Acoustical Ceiling Systems 2011 2012 - USG Middle East

Acoustical Ceiling Systems 2011 2012 - USG Middle East

Acoustical Ceiling Systems 2011 2012 - USG Middle East

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Acoustical</strong> <strong>Ceiling</strong> <strong>Systems</strong><br />

Superior <strong>Ceiling</strong> Tiles<br />

Plain / Laminated <strong>Ceiling</strong> Tiles<br />

Fissured <strong>Ceiling</strong> Tiles<br />

Face Cut <strong>Ceiling</strong> Tiles<br />

Specialty <strong>Ceiling</strong>s<br />

Technical Information<br />

<strong>2011</strong> <strong>2012</strong>

About <strong>USG</strong> About <strong>USG</strong><br />

2 3<br />

World wide<br />

<strong>USG</strong> has been a leader in the building materials industry for 100<br />

years. Our products can be found in buildings where people live and<br />

work, in more than 125 countries throughout the world.<br />

Headquartered in Chicago, USA, we have offices throughout the U.S.,<br />

Europe, Canada, Mexico, <strong>Middle</strong> <strong>East</strong> and Asia/Pacific.<br />

With sales in excess of $5 billion, we are the world’s largest<br />

producer of gypsum wallboard and a leading manufacturer of ceiling<br />

components and systems. <strong>USG</strong> is the world’s leading manufacturer<br />

of ceiling grid – in fact, DONN brand DX grid can be found in more<br />

ceilings, world wide, than any other supplier.<br />

<strong>Middle</strong> <strong>East</strong><br />

<strong>USG</strong> <strong>Middle</strong> <strong>East</strong> operations are coordinated from Dammam, Saudi<br />

Arabia with regional sales offices in Dammam, Riyadh and Jeddah in<br />

Saudi Arabia, Dubai in U.A.E, Bahrain, and Beirut in Lebanon.<br />

<strong>USG</strong> sales offices are established throughout the <strong>Middle</strong> <strong>East</strong> to<br />

provide local expertise and support to an extensive distribution and<br />

sales network that has been operating for more than 25 years.<br />

Manufacturing operations for mineral fibre, laminated mineral<br />

ceilings, DONN brand suspension systems, Dry wall partition and<br />

SHEETROCK brand joint treatment products and Tuff-Hide are based<br />

at Dammam K.S.A.<br />

BS EN 13964:2004<br />

Suspended <strong>Ceiling</strong>s<br />

is the new harmonised European standard, effective from 1st<br />

January 2005, which provides information for parties responsible for<br />

designing, manufacturing and specifying/selecting suspended ceilings<br />

used for interior applications. It covers suspended ceilings sold as<br />

kits, individual components & membrane components and describes<br />

test methods & methods of assessment as well as provisions for the<br />

evaluation of conformity of the products to the requirements of this<br />

standard.<br />

DONN ® Suspension <strong>Systems</strong><br />

<strong>USG</strong> is the world’s leading manufacturer of<br />

ceiling grid, offering the widest range of profiles<br />

and colours on the market today. DONN® grid<br />

from <strong>USG</strong> is compatible with all <strong>USG</strong> ceiling<br />

tiles and speciality ceilings, as well as most third<br />

party brands. The patented clip design makes it<br />

fast and easy to install but also easy to remove<br />

without the need for tools.

4<br />

Contents<br />

Pages Selector<br />

6-13 Market/application selectors<br />

14-19 Technical selectors<br />

20-27 Sustainability<br />

<strong>USG</strong> Superior ceiling tiles<br />

28-29 Clean Room ClimaPlus<br />

30-31 Glacier<br />

32-33 Mars ClimaPlus<br />

34-35 Radar Ceramic ClimaPlus<br />

36-37 Sandrift ClimaPlus<br />

38-39 Sonata<br />

40-41 Taiga II Hygiene TM<br />

<strong>USG</strong> Plain / Laminated ceiling tiles<br />

42-43 Olympia II<br />

44-45 Olympia II Micro Perforated<br />

46-47 Perforated<br />

48-49 Plain<br />

50-51 Sonatone White - Sparta<br />

<strong>USG</strong> Fissured ceiling tiles<br />

52-53 Cross Fissured<br />

54-55 Favia<br />

56-57 Favia Acoustic<br />

58-59 Radar<br />

60-61 Rocktone<br />

62-63 Omni<br />

<strong>USG</strong> Face Cut ceiling tiles<br />

64-65 Chessboard<br />

66-67 Comet Line<br />

68-69 Designer Squares<br />

70-71 Pedestals I<br />

<strong>USG</strong> Specialty ceilings<br />

72-73 Curvatura TM 3-D <strong>Ceiling</strong> System<br />

72-73 Compässo curved ceiling trim<br />

72-73 Metal ceiling systems<br />

Technical information<br />

74-75 Grid installation<br />

76-77 DONN DX24 Intermediate Duty<br />

78-79 DONN DX24 Heavy Duty-Standard<br />

80-81 DONN DXL24 Heavy Duty- Fire Rated<br />

82-83 DONN DX15 Centricitee<br />

84-85 <strong>USG</strong> <strong>Middle</strong> <strong>East</strong> Limited<br />

86 Grid/edge solutions<br />

87 Installation ,Maintenance and Custom products<br />

88-91 <strong>Ceiling</strong> <strong>Systems</strong>/ Warranties & Limitations<br />

How to use this catalogue?<br />

This catalogue is an easy-to-use reference guide for specifying <strong>USG</strong><br />

acoustical ceiling systems. To obtain the information you need, use<br />

one or several of the following options:<br />

• M arket/application selectors – start here if you are interested in<br />

a particular application area. We’ve identified several types of<br />

building environments, researched specific needs for each, and<br />

provided you with recommendations. You can rely on our expertise<br />

to help you select systems that work well in these spaces.<br />

• Technical selectors – start here if you have to meet specific<br />

requirements for acoustical, humidity or fire performance.<br />

• Products – start here if you know the exact product you need. <strong>USG</strong><br />

