goes live nGen goes live nGen - Hongkong International Terminals

goes live nGen goes live nGen - Hongkong International Terminals

goes live nGen goes live nGen - Hongkong International Terminals

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HIT<br />

Spring 2005 No.1<br />

HIT HI News<br />

The wait is finally over! <strong>nGen</strong> has<br />

arrived! Our completely<br />

redesigned terminal management<br />

system has gone <strong>live</strong> at <strong>Hongkong</strong><br />

<strong>International</strong> <strong>Terminals</strong> (HIT) on 16th<br />

February this year.<br />

The brand new <strong>nGen</strong> system replaces<br />

our award-winning 3P Terminal<br />

Management System that has served us<br />

faithfully for more than eight years. <strong>nGen</strong>,<br />

in short for Next Generation Terminal<br />

Management System, is a complete rewrite<br />

using enhanced process logics and the<br />

latest open computer technologies. With<br />

the implementation of <strong>nGen</strong>, the system<br />

4<br />

HIT Customer Survey 5 Focus on Gaolan 6 ICIS Scanning<br />

7 Hyundai Merchant Marine 11<br />

controls the entire scope of terminal<br />

operations from ship and yard planning,<br />

gate operations, vessel operations and<br />

interactions, yard configuration and<br />

performance, overall operations<br />

monitoring, equipment utilisation,<br />

productivity to costs optimisation. With<br />

extensive operational experience and<br />

powerful algorithms embedded in many<br />

different operating environments, <strong>nGen</strong> is<br />

able to offer the best automated operating<br />

solution to our customers.<br />

<strong>nGen</strong> is the first major system<br />

co-development project between HIT<br />

and Yantian <strong>International</strong> Container<br />

Entrepôt<br />

<strong>nGen</strong><br />

<strong>goes</strong> <strong>live</strong><br />

<strong>Terminals</strong> (YICT). Harnessing our expertise<br />

since day one, a diverse cross-terminal<br />

project team from Terminal Operations,<br />

Operations Development, and Information<br />

Services was pulled together to make <strong>nGen</strong><br />

a reality. The project team set a simple<br />

yet significant objective for itself to develop<br />

a scalable, functional, and reliable system<br />

that is better than any other commercially<br />

available terminal operation platform for<br />

the South China Division of Hutchison Port<br />

Holdings (HPH) and its subsidiaries<br />

throughout the world.<br />

This massive joint development effort<br />

has already proven itself when <strong>nGen</strong> went<br />

16<br />

Continued on page 2<br />

HIT News, Spring 2005<br />

Caring Company Award

2<br />

Leader’s Column<br />

A time for action:<br />

Meeting our<br />

customers’ needs<br />

Following the overwhelming response to our Customer<br />

Satisfaction Study last year, I mentioned that even though<br />

we think we are doing a good job, in some areas our<br />

customers think otherwise.<br />

As a result of the survey, we have taken concrete steps to address<br />

some of those issues and improve communications between HIT<br />

and our customers. The first step has been to launch the HIT<br />

Monthly Bulletin, an electronic bulletin which provides a regular<br />

update of events and news de<strong>live</strong>red directly to our customers on<br />

their desktops.<br />

We have also significantly reduced the waiting time at the Barge<br />

Centre, which will help improve efficiency, and save time and money<br />

for our customers.<br />

In terms of responsibility, we have now delegated customer<br />

account responsibility to our I.T. department, so that our clients<br />

know who to deal with directly when issues arise. This will help<br />

improve response time and provide peace of mind for our<br />

customers.<br />

We have also introduced a free shuttle bus service that links<br />

<strong>Terminals</strong> 4, 6 and 7 with Terminal 9. This service is free to all our<br />

customers and business associates.<br />

The overall message is that we always have to be aware of what<br />

our customers need; this can be accomplished through improving<br />

communications and de<strong>live</strong>ring the right solutions, or meeting those<br />

needs so that service excellence can be achieved.<br />

Eric Ip<br />

Managing Director<br />

<strong>Hongkong</strong> <strong>International</strong> <strong>Terminals</strong><br />

