PDF, 16Mb - Dayco Aftermarket

PDF, 16Mb - Dayco Aftermarket

PDF, 16Mb - Dayco Aftermarket

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

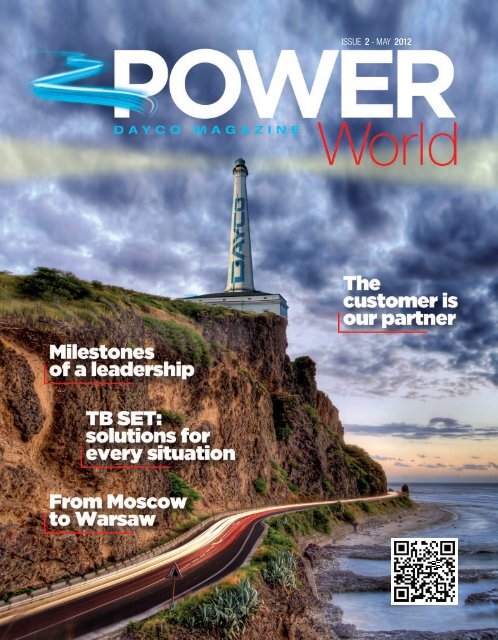

ISSUE 2 - MAY 2012

David Martínez<br />

President EU/SAO/Asia<br />

Editorial<br />

Listening to the market,<br />

looking to the future.<br />

Times are difficult, there is no<br />

denying it. The world economic<br />

crisis that has tormented the<br />

markets for over three years<br />

shows no sign of ending, at least<br />

for the time being, and many companies<br />

continue to move with hesitation. It is<br />

however in this context, that <strong>Dayco</strong> has<br />

successfully achieved significant results in<br />

the renewal process that we started to<br />

outline in the pages of this magazine, one<br />

year ago.<br />

We are convinced that any type of difficulty<br />

can be overcome if it is tackled with the right<br />

“weapon”: trust. And specifically, trust in<br />

the future. Trust is the major strength that<br />

has constantly driven and motivated our<br />

actions. It is trust that has allowed us to<br />

plan, decide and invest resources in the<br />

great renewal challenge we have launched.<br />

And again, it is trust that has allowed us to<br />

update and align our own model to the new<br />

economic model, envisioning a new<br />

strategy and new form of market. Because<br />

for <strong>Dayco</strong>, trust in the future also means<br />

trust in the market - in its capacity to<br />

undergo radical change and give anyone<br />

willing to listen, the instructions to face each<br />

change in the best possible way.<br />

Trust therefore, has been both our driving<br />

force and our investment over the years.<br />

And above all, it is at the basis of the<br />

increasingly strong relations we have with<br />

our customers - at all levels. Customers that<br />

for us, have always been much more than<br />

“numbers” with whom we simply<br />

communicate or provide a service or<br />

product to, but who are true partners and<br />

active players in the success of our<br />

company. And this will continue to be ever<br />

more important in the future.<br />

The stakes are high but not unachievable;<br />

they involve a new development model that<br />

aims at a growth strategy shared by and<br />

profitable to everyone - the company, the<br />

end users and the market. Because there<br />

cannot be trust in the future if there is not<br />

mutual trust to start with. Without the<br />

relationship with our partners, we could not<br />

express our positive vision of the future. And<br />

without our investment, our partners could<br />

not trust us. “Sharing” therefore, is our<br />

watchword, the foundation of a new type of<br />

market and a new way of being present in<br />

the market, focusing not only on growth but<br />

on stability and the strengthening of growth<br />

itself.<br />

Our mission, our vision and our strategies<br />

are based on the sharing of values,<br />

objectives and the successes represented<br />

by our positive results over the last year,<br />

which have shown, in some areas, highly<br />

substantial growth. A situation which is<br />

even more significant when considered<br />

within the demanding context of the<br />

present Global economic difficulties.<br />

Aware of these challenging circumstances,<br />

we have decided to face possible<br />

developments with fair and balanced<br />

optimism - a positive, yet realistic attitude<br />

resulting from the knowledge that there is<br />

a future and in order to reach it, we need to<br />

follow a new path without hesitation.<br />

A path that is shaping, day by day, this large<br />

global company where we speak a single<br />

language and listen to a single message but<br />

which can however, be translated into<br />

countless languages and dimensions. A<br />

company constantly focused on the<br />

achievement of growing loyalty among<br />

partners and customers who, even in the<br />

most difficult moments, have stood by us....<br />

and have continued to believe in us. For me,<br />