products are grouped into four key sections:<br />

• Superior<br />

• Plain / Laminated<br />

• Fissured<br />

• Face Cut<br />

• Specialty ceilings<br />

5

6<br />

Office Applications selector<br />

Application <strong>Ceiling</strong> panels Page<br />

Administration offices Sonata<br />

• • 38<br />

Olympia II Micro Perforated • • • • 44<br />

Radar<br />

• • • • 58<br />

Chessboard<br />

• 64<br />

Pedestals I<br />

• • • 70<br />

Conference areas Glacier<br />

• • • • 30<br />

Sonata<br />

• • 38<br />

Sandrift ClimaPlus<br />

• • • • 36<br />

Olympia II Micro Perforated • • • • 44<br />

Compässo/Curvatura<br />

72,73<br />

Corridors/ walkways Olympia II/Cross Fissured • • • • 42,52<br />

Omni/Radar<br />

• • • • 62,58<br />

Favia Acoustic<br />

• • • • 56<br />

Favia<br />

• • • • 54<br />

Comet Line<br />

• 66<br />

Executive areas Sonata<br />

• • 38<br />

Sandrift ClimaPlus<br />

• • • • 36<br />

Glacier<br />

• • • 30<br />

General offices Sonata<br />

• • 38<br />

Chessboard<br />

• 64<br />

Omni<br />

• • • • 62<br />

Favia<br />

• • • • 54<br />

Olympia II Micro Perforated • • • • 44<br />

Kitchens/food preparation areas Clean Room ClimaPlus<br />

• • 28<br />

Radar Ceramic ClimaPlus<br />

• • 34<br />

Offices with indirect lighting Sonata<br />

• • 38<br />

Plain<br />

• • • • 48<br />

Sandrift ClimaPlus<br />

• • • • 36<br />

Open plan offices Sonata<br />

• 38<br />

Glacier/Radar<br />

• • • • 30,58<br />

Compässo/Curvatura<br />

72,73<br />

Private offices Sonata<br />

• • 38<br />

Sandrift ClimaPlus<br />

• • • • 36<br />

Olympia II Micro Perforated • • • • 44<br />

Radar<br />

• • • • 58<br />

Parking garages Radar Ceramic ClimaPlus<br />

• 34<br />

Reception areas/ lobbies Sonata<br />

• • 38<br />

Sandrift ClimaPlus<br />

• • • • 36<br />

Chessboard<br />

• 64<br />

Designer Squares<br />

• • 68<br />

Compässo/Curvatura<br />

72,73<br />

Rest rooms/ utility areas Sonatone<br />

• • 50<br />

Omni/Radar<br />

• • • • 62,58<br />

Meridian<br />

Fineline<br />

DX15<br />

DONN grid options<br />

DX24<br />

Office space designs are now<br />

becoming a deciding factor in<br />

recruiting and retaining employees<br />

and workspaces must boost<br />

and enhance productivity while<br />

motivating employees. <strong>USG</strong> provides<br />

solutions for all your design needs<br />

from open plan offices to flexible<br />

office space requiring high sound<br />

absorption and attenuation.<br />

We offer various application options<br />

to help you design work areas that<br />

are:<br />

1) highly functional<br />

2) will obtain client approvaL<br />

3) within your budget criteria.<br />

Education Applications selector<br />

Application <strong>Ceiling</strong> panels Page<br />

Administration offices Sonata<br />

• • 38<br />

Olympia II Micro Perforated • • • • 44<br />

Radar<br />

• • • • 58<br />

Omni<br />

• • • • 62<br />

Favia Acoustic<br />

• • • • 56<br />

Auditoriums Sonatone<br />

• • 50<br />

Classrooms Perforated<br />

• • • • 46<br />

Radar<br />

• • • • 58<br />

Favia Acoustic<br />

• • • • 56<br />

Omni<br />

• • • • 62<br />

Cross Fissured<br />

• • • • 52<br />

Common rooms/ social areas Perforated<br />

• • • • 46<br />

Radar<br />

• • • • 58<br />

Favia<br />

• • • • 54<br />

Corridors/ walkways Sonata<br />

• • 38<br />

Olympia II Micro Perforated • • • • 44<br />

Perforated<br />

• • • • 46<br />

Gymnasiums Sonatone<br />

• • 50<br />

Kitchens/ food preparation areas Sonatone<br />

• • 50<br />

Locker rooms Sonatone<br />

• • 50<br />

Plain<br />

• • • • 48<br />

Media study areas Sonata<br />

• • 38<br />

Sandrift ClimaPlus<br />

• • • • 36<br />

Glacier<br />

• • • • 30<br />

Olympia II Micro Perforated • • • • 44<br />

Refectories/ dining halls Clean Room ClimaPlus<br />

• • 28<br />

Radar<br />

• • 34<br />

Plain<br />

• • • • 48<br />

Rest rooms/ utility areas Sonatone<br />

• • 50<br />

Radar<br />

• • • • 58<br />

Favia<br />

• • • • 54<br />

Swimming pools/ shower areas Radar Ceramic ClimaPlus<br />

• • 34<br />

Sonatone<br />

• • 50<br />

Meridian<br />

Fineline<br />

DX15<br />

DONN grid options<br />

DX24<br />

Designing an educational environment<br />

can be a learning experience. <strong>USG</strong><br />

takes an integrated approach in<br />

helping you design spaces that<br />

provide a balance between function<br />

and good design. With years of<br />

experience behind us, our acoustical<br />

ceiling system ranges are long lasting<br />

and will stand up to the abuse<br />

typically found in schools.<br />

We offer various application options<br />

to help you design an educational<br />

environment that is:<br />

1) highly functional<br />

2) will obtain client approval<br />

3) within your budget criteria.<br />

7

8<br />

Healthcare Applications selector<br />

Application <strong>Ceiling</strong> panels Page<br />

Administration offices Sonata<br />

• • 38<br />

Olympia II Micro Perforated • • • • 44<br />

Radar<br />

• • • • 34<br />

Favia Acoustic<br />

• • • • 56<br />

Omni<br />

• • • • 62<br />

Conference areas Sonata<br />

• • 38<br />

Olympia II Micro Perforated • • • • 44<br />

Plain<br />

• • • • 48<br />

Perforated<br />

• • • • 46<br />

Taiga II Hygiene<br />

• • • • 40<br />

Corridors/ walkways Sonata<br />

• • 38<br />

Compässo/Curvatura<br />

72,73<br />

Olympia II Micro Perforated • • • • 44<br />

Radar<br />

• • • • 58<br />

Favia Acoustic<br />

• • • • 56<br />

Kitchens/ food preparation areas Clean Room ClimaPlus<br />

• • 28<br />

Sonatone<br />

• • 50<br />

Laboratories Clean Room ClimaPlus<br />

• • 28<br />

Sonatone<br />

• • 50<br />

Radar Ceramic ClimaPlus<br />

• • 34<br />

Taiga II Hygiene<br />

• • • • 40<br />

Operating rooms Clean Room ClimaPlus<br />

• • 28<br />

Taiga II Hygiene<br />

• • • • 40<br />

Out patient care areas Sonatone<br />

• • 50<br />

Olympia II Micro Perforated • • • • 44<br />

Sonata<br />

• • 38<br />

Receptions/ waiting areas Sonatone<br />

• • 50<br />

Glacier<br />

• • • • 30<br />

Sandrift ClimaPlus<br />

• • • • 36<br />

Rest rooms/ utility areas Sonatone<br />

• • 50<br />

Radar<br />

• • • • 58<br />

Favia Acoustic<br />

• • • • 56<br />

Perforated<br />

• • • • 46<br />

Sterile and soiled utility rooms Clean Room ClimaPlus<br />

• • 28<br />

Sonatone<br />

• • 50<br />

Taiga II Hygiene<br />

• • • • 40<br />

Wards/ patient rooms Clean Room ClimaPlus<br />

• • 28<br />

Sonatone<br />

• • 50<br />

Sonata<br />

• • 38<br />

Favia<br />

• • • • 54<br />

Meridian<br />

Fineline<br />

DX15<br />

DX24<br />

DONN grid options<br />

Healthcare environments are now<br />

designed more holistically, promoting<br />

health, healing and well-being.<br />

What better way to help create such<br />

an environment than by using <strong>USG</strong><br />

ceiling systems? Our range includes<br />

clean, crisp ceiling products that are<br />

perfect for healthcare environments.<br />

Let your imagination and creativity<br />

guide you in developing innovative,<br />

health-conscious designs.<br />

We offer various application options<br />

to help you design a healthcare<br />

environment that is:<br />

1) highly functional<br />

2) will obtain client approvaL<br />

3) within your budget criteria.<br />

Retail Applications selector<br />

Application <strong>Ceiling</strong> panels Page<br />

Administration offices Sonatone<br />

• • 50<br />

Olympia II Micro Perforated • • • • 44<br />

Radar<br />

• • • • 58<br />

Favia Acoustic<br />

• • • • 56<br />

Omni<br />

• • • • 62<br />

Boutiques Sonatone<br />

• • 50<br />

Sandrift ClimaPlus<br />

• • • • 36<br />

Glacier<br />

• • • • 30<br />

Chessboard<br />

• 64<br />

Designer Squares<br />

• 68<br />

Comet Line<br />

• 66<br />

Pedestals I<br />

• 70<br />

Compässo/Curvatura<br />

72,73<br />

Department stores Sonatone<br />

• • 50<br />

Olympia II Micro Perforated • • • • 44<br />

Favia Acoustic<br />

• • • • 56<br />

Perforated<br />

• • • • 46<br />

Omni<br />

• • • • 62<br />

Favia<br />

• • • • 54<br />

Exterior soffits Radar Ceramic ClimaPlus<br />

• • 34<br />

Hypermarkets Radar<br />

• • • • 58<br />

Favia<br />

• • • • 54<br />

Olympia II Micro Perforated • • • • 44<br />

Kitchens/ food preparation areas Clean Room ClimaPlus<br />

• • 28<br />

Sonatone<br />

• • 50<br />

Malls Sonatone<br />

• • 50<br />

Pedestals I<br />

• 70<br />

Designer Squares<br />

• 68<br />

Radar<br />

• • • • 58<br />

Parking garages Radar Ceramic ClimaPlus<br />

• • 34<br />

Rest rooms/ utility areas Sonatone<br />

• • 50<br />

Radar<br />

• • • • 58<br />

Favia<br />

• • • • 54<br />

Restaurants/ Cafés Sonata<br />

• • 38<br />

Sandrift ClimaPlus<br />

• • • • 36<br />

Olympia II Micro Perforated • • • 44<br />

Shops Pedestals I<br />

• 70<br />

Radar<br />

• • • • 58<br />

Favia Acoustic<br />

• • • • 56<br />

Omni<br />

• • • • 62<br />

Chessboard<br />

• 64<br />

Meridian<br />

Fineline<br />

DX15<br />

DX24<br />

DONN grid options<br />

Retail stores are designed to leave<br />

an unforgettable impression on a<br />

customer - usually in the form of a<br />

unique identity. <strong>USG</strong> ceilings can meet<br />