HIT News, Spring 2005<br />

Launch of n<br />

(continued from cover)<br />

<strong>live</strong> at YICT in 2003. In addition, HIT and YICT have<br />

collectively laid a robust collaboration platform for all<br />

future <strong>nGen</strong> launches to other HPH ports.<br />

As the Chairperson of the <strong>nGen</strong> Steering Committee,<br />

Edmond Leung, who still wears his <strong>nGen</strong> badge on his<br />

sleeve, has every reason to be proud of what his team<br />

has achieved.<br />

“It was both an exciting and nerve-racking time,<br />

working in the Command Centre with staff from so<br />

many departments. To ensure smooth system migration<br />

with no interruption to serving our customers, our<br />

people worked selflessly throughout the Chinese New<br />

Year holidays, giving up the opportunity to return home<br />

and spend the festive season with their families. The<br />

pressure was high but our people handled it very well.<br />

More importantly, we need to thank our valued<br />

customers for their full support of <strong>nGen</strong>,” said Edmond.<br />

“What is different about <strong>nGen</strong> is that the system<br />

becomes more accessible to all our business partners as<br />

well as our operational staff - achieved through improved<br />

design, streamlined operational flow and broader<br />

connectivity by integrating the information flow<br />

seamlessly throughout the extended business<br />

community,” said Edmond. Indeed, the interactive and<br />

community-based system allows our customers to have<br />

greater control of the supply chain, again on a 24/7<br />

basis, inter-operable through the latest internet<br />

technology.<br />

Customers can be assured of the reliability of <strong>nGen</strong>,<br />

which has been validated under stringent independent<br />

review by the Hong Kong Polytechnic University, where<br />

eminent professors from the Hong Kong Polytechnic<br />

University visited our Development Centre and reviewed<br />

the design documentation, project standards and<br />

procedures, as well as interviewed members from the<br />

project team. “They fully endorsed <strong>nGen</strong>’s architectural<br />

design and that gave us the green light to move ahead<br />

with the phased introduction of the system at YICT and<br />

HIT,” said Edmond.<br />

There are many new and unique features in <strong>nGen</strong>,<br />

some of which include scalability, real-time operator<br />

alerts, and configurable business rules.<br />

Using industry standard open platform technologies<br />

such as Java and XML, <strong>nGen</strong> is truly scalable across all<br />

non-proprietary computer system hardware. From a

Gen at HIT<br />

small feeder terminal<br />

operation requiring a<br />

small-scale server setup<br />

to large hub ports<br />

relying on full server<br />

room support, <strong>nGen</strong><br />

has been designed to<br />

support all platforms.<br />

W ith real-time<br />

operator alerts, each<br />

control staff can<br />

customise more than a<br />

dozen automated alerts<br />

to suit different<br />

situations. These alerts<br />

not only allow the<br />

operators to take<br />

appropriate actions at<br />

appropriate times, but<br />

also relieve on-the-job<br />

pressure. Operators<br />

today don’t need to<br />

look at the computer screen for lengthy<br />

periods of time anymore to look for<br />

problem areas!<br />

Finally, <strong>nGen</strong> has over one hundred<br />

user-definable business rules that can be<br />

fine-tuned. For example, an operator can<br />

adjust the laden box grounding and<br />

internal tractor deployment rules to meet<br />

customers’ specific operating requirements.<br />

No more reprogramming and compiling,<br />

as <strong>nGen</strong> now adapts effortlessly.<br />

“<strong>nGen</strong> truly <strong>live</strong>s out our motto of<br />

doing more with less. With <strong>nGen</strong>, HIT and<br />

YICT are well positioned to meet<br />

increasing throughput and productivity<br />

requirements well into the next decade<br />

and beyond. With scalability in mind, we<br />

have designed <strong>nGen</strong> to work in all HPH<br />

ports around the globe. Most importantly,<br />

we have an experienced team with people<br />

who are committed to implementing<br />

<strong>nGen</strong> wherever our business is located,”<br />

concluded Edmond.<br />

Customs<br />

EDI<br />

Customer<br />

Customer<br />

Customer<br />

Plus Plus Plus<br />

IVRS<br />

SMS<br />

OnePort<br />

Community Interface<br />

<strong>nGen</strong> Interface<br />

Planning<br />

Execution<br />

&<br />

Control<br />

Reporting<br />

<strong>nGen</strong><br />

Intelligence<br />

Modules<br />

Interface<br />

Lead Story<br />

Guider<br />

Ship Planning<br />

OMS<br />

Operations<br />

Monitoring System<br />

TRACS<br />

Terminal Reporting<br />

& Communication System<br />

TOPS<br />

Terminal Operation<br />

Planning System<br />

EDR<br />

Enterprise Data<br />

Repository<br />

Billing<br />

System<br />

HIT News, Spring 2005<br />

3

4<br />

Latest Update<br />

Customers have their say<br />

in wide ranging study<br />

As the container<br />

terminal business<br />

becomes more<br />

competitive, understanding<br />

customer needs and<br />

de<strong>live</strong>ring timely solutions<br />

have become critical factors<br />

in sustaining the company’s<br />

reputation as a market leader.<br />

HIT recently completed its<br />

most comprehensive and<br />

detailed survey to find out what<br />

our customers really think of us.<br />

The 2004 Customer Satisfaction<br />

Survey was the most in-depth and wide<br />

ranging study to date, with a more<br />

sophisticated methodology that provided<br />

<strong>Hongkong</strong> <strong>International</strong> <strong>Terminals</strong> (HIT)<br />

with detailed feedback from its major<br />

shipping line clients on its performance<br />

and service levels.<br />

The objectives were to measure the<br />

operational performance of HIT services<br />

compared to its competitors and the level<br />

of interaction between HIT and its<br />

customers, which will allow the company<br />

to highlight areas that need special<br />

attention and consequently improve<br />

service quality in those areas.<br />

The survey was designed to solicit<br />

upfront feedback from a broad ‘band’ of<br />

managers and officers working for<br />

customers, with primary aim to have a linear<br />

set of responses rather than ‘top down’<br />

solely from senior managers. One-to-one<br />

interviews were carried out between HIT<br />

staff and nominated personnel from 18<br />

major carriers calling at HIT over a threemonth<br />

period.<br />

HIT News, Spring 2005<br />

Service levels and facilities received high<br />

marks from customers who took part in the<br />

survey, notably for Hong Kong and Asia.<br />

This took into account the friendliness of<br />

HIT staff, how they rated yard facilities, and<br />

how reliable services are. Customers were<br />

also asked about how confident they feel<br />

in using HIT and provided feedback on the<br />

level of efficiency on the services provided.<br />

The study also aimed to establish<br />

benchmarks and tracking that can be used<br />

in future studies. The purpose of the study<br />

was not to find fault, but rather to provide a<br />

consistent and valuable communication tool that<br />

opens up new channels with HIT’s customers.<br />

Overall, the results reflected confidence<br />

in HIT staff because of their positive attitude<br />

and responsiveness and generally HIT’s<br />

facilities and management were rated<br />

highly. Close attention also has to be paid<br />

to improving flexibility especially when<br />

dealing with customer representatives.<br />

There were also responses that indicated<br />

that a continuous process of improvement<br />

should be implemented.<br />

Immediate action has been taken to<br />

launch the HIT Monthly Bulletin to provide<br />

customers with the latest information<br />

regarding a wide range of events, operational<br />

changes, new IT initiatives and service<br />

information, all of which are aimed at<br />

improving communications with our<br />

customers. HIT will continue to make use<br />

of the survey findings to address longerterm<br />

organisational issues and regularly<br />

seek improvements on proactiveness in<br />

keeping customers informed and flexibility<br />

to meet special needs.<br />

“ HIT scored well in customer service levels compared to other<br />

terminals in Hong Kong, China and the rest of Asia, and staff attitude<br />

also ranked highly. However, a significant area that could have further<br />

improvement is being more proactive. We have already taken<br />

concrete steps to address this pressing issue by increasing the level of<br />

communication with our customers and we will continue to address<br />

this area in our organisational developments. ”<br />

Ken Chou, General Manager -Strategic Planning, said:

China<br />

Magazine<br />

Deep water container port<br />

development underway at Gaolan<br />

The expansion of China’s economy<br />

and the rapid industrial and<br />

commercial development in the<br />

South China region have presented Gaolan<br />

with vast opportunities in shaping it to<br />

become an important shipping centre<br />

for production, distribution and<br />

manufacturing platform for the world.<br />

Strategically located at Zhuhai, one of<br />

the earliest special economic zones<br />

in China and most popular spot for<br />

foreign investment, Gaolan Port, or<br />

Zhuhai <strong>International</strong> Container<br />

<strong>Terminals</strong> (Gaolan) (ZICT(G)) as it<br />

is more commonly-known, is the<br />

only natural deep-water port on<br />

the western side of the Pearl River<br />

Delta (PRD).<br />

Driving the expansion at the<br />

port are the numerous growing<br />

industrial and manufacturing<br />

zones in Zhuhai, where foreign<br />

joint-venture manufacturers have<br />

migrated across the Pearl River to<br />

take advantage of the lower land<br />

and labour costs, and a range of<br />

tax incentives offered to newlyestablished<br />

businesses.<br />

“For two decades we have<br />

seen the eastern side of the PRD<br />

thrive with Shenzhen and<br />

Guangzhou becoming major<br />

production centres for global companies.<br />

In the last five to six years, companies have<br />

moved across the river and the industrial<br />

zones are rapidly growing as there is<br />

plenty of lower-cost land still available for<br />

development. Local, provincial and<br />

national governments are very supportive<br />

of this initiative as it is in line with their<br />

“Go West” policy. This environment is<br />

highly conducive to the development of<br />

our new dedicated container facilities,”<br />

said Alfred Leung, General Manager,<br />

Hutchison Delta Ports (HDP).<br />

Strategically, Gaolan is well-positioned<br />

on the western side of the PRD to<br />

consolidate cargo from the smaller river<br />

ports along the West River (Xijiang). The<br />

Phase I multi-purpose terminals are<br />

positioned to accommodate both<br />

container and bulk cargo, particularly coal<br />

for the local power plants and steel for the<br />

booming construction sector. Together<br />

with well-connected highways and<br />

railways network, cargo originating from<br />

the flourishing manufacturing bases<br />

throughout the entire South-western<br />

China region can now directly access<br />

Gaolan. The new phase, with more<br />

dedicated container berths, enables<br />

shippers in the region to further access<br />

international markets via Gaolan, making<br />

this region the gateway to the world.<br />

Collectively, with the growing trade at<br />

the HDP river terminals at Jiangmen<br />

<strong>International</strong> Container <strong>Terminals</strong> (JMCT)<br />

and Nanhai <strong>International</strong> Container<br />

<strong>Terminals</strong> (NICT), feeder services for both<br />

general and containerised cargo are made<br />

available and this enables shipping lines<br />

to get closer to the manufacturing centres<br />

in the PRD. Gaolan Port and all the other<br />

Delta Ports under the Hutchison Port<br />

Holdings (HPH) umbrella operate<br />

seamlessly and play an important part in<br />

contributing to the success of the Group.<br />

“As well as the ports at Nanhai and<br />

Jiangmen, there are other smaller ports<br />

with growing barge traffic along the West<br />

Gaolan Port Transportation Network<br />

River. Moving cargo by barge means that<br />

shippers do not need to incur highway tolls<br />

and delays due to traffic congestion can<br />

be avoided. In addition, a barge can move<br />

a large number of containers compared to<br />

one or two on a truck and trailer,”said Leung.<br />

With the rapid growth of economic<br />

and trade co-operation between China<br />

and the ASEAN countries, China has<br />

capitalised on the flow of goods traded<br />

between the region’s countries. Gaolan’s<br />

status as an important shipping hub will<br />

be further enhanced as China’s trade<br />

reforms result in significant economic<br />

growth for the country.<br />

HIT News, Spring 2005 5

6<br />

Information<br />

Technology<br />

Advanced security system on trial<br />

at HIT<br />

Safety and security are<br />

top priorities at all<br />

major container<br />

terminals around the world,<br />

and it is the same at<br />

<strong>Hongkong</strong> <strong>International</strong><br />

<strong>Terminals</strong> (HIT), where we are<br />

taking pro-active actions to<br />

pioneer the latest scanning<br />

equipment to help track the<br />

content inside the containers.<br />

As part of the Hong Kong Container<br />

Terminal Operators Association (HKCTOA)<br />

initiative, HIT has joined forces with the<br />

Science Applications <strong>International</strong><br />

Corporation (SAIC), a US-based research<br />

and engineering company to test the<br />

Integrated Container Inspection System<br />

(ICIS), equipped with radiographic imaging,<br />

radiation detection and Optical Character<br />

Recognition (OCR) technologies. The<br />

scanners are able to detect if there is any<br />

radioactive material and also if there are any<br />

suspicious materials inside the containers.<br />

A specially-designated ICIS truck lane has<br />

been allocated close to HIT Terminal 6 entry<br />

gate for testing the system, and is capable<br />

of scanning high volumes of containers in<br />

the normal flow of traffic. At the moment,<br />

there is only one other terminal operator<br />

at Kwai Chung besides HIT who is taking<br />

part in the same pilot project.<br />

“The drive-through scanning system at<br />

the two terminals at Kwai Chung is the first<br />

of its kind in the world. Similar scanning<br />

systems that have been supplied by SAIC to<br />

the other parts of the world are mainly stopand-go<br />

systems which are not suitable for<br />

coping with the high volumes of container<br />

HIT News, Spring 2005<br />

traffic at sizeable terminals such as HIT.<br />

The collaboration between HKCTOA<br />

and SAIC is aimed at testing the ICIS and<br />

ensuring that it meets the requirements of<br />

