexico for South America and one in Austria for Central<br />

and Eastern Europe. ■<br />

C R E S C E N D O | L A FA R G E | M A Y 2 0 0 8 | P A G E 2 9

MOVING FORWARD IN OUR BUSINESSES<br />

© DR Médiathèque <strong>Lafarge</strong><br />

New Group safety standards<br />

have been developed with the<br />

aim of eventually eliminating<br />

severe work-related incidents.<br />

Safety, the basis of good performance, has long been<br />

an important issue for the Group and for a number of years<br />

<strong>Lafarge</strong> has ranked amongst the best performers within<br />

its sector. However in January 2006, newly appointed<br />

CEO Bruno Lafont decided that this was not enough: <strong>Lafarge</strong><br />

should do better, in order to fully reflect its values at work.<br />

Health & Safety:<br />

forging ahead<br />

with the arrival of the new CEO in 2006, a pledge was taken: <strong>Lafarge</strong><br />

should reach world-class status, be one of the “best of the best”, and<br />

join the world’s elite of industrial groups in terms of employee health<br />

and safety. In the words of Bruno Lafont, “we cannot be the sustainable<br />

leader if we are not excellent in safety.”<br />

<strong>The</strong> objectives were to halve the frequency rate of accidents at work<br />

between 2005 and 2008, with the aim of eventually eliminating all<br />

work-related fatalities. <strong>The</strong> process set in motion two years ago is<br />

bearing its fruits today. <strong>The</strong> first move was an extensive safety audit<br />

by external consultants that highlighted, above all, the need for a<br />

coherent Group policy and basic universal rules, and the need for<br />

line management to get more involved and committed.<br />

<strong>The</strong> audit quickly triggered action. In addition to the 400 health and<br />

safety professionals worldwide, a central Health & Safety Competency<br />

Centre was created and one of the Group’s top 25 managers,<br />

Dominique Calabrese, was appointed its head. <strong>The</strong> team worked to<br />

prepare a single Group policy and formulated eleven basic rules that,<br />

today, have been implemented throughout the organization. Across<br />

each of the 2,000 sites of the Group, the employees have signed the<br />

Safety Group policy with all the managers. Needless to say, our health<br />

and safety strategy goes far beyond implementing local statutory •••<br />

C R E S C E N D O | L A FA R G E | A P R I L 2 0 0 8 | P A G E 3 1

MOVING FORWARD IN OUR BUSINESSES<br />

OUR SAFETY<br />

POLICY SYMBOL<br />

TALKING IT THROUGH IN INDIA<br />

<strong>Lafarge</strong> Gypsum in Rajasthan, India, has understood one thing:<br />

raising safety awareness must adapt to the local culture. Here,<br />

in a country where people are not as aware of the risks, a very special<br />

initiative was created. In July 2006, a new business unit and<br />

manufacturing plant was created and, from the beginning, safety<br />

culture was made an integral part with training carried out on all<br />

subjects and in all departments, not just on site. We provide outdoor<br />

safety training for the sales and marketing team, and a very special<br />

concept known as the “Forum”. Tailor-made to the local environment<br />

where literacy is not high, the “Forum” invites the group of 250<br />

workers to gather together around 1pm every Monday for a meeting<br />

in the open. People assemble voluntarily, together with their entire<br />

families who have come from villages in the region to live beside the<br />

site. <strong>The</strong>y sit on the ground and talk about dangers on the site.<br />

“We moved from a situation of little safety to risk awareness.<br />

And there is lots of human value in it; it has helped us to connect<br />

with the workers socially. When a manager is present on site,<br />

he too comes to sit on the ground and takes part,” explains Jérémie<br />

Rombaut, Project & Safety Manager, India. “<strong>The</strong> message we give is:<br />