your store design needs by helping<br />

you create, define and enhance store<br />

identity. From new construction to<br />

refurbishment, <strong>USG</strong> has what you<br />

need in a ceiling.<br />

We offer various application options<br />

to help you design retail space that is:<br />

1) highly functional<br />

2) will obtain client approval<br />

3) within your budget criteria.<br />

9

10<br />

Hotels Applications selector<br />

Application <strong>Ceiling</strong> panels Page<br />

Administration offices Sonata<br />

• • 38<br />

Olympia II Micro Perforated • • • • 44<br />

Radar<br />

• • • • 58<br />

Favia Acoustic<br />

• • • • 56<br />

Omni<br />

• • • • 62<br />

Restaurants / Bars Sonata<br />

• • 38<br />

Compässo/Curvatura<br />

72,73<br />

Sandrift ClimaPlus<br />

• • • • 36<br />

Glacier<br />

• • • • 30<br />

Chessboard<br />

• 64<br />

Conference areas Sonata<br />

• • 38<br />

Glacier<br />

• • • • 30<br />

Olympia II Micro Perforated • • • • 44<br />

Compässo/Curvatura<br />

72,73<br />

Corridors / walkays Sonata<br />

• • 38<br />

Olympia II Micro Perforated • • • • 44<br />

Radar<br />

• • • • 58<br />

Omni<br />

• • • • 62<br />

Comet Line<br />

• 66<br />

Exterior Soffits Radar Ceramic ClimaPlus<br />

• • 34<br />

Gymnasiums Sonatone<br />

• • 50<br />

Kitchens/ food preparation areas Clean Room ClimaPlus<br />

• • 28<br />

Sonatone<br />

• • 50<br />

Parking garages Radar Ceramic ClimaPlus<br />

• • 34<br />

Reception areas/ lobbies Sonatone<br />

• • 50<br />

Compässo/Curvatura<br />

72,73<br />

Sandrift ClimaPLus<br />

• • • • 36<br />

Glacier<br />

• • • • 30<br />

Rest rooms/ utility areas Sonata<br />

• • 38<br />

Compässo/Curvatura<br />

• • • • 72,73<br />

Glacier<br />

• • • • 30<br />

Designer Squares<br />

• 68<br />

Chessboard<br />

• 64<br />

Accommodation Sonatone<br />

• • 50<br />

Radar<br />

• • • • 58<br />

Favia Acoustic<br />

• • • • 56<br />

Meridian<br />

Fineline<br />

DX15<br />

DONN grid options<br />

DX24<br />

Good hotel design can boost<br />

occupancy rates. <strong>USG</strong> offers<br />

numerous ceiling options for creating<br />

comfortable, inviting spaces that can<br />

be easily differentiated from other<br />

buildings.<br />

We offer various application options<br />

to help you design hotel<br />

environments that are:<br />

1) highly functional<br />

2) will obtain client approval<br />

3) within your budget criteria.<br />

Leisure Applications selector<br />

Application <strong>Ceiling</strong> panels Page<br />

Administration offices Sonata<br />

• • 38<br />

Olympia II Micro Perforated • • • • 44<br />

Radar<br />

• • • • 58<br />

Favia<br />

• • • • 54<br />

Pedestals I<br />

• • • • 70<br />

Casinos Sonata<br />

• • 38<br />

Sandrift ClimaPlus<br />

• • • • 36<br />

Glacier<br />

• • • • 30<br />

Chessboard<br />

• 64<br />

Pedestals I<br />

• 70<br />

Compässo/Curvatura<br />

72,73<br />

Cinemas/theatres Sonata<br />

• • 38<br />

Compässo/Curvatura<br />

72,73<br />

Glacier<br />

• • • • 30<br />

Sandrift ClimaPLus<br />

• • • • 36<br />

Clubs/discotheques Sonata<br />

• 38<br />

Sandrift ClimaPLus<br />

• • • • 36<br />

Glacier<br />

• • • • 30<br />

Pedestals I<br />

• 70<br />

Compässo/Curvatura<br />

72,73<br />

Comminity Centres / halls Sonatone<br />

• • 50<br />

Radar<br />

• • • • 58<br />

Favia<br />

• • • • 54<br />

Galleries / museums Sonata<br />

• • 38<br />

Sandrift ClimaPLus<br />

• • • • 36<br />

Glacier<br />

30<br />

Compässo/Curvatura<br />

72,73<br />

Chessboard<br />

• 64<br />

Designer Squares<br />

• 68<br />

Pubs/Bars Sandrift ClimaPLus<br />

• • • • 36<br />

Glacier<br />

• • • • 30<br />

Compässo/Curvatura<br />

• • 72,73<br />

Pedestals I<br />

• 70<br />

Reception areas/ lobbies Sonata<br />

• • 38<br />

Compässo/Curvatura<br />

72,73<br />

Pedestals I<br />

• 70<br />

Radar<br />

• • • • 58<br />

Favia Acoustic<br />

• • • • 56<br />

Rest rooms/ utility areas Sonatone<br />

• • 50<br />

Radar<br />

• • • • 58<br />

Restaurants Sonata<br />

• • 38<br />

Sandrift ClimaPlus<br />

• • • • 36<br />

Olympia II Micro Perforated • • • • 44<br />

Perforated<br />

• • • • 46<br />

Meridian<br />

Fineline<br />

DX15<br />

DONN grid options<br />

DX24<br />

11<br />

The leisure and entertainment industry<br />

has numerous design requirements<br />

and needs. Whether you are designing<br />

a cinema, casino or restaurant, <strong>USG</strong><br />

offers innovative, cutting edge ceiling<br />

systems to help you create distinctive<br />

showplaces. <strong>USG</strong> helps you design<br />

spaces that attract, excite, and thrill<br />

patrons, leaving a lasting expression<br />

of a magnificent experience.<br />

We offer various application options<br />

to help you design leisure and<br />

entertainment environments that are:<br />

1) highly functional<br />

2) will obtain client approval<br />

3) within your budget criteria.

12<br />

Sport Applications selector<br />

Application <strong>Ceiling</strong> panels Page<br />

Administration offices Sonatone<br />

• • 50<br />

Olympia II Micro Perforated • • • • 44<br />

Radar<br />

• • • • 58<br />

Favia Acoustic<br />

• • • • 56<br />

Omni<br />

• • • • 62<br />

Bowling alleys Sonata<br />

• • 38<br />

Radar<br />

• • • • 58<br />

Favia<br />

• • • • 54<br />

Gymnasiums Sonatone<br />

• • 50<br />

Locker rooms Sonatone<br />

• • 50<br />

Multifunctional sports centres Sonatone<br />

• • 50<br />

Reception areas/ lobbies Radar Ceramic ClimaPlus<br />

• • 34<br />

Sandrift ClimaPlus<br />

• • • • 36<br />

Glacier<br />

• • • • 30<br />

Radar<br />

• • • • 58<br />

Compässo/Curvatura<br />

72,73<br />

Favia<br />

• • • • 54<br />

Rest rooms/ utility areas Sonatone<br />

• • 50<br />

Radar<br />

• • • • 58<br />

Swimming pools/ shower areas Radar Ceramic ClimaPlus<br />

• • 34<br />

Sonatone<br />

• • 50<br />

Clean Room ClimaPlus<br />

• • 28<br />

Meridian<br />

Fineline<br />

DX15<br />

DONN grid options<br />

DX24<br />

Sports activity spaces, from ball<br />

courts to swimming pools, are<br />

demanding environments that require<br />

an integrated system approach to<br />

balance the functional and aesthetic<br />

design needs. <strong>USG</strong> offers a wide<br />

range of long lasting, high humidity<br />

resistant ceiling systems that stand<br />

up to the abuse found in sports<br />

environments.<br />

We offer various options to help you<br />

design sports areas that are:<br />

1) highly functional<br />

2) will obtain client approvaL<br />

3) within your budget criteria.<br />

Controlled environments Applications selector<br />

Application <strong>Ceiling</strong> panels Page<br />

Clean Rooms - class 100 Clean Room ClimaPlus<br />

• • 28<br />

Computer rooms Clean Room ClimaPlus<br />

28<br />

Sonatone<br />

• • 50<br />

Food/ beverage processing Clean Room ClimaPlus<br />

• • 28<br />

Sonatone<br />

• • 50<br />

Laboratories Clean Room ClimaPlus<br />

• • 28<br />

Sonata<br />

• • 38<br />

Radar Ceramic ClimaPlus<br />

• • 34<br />

Taiga II Hygiene<br />

• • • • 40<br />

Operating rooms Clean Room ClimaPlus<br />

• • 28<br />

Taiga II Hygiene<br />

• • • • 40<br />

Sterile and soiled utility rooms Clean Room ClimaPlus<br />

• • 28<br />

Sonata<br />

• • 38<br />

Taiga II Hygiene<br />

• • • • 40<br />

Security rooms Clean Room ClimaPlus<br />

• • 28<br />

Sonatone<br />

• • 50<br />

Meridian<br />

Fineline<br />

DX15<br />

DX24<br />

DONN grid options<br />

Controlled environments must meet<br />

stringent guidelines and requirements.<br />

<strong>USG</strong> understands that and takes<br />

nothing for granted. Every component<br />

of our controlled environment<br />

products maintains and assures the<br />

system integrity. We offer a complete<br />

range of ceiling systems solutions for<br />

industry environments ranging from<br />

food processing to aerospace and<br />

microscope assembly rooms.<br />

We offer various application options<br />

to help you design rooms that are:<br />

1) highly functional<br />

2) will obtain client approval<br />

3) within your budget criteria.<br />

13

14<br />

<strong>Acoustical</strong> Mineral Fiber<br />

<strong>USG</strong>-ME Products are Classified according to ASTM E1264 as the<br />

following:<br />

1 | Types (III, IV, X, XII, XX)<br />

Type III: Mineral base with painted finish<br />

Type IV: Mineral base with membrane-faced overlay.<br />

Type X: Mineral base with plastic or aluminium membrane- faced<br />

overlay, or both.<br />

Type XII: Glass fiber base with membrane-faced.<br />

Type XX: Other types.<br />

2 | Forms (1,2,4)<br />

Form 1: Nodular (X-Technology)<br />

Form 2: Water felted<br />

Form 4: Cast or moulded<br />

3 | Patterns (C, D, E, F, G, I, K, Z)<br />

C: Perforated, small holes<br />

D: Fissured<br />

E: Lightly textured<br />

F: Heavily textured<br />

G: Smooth<br />

I: Embossed<br />

K: Surface scored<br />

Z: Other Patterns( describe)<br />

4 | <strong>Acoustical</strong> ratings (NRC, CAC)<br />

5 | Light reflectance values (LR)<br />

6 | Fire class ( Class A, Fire Code)<br />

<strong>USG</strong> is curently the only manufacturer in the industry with<br />