collecting the scanned images and data of<br />

all the containers entering the terminal<br />

through the gate, without disrupting<br />

normal terminal operations. If the ICIS is<br />

proven to be an effective solution for<br />

enhancing container security at the terminal<br />

and supported by the relevant authorities<br />

and the shipping community, it will be a<br />

natural progression for all terminal operators<br />

to adopt ICIS permanently throughout their<br />

terminals,” said Eddy Ma, General Manager,<br />

Terminal Operations.<br />

“We are anticipating that the US<br />

Customs will introduce tougher security<br />

measures, including the use of non-intrusive<br />

inspection devices to pre-screen containers<br />

at loading ports before they are loaded on<br />

ships bound for the United States. We are<br />

very confident that ICIS can meet even<br />

tougher requirements that are set forth by<br />

the US Customs,” he added.<br />

Also important to HIT is the impact the<br />

system has on traffic management both<br />

in the yard and also on the public highways<br />

leading to the terminal.<br />

“We have been monitoring the traffic<br />

flow through ICIS and whether it is causing<br />

a tailback onto the approach roads during<br />

peak periods. And the impact has been<br />

manageable so far,” added Eddy.<br />

“We have been in contact with the<br />

relevant government authorities to seek<br />

their views on the use of ICIS. For now,<br />

we are appraising the system with SAIC<br />

and HKCTOA and eventually when the<br />

system has been successfully tried, we will<br />

then consider the official use of the<br />

system,” said Eddy.<br />

ICIS System<br />

. Enables terminals to scan high<br />

volumes in normal traffic<br />

. Integrates data from many sources<br />

.<br />

.<br />

Reduces delays by collecting data<br />

quickly for later analysis<br />

Open architecture design facilitates<br />

integration and expansion

Customer<br />

Focus<br />

Hyundai Merchant Marine<br />

<strong>goes</strong> from strength-to-strength<br />

Hyundai Merchant Marine (HMM),<br />

one of the world’s major shipping<br />

lines, is expanding its container<br />

shipping operations on East-West and<br />

Intra-Asia routes over the next three years,<br />

according to Mr. J. K. Kim, Managing<br />

Director, HMM (HK) Ltd.<br />

“We have enjoyed considerable<br />

growth during the last three years and in<br />

order to meet future demand from our<br />

customers, we have ordered four Super<br />

Post-Panamax vessels with a capacity of<br />

8,600-TEU each, which will be de<strong>live</strong>red<br />

in 2008,” said Kim.<br />

“We will continue to achieve significant<br />

economies of scale by deploying these<br />

larger vessels on key routes, saving<br />

additional costs and making our operations<br />

more competitive. These ships will have a<br />

speed limit of up to 27 knots, which will<br />

help us become more responsive to<br />

customer demand.”<br />

These very large vessels have a<br />

maximum capacity of 9,000-TEU and<br />

comprise of the length of three football<br />

fields, some 339 metres from bow to stern.<br />

They also have a 45.6 metre beam and a<br />

draft of 24.6 metres.<br />

Additional HMM new vessels include<br />

an order for eight 6,800-TEU vessels, the<br />

first of which will be de<strong>live</strong>red during the<br />

second quarter of 2006 through to 2007.<br />

These larger vessels will be deployed on<br />

East-West routes, to be decided based on<br />

market demand.<br />

Completing the additions to the new<br />

container ship fleet are three 4,700-TEU<br />

vessels ordered in 2003 which are now<br />

under construction, and a further five<br />

vessels of a similar capacity which are due<br />

for de<strong>live</strong>ry in 2008.<br />

“We will be deploying some of the<br />

4,700-TEU vessels on Intra-Asia routes,<br />

again seeking economies of scale and<br />

competitive advantage by replacing<br />

smaller vessels,” said Kim.<br />

HMM is also looking to expand its<br />

presence in key Asian markets, notably in<br />

China, India and Vietnam during 2005.<br />

“We are opening our own offices in<br />

Ningbo, Mumbai and Ho Chi Minh City<br />

later this year to strengthen HMM’s<br />

presence in those markets. We have<br />

enjoyed sound financial results and are<br />

now looking to invest in areas where we<br />

see significant growth in the future,”<br />

said Kim.<br />

The HMM Group also has significant<br />

interests in bulk shipping, as well as a<br />

rapidly expanding fleet of petroleum<br />

product carriers.<br />

“HMM is also involved in container<br />

terminal operations and inland logistics,<br />

and we are continuing with our strategic<br />

investments in these sectors across Asia and<br />

around the world,” concluded Kim.<br />

HIT News, Spring 2005 7

8<br />

Quayside<br />

New crane de<strong>live</strong>ry to meet<br />

of giant carriers<br />

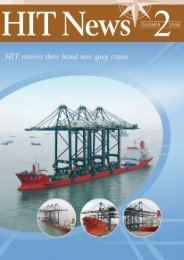

The next generation<br />

of Super Post-<br />

Panamax vessels are<br />

moving off the drawing<br />

board and into production<br />

in shipyards across Europe<br />

and Asia. Now HIT is taking<br />

steps to ensure that it can<br />

provide sufficient quay cranes<br />

to handle these new giants of<br />

the sea, well into the future.<br />

Five new quay cranes arrived at Kwai<br />

Chung recently from the Zhenhu Port<br />

Machinery Company (ZPMC) fabrication<br />

sites in Shanghai, all equipped to handle a<br />

reach of 23 containers across and a height<br />

of 43 metres. Three of these cranes have<br />

been deployed at designated HIT terminals<br />

throughout Kwai Chung.<br />

With vessels of 8,000-TEU already sailing<br />

the seas and plans for ships of more than<br />

10,000-TEU in the planning stage, container<br />

terminals have to ramp up their own facilities<br />

in order to accommodate these behemoths.<br />

These new 1,400 tonne cranes are part<br />

of an ongoing process at HIT to maximise<br />

the limited land available in the yard<br />

through automation, improved efficiency<br />

and increased productivity, according<br />

to Simon Wong, General Manager,<br />

Engineering Department.<br />

“In order to meet the need of handling<br />

a larger throughput of containers from<br />

