Luzenac 20-pages - Rio Tinto

Luzenac 20-pages - Rio Tinto

Luzenac 20-pages - Rio Tinto

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

talc the mineral<br />

14 <strong>Luzenac</strong><br />

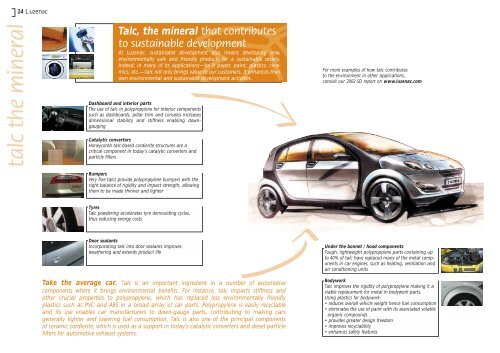

Talc, the mineral that contributes<br />

to sustainable development<br />

At <strong>Luzenac</strong>, sustainable development also means developing new,<br />

environmentally safe and friendly products for a sustainable society.<br />

Indeed, in many of its applications—be it paper, paint, plastics, ceramics,<br />

etc.—talc not only brings value to our customers, it enhances their<br />

own environmental and sustainable development activities.<br />

Dashboard and interior parts<br />

The use of talc in polypropylene for interior components<br />

such as dashboards, pillar trim and consoles increases<br />

dimensional stability and stiffness enabling downgauging<br />

Catalytic converters<br />

Honeycomb talc-based cordierite structures are a<br />

critical component in today’s catalytic converters and<br />

particle filters<br />

Bumpers<br />

Very fine talcs provide polypropylene bumpers with the<br />

right balance of rigidity and impact strength, allowing<br />

them to be made thinner and lighter<br />

Tyres<br />

Talc powdering accelerates tyre demoulding cycles,<br />

thus reducing energy costs<br />

Door sealants<br />

Incorporating talc into door sealants improves<br />

weathering and extends product life<br />

Take the average car. Talc is an important ingredient in a number of automotive<br />

components where it brings environmental benefits. For instance, talc imparts stiffness and<br />

other crucial properties to polypropylene, which has replaced less environmentally friendly<br />

plastics such as PVC and ABS in a broad array of car parts. Polypropylene is easily recyclable<br />

and its use enables car manufacturers to down-gauge parts, contributing to making cars<br />

generally lighter and lowering fuel consumption. Talc is also one of the principal components<br />

of ceramic cordierite, which is used as a support in today’s catalytic converters and diesel particle<br />

filters for automotive exhaust systems.<br />

For more examples of how talc contributes<br />

to the environment in other applications,<br />

consult our <strong>20</strong>02 SD report on www.luzenac.com<br />

Under the bonnet / hood components<br />

Tough, lightweight polypropylene parts containing up<br />

to 40% of talc have replaced many of the metal components<br />

in car engines, such as heating, ventilation and<br />

air conditioning units<br />

Bodywork<br />

Talc improves the rigidity of polypropylene making it a<br />

viable replacement for metal in bodywork parts.<br />

Using plastics for bodywork:<br />

• reduces overall vehicle weight hence fuel consumption<br />

• eliminates the use of paint with its associated volatile<br />

organic compounds<br />

• provides greater design freedom<br />

• improves recyclability<br />

• enhances safety features

![Download pdf file [PDF: 1.26 MB] - Rio Tinto](https://img.yumpu.com/10319684/1/190x253/download-pdf-file-pdf-126-mb-rio-tinto.jpg?quality=85)