the capabilities to produce ceiling panels with five different<br />

substrate technologies for various uses and needs.<br />

1 | Water - Felted<br />

2 | Cast<br />

3 | X-Technology<br />

4 | Fiberglass<br />

5 | Gypsum based ceilings<br />

Manufacturing Technologies<br />

• “ X” Technology is a unique manufacturing method wich was<br />

developed and introduced to the market by <strong>USG</strong> in 1989.<br />

This technology produces ceiling panels with ClimaPlus sag<br />

resistance and exceptional acoustical performance.<br />

• Wet-felted panels are typically mechanically perforated and<br />

fissured. They are very dense and more economical than other types<br />

of ceiling panels.<br />

• Cast panels are naturally textured and provide a unique, integral<br />

colour throughout the panel substrate with very good acoustical<br />

performance and enhanced extreme durability.<br />

Production Technologies:<br />

Wet-felt technology ASTM E1264, Type III, Form 2<br />

➊ Cross Fissured<br />

➋ Olympia II<br />

Production Technologies:<br />

Cast molding technology for special textures ASTM E1264, Type III,<br />

Form 4<br />

➊ Sandrift ➋ Glacier<br />

➌ Radar<br />

➌ Frost (Fine textured panel)<br />

Production Technologies:<br />

X-technology, A <strong>USG</strong> Innovation for<br />

High NRC & Smooth Surface<br />

ASTM E 1264, Type III, Form 1 or 2.<br />

➊ Eclipse ClimaPlus Illusions and Pedestals<br />

(Fine textured panel)<br />

➋ Millennia ClimaPlus (Smooth textured panel)<br />

15

16<br />

<strong>Acoustical</strong> Performance selector<br />

A balanced acoustical environment often plays an important part in<br />

improving productivity, comfort and peoples’ sense of well being.<br />

Through appropriate selection and placement of <strong>USG</strong> acoustical<br />

ceiling systems, it is possible to improve speech intelligibility, reduce<br />

unwanted noise or increase privacy within a space or between<br />

adjacent offices.<br />

Sound attenuation:<br />

“Sound attenuation” refers to the attenuation of<br />

noise passing into a room from outside, such as<br />

room-to-room noise or noise from above ceiling<br />

services. The test data in dB (DncW) for each tile<br />

gives guidance on the sound insulation, but they<br />

should be seen in the context of the overall room<br />

construction as per ASTM C423. fast and easy to<br />

install but also easy to remove without the need<br />

for tools.<br />

Sound absorption:<br />

“Sound absorption” describes the reduction of<br />

noise within a room. Acoustic ceiling tiles absorb<br />

sound energy and serve to control acoustic<br />

reverberation time. Different tile patterns provide<br />

different levels of sound absorption as per ASTM<br />

E1414.<br />

• NRC stands for Noise Reduction Coefficient. It is a measure of how<br />

sound is absorbed by a given material. It is listed as a decimal and<br />

relates to percentage sound absorbed.<br />

• CAC stands for <strong>Ceiling</strong> Attenuation Class. It is the measure of the<br />

blocking of sound through one ceiling plane, into the plenum above,<br />

and through the other ceiling plane to an adjacent space.<br />

Humidity resistance selector<br />

Extreme heat, humidity and fluctuating climatic conditions can<br />

shorten the life of a ceiling system. The connection of temperature to<br />

relative humidity (RH) is crucial in determining the best product for<br />

any application. <strong>USG</strong>’s specially formulated ceiling panels resist high<br />

heat and humidity without visible sag and are available in a range of<br />

performance options up to 100% RH/40°C.<br />

<strong>Acoustical</strong> ceilings absorb and/or<br />

attenuate sound. The two main acoustical<br />

performance ratings indicate panel<br />

performance:<br />

CAC: defines the amount of sound passing<br />

through a panel and the plenum into an<br />

adjacent space<br />

W, NRC: defines the average sound<br />

absorption of a ceiling system<br />

DncW: defines the average ‘room to room’<br />

sound attenuation of a ceiling system.<br />

The <strong>USG</strong> ceiling tile range meets or exceeds the minimum requirements of BS8290<br />

(1991) as defined as:<br />

a. Normal environments<br />

(max. 25±2°C/65±5%RH)<br />

b. High humidity environments<br />

(max. 40±2°C/90±5%RH)<br />

• For applications in extreme environmental conditions such as exterior soffits,<br />

parking garages or swimming pools, products with 100% RH/40°C are<br />

recommended.<br />

Install with DONN Brand DX24-K corrosion resistant grid.<br />

• For applications with uncontrolled<br />

environmental conditions, natural ventilation systems or in humid areas such as<br />

washrooms, kitchens or wet process areas, products with 95-99%RH/40°C or better<br />

are recommended.<br />

• For applications with intermittent heating and cooling systems, products with<br />

90%RH/32°C or better are recommended.<br />

• For applications with normal controlled environmental conditions, products with<br />

70% RH/29°C or better are suitable.<br />

Fire rating selector<br />

Life safety and protection of property are important considerations in<br />

the design and specification of acoustical ceiling systems. Specially<br />

formulated Firecode (FC) rated ceiling panels are a crucial component<br />

of <strong>USG</strong>’s tested fire protection systems. Specification and installation<br />

must be in accordance with the selected fire test description of the<br />

system.<br />

Fire protection<br />

Structural fire protection BS 476 parts 21 and 23.<br />

Suspended ceilings can be used to provide protection to the structural elements of a<br />

building. In the event of a fire, the ceiling membrane protects the structure for a<br />

period of time enabling evacuation and fire fighting. The period of protection is<br />

determined by testing to BS 476 p23. Testing to BS 476 part 21, section 7, determines<br />

the protection provided to a loaded timber floor structure.<br />

In order to ensure the validity of a “fire protecting” ceiling, installation must be as<br />

described in the relevant test report. Any alteration may affect the fire protection<br />

capabilities of that ceiling system.<br />

Class A signifies that a panel is non-combustible based and has attained a flame<br />

spread index of 25 or less on ASTM E-84 testing procedures.<br />

Firecode signifies that a panel has been classified as a protective membrane in<br />

accordance with the standard ASTM E 119. It can be used in a UL fire-rated assembly<br />

to achieve a time-rated assembly. The time rated assembly includes the entire floor-<br />

ceiling or roof-ceiling assembly. All firecode protective membranes offered by <strong>USG</strong><br />

have attained a Class A rating.<br />

Warranty<br />

<strong>USG</strong> offers a lifetime (30 year) limited<br />

warranty on ultra high performance tiles<br />

and a 15 year limited warranty on high<br />

performance tiles when installed on <strong>USG</strong>’s<br />

DONN Brand suspension grid. Refer to <strong>USG</strong><br />

technical services for details.<br />

<strong>USG</strong> ceiling systems must be installed and<br />

maintained in accordance with current<br />

<strong>USG</strong> written instructions and industry best<br />

practice as defined by<br />

BS 8290.<br />

Reaction to fire<br />

17<br />

<strong>Ceiling</strong> products are generally considered<br />

suitable for multi-use buildings when the<br />

products conform to BS 476 part 6 and 7.<br />

BS 476 part 6 is the fire propagation<br />

classification which compares the constitution<br />

of combustible materials to the development of<br />

fire – performance class 0.<br />

BS 476 part 7 is the surface spread of flame<br />

classification which indicates the tendency of<br />

materials to support the spread of flame across<br />

the surface. (Best performance Class 1, worst<br />

performance Class 4.)<br />

All <strong>USG</strong> tiles achieve Class 1 and Class 0 as<br />

designated by BS 476 part 7 and 6, and as<br />

required by Building Regulations Approved<br />

Document B. Per ASTM E84.<br />

For further information or advice on our testing,<br />

products or relevant standards, please contact<br />

your local representative or our Technical<br />

Services Department.

18<br />

Light reflectance selector<br />

The Light Reflectance selector identifies <strong>USG</strong> ceiling panels that<br />

efficiently reflect light within a space to enhance indirect lighting,<br />

reduce energy consumption and create a warm, luminous aesthetic.<br />

Measured per ASTM E14771, LR value represents the percentage of<br />

light reflected from the surface of a material. The industry average for<br />

panels is LR .70 to .80, and values above LR .85 are considered high.<br />

<strong>USG</strong> offers numerous panels with LR values at these levels, including<br />