Super Post-Panamax vessels, we have<br />

improved space management by stacking<br />

one over six and improved the<br />

performance of Rubber Tyred Gantry<br />

HIT News, Spring 2005<br />

Cranes through auto steering. This has been<br />

beneficial to overall yard handling<br />

performance. We have also upgraded<br />

container positioning determination equipment<br />

on yard cranes to accurately detect and<br />

retrieve containers,” said Simon.<br />

Saving precious seconds from quay crane<br />

move has a beneficial and cumulative impact<br />

on quay side efficiency. And the tractor<br />

alignment system has also proved to be a<br />

simple yet effective way of guiding drivers to<br />

the correct position for quay crane lifts. The<br />

yard crane lifts will be looked at next.<br />

“We use a set of lights that are<br />

illuminated when the tractor and trailer are<br />

in the correct position, without this the driver<br />

has to move his chassis backwards and<br />

forwards until the right alignment with the<br />

crane hoist,” said Simon.<br />

Eddy Ma, General Manager of Terminal<br />

Operations, looked at how the market was<br />

driving the change for larger vessels.<br />

“We are seeing an increasing demand<br />

for raw materials from China and<br />

manufactured products made in China for<br />

export around the world. Shipping lines are<br />

looking for economies of scale so as to reduce<br />

the cost of adding frequency to meet this<br />

growing demand for additional capacity on<br />

major east-west line haul routes,” said Eddy.<br />

“As a result of this, shipping lines are looking<br />

to deploy larger vessels to ensure that they have<br />

the capacity to meet this growing demand,<br />

particularly at the hub ports,” he added.<br />

With the larger vessels, increased draft<br />

is required in the access channel and also<br />

alongside the berth; and HIT has also taken<br />

the necessary steps to address this issue.<br />

“We have to pay close attention to the market<br />

and look at what is on the horizon in order to<br />

plan ahead. We have taken an holistic approach at<br />

HIT looking at how we can maximise efficiency<br />

in our 92 hectares facility which extends to<br />

operations on the quayside, quay lanes, container<br />

yard and the gates,” concluded Eddy.

demand<br />

HIT News, Spring 2005 9

10<br />

News<br />

A view from the top<br />

Ever wondered what it takes to<br />

become a quay crane operator?<br />

Well, it starts with a 24-day training<br />

schedule that includes theory, safety and<br />

on-the-job practical experience.<br />

Continuous assessment during the<br />

training period followed by a written test<br />

decides who will be selected to operate the<br />

giant waterfront cranes or the Rubber Tyred<br />

Gantry Cranes in the yard.<br />

“Our crane operators are given broad<br />

experience in handling all models of cranes at<br />

HIT during the training period,” said Lee Wing<br />

Chung, Superintendent, Terminal Operations.<br />

Such is the quality of the crane operator<br />

training in the yard, unmatched elsewhere,<br />

that the Hong Kong Government Labour<br />

Department has specially designated<br />

<strong>Hongkong</strong> <strong>International</strong> <strong>Terminals</strong> (HIT) as<br />

an approved centre for this course.<br />

“As an approved centre, we are<br />

authorised to train operators from outside<br />

HIT and upon the completion of the<br />

course, a list of licensed operators who<br />

passed our training programme will be<br />

submitted to the Labour Department<br />

where they maintain a record of all the<br />

certified cranes operators,” added Lee.<br />

This training also includes contractors from<br />

outside HIT who have no prior experience<br />

in handling the sophisticated machinery.<br />

It is a full-time job training and<br />

Cross-border rule relaxed<br />

China’s customs authorities have<br />

relaxed their cross border<br />

trucking rules, which would be<br />

greatly beneficial to shippers and trucking<br />

companies as their efficiency would be<br />

significantly improved.<br />

The old ‘four-up-four-down’ rule<br />

meant that driver, truck, chassis and<br />

container were considered one dutiable<br />

‘unit’ entering China from Hong Kong,<br />

and the same ‘unit’ had to return to<br />

Hong Kong complete, that is, in unit with<br />

the same registration details, in order to<br />

HIT News, Spring 2005<br />

deploying staff to operate HIT’s quay<br />

cranes, numbering more than forty to date.<br />

In addition, there are also on-the-job<br />

re-training programmes in place for new<br />

crane de<strong>live</strong>ries.<br />

“We ensure that our operators are kept<br />

well-informed, and trained only by highly<br />

qualified and experienced instructors, if<br />

there are any changes to the control<br />

systems of new cranes,” said Lee.<br />

The quay cranes at HIT are an integral<br />

part of Hong Kong’s skyline and the<br />

operators handling these 1,400 tonne<br />

machines have to have two to three years<br />

experience in the yard before they are<br />

considered to operate the cranes.<br />

“After two to three years in the yard,<br />

we look for RTGC operators who have the<br />

temperament and capability to handle the<br />

quay cranes and they then undergo<br />

retraining before they move onto the<br />

waterfront,” said Lee.<br />

So the next time you look at the giant<br />

quay cranes, remember the training and<br />

dedication that the operators need to<br />

operate the machines seamlessly. It is a<br />

wonderful feeling to operate the cranes,<br />

and a beautiful view from the top.<br />

avoid customs’ duty.<br />

Now the rule has relaxed. It is no longer<br />

a requirement for a driver with a laden<br />

container commencing its journey from Hong<br />

Kong to China to return in the same chassis<br />

and empty container. Now, only the same<br />

driver and truck have to return to Hong Kong.<br />

This change of rule means that truck<br />

drivers should be able to complete more<br />

journeys in one day, speeding up the flow<br />

of goods across the border and helping to<br />

improve the utilisation of trucks and drivers<br />

and equipment. Lok Ma Chau Border Crossing (photo courtesy of PMB)

