une approche de programmation lineaire pour la conception des ...

une approche de programmation lineaire pour la conception des ...

une approche de programmation lineaire pour la conception des ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

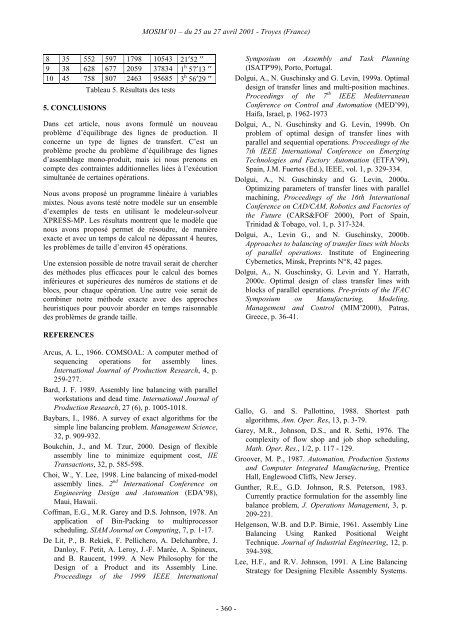

MOSIM’01 – du 25 au 27 avril 2001 - Troyes (France)8 35 552 597 1798 10543 21′52 ′′9 38 628 677 2059 37834 1 h 57′13 ′′10 45 758 807 2463 95685 3 h 56′29 ′′Tableau 5. Résultats <strong>de</strong>s tests5. CONCLUSIONSDans cet article, nous avons formulé un nouveauproblème d’équilibrage <strong>de</strong>s lignes <strong>de</strong> production. Ilconcerne un type <strong>de</strong> lignes <strong>de</strong> transfert. C’est unproblème proche du problème d’équilibrage <strong>de</strong>s lignesd’assemb<strong>la</strong>ge mono-produit, mais ici nous prenons encompte <strong>de</strong>s contraintes additionnelles liées à l’exécutionsimultanée <strong>de</strong> certaines opérations.Nous avons proposé un programme linéaire à variablesmixtes. Nous avons testé notre modèle sur un ensembled’exemples <strong>de</strong> tests en utilisant le mo<strong>de</strong>leur-solveurXPRESS-MP. Les résultats montrent que le modèle quenous avons proposé permet <strong>de</strong> résoudre, <strong>de</strong> manièreexacte et avec un temps <strong>de</strong> calcul ne dépassant 4 heures,les problèmes <strong>de</strong> taille d’environ 45 opérations.Une extension possible <strong>de</strong> notre travail serait <strong>de</strong> chercher<strong>de</strong>s métho<strong>de</strong>s plus efficaces <strong>pour</strong> le calcul <strong>de</strong>s bornesinférieures et supérieures <strong>de</strong>s numéros <strong>de</strong> stations et <strong>de</strong>blocs, <strong>pour</strong> chaque opération. Une autre voie serait <strong>de</strong>combiner notre métho<strong>de</strong> exacte avec <strong>de</strong>s <strong>approche</strong>sheuristiques <strong>pour</strong> pouvoir abor<strong>de</strong>r en temps raisonnable<strong>de</strong>s problèmes <strong>de</strong> gran<strong>de</strong> taille.Symposium on Assembly and Task P<strong>la</strong>nning(ISATP'99), Porto, Portugal.Dolgui, A., N. Guschinsky and G. Levin, 1999a. Optimal<strong>de</strong>sign of transfer lines and multi-position machines.Proceedings of the 7 th IEEE MediterraneanConference on Control and Automation (MED’99),Haifa, Israel, p. 1962-1973Dolgui, A., N. Guschinsky and G. Levin, 1999b. Onproblem of optimal <strong>de</strong>sign of transfer lines withparallel and sequential operations. Proceedings of the7th IEEE International Conference on EmergingTechnologies and Factory Automation (ETFA’99),Spain, J.M. Fuertes (Ed.), IEEE, vol. 1, p. 329-334.Dolgui, A., N. Guschinsky and G. Levin, 2000a.Optimizing parameters of transfer lines with parallelmachining, Proceedings of the 16th InternationalConference on CAD/CAM, Robotics and Factories ofthe Future (CARS&FOF 2000), Port of Spain,Trinidad & Tobago, vol. 1, p. 317-324.Dolgui, A., Levin G., and N. Guschinsky, 2000b.Approaches to ba<strong>la</strong>ncing of transfer lines with blocksof parallel operations. Institute of EngineeringCybernetics, Minsk, Preprints N°8, 42 pages.Dolgui, A., N. Guschinsky, G. Levin and Y. Harrath,2000c. Optimal <strong>de</strong>sign of c<strong>la</strong>ss transfer lines withblocks of parallel operations. Pre-prints of the IFACSymposium on Manufacturing, Mo<strong>de</strong>ling,Management and Control (MIM’2000), Patras,Greece, p. 36-41.REFERENCESArcus, A. L., 1966. COMSOAL: A computer method ofsequencing operations for assembly lines.International Journal of Production Research, 4, p.259-277.Bard, J. F. 1989. Assembly line ba<strong>la</strong>ncing with parallelworkstations and <strong>de</strong>ad time. International Journal ofProduction Research, 27 (6), p. 1005-1018.Baybars, I., 1986. A survey of exact algorithms for thesimple line ba<strong>la</strong>ncing problem. Management Science,32, p. 909-932.Boukchin, J., and M. Tzur, 2000. Design of flexibleassembly line to minimize equipment cost, IIETransactions, 32, p. 585-598.Choi, W., Y. Lee, 1998. Line ba<strong>la</strong>ncing of mixed-mo<strong>de</strong><strong>la</strong>ssembly lines. 2 nd International Conference onEngineering Design and Automation (EDA’98),Maui, Hawaii.Coffman, E.G., M.R. Garey and D.S. Johnson, 1978. Anapplication of Bin-Packing to multiprocessorscheduling. SIAM Journal on Computing, 7, p. 1-17.De Lit, P., B. Rekiek, F. Pellichero, A. Delchambre, J.Danloy, F. Petit, A. Leroy, J.-F. Marée, A. Spineux,and B. Raucent, 1999. A New Philosophy for theDesign of a Product and its Assembly Line.Proceedings of the 1999 IEEE InternationalGallo, G. and S. Pallottino, 1988. Shortest pathalgorithms, Ann. Oper. Res, 13, p. 3-79.Garey, M.R., Johnson, D.S., and R. Sethi, 1976. Thecomplexity of flow shop and job shop scheduling,Math. Oper. Res., 1/2, p. 117 - 129.Groover, M. P., 1987. Automation, Production Systemsand Computer Integrated Manufacturing, PrenticeHall, Englewood Cliffs, New Jersey.Gunther, R.E., G.D. Johnson, R.S. Peterson, 1983.Currently practice formu<strong>la</strong>tion for the assembly lineba<strong>la</strong>nce problem, J. Operations Management, 3, p.209-221.Helgenson, W.B. and D.P. Birnie, 1961. Assembly LineBa<strong>la</strong>ncing Using Ranked Positional WeightTechnique. Journal of Industrial Engineering, 12, p.394-398.Lee, H.F., and R.V. Johnson, 1991. A Line Ba<strong>la</strong>ncingStrategy for Designing Flexible Assembly Systems.- 360 -