www.futurepipe.com/usa

www.futurepipe.com/usa

www.futurepipe.com/usa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Page 10 of 51<br />

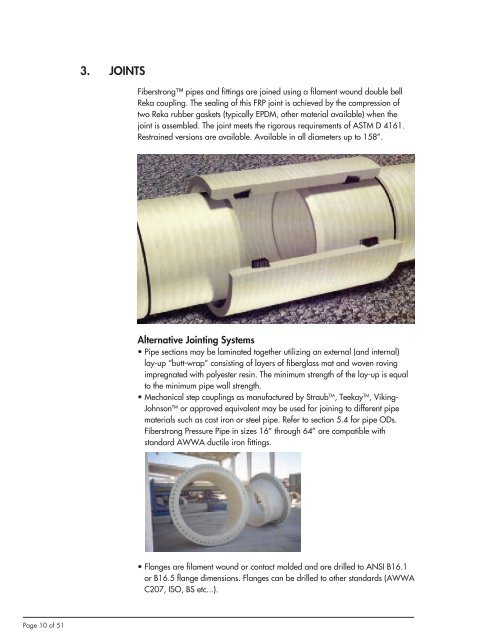

3. JOINTS<br />

Fiberstrong pipes and fittings are joined using a filament wound double bell<br />

Reka coupling. The sealing of this FRP joint is achieved by the <strong>com</strong>pression of<br />

two Reka rubber gaskets (typically EPDM, other material available) when the<br />

joint is assembled. The joint meets the rigorous requirements of ASTM D 4161.<br />

Restrained versions are available. Available in all diameters up to 158”.<br />

Alternative Jointing Systems<br />

• Pipe sections may be laminated together utilizing an external (and internal)<br />

lay-up “butt-wrap” consisting of layers of fiberglass mat and woven roving<br />

impregnated with polyester resin. The minimum strength of the lay-up is equal<br />

to the minimum pipe wall strength.<br />

• Mechanical step couplings as manufactured by Straub TM , Teekay TM , Viking-<br />

Johnson TM or approved equivalent may be used for joining to different pipe<br />

materials such as cast iron or steel pipe. Refer to section 5.4 for pipe ODs.<br />

Fiberstrong Pressure Pipe in sizes 16” through 64” are <strong>com</strong>patible with<br />

standard AWWA ductile iron fittings.<br />

• Flanges are filament wound or contact molded and are drilled to ANSI B16.1<br />

or B16.5 flange dimensions. Flanges can be drilled to other standards (AWWA<br />

C207, ISO, BS etc...).