You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

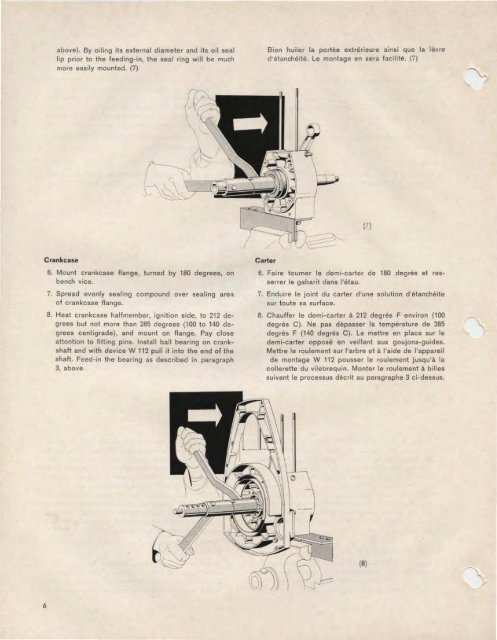

above). By oiling its external diameter and its oil seal<br />

lip prior to the feeding-in, the seal ring will be much<br />

more easily mounted. (7)<br />

Bien huiler Ia portee extrerieure ainsi que Ia levre<br />

d·etanchldte. Le montage en sera facilite. (7)<br />

(i )<br />

Crankcase<br />

6. Mount crankcase flange, turned by 180 degrees, on<br />

bench vice.<br />

7. Spread evenly sealing compound over sealing are~\<br />

of crankcase flange.<br />

8. Heat crankcase halfmember, ignition side, to 212 degrees<br />

but not more than 285 degrees (100 to 140 degrees<br />

centigrade), and mount on flange. Pay close<br />

attention to fitting pins. Install ball bearing on crankshaft<br />

and with device W 112 pull it into the end of tho<br />

shaft. Feed-in the bearing as described in paragraph<br />

3, above.<br />

Carter<br />

6. Faire tourner le demi-carter de 180 degres et resserrer<br />

le gabarit dans l'etau.<br />

7. Enduire le joint du carter d'une solution d'etancheite<br />

sur toute sa surface.<br />

8. Chauffer le demi-carter a 212 degres F environ {100<br />

degres C). Ne pas depasser Ia temperature de 285<br />

degres F {140 degres C). Le mettre en place sur le<br />

demi-carter oppose en veillant aux goujons-guides.<br />

Mettre le roulement sur l'arbre et a l'aide de l'appareil<br />

de montage W 112 pousser le roulement jusqu'a Ia<br />

collerette du vilebrequin. Monter le roulement a billes<br />

suivant le processus decrit au paragraphe 3 ci-dessus.<br />

(8)<br />

6