SONATA, MARS CLIMAPLUS, OLYMPIA II and OLYMPIA MICRO<br />

PERFORATED, with LR .89.<br />

• Choosing high-LR ceiling panels is a great way to improve the utility and comfort<br />

of the spaces you design and make your projects bright and inviting. Indirect lighting,<br />

combined with high-LR panels, can eliminate dark, shadowy areas and too-bright hot<br />

spots, improving the look and feel of a space and minimizing eyestrain (a cause of<br />

employee fatigue).<br />

High-LR ceilings can also help conserve energy and cut operating costs by achieving<br />

the same light levels with fewer fixtures and lower-wattage bulbs. Fewer fixtures also<br />

mean less repairs and lower maintenance costs.<br />

Architects typically select high-LR ceiling for spaces that make extensive use of<br />

indirect lighting. However, these panels can enhance almost any lighting scheme and<br />

so can be an effective choice for many design applications.<br />

Many <strong>USG</strong> panels with high LR values also feature high NRC and CAC ratings so you<br />

dont have to compromise acoustics for aesthetics. Panels are available in a range of<br />

textures including smooth and very fine, many include CLIMAPLUS performance, and<br />

several are cast products, which provide a higher level of durability to resisit and hide<br />

scrapes and scratches.<br />

Sonata .89 Fine 38<br />

Clean Room ClimaPlus .79 Smooth / Fine 28<br />

Mars ClimaPlus .89 Fine 32<br />

Radar Ceramic ClimaPlus .82 Medium 34<br />

Sonatone White - Sparta .84 Fine 50<br />

Glacier .70 Heavy 30<br />

Olympia II Micro Perforated .89 Fine 44<br />

Pedestals I .85 Smooth 70<br />

Sandrift ClimaPlus .83 Medium 36<br />

Comet Line .75 Medium 66<br />

Chessboard .75 Medium 64<br />

Cross Fissured .82 Medium 52<br />

Designer Squares .88 Medium 68<br />

Favia .85 Medium 54<br />

Favia Acoustic .75 Medium 56<br />

Olympia II .89 Fine 42<br />

Omni .85 Medium 62<br />

Perforated .84 Fine 46<br />

Plain .85 Smooth 48<br />

Radar .85 Medium 58<br />

Rocktone .85 Medium 60<br />

Taiga Hygiene IITM <strong>Ceiling</strong> Panels LR1 Textures Page<br />

.85 Medium 40<br />

1. Standard Test Method for Luminous Reflectance Factor of <strong>Acoustical</strong> Materials by Use of<br />

Integrating-Sphere Reflectometers.<br />

Light Reflectance<br />

It is a measure of the percentage of light<br />

which is reflected off of a given panel surface.<br />

Typically, the whiter and smoother the panel,<br />

the higher the LR value.<br />

• Enhance Indirect Lighting<br />

• Reduce Energy Consumption<br />

• Create Warm Lumnous Aesthetics<br />

<strong>USG</strong> <strong>Ceiling</strong>s Provide<br />

LR (Light Reflectance)<br />

(70-90%)<br />

Product name Page Type<br />

Fire Reaction<br />

BS 476<br />

Part 6/7<br />

Fire Resistance BS-476 Humidity<br />

Resistance<br />

Steel Beam Timber Floor<br />

Maximum<br />

(pt.23) (pt.21) % RH/C/°F<br />

<strong>Acoustical</strong><br />

Performance<br />

NRC CAC Range<br />

LR1<br />

Sonata 38-39 CP Class 1,0 30 min 30 min 95/40/104 0.70 35-45 .89<br />

Clean Room ClimaPlus 28-29 FC+CP Class 1,0 120 min 120 min 90/40/104 0.15-0.55 35 .79<br />

Mars ClimaPlus 32-33 CP Class 1,0 30 min 30 min 95/40/104 0.70 35-45 .89<br />

Radar Ceramic ClimaPlus 34-35 FC Class 1,0 120 min 120 min 100/40/104 0.55 40 .82<br />

Sonatone White - Sparta 50-51 R Class 1,0 30 min 30 min 95/32/90 0.20 35 .84<br />

Glacier 30-31 R+FC Class 1,0 120 min 120 min 70/29/84 0.65 35-45 .70<br />

Olympia II Micro Perforated 42-45 R+CP Class 1,0 30 min 30 min 90/32/90 0.60 35-39 .89<br />

Pedestals I 70-71 R Class 1,0 30 min 30 min 90/32/90 0.15 35-39 .85<br />

Sandrift ClimaPlus 36-37 FC+CP Class 1,0 120 min 120 min 70/29/84 0.70 38-48 .83<br />

Comet Line 66-67 R Class 1,0 30 min 30 min 90/32/90 0.15 35-39 .75<br />

Chessboard 64-65 R Class 1,0 30 min 30 min 90/32/90 0.15 35-39 .75<br />

Cross Fissured 52-53 R+FC+CP Class 1,0 30/120 min 30/120 min 90/32/90 0.45-0.60 35-39 .82<br />

Designer Squares 68-69 R Class 1,0 30 min 30 min 90/32/90 0.15-0.60 35-39 .88<br />

Favia 54-55 R Class 1,0 30 min 30 min 90/32/90 0.40 35-39 .85<br />

Favia Acoustic 56-57 R+CP Class 1,0 30 min 30 min 90/32/90 0.50-0.60 35-39 .75<br />

Olympia II 42-43 R+FC+CP Class 1,0 30/120 min 30/120 min 90/32/90 0.15 35-39 .89<br />

Omni 62-63 R+FC+CP Class 1,0 30/120 min 30/120 min 90/32/90 0.50-0.60 35-39 .85<br />

Perforated 46-47 R Class 1,0 30 min 30 min 90/32/90 0.45-0.60 35-39 .84<br />

Plain 48-48 R Class 1,0 30 min 30 min 90/32/90 0.15 35-39 .85<br />

Radar 58-59 R+FC+CP Class 1,0 30/120 min 30/120 min 90/32/90 0.50-0.60 35-39 .85<br />

Rocktone 60-61 R Class 1,0 30 min 30 min 90/32/90 0.50 35-39 .85<br />

Taiga Hygiene IITM 40-41 R Class 1,0 30 min 30 min 90/32/90 0.15 35-39 .85<br />

• Radar Ceramic ClimaPlus also certified to BS 476 pt. 4 - non-combustible. ** Summary table<br />

19

20<br />

Specialized Performance<br />

Many interior environments with demanding functions (such<br />

as food preparation, hydrotherapy, exercise, athletics and<br />

cleanroom control) require performance beyond aesthetics,<br />

sound control and sustainability. <strong>USG</strong> offers many options to<br />

meet a diverse range of specialized performance needs.<br />

Abuse resistance<br />

Routine plenum access can blemish panels with unsightly scratches,<br />

and chips and dents can occur in high – traffic areas such as<br />

hallways, classrooms and gyms. When durability is key, consider the<br />

following products.<br />

Specially formulated mineral-fiber ceiling panels feature higherdensity<br />

construction and special finishes to enhance durability and<br />

damage resistance. Panel include:<br />

RADAR TM CLIMAPLUS TM High-Durability panels deliver 20% greater<br />

durability than competitive “school products” and 50% more than<br />

standard acoustical panels.<br />

MARS TM CLIMAPLUS TM panels resist visible damage in independently<br />

verified surface scratch tests and withstand 150 scrub cycles without<br />

surface break using the Gardner Scrubability Test, per ASTM D24861<br />

Cast ceiling panels, available exclusively from <strong>USG</strong>, are formed<br />

and cured in molds, making them up to three times stronger than<br />

standard panels. Cast panels feature an integrally color-coordinated<br />

substrate to mask nicks or scrapes. Panels include:<br />

• Frost TM CLIMAPLUS TM<br />

• Glacier TM<br />

• Sandrift TM CLIMAPLUS TM<br />

Humidity Resistance<br />

Moist air in indoor pool areas, shower and locker rooms, and<br />

buildings not fully enclosed can cause standard panels to visibly<br />

sag. For high-humidity areas, choose panels with CLIMAPLUS<br />

performance. These products resist sag in up to 95% relative humidity<br />

and up to 104 °F. RADAR TM Ceramic CLIMAPLUS TM panels even resist<br />

sag in up to 100% relative humidity. CLIMAPLUS products carry a<br />

limited warranty of up to 30 years when installed in a DONN ® brand<br />

suspension system.<br />

Fire Resistance<br />

<strong>USG</strong> offers many ceiling panels with<br />

FIRECODE TM formulation, which provides special<br />

additives for increased fire resistance. Fire-rated<br />

suspension main tees are manufactured with<br />

relief notches that will contract in high heat to<br />

hold the ceiling assembly together and prevent<br />

collapse. Fire-rated panels and suspension<br />

system components are identified with the fire<br />

icon on the individual product pages in this<br />

catalog.<br />

CLEANLINESS<br />

Cleanrooms, food preparation areas and<br />

computer rooms require ceilings with specific<br />

attributes and performance levels. CLEAN<br />

ROOM TM CLIMAPLUS TM Class 10M-100M and<br />

Class 100 panels feature vinyl laminated<br />

surfaces and meet Federal Standard 209E,<br />

“Clean Room and Work Station Requirements<br />

Controlled Environments”. SHEETROCK ® brand<br />

CLEAN ROOM TM lay-in ceiling panels with<br />

gypsum core, sealed edges and vinyl face and<br />

back, can also be used in cleanrooms up to<br />

Class 100. Cleanroom-rated applications require<br />

a suspension system with gasketed tees such as<br />

the DONN ® CE system.<br />

For food preparation areas, choose Class 100<br />

panels or SHEETROCK ® Vinyl CLIMAPLUS TM layin<br />

ceiling panels, which meet U.S. Department<br />

of Agriculture Food Safety Inspection Service<br />

requirements.<br />

Exterior Applications<br />

Exterior soffits and ceilings in open parking<br />

garages and marine environments are subjected<br />

to large temperature swings, wind, humidity<br />

and incidental water exposure. <strong>USG</strong> offers<br />

several products that can be used in these<br />

challenging applications:<br />

• DONN ® ZXLA TM hot-dipped galvanized<br />

suspension system with aluminum cap<br />

• PARALINE ® linear metal ceiling system, windload<br />

tested to 120 mph.<br />

• <strong>USG</strong> drywall suspension system for flat<br />

ceilings.<br />

Sustainability<br />

Sustainable Design<br />

Sustainable design seeks to create structures that require fewer<br />

natural resources to build, maintain and adapt to future uses. Key<br />

strategies include choosing quality, lasting materials and creating<br />

flexible, multi - functional spaces.<br />

Consumers have become increasingly aware of the need to conserve<br />

energy, manage raw materials, reduce waste and safeguard against<br />

pollutants. In response, many developers and owners now demand<br />

buildings that will help save energy, preserve the integrity of<br />

surrounding land and assure a clean, healthy indoor environment.<br />

Sustainable Table - <strong>USG</strong> <strong>Middle</strong> <strong>East</strong><br />

