SEG ECONOMY D Bedienungs- und Montageanleitung Operating ...

SEG ECONOMY D Bedienungs- und Montageanleitung Operating ...

SEG ECONOMY D Bedienungs- und Montageanleitung Operating ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

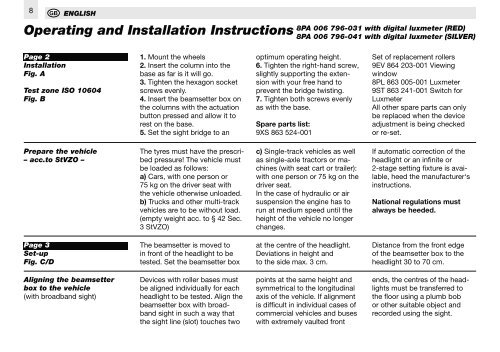

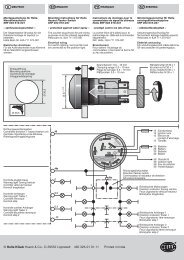

8GBENGLISH<strong>Operating</strong> and Installation Instructions8PA 006 796-031 with digital luxmeter (RED)8PA 006 796-041 with digital luxmeter (SILVER)Page 2InstallationFig. ATest zone ISO 10604Fig. B1. Mount the wheels2. Insert the column into thebase as far is it will go.3. Tighten the hexagon socketscrews evenly.4. Insert the beamsetter box onthe columns with the actuationbutton pressed and allow it torest on the base.5. Set the sight bridge to anoptimum operating height.6. Tighten the right-hand screw,slightly supporting the extensionwith your free hand toprevent the bridge twisting.7. Tighten both screws evenlyas with the base.Spare parts list:9XS 863 524-001Set of replacement rollers9EV 864 203-001 Viewingwindow8PL 863 005-001 Luxmeter9ST 863 241-001 Switch forLuxmeterAll other spare parts can onlybe replaced when the deviceadjustment is being checkedor re-set.Prepare the vehicle– acc.to StVZO –The tyres must have the prescribedpressure! The vehicle mustbe loaded as follows:a) Cars, with one person or75 kg on the driver seat withthe vehicle otherwise unloaded.b) Trucks and other multi-trackvehicles are to be without load.(empty weight acc. to § 42 Sec.3 StVZO)c) Single-track vehicles as wellas single-axle tractors or machines(with seat cart or trailer):with one person or 75 kg on thedriver seat.In the case of hydraulic or airsuspension the engine has torun at medium speed until theheight of the vehicle no longerchanges.If automatic correction of theheadlight or an infinite or2-stage setting fixture is available,heed the manufacturer‘sinstructions.National regulations mustalways be heeded.Page 3Set-upFig. C/DThe beamsetter is moved toin front of the headlight to betested. Set the beamsetter boxat the centre of the headlight.Deviations in height andto the side max. 3 cm.Distance from the front edgeof the beamsetter box to theheadlight 30 to 70 cm.Aligning the beamsetterbox to the vehicle(with broadband sight)Devices with roller bases mustbe aligned individually for eachheadlight to be tested. Align thebeamsetter box with broadbandsight in such a way thatthe sight line (slot) touches twopoints at the same height andsymmetrical to the longitudinalaxis of the vehicle. If alignmentis difficult in individual cases ofcommercial vehicles and buseswith extremely vaulted frontends, the centres of the headlightsmust be transferred tothe floor using a plumb bobor other suitable object andrecorded using the sight.