this observation is a great source of pride<br />

and hope for the future.<br />

Because people are truly the most<br />

important part of our business: A company<br />

lives from the market and the market<br />

consists of people. Believing in a market<br />

therefore, means believing in the people<br />

that make up that market, and knowing<br />

how to listen to them.<br />

If we have some merit in this success<br />

therefore, I believe it is in our ability to listen<br />

to the market, to understand it without<br />

conditioning it. Without this quality, we<br />

probably would not have made the same<br />

choices and the same investments. And we<br />

would not have found the right way to<br />

transmit our message of trust to our<br />

partners.<br />

Partners who have not only understood us,<br />

but who have in turn, rewarded us with their<br />

optimism, confidence and commitment to<br />

a brighter future.<br />

MAY 2012<br />

®<br />

1

4The<br />

customer is<br />

our partner<br />

6<br />

7<br />

2 POWER WORLD<br />

®<br />

Index<br />

Optimising<br />

the brand<br />

together<br />

All-out<br />

information<br />

ISSUE 2<br />

Periodical<br />

Registered at the Ordinary Court of Pescara<br />

N. 488/2011 V.G.<br />

N. 07/2011 Print Reg.<br />

N. 72/2011 Cron.<br />

Editor<br />

Daniela Panosetti<br />

10<br />

18 The eastern<br />

frontier<br />

Milestones<br />

of a leadership<br />

15<br />

Editorial coordination<br />

Franca Pierobon<br />

Graphics<br />

Pomilio Blumm srl<br />

Via Venezia, 4 - 65121 Pescara<br />

Printing<br />

Ivrea Grafica, Ivrea - To<br />

TB SET:<br />

solutions for<br />

every situation

16<br />

From Moscow<br />

to Warsaw<br />

28<br />

Response from the TAM<br />

30<br />

The <strong>Dayco</strong><br />

mechanic<br />

D A Y C O M A G A Z I N E<br />

Editorial<br />

Marketing<br />

World<br />

May<br />

2012<br />

20 Sustainability<br />

and<br />

innovation:<br />

a team work<br />

Communication and Promotion<br />

Product<br />

Zoom<br />

Research & Development<br />

Garage<br />

Update<br />

MAY 2012<br />

3<br />

1<br />

4<br />

6<br />

10<br />

16<br />

20<br />

26<br />

36

Awhole new model at the<br />

production, logistic and<br />

marketing level. A truly<br />

innovative vision, based on two<br />

closely related principles: trust and quality.<br />

This is a strategic approach that enables<br />

<strong>Dayco</strong> to respond to change with change,<br />

reacting by relaunching rather than<br />

resisting, “betting” on the future without<br />

losing touch with the present. This is the<br />

objective that <strong>Dayco</strong> has been pursuing for<br />

some years with great conviction.<br />

A demanding choice, which has involved<br />

all company divisions, at all levels, but one<br />

that has quickly proved to be successful.<br />

EMERGING COUNTRIES,<br />

DEMANDING MARKETS<br />

Marketing<br />

The customer<br />

is our partner<br />

Bruno Vallillo<br />

Vice President<br />

General Manager Europe<br />

«In a period when most manufacturing<br />

sectors continue to feel the effects of the<br />

world economic crisis, <strong>Dayco</strong> holds a<br />

position of leader in many product families<br />

and on many markets» -, Bruno Vallillo,<br />

Vice President, General Manager Europe<br />

- declares with pride. «This year for<br />

instance, the kit range has positioned<br />

<strong>Dayco</strong> as a dominant player in the mature<br />

markets, but the demand for kits is also<br />

increasing strongly in the Eastern Europe<br />

and BRIC areas which are characterised<br />

by vehicle fleets that are often very<br />

different in terms of range and<br />

size». Today, it is these emerging<br />

markets that represent the<br />

A strategy with global objectives but local implementation.<br />

A logistic network increasingly adaptable to single markets.<br />

A “widened” sales process that only ends with the installation<br />

of the product. Bruno Vallillo, Vice President, General Manager Europe,<br />

explains the <strong>Dayco</strong> model. And the reasons for its success.<br />

