FRIDA Diamant-Wandsäge WS75, WS75H - WEKA Elektrowerkzeuge

FRIDA Diamant-Wandsäge WS75, WS75H - WEKA Elektrowerkzeuge

FRIDA Diamant-Wandsäge WS75, WS75H - WEKA Elektrowerkzeuge

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3. T E C H N I C A L D E S C R I P T I O N<br />

Your WS 75 is a full electrical wall saw which is only to be used for cutting masonry, stone and concrete<br />

in industrial usage by trained personnel.<br />

Water is absolutely required for cooling the motor and for cooling and for cleaning the saw blade.<br />

The diamond saw blade consists of a prestressed metal disk which is at its circuit fixed with segments made<br />

of a sintered mixture of diamond grains and metal powder.<br />

The sawing process is introduced by dipping the saw blade into the material, which is to be cutted. By<br />

switching the feed direction over, the sawing support moves now along the guide-way to a desired point on<br />

which is once more dipped in, in order to switch over to longitudinal direction for continuing the sawing<br />

process.<br />

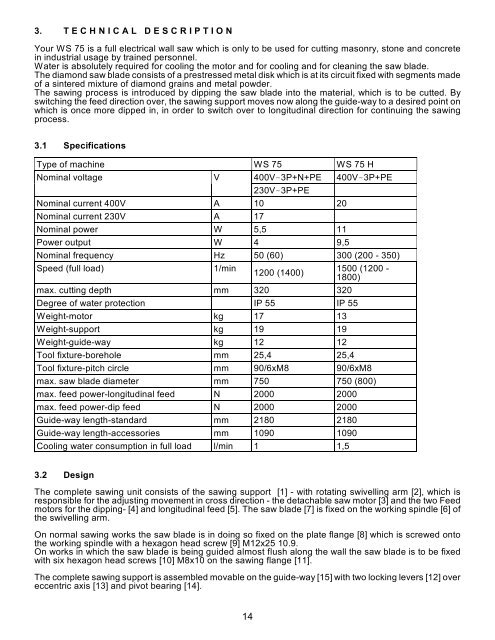

3.1 Specifications<br />

Type of machine WS 75 WS 75 H<br />

Nominal voltage V 400V3P+N+PE 400V3P+PE<br />

14<br />

230V3P+PE<br />

Nominal current 400V A 10 20<br />

Nominal current 230V A 17<br />

Nominal power W 5,5 11<br />

Power output W 4 9,5<br />

Nominal frequency Hz 50 (60) 300 (200 - 350)<br />

Speed (full load) 1/min<br />

1200 (1400)<br />

max. cutting depth mm 320 320<br />

Degree of water protection IP 55 IP 55<br />

Weight-motor kg 17 13<br />

Weight-support kg 19 19<br />

Weight-guide-way kg 12 12<br />

Tool fixture-borehole mm 25,4 25,4<br />

1500 (1200 -<br />

1800)<br />

Tool fixture-pitch circle mm 90/6xM8 90/6xM8<br />

max. saw blade diameter mm 750 750 (800)<br />

max. feed power-longitudinal feed N 2000 2000<br />

max. feed power-dip feed N 2000 2000<br />

Guide-way length-standard mm 2180 2180<br />

Guide-way length-accessories mm 1090 1090<br />

Cooling water consumption in full load l/min 1 1,5<br />

3.2 Design<br />

The complete sawing unit consists of the sawing support [1] - with rotating swivelling arm [2], which is<br />

responsible for the adjusting movement in cross direction - the detachable saw motor [3] and the two Feed<br />

motors for the dipping- [4] and longitudinal feed [5]. The saw blade [7] is fixed on the working spindle [6] of<br />

the swivelling arm.<br />

On normal sawing works the saw blade is in doing so fixed on the plate flange [8] which is screwed onto<br />

the working spindle with a hexagon head screw [9] M12x25 10.9.<br />

On works in which the saw blade is being guided almost flush along the wall the saw blade is to be fixed<br />

with six hexagon head screws [10] M8x10 on the sawing flange [11].<br />

The complete sawing support is assembled movable on the guide-way [15] with two locking levers [12] over<br />

eccentric axis [13] and pivot bearing [14].