ZT 71 ZT 72 - Cyclon Engineering

ZT 71 ZT 72 - Cyclon Engineering

ZT 71 ZT 72 - Cyclon Engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

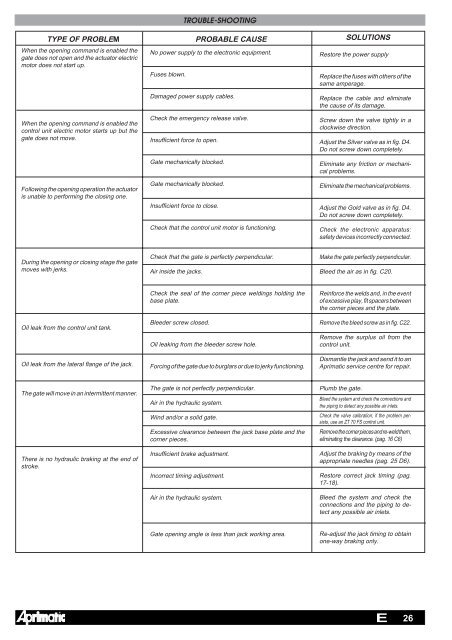

TROUBLE-SHOOTING<br />

TYPE OF PROBLEM PROBABLE CAUSE SOLUTIONS<br />

When the opening command is enabled the<br />

gate does not open and the actuator electric<br />

motor does not start up.<br />

When the opening command is enabled the<br />

control unit electric motor starts up but the<br />

gate does not move.<br />

Following the opening operation the actuator<br />

is unable to performing the closing one.<br />

During the opening or closing stage the gate<br />

moves with jerks.<br />

Oil leak from the control unit tank.<br />

Oil leak from the lateral flange of the jack.<br />

The gate will move in an intermittent manner.<br />

There is no hydraulic braking at the end of<br />

stroke.<br />

No power supply to the electronic equipment.<br />

Fuses blown.<br />

Damaged power supply cables.<br />

Check the emergency release valve.<br />

Insufficient force to open.<br />

Gate mechanically blocked.<br />

Gate mechanically blocked.<br />

Insufficient force to close.<br />

Check that the control unit motor is functioning.<br />

Check that the gate is perfectly perpendicular.<br />

Air inside the jacks.<br />

Check the seal of the corner piece weldings holding the<br />

base plate.<br />

Bleeder screw closed.<br />

Oil leaking from the bleeder screw hole.<br />

Forcing of the gate due to burglars or due to jerky functioning.<br />

The gate is not perfectly perpendicular.<br />

Air in the hydraulic system.<br />

Wind and/or a solid gate.<br />

Excessive clearance between the jack base plate and the<br />

corner pieces.<br />

Insufficient brake adjustment.<br />

Incorrect timing adjustment.<br />

Air in the hydraulic system.<br />

Gate opening angle is less than jack working area.<br />

Restore the power supply<br />

Replace the fuses with others of the<br />

same amperage.<br />

Replace the cable and eliminate<br />

the cause of its damage.<br />

Screw down the valve tightly in a<br />

clockwise direction.<br />

Adjust the Silver valve as in fig. D4.<br />

Do not screw down completely.<br />

Eliminate any friction or mechanical<br />

problems.<br />

Eliminate the mechanical problems.<br />

Adjust the Gold valve as in fig. D4.<br />

Do not screw down completely.<br />

Check the electronic apparatus:<br />

safety devices incorrectly connected.<br />

Make the gate perfectly perpendicular.<br />

Bleed the air as in fig. C20.<br />

Reinforce the welds and, in the event<br />

of excessive play, fit spacers between<br />

the corner pieces and the plate.<br />

Remove the bleed screw as in fig. C22.<br />

Remove the surplus oil from the<br />

control unit.<br />

Dismantle the jack and send it to an<br />

Aprimatic service centre for repair.<br />

Plumb the gate.<br />

Bleed the system and check the connections and<br />

the piping to detect any possible air inlets.<br />

Check the valve calibration; if the problem persists,<br />

use an <strong>ZT</strong> 70 FS control unit.<br />

Remove the corner pieces and re-weld them,<br />

eliminating the clearance. (pag. 16 C6)<br />

Adjust the braking by means of the<br />

appropriate needles (pag. 25 D6).<br />

Restore correct jack timing (pag.<br />

17-18).<br />

Bleed the system and check the<br />

connections and the piping to detect<br />

any possible air inlets.<br />

Re-adjust the jack timing to obtain<br />

one-way braking only.<br />

E<br />

26<br />

39