‘we are all equal’. We have cared for them more than their contractors<br />

who are normally responsible for this training.” <strong>The</strong> high point came<br />

one day when the ladies sat in a circle and began singing a song they<br />

had composed on safety in <strong>Lafarge</strong>! <strong>The</strong> workers have adopted our<br />

safety spirit. Not surprisingly, this initiative has been selected<br />

as one of the best and most innovative Group-wide safety projects. ■<br />

P A G E 3 2 | L A FA R G E | A P R I L 2 0 0 8 | C R E S C E N D O<br />

••• regulations. We have tried to understand how accidents occur and<br />

have isolated the four most dangerous processes in our activities:<br />

working at height, insulation, confined space entry and mobile<br />

equipment. We have begun to develop Group standards for all of<br />

these activities.<br />

A long-term link between safety and performance<br />

To eliminate the risks associated with these tasks, each of our<br />

2,000 production plants are undertaking specific safety initiatives<br />

adapted to their local needs and culture. Sometimes the idea can be<br />

simple, such as in Latin America where large stickers have been pasted<br />

to the walls of offices and factories, showing the height over which extra<br />

precautions such as personal protective equipment or scaffolding must<br />

be taken. By April 2008, our goal is that all employees will work at height<br />

in a safe manner. Or more complex, as in Germany where <strong>Lafarge</strong><br />

Gypsum now organizes full training for employees and clients on how to<br />

correctly and safely load a truck, in order to avoid loss of load leading to<br />

accidents or road obstruction. <strong>The</strong> desire to reduce fatalities and injuries<br />

likewise prompted the creation of the Forklift Challenge, an international<br />

competition involving eight of our Asian countries that raises awareness<br />

and competency levels, while also being fun and motivating for everyone.<br />

Apart from saving lives, there is a long-term link between safety and<br />

performance. When people are employed in a safe environment, it<br />

affects how they work in general. Some plants, such as in Concrete in<br />

Eastern Canada, find that an early morning safety talk by the foreman,<br />

called the “Daily Tool Box Talk”, is a good way to start the day. Our<br />

plants in Chile and Mexico, have found that an excellent way to raise<br />

safety awareness is to invite employees’ children to a safety workshop<br />

on how to ride a bicycle or what to do in case of an earthquake.<br />

Experiences such as these make safety a focal point and a subject<br />

everyone has in common.<br />

Zero tolerance<br />

<strong>The</strong> construction site of the Tula cement plant, in Northern Mexico,<br />

demonstrates the priority given to safety through its “zero tolerance”<br />

principle, with a number of accidents eleven times lower than the<br />

country’s national average. <strong>The</strong> construction site was finished four<br />

months ahead of schedule due to the low rate of accidents and as a<br />

result, Tula has become one of the most competitive cement plants in<br />

the region through its commitment to safety.<br />

A “safety month” will be organized in June 2008 in all <strong>Lafarge</strong> sites<br />

around the world in order to raise safety awareness even more. During<br />

this period, health and safety will be promoted internally and externally<br />

on all the sites, through dedicated operations: competitions, educational<br />

activities, open doors days… <strong>The</strong>se kinds of action mandate and improve<br />

communication and team spirit; moreover, they represent an<br />

unprecedented global movement in terms of safety in the workplace<br />

© Shaun Browne<br />

BRINGING TRAINING CENTRES ON SITE IN MALAYSIA<br />

A shining example for the rest of the Group comes from the Malaysian<br />

cement plants of Langkawi, Rawang, Pasir Gudang, and Kanthan.<br />

A dedicated safety training center has been deployed at the heart of each<br />

site. Each in-house centre is composed of two spaces, one<br />

for theoretical training and one for hands-on experience with equipment<br />

and the chance to become familiarized with all potentially dangerous<br />

situations. Conceived as a means of accelerating good practices in safety,<br />

employees are taught existing safety standards and are immediately<br />

brought up to date with new Group standards as they arrive. <strong>The</strong>y have<br />

the opportunity to try out the Personal Protective Equipment, including<br />

the full harness and the equipment used in operations during cyclones.<br />

Conditions, such as working at height or in confined spaces, are<br />

replicated in the center and give employees the chance to test their<br />

reactions. <strong>The</strong>y can improve their practical understanding of energy<br />

insulation using junction boxes and fuse boards. <strong>The</strong> centers also<br />

facilitate the integration of new employees and their training<br />

as well as that of sub-contractors and visitors.<br />

Through showing dedication and commitment to the subject of safety<br />

across all the sites, we are able to send a clear message that the Group<br />

puts safety at the forefront of its operations. ■<br />

Raising risk awareness,<br />

changing our culture and<br />

reducing our accident rates<br />

are top priorities at <strong>Lafarge</strong>.<br />

which ultimately affects performance. <strong>The</strong> methodology, process and<br />

