Mini Pub - Avanti Products

Mini Pub - Avanti Products

Mini Pub - Avanti Products

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

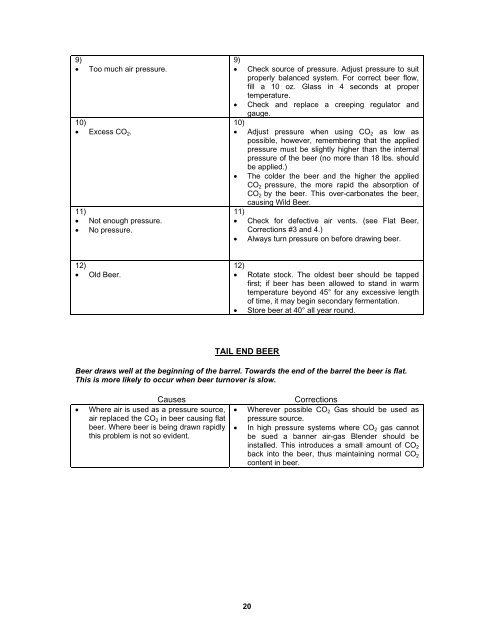

9)• Too much air pressure.10)• Excess CO 2 .11)• Not enough pressure.• No pressure.9)• Check source of pressure. Adjust pressure to suitproperly balanced system. For correct beer flow,fill a 10 oz. Glass in 4 seconds at propertemperature.• Check and replace a creeping regulator andgauge.10)• Adjust pressure when using CO 2 as low aspossible, however, remembering that the appliedpressure must be slightly higher than the internalpressure of the beer (no more than 18 lbs. shouldbe applied.)• The colder the beer and the higher the appliedCO 2 pressure, the more rapid the absorption ofCO 2 by the beer. This over-carbonates the beer,causing Wild Beer.11)• Check for defective air vents. (see Flat Beer,Corrections #3 and 4.)• Always turn pressure on before drawing beer.12)• Old Beer.12)• Rotate stock. The oldest beer should be tappedfirst; if beer has been allowed to stand in warmtemperature beyond 45° for any excessive lengthof time, it may begin secondary fermentation.• Store beer at 40° all year round.TAIL END BEERBeer draws well at the beginning of the barrel. Towards the end of the barrel the beer is flat.This is more likely to occur when beer turnover is slow.Causes• Where air is used as a pressure source,air replaced the CO 2 in beer causing flatbeer. Where beer is being drawn rapidlythis problem is not so evident.Corrections• Wherever possible CO 2 Gas should be used aspressure source.• In high pressure systems where CO 2 gas cannotbe sued a banner air-gas Blender should beinstalled. This introduces a small amount of CO 2back into the beer, thus maintaining normal CO 2content in beer.20