most promising opportunity for our “bet on<br />

the future”. Alongside the already<br />

consolidated positions, the <strong>Dayco</strong> brand<br />

has experienced a remarkable growth of<br />

market share in many developing areas,<br />

notably Russia and Brazil.<br />

«Emerging, but most of all demanding<br />

countries – underlines Vallillo – with<br />

markets that are now modern and ready to<br />

receive new methods and new services».<br />

Among the most promising sectors is the<br />

Heavy Duty line, where <strong>Dayco</strong> is already<br />

the absolute leader as far as the OE offer<br />

is concerned. «A market that is<br />

becoming more demanding each<br />

month, especially for the<br />

medium vehicle range from<br />

3.5 to 7.0 tonnes. This is in<br />

line with the general trend of<br />

the present economic model<br />

which is to transport less<br />

goods, but with a<br />

higher frequency».<br />

Hence the<br />

decision to<br />

prepare a<br />

n e w<br />

catalogue and a specific product line for<br />

this vehicle category that can cover the<br />

whole of “mature” Europe as well as the<br />

emerging markets with a single range.<br />

HIGH QUALITY<br />

AND DIVERSIFIED SERVICES<br />

<strong>Dayco</strong>’s commitment therefore, is to<br />

further increase its already highly extended<br />

offer, by gradually integrating into its<br />

catalogue, the total range of applications<br />

present in the emerging<br />

markets. Many<br />

resources, for<br />

instance, have been<br />

allocated to those<br />

segments of the<br />

vehicle parc that,<br />

due to their age,<br />

are less and less covered by the official<br />

networks, but which need however, the<br />

same OE quality level. This is an extremely<br />

strategic sector in which significant<br />

investment has been made in the area of<br />

testing with the extension of the European<br />

R&D programme to the Asian and South<br />

American areas.<br />

On the other hand, explains Vallillo: «Not<br />

everything can be standardized. Each<br />

country has its own specifics not only in<br />

terms of age and range of vehicle parc, but<br />

also in terms of culture, language, infrastructure<br />

and even climate (for example<br />

seasonal differences)». Therefore, the first<br />

step to meet these diversified needs is to<br />

listen to the market, «being able to<br />

understand its needs in advance and being<br />

ready to respond promptly to the<br />

customers’ requests at all levels: from the<br />

distributor to the spare parts dealer to the<br />

mechanic installing the component».<br />

At an organisational level, this approach<br />

has led to the distribution of the different<br />

market needs into three major divisions:<br />

marketing, logistics and sales. «The<br />

sales division, in particular, has been<br />

completely restructured, abandoning the<br />

“classic” sales concept in favour of an<br />

approach aimed at adapting, as much as<br />

possible, the global strategy to the<br />

different markets». In Europe, for<br />

instance, the sales activities are<br />

now structured around three sales<br />

areas corresponding to<br />

South, Centre-North

A relationship<br />

based on trust<br />

“<br />

The workshop represents the<br />

crucial point of our “value chain”.<br />

It is in the workshop that our<br />

product really comes to life, thanks to the<br />

mechanic’s experience and skills».<br />

Therefore, this stage must be as smooth<br />

as possible, and the workshops must<br />

know that they will not only get the best<br />

quality from <strong>Dayco</strong>, but also the best<br />

service and maximum availability of<br />

products». This is how Bruno Vallillo<br />

describes the great importance of the<br />

relationship between the company and the<br />

workshop in the <strong>Dayco</strong> model.<br />

From this viewpoint, we are further<br />

improving and developing the packaging<br />

and preparation of our products with the<br />

aim of providing, in a single package, not<br />

only the single component but also the<br />

specific accessories required for its correct<br />

installation.<br />

In the <strong>Dayco</strong> model therefore, the<br />

workshop is not merely the final stage of<br />

the sales process, but an active part of the<br />

company’s strategic decisions. «And if, as<br />

we have seen, these decisions have<br />

proved rewarding, it is because – says<br />

Vallillo – that the most important decision<br />

has been made by our customers, both<br />

and Eastern Europe, i.e. macro-areas<br />

characterised by countries with similar or<br />

comparable commercial and productive<br />

needs or which can be managed within<br />

some form of common framework. «In line<br />

with this approach, sales are currently<br />

being developed, particularly in some<br />

areas showing interesting growth levels<br />

including both “mature” markets such as<br />

the UK and above all, Eastern Europe<br />

where countries like Poland are becoming<br />

extremely promising areas».<br />

FROM THE WAREHOUSE<br />

TO THE WORKSHOP<br />

<strong>Dayco</strong>’s main objective is to guarantee a<br />

diversified offer, as suitable as possible for<br />

each country at a local level, whilst<br />

ensuring high and uniform quality<br />

standards for each area and aspect of the<br />

direct and indirect, who have responded<br />