discipline rub off on to everyone’s general way of behaving. Group-wide,<br />

100 million euros have been invested so far in plant improvement and<br />

each product line has phased in an improvement plan. None of this<br />

would be feasible if we didn’t have our managers on board. To mobilize<br />

them, a “Leading with Safety” workshop was run for each of our senior<br />

managers and the objective for 2009 is to carry out this same training<br />

nationwide.<br />

Encouraging results<br />

Managers are fully involved through a bonus scheme related to safety<br />

performances. Already the results have proved to be encouraging. In<br />

2005, the pledge was made to cut the LTI (Lost Time Incident) rate in<br />

half by 2008. <strong>The</strong> accident frequency rate is going down: from 3.09 in<br />

2005 to 1.66 by the end of 2007, which is almost half. <strong>The</strong> severity rate<br />

has also been decreasing.<br />

<strong>The</strong> next step includes also raising contractors’ standards. Last<br />

September we issued a contractor safety standard to control who we hire<br />

and how we pre-select, and we are looking at creating safety standards<br />

to be used internally by our contractors.<br />

One thing is certain: the awareness created at <strong>Lafarge</strong> over the last two<br />

years has taken on a momentum that is not ready to subside. As the<br />

saying goes, the heat is on, and is here to stay. ■<br />

C R E S C E N D O | L A FA R G E | A P R I L 2 0 0 8 | P A G E 3 3

contributing<br />

to a sustainable world<br />

© Hamilton de Oliveira

CONTRIBUTING TO A SUSTAINABLE WORLD<br />

P A G E 3 6 | L A FA R G E | O C T O B R E 2 0 0 7 | C R E S C E N D O<br />

© Jacques Ferrier architecture<br />

<strong>The</strong> French Pavilion for the Shanghai Exhibition<br />

in 2010. Designed by the architect Jacques Ferrier,<br />

its insulation and utility systems reduce energy<br />

consumption and therefore CO 2 emissions. Its<br />

envelope is made of high-performance concrete.<br />

Objective:<br />

“zero net energy”<br />

<strong>The</strong> vast spurt of economic growth over the last<br />

two centuries has been based on burning fossil<br />

fuels. This is not sustainable, as it leads to an<br />

increase in carbon dioxide and other greenhouse<br />

gases in the atmosphere, which in turn<br />

causes climate change. This is why we must<br />

transition to a low-carbon model. But what does<br />

this have to do with buildings? A very great<br />

deal… Buildings, through their construction,<br />

their use, and their demolition, represent<br />

40% of world energy demand. This demand<br />

splits roughly one-third from commercial and<br />

two-thirds from residential buildings. <strong>The</strong><br />

challenge is growing. With a business-as-usual<br />

scenario, worldwide energy consumption in<br />

buildings is expected to grow 45% from 2002<br />

to 2050 and to increase as a proportion of all<br />

energy consumed.<br />

A four-step process<br />

Embarking several companies in this challenge,<br />

<strong>Lafarge</strong> has committed to the Energy Efficiency<br />

in Buildings (EEB) project under the umbrella<br />

of the WBCSD. <strong>The</strong> main aim of the project is<br />

to map out a transition to a 2050 world where<br />

buildings use zero net energy. <strong>The</strong> basic idea<br />

behind zero net energy is that the energy<br />

consumed by a building is equal to or lesser<br />

than the energy it produces. It is easy to state<br />

the goal but hard to get there. Such a profound<br />

change can only be built on a thorough and<br />

detailed understanding of the complex factors<br />

that determine energy use in buildings. So EEB<br />

WORLD<br />

Through chairing the “Energy Efficiency in Buildings” project, <strong>Lafarge</strong> shows<br />

