Manuale di istruzioni completo (12 lingue)

Manuale di istruzioni completo (12 lingue)

Manuale di istruzioni completo (12 lingue)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INSTRUCTION MANUAL FOR PLASMA CUTTER<br />

IMPORTANT: BEFORE STARTING THE<br />

EQUIPMENT, READ THE CONTENTS OF<br />

THIS MANUAL, WHICH MUST BE STO-<br />

RED IN A PLACE FAMILIAR TO ALL USERS FOR THE ENTI-<br />

RE OPERATIVE LIFE-SPAN OF THE MACHINE.<br />

THIS EQUIPMENT MUST BE USED SOLELY FOR WEL-<br />

DING OPERATIONS.<br />

1 SAFETY PRECAUTIONS<br />

WELDING AND ARC CUTTING CAN BE HARMFUL TO<br />

YOURSELF AND OTHERS. The user must therefore be educated<br />

against the hazards, summarized below, deriving from<br />

wel<strong>di</strong>ng operations. For more detailed information, order the<br />

manual code 3.300.758<br />

ELECTRIC SHOCK - May be fatal.<br />

· Install and earth the wel<strong>di</strong>ng machine accor<strong>di</strong>ng to<br />

the applicable regulations.<br />

· Do not touch live electrical parts or electrodes with<br />

bare skin, gloves or wet clothing.<br />

· Isolate yourselves from both the earth and the workpiece.<br />

· Make sure your working position is safe.<br />

FUMES AND GASES - May be hazardous to your health.<br />

· Keep your head away from fumes.<br />

· Work in the presence of adequate ventilation, and<br />

use ventilators around the arc to prevent gases from<br />

forming in the work area.<br />

ARC RAYS - May injure the eyes and burn the skin.<br />

· Protect your eyes with wel<strong>di</strong>ng masks fitted with filtered<br />

lenses, and protect your body with appropriate<br />

safety garments.<br />

· Protect others by installing adequate shields or curtains.<br />

RISK OF FIRE AND BURNS<br />

· Sparks (sprays) may cause fires and burn the skin;<br />

you should therefore make sure there are no flammable<br />

materials in the area, and wear appropriate<br />

protective garments.<br />

NOISE<br />

This machine does not <strong>di</strong>rectly produce noise excee<strong>di</strong>ng<br />

80dB. The plasma cutting/wel<strong>di</strong>ng procedure<br />

may produce noise levels beyond said limit; users<br />

must therefore implement all precautions required by law.<br />

PACEMAKERS<br />

· The magnetic fields created by high currents may affect the<br />

operation of pacemakers. Wearers of vital electronic equipment<br />

(pacemakers) should consult their physician before<br />

beginning any arc wel<strong>di</strong>ng, cutting, gouging or spot wel<strong>di</strong>ng<br />

operations.<br />

EXPLOSIONS<br />

· Do not weld in the vicinity of containers under pressure,<br />

or in the presence of explosive dust, gases or<br />

fumes. · All cylinders and pressure regulators used in<br />

wel<strong>di</strong>ng operations should be handled with care.<br />

ELECTROMAGNETIC COMPATIBILITY<br />

This machine is manufactured in compliance with the<br />

6<br />

instructions contained in the harmonized standard EN50199,<br />

and must be used solely for professional purposes in an<br />

industrial environment. There may be potential <strong>di</strong>fficulties<br />

in ensuring electromagnetic compatibility in nonindustrial<br />

environments.<br />

IN CASE OF MALFUNCTIONS, REQUEST ASSISTANCE<br />

FROM QUALIFIED PERSONNEL.<br />

2 GENERAL DESCRIPTION<br />

This machine is a constant <strong>di</strong>rect current power source,<br />

designed for cutting electrically conductive materials<br />

(metals and alloys) using the plasma arc procedure. The<br />

plasma gas may be air or nitrogen.<br />

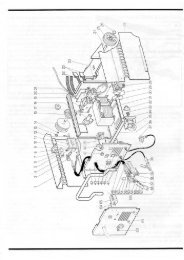

2.1 DESCRIPTION OF DEVICES ON THE MACHINE<br />

A) Power cord<br />

B) Compressed air fitting (1/4" female gas thread)<br />

C) Mains power switch<br />

D) Mains power led<br />

E) Pressure regulator knob<br />

F) Pressure gauge<br />

G) Thermostat LED<br />

H) Groun<strong>di</strong>ng cord<br />

I) Water trap<br />

L) Low air pressure LED<br />

M) Cutting current regulator knob<br />

N) Blocked LED; lights when hazardous con<strong>di</strong>tions<br />

arise.<br />

O) LED that lights when the "SELF-RESTART PILOT"<br />

function is active<br />

P) Push-button to activate and deactivate the "SELF-<br />

RESTART PILOT" function.<br />

O) Plasma torch.<br />

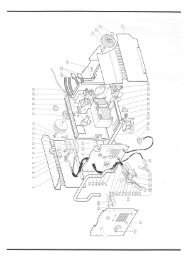

2.2 SAFETY DEVICES<br />

This system comes equipped with the following safety<br />

devices:<br />

Overload cutout:<br />

To avoid overload while cutting.<br />

The LED G (see fig 1) lights when active.<br />

Pneumatic:<br />

Located on the torch inlet to prevent low air pressure.<br />

The LED L lights when tripped (see fig.1).<br />

➡➡<br />

Electrical:<br />

1) In the event of a short-circuit between the nozzle and<br />

electrode during arc striking<br />

2) In the event of a short-circuit between the contacts of<br />

the reed relay on circuit 22 (see exploded drawing).<br />

3) When the electrode is worn to the point it must be<br />

replaced.<br />

These con<strong>di</strong>tions block the machine, and are signalled by<br />

the lit LED N.<br />

4) In ad<strong>di</strong>tion, this machine is equipped with automatic<br />

selection of the supply voltage and the following protections:<br />

A) 230V Power supply: during start-up, the machine<br />

remains blocked (LED N lit) if the voltage is below 200V.<br />

After start-up, the machine runs at as low as 180V.