ings<br />

virtual one-stop-shop to HIT<br />

IE<br />

ShareRing<br />

Crystal<br />

Outlook HRMS<br />

Enterprise<br />

HRMS<br />

Enterprise<br />

Emails &<br />

Calendar<br />

Past<br />

Throughput<br />

Reports<br />

Entrepôt is an inhouse<br />

portal that<br />

allows users to<br />

access a wide range of<br />

information and data through<br />

an integrated system.<br />

Key features include individual web<br />

pages that enable the user to customise<br />

their own home portal page incorporating<br />

a simplified log-in.<br />

“The idea is that everyone saves time by<br />

having access to job and task relevant<br />

information as soon as they log on to their<br />

home page. Previously, staff would spend<br />

an enormous amount of time searching for<br />

the information they need and accessing<br />

individual websites and databases. Now<br />

multiple links are accessible on one computer<br />

screen,” said Dr. K. K. Lai, Project Manager<br />

of Operations Development Department.<br />

Word documents, emails, Excel<br />

spreadsheets, charts and web pages can<br />

now be accessed directly through Entrepôt.<br />

HR<br />

Information<br />

“Ultimately the portal<br />

will save staff time and<br />

improve productivity for<br />

staff at HIT”<br />

ShareRing<br />

There are a range of e-services which<br />

all come under the Entrepôt umbrella,<br />

which means that much of the workflow<br />

can be automated.<br />

“For instance, we are currently<br />

working with Human Resources to enable<br />

staff to check their leave entitlement<br />

through Entrepôt, saving staff time in<br />

making individual enquiries via email or<br />

phone. In other areas we are also<br />

incorporating the regional engineering<br />

databases to see if there are some<br />

synergies between Business Units<br />

regarding availability and deployment of<br />

information,” added K. K.<br />

There are also useful external sources<br />

of information that HIT users can<br />

incorporate into their portal page such as<br />

general market information about the<br />

shipping market.<br />

Emails &<br />

Calendar<br />

Entrepot<br />

Throughput<br />

Reports<br />

Present<br />

HR<br />

Information<br />

“We wanted to develop a portal that<br />

was an aggregator of both day-to-day<br />

functional information such as email,<br />

calendar, tasks that were Internet-enabled<br />

with a high level of security that ensured<br />

that access to specific web pages was<br />

predetermined through the system, on a<br />

need-to-know basis,” said K. K.<br />

The next phase was really to provide a<br />

platform that incorporates the shared<br />

access of information between Business<br />

Units, strategic information related<br />

to all aspects of yard management,<br />

procurement, inventory and commercial<br />

information about customers.<br />

“Entrepôt also allows researchers to<br />

trace the authors of documents so they can<br />

quickly get to the source of the information<br />

they need,” added K. K.<br />

Finally K. K. looked to the future<br />

and considered the next phases of<br />

development for Entrepôt: “Ultimately the<br />

portal will save staff time and improve<br />

productivity for staff at HIT, our next goal<br />

is to extend Entrepôt to the Business Units<br />

under Hutchison Port Holdings in<br />

Southern China, then to all its global<br />

Business Units.”<br />

HIT News, Spring 2005<br />

11

12<br />

Events<br />

Record Turnout for HIT’s<br />

35th Anniversary Annual Dinner<br />

More than 60 percent of <strong>Hongkong</strong> <strong>International</strong> Terminal (HIT) staff, that is more than 1,000 people in<br />

numbers, turned up at the company’s Annual Dinner that was held at the <strong>Hongkong</strong> <strong>International</strong> Trade &<br />

Exhibition Centre on the evening of 24 February 2005.<br />

Marking the thirty-fifth anniversary of HIT, this event also featured an exhibition of photographs highlighting key<br />

events and milestones in the company’s history. The purpose of the exhibition was to enable new staff members to<br />

have an opportunity to learn more about the history of the company and its achievements.<br />

This event was made even more special with the attendance of three former senior managers, I. B. Kitchell, C<strong>live</strong><br />

Flegg and David Lewer.<br />

Guests were entertained throughout the night by a troupe of Indian drummers and dancers, a <strong>live</strong> band and group<br />

dancing, and left the night high in spirits.<br />

2005 South China Division (SCD)<br />

Management Seminar<br />

The annual HIT SCD Management Seminar 2005 was held on 20 &<br />

21 March in Macau this year, attended by more than 200 managers<br />

from the division.<br />

Mr. Eric Ip, Managing Director of HIT, kicked-off the seminar by<br />

giving an overview of the competitive environment of Southern China<br />

and providing an update on the new players in the industry.<br />

The focus of this year’s seminar is on “team building,” and several<br />

team activities were carried out to induce team spirits and generate cooperation<br />