Related <strong>USG</strong>BC LEED<br />

for Schools Credits<br />

Leed Category<br />

RADAR TM ClimaPlus TM<br />

15mm<br />

RADAR TM ClimaPlus TM<br />

19mm<br />

Olympia TM ClimaPlus TM<br />

Microperf<br />

15mm<br />

Olympia TM ClimaPlus TM<br />

Microperf<br />

19mm<br />

Perforated TM<br />

ClimaPlus TM<br />

15mm<br />

MR 4.1 and 4.2 EQ8 EQ Pre 3 &<br />

EQ 3.2 & MR6 MR 5.1/5.2 EQ 10<br />

EQ 9<br />

EQ 4<br />

Post Consumer Pre-Consumer<br />

Class A FC Class A FC<br />

18.43%<br />

18.43%<br />

17.3%<br />

17.3%<br />

17%<br />

6%<br />

6%<br />

N/A<br />

N/A<br />

6%<br />

13%<br />

13%<br />

39%<br />

39%<br />

13%<br />

LR NRC CAC Approx.<br />

Weight<br />

lb/sq.ft<br />

CHPS<br />

Formaldehyde<br />

& VOC<br />

Emissions<br />

Rapid<br />

Renew<br />

42.3% .85 .55 35/39 .70-.72 Pass Low 7%<br />

42.3%<br />

N/A<br />

N/A<br />

42.3%<br />

Business Sustainability<br />

.85 .60 35/39 .90-.92 Pass Low 7%<br />

.89 .60 35/39 .84-.86 PASS Low 8%<br />

.89 .65 35/39 .94-.96 Pass Low 8%<br />

.85 .50 35/39 .70-.72 Pass Low 7%<br />

21<br />

Raw Materials/ Comments ( %<br />

by wt.) values based on average<br />

during 2009 January through<br />

Wet Felt Products<br />

manufactured at at<br />

Dammam, Saudi Arabia<br />

Mineral Wool (Preconsumer<br />

%) from<br />

China /US; Perlite 20-<br />

50%; Recycled Paper<br />

(Post -consumer %) ;<br />

Stratch(Rapid renew<br />

%); and Clay 2-12%<br />

Product<br />

<strong>USG</strong>'s commitment to health, safety<br />

and environmental responsibility is<br />

evident at every stage in the life cycle<br />

chain.

22<br />

Sustainability<br />

Design that require fewer Natural resources:<br />

• Energy conservation<br />

• Raw Material Management<br />

• Waste Reduction<br />

• Safeguard against pollutants<br />

In response, many developers and owners now demand buildings that<br />

will help save energy, preserve the integrity of surrounding land and<br />

assure a clean, healthy indoor environment.<br />

1 | Indoor Environmental Quality:<br />

Indoor environmental quality (IEQ) refers to all environmental factors<br />

that affect the health and well-being of building occupants. IEQ<br />

includes such factors as Indoor Air Quality (IAQ), comfort, humidity,<br />

air exchange, acoustics and lighting quality.<br />

Many <strong>USG</strong> ceiling panels help to support healthy environments with<br />

reduced Volatile Organic Compound (VOC) emissions<br />

Formaldehyde Performance:<br />

Formaldehyde is an important industrial chemical used to make<br />

chemicals, building materials, and household products.<br />

Exposure The OSHA Permissible Exposure Limit (PEL) for<br />

formaldehyde is 750 ppb (0.75 ppm) per 8-hour TWA (Time Weighted<br />

Average, the average exposure over an 8-hour work period).<br />

Content The presence of formaldehyde must be reported if the<br />

concentration of formaldehyde exceeds 0.1 percent of weight. All<br />

<strong>USG</strong> ceilings are well below these levels.<br />

To help building professionals create healthy spaces, <strong>USG</strong> offers many<br />

ceiling panels and tiles that emit no formaldehyde or such low levels<br />

as to exceed stringent standards established by the collaborative<br />

for High-Performance Schools (CHPS). This high performance comes<br />

standard on these products, with no additional charge or lead time.<br />

<strong>Ceiling</strong> with Little or No Formaldehyde Requirements as per<br />

CHPS (Collaborative For High Performance Schools)<br />

• Zero VOC Emission for All CAST <strong>Ceiling</strong>s (level 13.5<br />

Meets Minimum Standarts<br />

Less than 50 ppb<br />

><br />

50<br />

Post-Industrial (Pre-Consumer) materials<br />

are generated by manufacturers and processors,<br />

and may consist of scrap, trimmings and<br />

other by-products that were never used in<br />

the consumer market. Post-Industrial and<br />

Pre-Consumer are one in the same under the<br />

<strong>USG</strong>BC LEED ® rating systems.<br />

Post-Consumer material is an end product<br />

that has completed its life cycle as a consumer<br />

item and would otherwise have been disposed<br />

of as a solid waste. Post-consumer materials<br />

include recyclables collected in commercial and<br />

residential recycling programs, such as officer<br />

paper, cardboard, aluminum cans, plastics and<br />

metals.<br />

Binders are derived from corn and wheat starch, which are renewable<br />

agricultural resources. The metal in many of our specialty ceiling and<br />

drywall suspension systems includes recycled content. Aluminum<br />

offers additional benefits in that it can be fully re-purposed by<br />

re-melting and salvaging the metal.<br />

Responsible Manufacturing<br />

<strong>USG</strong> ceilings = high recycled content (HRC)<br />

Recycling is only a part of the story. Careful production methods<br />

are good for the environment and increase efficiency. Our practices<br />

include:<br />

• Using clean fuels (NG)<br />

• Treating and recycling water (Saving of 300 m3 daily at <strong>USG</strong>ME)<br />

• Reducing waste (Recycling)<br />

• Offering specialized ceiling panels<br />

• Recycling old ceiling panels<br />

• Product life cycle<br />

Antimicrobial Treatments to Counter Mold<br />

C+ Superior Performance (Treatment areas in ceiling panels include<br />

face and back surfaces, as well as the formulation of the materials<br />

used to create the ceiling substrate)<br />

3 | LEED<br />

LEED ® is a guideline for building solutions established by the <strong>USG</strong>BC<br />

(United States Green Building Council) members. <strong>USG</strong> Corporation is<br />

a founding member of the U.S. Green Building Council.<br />

The Leadership in Energy and Environmental Design (LEED) is a<br />

rating system that encourages the design and construction of<br />

environmentally friendly buildings<br />

LEED was created to define “green building” by establishing a<br />

common standard of measurement and promote integrated, wholebuilding<br />

design practices.<br />

Credit are awarded based on the five key areas of human and<br />

environmental health: sustainable site development, water savings,<br />

energy efficiency, materials selection, and indoor environmental<br />

quality.<br />

Choosing zero-emitting and low-emitting ceiling products can also<br />

help earn LEED credits. Section 3.2, IAQ Management Plan, Before<br />

Occupancy, requires a total formaldehyde concentration of 50 ppb or<br />

less. As one of the largest surfaces in a space, a ceiling with zero – or<br />

low – emitting panels makes a strong contribution toward achieving<br />

valuable credits – and creating healthy, sustainable environments.<br />

Energy & Atmosphere<br />

• EA Credit 1 – Optimize Energy<br />

Performance<br />

High light reflectance (LR) of ceiling materials<br />

can reduce the Energy Consumption<br />

Materials & Resources<br />

• MR Credit 1 – Building Reuse:<br />

Maintain Interior<br />

Product Abuse Resistant surface like Cast<br />

Mineral Fiber Panels<br />

• MR Credit 2 – Construction Waste<br />

Management: Divert From Disposal<br />

Project waste (by weight) from landfill<br />

(Recycling Program)<br />

• MR Credit 3 – Material Reuse<br />

Products may contain synthetic material and<br />

metal ceilings/components<br />

• MR Credit 4 – Recycled Content<br />

Pre & Post-Consumer<br />

• MR Credit 5 – Local/Regional<br />

Materials: Extracted, Processed &<br />

Manufactured Regionally<br />

Raw materials are obtained within 500 miles<br />

• MR Credit 6 – Rapidly Renewable<br />

Materials<br />

Products may contain corn/Potato starch<br />

binders, renewable alternatives to petroleumbased<br />

binders.<br />

Indoor Environmental Quality<br />

• EQ Credit 4 – Low-Emitting Materials<br />

Products emit no formaldehyde or only a very<br />

low amount<br />

• EQ Credit 8 – Daylight and Views<br />

High LR can improve the quality and quantity of<br />

natural light by enhancing indirect lighting<br />

• EQ Credit 9 – Enhanced <strong>Acoustical</strong><br />

Performance for Schools<br />

Products used in tested assemblies may reduce<br />

sound transmission in spaces<br />

• EQ Credit 10 – Mold Prevention<br />

Products may contain ingredients that reduce<br />

the potential growth of mold<br />

Innovation<br />

• ID Credit 1 – Innovation<br />

Exception performance above LEED<br />

requirements can be awarded extra points<br />

23

24<br />

Sustainability<br />

Leed Category Available Credits Products/ Programs that may assist in Qualifying or Credit<br />