it wants to play a leading role in securing the goal of zero net energy in<br />

buildings. This is an ambitious goal that involves the whole construction<br />

chain from the regulator to the end-user, and requires profound behavioral<br />

changes. Both a challenge and an opportunity for the future.<br />

has set out a four-step process. First, gather<br />

key facts and trends; then identify what needs<br />

to change; develop a roadmap, and finally in<br />

2009 deliver a call for action to achieve a world<br />

where buildings consume zero net energy.<br />

Throughout its work EEB is actively engaging<br />

all stakeholders, seeking ideas and opinions,<br />

using market research to understand the<br />

barriers to zero net energy and how to overcome<br />

them. In August 2007 EEB published EEB:<br />

Business Realities and Opportunities. What was<br />

particularly striking in the study was that 84%<br />

of energy use in the life cycle of a building<br />

comes from its use and 16% from all other<br />

phases: manufacturing the building materials,<br />

construction, maintenance or demolition.<br />

Clearly, increased energy efficiency at any stage<br />

in the life cycle is welcome but the biggest gains<br />

are available from use. <strong>The</strong> study concludes:<br />

“Technology available today can achieve<br />

dramatic improvements in energy efficiency,<br />

but market failures and behavioural barriers are<br />

blocking progress…”. <strong>The</strong> cost of green buildings,<br />

for example, is vastly overestimated. Now<br />

EEB is pursuing its efforts and is drafting a<br />

preliminary roadmap action plan setting out<br />

how the challenges may be solved. ■<br />

THE WBCSD<br />

<strong>The</strong> World Business<br />

Council for Sustainable<br />

Development (WBCSD) is<br />

a CEO-led, global<br />

association of some<br />

200 companies dealing<br />

exclusively with business<br />

and sustainable<br />

development. Members<br />

are drawn from more<br />

than 35 countries and<br />

20 major industrial<br />

sectors. <strong>The</strong> Council<br />

also benefits from a global<br />

network of about<br />

55 national and regional<br />

business councils<br />

and regional partners.<br />

CORE EEB<br />

MEMBERS<br />

<strong>Lafarge</strong> (Co-chair),<br />

United Technologies<br />

Corp. (Co-chair),<br />

Actelios, ArcelorMittal,<br />

Bosch, Cemex, DuPont,<br />

EDF, Gaz de France,<br />

Kansai Electric Power<br />

Company, Philips,<br />

Skanska, Sonae Sierra,<br />

Tepco.<br />

C R E S C E N D O | L A FA R G E | A P R I L 2 0 0 8 | P A G E 3 7

In the aftermath of the devastating fires which swept through Greece in 2007,<br />

<strong>Lafarge</strong>’s local subsidiary, continues its long-term<br />

work in helping the local population to rebuild their lives and communities.<br />

Rebuilding<br />

a community<br />

In August 2007, extremely violent fires<br />

ravaged Greece for ten long days. <strong>The</strong><br />

<strong>Lafarge</strong> plant in Volos, on the island of<br />

Euboea, was particularly badly hit. It quickly<br />

mobilized human and physical resources to<br />

help the local population.<br />

<strong>The</strong> municipality of Tamyna, the immediate<br />

neighbouring community to the Milaki plant,<br />

was severely hit by the fires on Euboea.<br />

According to initial estimates, the fire<br />

destroyed 80% of the municipality.<br />

<strong>The</strong> environment in the mountainous<br />

settlements of the municipality was completely<br />

devastated. <strong>The</strong> most pronounced<br />

effect of the burning and deforestation was<br />

soil erosion. With rainfall, this would increase<br />

the risk of flooding, which would jeopardize<br />

the area because most torrents run through<br />

the community before reaching the sea.<br />

<strong>The</strong> situation was urgent. <strong>The</strong> fires had to<br />