among the members. Role-plays on selective market players<br />

were also carried out to enable participants to better understand the<br />

market situation and explore ways to react to unexpected changes in<br />

the marketplace.<br />

This year’s seminar was once again a huge success.<br />

HIT News, Spring 2005

Maiden<br />

Vessel Calls<br />

The M.V. MSC Maeva made its maiden call at HIT<br />

on 8 March 2005. The 8,089-TEU vessel originated from<br />

Chiwan and berthed at Kwai Chung for its onward<br />

voyage to Oakland, United States.<br />

Rugby Sevens<br />

More than fifty HIT staff and customers attended<br />

the Rugby Sevens 2005 that was held in Hong Kong<br />

over the third weekend of March. It was an exciting<br />

weekend that was full of adrenalin, as well as cheers<br />

and beers. Some were not so lucky though, who finished<br />

the games with a serious hangover!<br />

Visits<br />

Mexican Delegation<br />

HIT was delighted to receive a visit from Members of the<br />

Commission of Border Affairs of the Chamber of Senators<br />

of Mexico, Central Administrator of Customs Regulations<br />

of the Finance Ministry and the Consulate General of<br />

Mexico in Hong Kong on 26 January 2005.<br />

2005 Vice-Mayor of<br />

Xiamen Municipal<br />

Government and<br />

Delegation<br />

On 11 December 2004, a delegation comprising of senior<br />

officials from various Xiamen Government Bureaus and<br />

senior management of Xiamen-based companies visited HIT.<br />

Leading the delegation was Mr. Xu Mo, Vice-Mayor of<br />

Xiamen Municipal Government (fifth from right).<br />

HIT News, Spring 2005 13

14<br />

HIT People<br />

Looking at<br />

the changing face of HIT<br />

C. K. Poon, or better<br />

known to everyone<br />

as PCK, joined HIT<br />

in 1976 and has experienced<br />

some dramatic changes in yard<br />

operations and the industry as<br />

a whole. Now as Container<br />

Yard Operations Manager, he<br />

is surrounded by new<br />

technology, I.T. experts<br />

and is at the centre of<br />

HIT’s ongoing automation<br />

of yard operations.<br />

“The single biggest change in the last<br />

29 years is that there used to be many more<br />

workers in the yard, as we relied heavily on<br />

manual labour for our day-to-day<br />

operations in the seventies and eighties.<br />

Competitive pressure has led to many<br />

functions becoming automated and we<br />

now utilise technology more extensively.”<br />

“The next big change is the attitude of<br />

workers in the yard. In years gone by, many<br />

employees were happy to just do their work<br />

and return home. Now, there is a greater<br />

understanding that we are all working<br />

together to improve operations in order<br />

to benefit our customers,”said PCK.<br />

“Our staff now understand how HIT has<br />

to be more competitive and that everyone<br />

has a part to play in meeting our<br />

customers’ expectations. The company<br />

also provides adequate training to enable<br />

all staff members to improve in their jobs.<br />

Schemes like the Port Worker Development<br />

HIT News, Spring 2005<br />

Programme have been very successful, and<br />

it has enabled yard operations staff to move<br />

into management positions,” he added.<br />

Safety and security have also become<br />

primary considerations in recent times.<br />

Twenty years ago, yard staff relied on luck<br />

as a more relaxed attitude prevailed in<br />

waterfront operations in Hong Kong.<br />

“Now protective equipment is<br />

mandatory in the yard, safety helmets have<br />

to be worn and training is provided to all<br />

workers to reduce the risk of accidents. It<br />

is a lot safer now than in the early days<br />

when we relied on sheer luck,” added PCK.<br />

Security has also been a major<br />

consideration in yard operations,<br />

particularly during the last two years, and<br />

now sophisticated scanning equipment<br />

has been installed at HIT to reduce the<br />

risk of dangerous materials passing<br />

through HIT (Please refer to article on “ICIS<br />

Scanning” on Page 6).<br />

“We have a very well-trained safety and<br />

security department that works very closely<br />

with government inspectors and the<br />

police. They have very strict guidelines for<br />

all staff and contractors which help to keep<br />

the yard safe and secure. This is also a<br />

dramatic improvement from the days<br />

when I first worked for HIT.”<br />

On a social side, PCK is also the Head<br />

of HIT Annual Dinner Committee,<br />

whereby he helped to oversee and<br />

organised this annual event that was<br />

attended by more than 1,000 HIT<br />

employees in Hong Kong. (Please refer<br />

to the feature on “HIT 35th Anniversary<br />

Annual Dinner” on Page 12)<br />

PCK has been married for 31 years and<br />

has two daughters, Lai-yie, 29 years old,<br />

and Lai-ting, 27, and a son Cheung-hei<br />

who is 23. During his leisure time, PCK<br />

enjoys his time as a mahjong maestro,<br />

karaoke singing and horse-racing.