to the company’s renewal effort by<br />

choosing our quality, our complete range<br />

of products, and our logistics, thus<br />

acknowledging the value of the investment<br />

we have made in this truly new operating<br />

model». And after all, the sharing of<br />

objectives and prospects with our<br />

customers is one of the most important<br />

aspects of the model which <strong>Dayco</strong> is<br />

defining year after year “We are trying to<br />

create an increasingly “closer” and more<br />

participative relationship, through direct<br />

involvement of our customers, as true<br />

partners, in the development of product<br />

and process innovation. I am referring, for<br />

instance to the creation of large<br />

purchasing groups – continues Vallillo –<br />

and the considerable investments made in<br />

communication, particularly in terms of<br />

service and information aimed specifically<br />

to the workshops».<br />

It is in this context that the challenge<br />

launched (and won) by <strong>Dayco</strong> on the<br />

“guarantee front”, must be considered. In<br />

fact, <strong>Dayco</strong>’s products are presently<br />

supported by a level of guarantee which<br />

exceeds that imposed by the law: «A<br />

“plus” that we are able to offer because we<br />

offer at a global level. Not only with the<br />

quality of the product in mind but also the<br />

quality of the organisation, information and<br />

general service.<br />

«Clearly, we are talking about a process<br />

that will need a certain amount of time to<br />

be completely established, but the work<br />

is already well under way and will continue<br />

to keep us increasingly busy in the near<br />

future», points outs Vallillo.<br />

For example, we are continuing with<br />

substantial investment and development<br />

of our logistics department. Over the last<br />

few years, our distribution network has<br />

been gradually adapted to a model of<br />

increased “proximity” to each reference<br />

market, aligning it to the diverse infrastructures<br />

present in the various countries.<br />

«Our investment in logistics started about<br />

three years ago with the decision to move<br />

away from the concept of “central”<br />

warehouses and focus on peripheral<br />

<strong>Dayco</strong>`s strategy is to build a strong<br />

relationship and trust to the garage and<br />

motor factor.<br />

This is gained by sharing our mutual goals.<br />

are convinced that we are proceeding,<br />

together with our partners, towards<br />

increasingly high quality levels in all areas<br />

of our activity».<br />

This confidence can also be seen in our<br />

marketing decisions, which have included<br />

decidedly ambitious objectives, which can<br />

certainly be reached if we continue on the<br />

path we have defined. «Unlike our<br />

competitors, we have set ourselves one<br />

simple rule – reveals Vallillo - to always be<br />

distribution branches, in order to get the<br />

products as near as possible to the areas<br />

they are effectively used and thus<br />

providing our workshop partners with a<br />

guarantee of maximum product<br />

availability».<br />

Today, the process is continuing in two<br />

directions: the opening of new local<br />

warehouses, and the expansion of those<br />

existing ones. Furthermore, in addition to<br />

the direct regional investments, we have<br />

also allocated funds for specific studies<br />

aimed at identifying and developing the<br />

most suitable systems to reduce lead<br />

times and guarantee maximum logistic<br />

efficiency. In fact, as Vallillo explains, «for<br />

<strong>Dayco</strong>, the sale does not end simply when<br />

a component is ordered, but when it has<br />

been effectively and correctly installed on<br />

the vehicle.<br />

In other words, our “work” can only be<br />

considered complete when we have met<br />

an active player, and not a follower. Which<br />

means firstly observing the market and its<br />

evolution and only at a second stage, the<br />

competition. Because we believe that in<br />

order to lead the market, we must allow<br />

the market to lead us; in other words<br />

knowing how to listen to it.<br />

A model – concludes Vallillo – which I am<br />

certain, will always be successful, in all<br />

business contexts».<br />

fully, all the requirements of our end<br />

customer, in terms of quality and service».<br />

Therefore, our intention is to supply an<br />

increasingly wide range of additional<br />

services and facilities especially designed<br />

to make the installation procedures<br />

simpler, faster and more efficient;<br />

including “tools” ranging from the<br />

availability of specific Technical Information<br />

for each product and the constant support<br />

of our <strong>Aftermarket</strong> Technicians, to the<br />

organisation of seminars and training<br />

workshops within the different regions at<br />

a local level.<br />

MAY 2012<br />

5

6 POWER WORLD<br />

Communication and Promotion<br />

Optimising<br />

the brand together<br />

An increase in technical communication, structured around the requirements<br />

and specific requests of the end user: the installer. From the intensification of<br />

events in the market to the success of the Garage sector, let’s have a look at<br />

the various means used by <strong>Dayco</strong> to “communicate” to its target.<br />