be put out, but many people also had to be<br />

relocated to hotels, their animals had to be<br />

fed, and the population had to be warned of<br />

the danger of flooding, and the associated<br />

health risks.<br />

Fifteen cement silos were transformed into<br />

water towers in villages, and aid was given to<br />

employees whose homes were destroyed in<br />

the fire. Ms. Ecaterini Karapa, mayor of<br />

Tamyna, gratefully accepted the assistance<br />

of all employees in Milaki who volunteered to<br />

assist in the emergency work. <strong>The</strong> company<br />

cooperated not only by making the plant<br />

facilities and equipment available, but also<br />

P A G E 3 8 | L A FA R G E | A P R I L 2 0 0 8 | C R E S C E N D O<br />

GREECE<br />

by responding to the immediate emergency<br />

needs and the longer-term rebuilding effort.<br />

One of <strong>Lafarge</strong>’s contributions is a special<br />

3-million-euro aid programme called PRAKSH;<br />

one million of it has been allocated to a national<br />

solidarity fund. <strong>The</strong> rest of the money will be<br />

dedicated to efforts to revive the local economy<br />

and re-establish the environment. Plans are<br />

also underway to build infrastructures to protect<br />

against fire and flooding, as well as to reforest<br />

the area.<br />

Helping to get back on track<br />

<strong>Lafarge</strong> in Greece has decided to make sure<br />

such a disaster never happens again. Funds<br />

donated by <strong>Lafarge</strong> have already enabled the<br />

municipalities of Euboea to buy six four-by-four<br />

vehicles equipped with fire-fighting systems.<br />

<strong>Lafarge</strong> has also committed itself to leading a<br />

more long-term policy, via a partnership with<br />

the French Embassy, to utilize the technical<br />

assistance of the specialists in the National<br />

Forestry Office toward efforts like fire prevention<br />

and reforestation.<br />

<strong>The</strong> next step is deciding how best to contribute<br />

to reconstructing public buildings and restarting<br />

agricultural activity on Euboea, which includes<br />

olive groves, vines, beehives, and animal farms.<br />

Slowly, but surely, life is being revived from<br />

among the ashes. ■<br />

THE PRAXI<br />

PROGRAMME,<br />

IN FIGURES<br />

Out of the 3 million euro<br />

budget for <strong>Lafarge</strong>’s<br />

Praxi programme,<br />

1 million euros will go<br />

to a national solidarity<br />

fund and the<br />

2 other million euros<br />

will be used in schemes<br />

to revive the local<br />

economy and rehabilitate<br />

the environment.<br />

A Canadair helicopter<br />

fighting the forest blaze<br />

in Greece last year.<br />

© REA<br />

CONTRIBUTING TO A SUSTAINABLE WORLD

CONTRIBUTING TO A SUSTAINABLE WORLD<br />

© Pro Patrimonio<br />

<strong>The</strong> renovation of the villa<br />

marks the first major step<br />

to safeguard 20th-century<br />

Romanian heritage.<br />

Built in 1910 by one of Romania’s oldest aristocratic<br />

families, known for its avant-garde ideas,<br />

the Villa Golescu is a wonderful reminder of a<br />

bygone era. Indeed, in the past, owners were<br />

evicted from similar villas and the buildings<br />

eventually left to rack and ruin. Miraculously, this<br />

house, located downtown in Campulung-<br />

Muscel, in central Romania, and occupied by<br />

two of the family’s descendants until 2002,<br />

managed to escape such a grim destiny.<br />

Despite extensive deterioration, Villa Golescu<br />

remains as it was and is now a classified building.<br />

Its neo-Romanian style dates back to the<br />

early 20th century.<br />

“<strong>The</strong> house was donated to the Pro Patrimonio<br />

Foundation by the last descendants of the<br />

Golescu family,” explains Maria Berza, vicepresident<br />

of the foundation, which works to<br />

conserve Romania’s historical and natural<br />

heritage, and to raise the awareness of the local<br />

communities in terms of respecting and reviving<br />

their national heritage. “Restoring the Villa<br />

Golescu is a way of encouraging Romanians to<br />

see their history differently. It makes them stop<br />

and think about their national heritage.”<br />

Distinctive features of the house include its<br />

beautiful loggia, its arches and its carved pink<br />

Albesti stone window surrounds. Inside, the furniture<br />

attests to the occupants’ exquisite taste.<br />

UNESCO originally financed the renovation of<br />

the garden and has since been replaced by the<br />

Compagnons du Devoir, professionals who now<br />

ROMANIA<br />

<strong>The</strong> restoration of the Villa Golescu is a fantastic example of Romanian<br />

heritage, at a time when the country is coming to terms<br />

with its past. <strong>The</strong> Pro Patrimonio Foundation, sponsored by <strong>Lafarge</strong>,<br />

plans to commemorate a bygone era and lifestyle.<br />

Renovated<br />

Romanian heritage<br />

tend the array of plants, bushes and trees. <strong>The</strong><br />