End of Legal Battle for<br />

River Trade Terminal<br />

Hong Kong’s River Trade Terminal (RTT)<br />

lost a six-year legal fight, meaning that it<br />

can no longer service ships carrying trade<br />

outside the Pearl River Delta. The decision<br />

by the Court of Final Appeal could slash<br />

the RTT’s revenues by as much as 50%.<br />

Singapore Signed New<br />

Agreement With US<br />

Singapore has signed an agreement<br />

with the US that allows the deployment of<br />

equipment to detect potential “dirty<br />

bombs” being trafficked through its port.<br />

The US and Singapore governments signed<br />

a declaration of principles that will lead to<br />

what described as “state of the art<br />

equipment” being deployed at the Port of<br />

Singapore to detect hidden nuclear and<br />

radioactive materials in shipments. The<br />

republic will be the first country in<br />

Southeast Asia to use the detection system<br />

in co-operation with the US.<br />

Planned IPO from<br />

Panalpina Group<br />

The Panalpina Group is set to go public,<br />

despite abandoning the idea a few years<br />

ago. The company said preparations for<br />

the planned initial public offering were<br />

scheduled to take place during the next<br />

few months to enable Panalpina to enter<br />

the stock market in Europe this year.<br />

FESCO Launches<br />

New Service<br />

Russia-based Far Eastern Shipping<br />

Company (FESCO) has launched a new<br />

service between the port of Busan in Korea<br />

and Sakhalin Island, Russia with a regular call<br />

every 12 days to support increased trading<br />

between the two fast-growing regions.<br />

Known as FESCO Korea Sakhalin Line (FKSL),<br />

the service’s port rotation includes: Busan -<br />

Ulsan or Masan (on inducement) - Korsakov<br />

- Kholmsk - Busan. FKSL is utilising one MV<br />

Pioneer vessel to handle all types of<br />

shipments, including heavy lift, breakbulk,<br />

roll-on/roll-off, and containerloads for<br />

bilateral and transshipment cargo from<br />

North America, Europe and Asia. If demand<br />

for the service is strong, a second vessel will<br />

be deployed to provide a fixed-day weekly<br />

service, says the company.<br />

New Rate Restorations<br />

To Be Implemented<br />

Members of the South East Asia and<br />

South Asia / Australia Trade Facilitation<br />

Agreement plan to implement rate<br />

restorations next month and later in the<br />

year. From April 1, rates for shippers<br />

sending cargo from Singapore, Malaysia,<br />

Indonesia, Thailand, Vietnam, India, Sri<br />

Lanka, Pakistan and Bangladesh to Australia<br />

are up by a minimum of $300 per TEU.<br />

Further hikes are expected in July and<br />

October. Member lines are: ANL<br />

Singapore, APL, Gold Star Line, Hanjin<br />

Shipping, HMM, K Line, Maersk Sealand,<br />

MISC, MOL, NYK Line, OOCL, P T Djakarta<br />

Lloyd, P&O Nedlloyd Limited, PIL and<br />

Regional Container Lines.<br />

Indian Government<br />

Committed to<br />

IWT Infrastructure<br />

The Indian government has made a<br />

commitment to improve the country’s Inland<br />

Water Transport (IWT) infrastructure.<br />

According to Minister of Shipping, Road<br />

Transport and Highways, Shri TR Baalu,<br />

priorities include: making the existing national<br />

waterways fully functional by providing the<br />

requisite infrastructure - terminals,<br />

navigational aids and so on; assisting IWT<br />

operators in acquiring suitable vessels<br />

through a vessel-building subsidy scheme;<br />

and encouraging private sector participation<br />

and public-private joint ventures.<br />

Asia Diary<br />

Drought Affects<br />

Thai - Laos Shipment<br />

Vessels transporting cargo between<br />

Loei in Thailand and the Luangprabang<br />

province of Laos stopped operating in<br />

February as this particular section of the<br />

Mekong River is drying up. According<br />

to Somchai Teeradamrongsak, deputy<br />

chief customs officer of the Chiang Khan<br />

checkpoint, Thai cross-border trade has<br />

ground to a virtual halt after seven<br />

months without rain. Cargo ships of<br />

between 100 and 200-tonne capacity<br />

could not make their regular journey<br />

between Thailand and Luangprabang,<br />

from where goods are normally<br />

distributed further inland in Laos.<br />

Vinpac Group Awarded<br />

Class A licence<br />

Hong Kong-based logistics company<br />

Vinpac Group has been awarded a Class-<br />

A licence for its branch office in Shanghai<br />

under the CEPA agreement. The Shanghai<br />

office is operating under the name<br />

of Vinpac Multitrans (China). Services<br />

include sea and air freight, land<br />

transportation, warehousing,<br />

transshipment, consolidated cargo,<br />

customs clearance, insurance, commercial<br />

inspections and transportation<br />

consultation in China.<br />

Many thanks to<br />

HIT News, Spring 2005 15

Community<br />

News<br />

Caring Company Award<br />

<strong>Hongkong</strong> <strong>International</strong> <strong>Terminals</strong><br />

(HIT) has, for the second<br />

consecutive year, won the<br />

“Caring Company Award” that was<br />

presented by The Hong Kong Council<br />

of Social Service (HKCSS). The Caring<br />

Company Award scheme recognises<br />

companies that fulfill at least two criteria<br />

among the following: volunteerism, being<br />

family friendly, employing vulnerable<br />

segments, partnering with the social<br />

service sector, mentoring of social<br />

organisations and giving to the<br />

community. This latest win establishes<br />

HIT’s ongoing efforts as a good<br />

HIT News, Spring 2005<br />

Chief Editor: Lily Chan<br />

Editor: Shirley Teo-Lam<br />

Writer: Russell Green - RTG Communications<br />

Graphic Designer: Derek Ying<br />

Terminal 4, Container Port Road South,<br />

Kwai Chung, Hong Kong<br />

Tel: (852) 2619 7557 Fax: (852) 2612 0083<br />

Email: gca@hit.com.hk<br />

www.hit.com.hk<br />

HIT News, Spring 2005<br />

corporate citizen, and recognises the<br />

firm’s active involvement and contribution<br />

to the community.<br />

Tsunami Relief<br />

Last Christmas should be a joy for all, but there was much heartache in<br />

Asia as a result of the Asia earthquake and tsunami. To help ease the<br />

sufferings and re-build the homelands for those affected, Hutchison<br />

Whampoa Limited (HWL) and Li Ka Shing Foundation have generously donated<br />

a total of HK$24 million specifically to this cause.<br />

Published by:<br />

<strong>Hongkong</strong> <strong>International</strong> <strong>Terminals</strong><br />

A member of the Hutchison Port Holdings Group<br />

"HIT News" is a quarterly publication by<br />

<strong>Hongkong</strong> <strong>International</strong> <strong>Terminals</strong> and is<br />

intended only as an informative journal on<br />

the company's business activities and<br />

issues related to the industry. No part of<br />

this magazine may be reproduced without the<br />

written permission of <strong>Hongkong</strong> <strong>International</strong><br />

<strong>Terminals</strong>. All rights reserved.<br />

The port operations of<br />

Hutchison Whampoa Limited