Energy and Atmosphere<br />

Materials and Resources<br />

Indoor Environment<br />

Quality<br />

EA 1: Optimize Energy Performance<br />

MR 1.3: Building Reuse - Maintain<br />

Interior<br />

MR 2.1 and 2.2: Construction waste<br />

Management- Divert from Disposal<br />

MR 3.1 and 3.2: Resource Reuse<br />

MR 4.1 and 4.2: Recycled Content<br />

MR 5.1 and 5.2: Regional Materials<br />

-Extracted, Processed and Manufractured<br />

Regionally<br />

MR 6: Renewable Materials<br />

EQ 4.1, 4.2, 4.3 and 4.4: Low-<br />

Emitting Materials<br />

EQ 8.1 and 8.2: Daylight and views<br />

<strong>Ceiling</strong> panels with high light reflectance(LR) can reduce the number the<br />

number of light fixtures needed, curbing energy consumption.<br />

Cast-minereal-fiber panels are baked solid in molds for abuse resistance and<br />

through color to resist abrasion and mask scrapes.<br />

<strong>USG</strong> offers a nationwide recycling program that can take back approved<br />

mineral-fiber panels, reducing impact on landfills.<br />

Panels may contain synthetic mineral fiber converted from slag, a by product<br />

of steel making. Metal ceilings and components may include recycled<br />

aluminum.<br />

Panels may contain paper recovered from both pre-consumer and postconumer<br />

use.<br />

See the Sustainability section of <strong>USG</strong>'s <strong>Ceiling</strong> System 2007/2008 (SC 2000).<br />

Panels may contain corn and wheat-strach binders, renewable alternatives to<br />

traditional petroleum-based binders.<br />

All <strong>USG</strong> products are low-VOC emmitters and many panels emit no<br />

formaldehyde or only a very low amount.<br />

<strong>Ceiling</strong> panels with high light reflectance(LR) can improve the quality and<br />

quantity of natural light by enhancing indirect lighting.<br />

Sustainability<br />

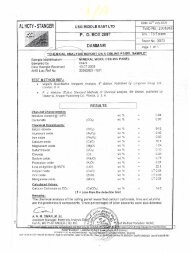

Example for product compliance with LEED<br />

Proj. No: S08087<br />

Princess Noura Bint Abdulrahman<br />

University for Women<br />

LEED - NC V2-PRODUCT COMPLIANCE DATA SHEET / MARS ClimaPlus<br />

Engineer Contractor<br />

Credit Topic [YES] [NO]<br />

MRc4 Recycled Content<br />

MRc5 Recycled Materials<br />

Employer:<br />

Ministry of Finance - KSA<br />

Request No.<br />

M/SO/000 RO<br />

Date<br />

05/04/2010<br />

Is this product concerned by LEED Certification process? X<br />

Is this product complied with LEED requirements in tender specifications?<br />

If no, explain why:<br />

X<br />

Does this product contain Recycled Content? X<br />

If yes, what percentage of the following<br />

Post-consumer (%) 0%<br />

Pre-consumer (%) 76%<br />

Does this product come from within 500miles of Riyadh X<br />

If yes, please provide of the following<br />

Point of final assembly (add location map): Cloquet, Minnisota, USA thru Dammam, KSA<br />

Distance to project site (air miles):<br />

Point of extraction, harvest or recovery (add location map):<br />

Distance to project site (air miles):<br />

MRc7 Certified wood<br />

Is this product made from wood that has been certified by the Forest Stewardship Council (FS)? X<br />

% ( Weight, volume or cost) of FSC wood<br />

EQc 4.1-1.4 Low-Emitting Materials<br />

Does this Product meet the LEED criteria for Low-Emitting Materials? X<br />

For adhesives, sealants, paints & coatings, what is the VOC content (g/L)?<br />

For carpet systems, do they compky with the CRI Green Label Plus testing program?<br />

For composite wood & agrifiber products, is there any added urea-formaldehyde?<br />

Notes<br />

1. MRc4. MRc5 & MRc7 only apply to CSI Division 02 to 10<br />

2. Refer to General Note (Tender Package colume 2) to see the buildings concerned by<br />

the LEED process<br />

3. Please provide all necessary back - up for all of the information given above<br />

4. Refer to LEED NC v2.2 3rd Edition for additional information<br />

5. Electronic format is preferred<br />

OI-PN-043 LC ind B<br />

25

26<br />

Taiga II Hygiene<br />

Antibacterial Performance<br />

• Noise Reduction coefficient (NRC) : 15%<br />

• <strong>Ceiling</strong> Attenuation Class (CAC): 35 - 39 dB<br />

• Light Reflectance ( LRC): 85 %<br />

Mold has become a significant<br />

concern due to today's fact-track<br />

scheduling, which can allow high levels<br />

of moisture to become trapped in a<br />

structure during construction.<br />

• <strong>USG</strong> helps architects and specifiers<br />

to eliminate the issue of mold and<br />

microbial growth by offering ceiling<br />

panels with ClimaPlus Superior<br />

Performance, which provides<br />

guaranteed resistance against sagging,<br />

mold and mildew growth, subject to<br />

use under normal conditions.<br />

• Face and back surfaces of these<br />

ceiling panels feature a patented<br />

antimicrobial treatment that provides<br />

broad-spectum control for mold,<br />

mildew and fungi over the warranty<br />

period tested in accordance with<br />

ASTM D3273 and evaluated per ASTM<br />

D3274.<br />

Water Resistance <strong>Ceiling</strong> Tiles<br />

"Water Shield"<br />

In its continuous improvement, <strong>USG</strong>ME offers<br />

an invention in mineral fiber<br />

ceiling tiles.<br />

Normally, the ceiling tiles have a tendency to stain when in contact<br />

with water due to condensation on pipes and duct work<br />

above the ceiling.<br />

The condensate can drip into the backside of the ceiling tiles and<br />

migrate to the visible side of the tile.<br />

The water droplets can leach tannin from recycled materials and<br />

other cellulosic based materials and staining agent from the<br />

paint surface of the tile.<br />

<strong>USG</strong>’s new invention provides an economical solution to minimize<br />

