DETECTEUR DE POSITION POUR "PROFIL T ... - ASCO Numatics

DETECTEUR DE POSITION POUR "PROFIL T ... - ASCO Numatics

DETECTEUR DE POSITION POUR "PROFIL T ... - ASCO Numatics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

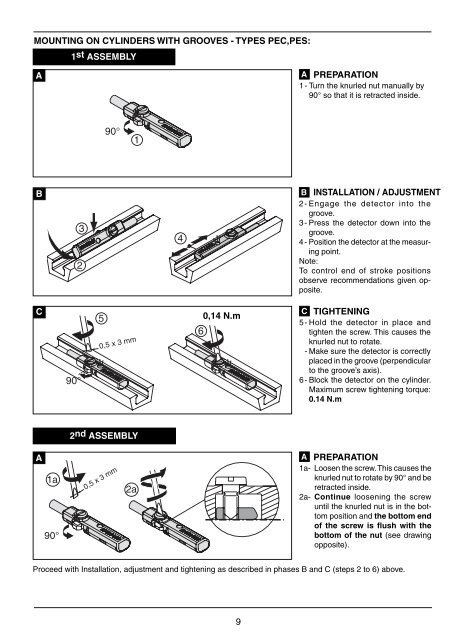

MOUNTING ON CYLIN<strong>DE</strong>RS WITH GROOVES - TYPES PEC,PES:<br />

A<br />

B<br />

C<br />

A<br />

1a<br />

90°<br />

1st ASSEMBLY<br />

2<br />

90°<br />

3<br />

5<br />

90°<br />

0,5 x 3 mm<br />

0,5 x 3 mm<br />

1<br />

2nd ASSEMBLY<br />

2a<br />

4<br />

6<br />

0,14 N.m<br />

9<br />

A PREPARATION<br />

1 - Turn the knurled nut manually by<br />

90° so that it is retracted inside.<br />

B INSTALLATION / ADJUSTMENT<br />

2 - Engage the detector into the<br />

groove.<br />

3 - Press the detector down into the<br />

groove.<br />

4 - Position the detector at the measuring<br />

point.<br />

Note:<br />

To control end of stroke positions<br />

observe recommendations given opposite.<br />

C TIGHTENING<br />

5 - Hold the detector in place and<br />

tighten the screw. This causes the<br />

knurled nut to rotate.<br />

- Make sure the detector is correctly<br />

placed in the groove (perpendicular<br />

to the groove’s axis).<br />

6 - Block the detector on the cylinder.<br />

Maximum screw tightening torque:<br />

0.14 N.m<br />

A PREPARATION<br />

1a- Loosen the screw. This causes the<br />

knurled nut to rotate by 90° and be<br />

retracted inside.<br />

2a- Continue loosening the screw<br />

until the knurled nut is in the bottom<br />

position and the bottom end<br />

of the screw is fl ush with the<br />

bottom of the nut (see drawing<br />

opposite).<br />

Proceed with Installation, adjustment and tightening as described in phases B and C (steps 2 to 6) above.