Franca Pierobon<br />

Communication Manager<br />

Direct dialogue with repair<br />

shops, participation in fairs<br />

and events in the market and<br />

provision of clear, complete<br />

and technically detailed information.<br />

These are the three “pillars” at the basis<br />

of <strong>Dayco</strong>’s targeted communication. A<br />

strategy in line with the model of<br />

participation and partnership between<br />

company and customer, which appears<br />

heavily focused on what could be defined<br />

as the product “end user” who, as such,<br />

is in a position to express better than<br />

anyone else the specific requirements of<br />

the market and thus provide the most<br />

detailed image of the “demand” that the<br />

communication attempts to meet. The<br />

objective is therefore to stimulate this<br />

demand as much as possible so that, at<br />

the time of the purchase, the installer has<br />

a very clear idea of the <strong>Dayco</strong> brand, the<br />

quality of its products and the full range<br />

of products offered.<br />

A DIRECT DIALOGUE<br />

Reaching this type of target, however,<br />

implies a complicated process. As Franca<br />

Pierobon, <strong>Dayco</strong> Communication<br />

Manager, explains, «we are talking about<br />

a reference pool that includes over<br />

300,000 referents in Europe only. This<br />

clearly shows how difficult it is to create<br />

direct contacts and, even more so, to<br />

establish a stable loyal relationship. With<br />

the correct tools and a clear motivation,<br />

we are convinced that this dialogue is<br />

possible. Actually, in some context, it has<br />

already started». In this respect, Italy<br />

represents a pioneering market, with a<br />

global database of 2000 contacts, mainly<br />

“collected” during events held in the<br />

market and already involved in a series of<br />

interesting loyalty-related operations.<br />

The major initiative in this sense is<br />

certainly the creation of the Garage<br />

Section: «A section of <strong>Dayco</strong>’s website<br />

specifically dedicated to car repair shops<br />

that, after registration, gives access to a<br />

kind of “virtual work space”, making<br />

available some very useful tools for the<br />

daily activity of the workshops, such as<br />

online diagnostics, or technical and<br />

service information: (TI and SI Bulletins).<br />

The database currently available includes<br />

some 4000 transmission layouts and<br />

over 200 TI and SI bulletins.<br />

The TI and SI bulletins present clear and<br />

detailed technical characteristics of the<br />

product and the assembly procedure.<br />

They can also be accessed through the<br />

newsletter which is sent regularly to all the<br />

people registered to the portal and<br />

contains all the latest news on <strong>Dayco</strong>’s<br />

world: from the introduction of a new<br />

product line to the report on the last trade<br />

fair where <strong>Dayco</strong> were present. As<br />

Pierobon anticipates «During 2012, this<br />

channel will be further updated in its form<br />

and contents: its commercial and<br />

promotional function will be developed,<br />

making it a suitable vehicle for launching<br />

initiatives and special offers, and its<br />

increased frequency will make contacts<br />

with our interlocutors as continuous and<br />

rich as possible ». Another important<br />

move from <strong>Dayco</strong> in the last few months<br />

is the launching, from this issue of the<br />

magazine, of the “<strong>Aftermarket</strong> Technical<br />

Column” in hard copy: «A space designed<br />

to answer accurately the questions<br />

frequently asked by the repairers to our<br />

technicians».<br />

MEETING OPPORTUNITIES<br />

It is clear that all these initiatives are<br />

aimed at extending as much as possible<br />

the customer loyalty process, already<br />

relatively developed in Italy, to the other<br />

European markets.<br />

To this end, the pool of direct contacts<br />