water stains at the visible face of the panel.<br />

This invention creates a barrier to water droplets at the backside of<br />

the panel allowing the droplet to evaporated before<br />

it can migrate through the panel.<br />

This treatment provides a Water Shield to mineral fiber tiles<br />

in a practical and cost effective way.<br />

27

28<br />

Clean Room ClimaPlus<br />

Clean Room/DONN DX24<br />

Warranty<br />

10 year panel or 30 year system warranty<br />

Classification<br />

ASTM E 1264 classification, type X, Pattern<br />

G,I and C, G, I.<br />

Composition<br />

Contains recycled material, no asbestos. Tile is<br />

a patented process blend of NC mineral fiber,<br />

inorganic fillers and specialty hydrophobic<br />

organic binders. Pre-finished with primer and<br />

top coat paints. Material safety data sheet<br />

available on request.<br />

Fire Reaction<br />

BS 476 pt 6/7 Class 1/0<br />

ASTM E84, Class A<br />

Flame spread: 25<br />

Smoke developed:45<br />

Fire Resistance<br />

Firecode<br />

BS 476 Pt 21/23<br />

120 min. protection to steel beams and<br />

timber floor.<br />

ASTM E-119 UL labelled<br />

Humidity Resistance<br />

Maximum 90% RH / 40° C (Climaplus)<br />

without visible sag and with no delamination<br />

Thermal Resistance<br />

R 1.6<br />

Weight<br />

5.4 kg/m²<br />

Maintenance:<br />

Easily cleaned using soft brush or vacuum, or<br />

a damp sponge<br />

Clean Room ClimaPlus<br />

Description<br />

• Accessible acoustical ceiling<br />

• System sealed edges, embossed vinyl laminated face and sealed back<br />

Features and Benefits<br />

• Cleanroom classified, Federal Spec. 209 E class 100<br />

• Anti-microbial, washable<br />

• Air filtration resistant<br />

•Panels meet USDA/FSIS requirements for food processing areas<br />

• High humidity resistant<br />

• Easy to install<br />

Clean Room<br />

Clean Room<br />

Clean Room Perforated<br />

Clean Room Perforated<br />

*Type: CP: ClimaPlus , FC: Firecode<br />

G<br />

FC+CP<br />

FC+CP<br />

FC+CP<br />

FC+CP<br />

SQ<br />

SQ<br />

SQ<br />

SQ<br />

600 x 600 x 15<br />

24’’ x 24’’ x 5/8’’<br />

1200 x 600 x 15<br />

48’’ x 24’’ x5/8‘‘<br />

600 x 600 x 15<br />

24’’ x 24’’ x5/8‘‘<br />

1200 x 600 x 15<br />

48’’ x 24’’ x5/8‘‘<br />

ME 56099<br />

56099<br />

ME 56091<br />

56091‘<br />

ME 56060<br />

56060<br />

ME 56090<br />

56090<br />

0.15 35<br />

0.15 35<br />

0.55 35<br />

0.55 35<br />

Applications<br />

• Sterile rooms<br />

• Healthcare<br />

• Food/ beverage processing<br />

• Laboratories<br />

• Office computer rooms<br />

• Operating rooms<br />

79%<br />

79%<br />

79%<br />

79%<br />

White<br />

White<br />

White<br />

White<br />

A, B1<br />

A, B1<br />

A, B1<br />

A, B1<br />

29

30<br />

Glacier<br />

Glacier/ DONN Fineline<br />

Classification<br />

ASTM E 1264 classification, type III, Form 4,<br />

Pattern F<br />

Composition<br />

Contains recycled material, no asbestos. Tile is<br />

a patented process blend of NC mineral fiber,<br />

inorganic fillers and specialty hydrophobic<br />

organic binders. Pre-finished with primer and<br />

top coat paints. Manufactured in cast mineral<br />

fiber technology. Material safety data sheet<br />

available on request.<br />

Fire Reaction<br />

BS 476 Pt 6/7 Class 1/0<br />

ASTM E84, Class A<br />

Flame spread: 25<br />

Smoke developed: 15<br />

Fire Resistance<br />

Regular;<br />

BS 476 Pt 23<br />

30 min. protection to steel beams and timber<br />

floor.<br />

Firecode<br />

BS 476 Pt 21/23; 120 min. protection to steel<br />

beams and timber floor.<br />

Thermal Resistance<br />

R 1.7 (Regular) | R 1.2 (Firecode)<br />

Weight<br />

7.3 kg/m 2 (Firecode) | 7.1 kg/m 2 (Regular)<br />

Maintenance<br />

Easily cleaned using soft brush or vacuum.<br />

Scrubbability<br />

High scratch resistance, durable and cleanable<br />

surface.<br />

Glacier<br />

Description<br />

• Accessible acoustical ceiling system with heavy textured cast panels<br />

Features and Benefits<br />

• Naturally textured cast mineral fiber panels, adds life to suspended ceiling<br />

• Aluminium foil or paper backing acts as a sound barrier and resists air filtration for<br />

cleaner panels<br />

• Heavy texture, ideal for critical lighting applications<br />

• High range sound absorption, provides balance to room acoustics<br />

• Mid range sound attenuation, ideal for general commercial construction<br />

• Extensive color selection with DONN Suspension System for multiple design options<br />

Glacier<br />

Glacier<br />

Glacier<br />

Glacier<br />

*Type: FC: Firecode, R: Regular<br />

G<br />

G<br />

SL/<br />

DX24<br />

FC<br />

FC<br />

R<br />

R<br />

FL<br />

SL<br />

SL<br />

FL<br />

600 x 600 x 19<br />

24’’ x 24’’ x 3/4’’<br />

600 x600 x 19<br />

24’’ x 24’’ x3/4‘‘<br />

600 x 600 x 19<br />

24’’ x 24’’ x3/4‘‘<br />

60 x 600 x 19<br />

24’’ x 24’’ x3/4‘‘<br />

ME 716<br />

716<br />

ME 715<br />

715<br />

ME 707<br />

707<br />

ME 708<br />

708<br />

Applications<br />

• Education<br />

• Libraries<br />

• Hotels<br />

• Leisure<br />

• Office<br />

• Retail<br />

• Restaurants / Food Courts<br />

0.65 35 - 45<br />

0.65 35 - 45<br />

0.65 35 - 45<br />

0.65 35 - 45<br />

Hz 125 250 500 1000 2000 4000<br />

αS 0.51 0.31 0.49 0.92 1.05 0.98<br />

70%<br />

70%<br />

70%<br />

70%<br />

White<br />

White<br />

White<br />

White<br />

H, J<br />

G<br />

G<br />

H, J<br />

31

32<br />

Mars ClimaPlus<br />

Mars/DONN DX24<br />

Warranty<br />

10 year panel or 30 year system warranty<br />

Classification<br />

ASTM E 1264 classification type IV, Forms 1<br />

&2, Pattern E,G<br />

Composition<br />

Contains recycled material, no asbestos.<br />

Tile is a patented process blend of NC<br />

mineral fiber, inorganic fillers and specialty<br />

hydrophobic organic binders. Pre-finished<br />

with primer fiber glass facing and top coat<br />

paints. Manufactured in X-Technology Mineral<br />

Fiber. Material safety data sheet available on<br />

request.<br />

Fire Reaction<br />

ASTM E84, Class A<br />

Flame spread: 25<br />

Smoke developed:25<br />

Fire Resistance<br />

BS 476 Pt 23<br />

30 min. protection to steel beams and timber<br />

floor.<br />

Humidity Resistance<br />

Maximum 95% RH / 40° C<br />

Thermal Resistance<br />

R 2.2<br />

Weight<br />

4.7 kg/m²<br />

Maintenance:<br />

Easily cleaned using soft brush or vacuum<br />

Scrubbability<br />

High scratch resistance, durable and<br />

cleanable surface<br />

Mars ClimaPlus<br />

Description<br />

• Accessible acoustical ceiling system with smooth monolithic texture<br />

Features and Benefits<br />

• Offer newly installed look for years to come<br />

• Industry’s highest light reflectancy LR 0.89 is part of indirect lighting<br />

• Excellent noise reduction with NRC 0.70<br />

• Climaplus lifetime system warranty to withstand high humid conditions up to 40°C<br />

and 95% relative humidity when used with Donn brand suspension system<br />

Mars ClimaPlus<br />

Mars ClimaPlus<br />

Mars ClimaPlus<br />

Mars ClimaPlus<br />

*Type: CP: ClimaPlus<br />

CP<br />

CP<br />

CP<br />

CP<br />

SQ<br />

SQ<br />

SLT<br />

FLB<br />

600 x 600 x 19<br />

24’’ x 24’’ x 3/4’’<br />

600 x1200 x 19<br />

24’’ x 48’’ x3/4‘‘<br />

600 x 600 x 19<br />

24’’ x 24’’ x3/4‘‘<br />

600 x 600 x 19<br />

24’’ x 24’’ x3/4‘‘<br />

ME 86185<br />

86185<br />

ME 88185<br />

88185<br />

ME 86785<br />

86785<br />

ME 86985<br />

86985<br />

0.70 35 - 45<br />

0.70 35 - 45<br />

0.70 35 - 45<br />

0.70 35 - 45<br />

Climaplus Antimicrobical Treatment: provides dual inhibition of mold/mildew and odor/stain-causing bacteria.<br />

Inhibits or retards the growth of Gram-positive and Gram-negative bacteria.<br />

G<br />

Hz 125 250 500 1000 2000 4000<br />

αS 0.67 0.39 0.67 0.97 1.02 1.04<br />

Applications<br />

• Corridors<br />

• Executive Office<br />

• Lobby areas<br />

• Retail<br />

L<br />

FLB/<br />

MERIDIAN<br />

89%<br />

89%<br />

89%<br />

89%<br />

White<br />

White<br />

White<br />

White<br />

A, B1<br />

A, B1<br />

E<br />

H, J ,L<br />

33

34<br />

Radar Ceramic ClimaPlus<br />

Radar Ceramic/DONN DX24<br />

Warranty<br />

10 year panel or 30 year system warranty<br />

Classification<br />

ASTM E 1264 classification, type XX, Pattern<br />

C,E,G<br />

Composition<br />

Contains recycled material, no asbestos. Tile is<br />

a patented process blend of NC mineral fiber<br />

inorganic fillers and specialty hydrophobic<br />

organic binders. Pre-finished wih primer and<br />

top coat paints. Manufactured in water felted,<br />

ceramic bonded mineral fiber technology.<br />

Material safety data sheet available on<br />

request.<br />

Fire Reaction<br />

BS 476 Pt 4<br />

ASTM E84, Class A<br />

Flame spread: 0<br />

Smoke developed:0<br />

Fire Resistance<br />

BS 476 Pt 21/23<br />

120min. protection to steel beams and timber<br />

floor.<br />

UL labelled when tested to ASTM E119<br />

(U.L.263)<br />

Humidity Resistance<br />

Maximum 100% RH / 40° C<br />

Thermal Resistance<br />

R 1.3<br />

Weight:<br />

7.8 kg/m 2<br />

Maintenance:<br />

Easily cleaned using soft brush or damp<br />

sponge.<br />

Radar Ceramic ClimaPlus<br />

Description<br />

• Accessible acoustical ceiling system with ceramified mineral panels<br />

Features and Benefits<br />

• Ceramic bonded mineral fiber<br />

• Construction inert, and non combustible. Tested in live steam temperatures up to<br />

135°C such as saunas and steam rooms<br />

• Ultra high humidity resistant<br />

• Ensures Durability in standard or extreme environmental conditions<br />

• High sound attenuation, for room to room privacy<br />

• Install with DX ZXA corrosion-resistant grid system<br />

G<br />

αS<br />

12<br />

Applications<br />

• Parking garages<br />

• Extrior soffits<br />

• Pools and shower areas<br />

• Saunas and steam rooms<br />

35

36<br />

Sandrift ClimaPlus<br />

Sandrift/DONN DX24<br />

Warranty<br />

10 year panel or 30 year system warranty<br />

Classification<br />

ASTM E 1264 classification, type III,Form 4,<br />

Pattern Z.<br />

Composition<br />

Contains recycled material, no asbestos. Tile is<br />

a patented process blend of NC mineral fiber<br />