with the repair shops is implemented<br />

month after month, mainly through the<br />

increasing number of events in the<br />

market, ranging from the participation in<br />

fairs to the organisation of seminars and<br />

technical courses for car repairers,<br />

«meeting opportunities that are essential<br />

to establish an effective dialogue with our<br />

targets and, above all, to follow their<br />

suggestions and requirements».<br />

In particular, the importance and number

Communication and Promotion<br />

of training courses are going to be increased on all<br />

markets, through the implementation of a new course<br />

concept and the reorganisation of the whole aftermarket<br />

technicians’ area, both aimed at greater physical proximity<br />

to the working place.<br />

These technical and training opportunities will be<br />

supported by a dense schedule of local events,<br />

conventions and road-shows with a more commercial<br />

purpose, both on the mature markets – France, England,<br />

Germany – and on the emerging market, in particular<br />

Eastern Europe – Poland, Romania, Hungary and,<br />

naturally, Russia.<br />

«Among the events already scheduled – indicates<br />

Pierobon – the annual Frankfurt Fair is definitely the<br />

unmissable event for the automotive industry at the<br />

European level, where <strong>Dayco</strong> will present many new<br />

products ».<br />

All-out information<br />

This intense communication activity below<br />

the line is obviously supported by the<br />

consistent use of more traditional forms,<br />

including the distribution of leaflets, flyers,<br />

brochures, with particular attention to the<br />

organisation of the selling points, whether it be<br />

workshops or spare parts shops, considered as perfect<br />

“showcases” for the brand.<br />

<strong>Dayco</strong> also pays great attention to the opportunities of<br />

involvement and direct interaction related to the new<br />

media. «The use of new technologies in the workshops<br />

is actually growing, encouraged by the parallel<br />

development of the mechanic figure, increasingly<br />

“high-tech” and increasingly used to making the most<br />

of the simplified opportunities offered by network communications».<br />

In line with this trend, <strong>Dayco</strong> is planning to launch an<br />

online version of the magazine in the near future, and<br />

to develop the use of QR codes, inserted in the<br />

advertising pages or on the product labels, starting<br />

from the kits to gradually include the timing belts and<br />

rigid components. «In this way, as soon as the product<br />

is opened, the installer will have immediate access,<br />

through the smartphone technology, to the relevant TI<br />

or SI bulletin, directly from the site and in the language<br />

of the market. Alternatively, if he does not have a<br />

smartphone technology is unavailable, the same<br />

information can be accessed by entering a numeric<br />

version of the code through the website.<br />

COMMUNICATION CHANNEL<br />

The portal actually represents the real lynchpin of<br />

<strong>Dayco</strong>’s communication strategy. «The number of<br />

contacts and registrations, particularly to the garage<br />

section, is increasing, probably owing to the fact that the<br />

target perceives <strong>Dayco</strong>’s will “speak the same<br />

language”, strongly aiming at a communication focused<br />

on the technical aspect of the products and their use».<br />

Besides the website, however, a critical part is played at<br />

communication level by the distribution chain. In fact,<br />

whilst the installer is the “end” target of <strong>Dayco</strong>’s<br />

communication, the role played by the spare part dealers<br />

and distributors is just as important for the company, as<br />

they can transfer the technical and product information<br />

in the most complete and efficient way to all the levels<br />

of the chain. «For example, the courses are often<br />

organised to answer specific requests from the<br />

distributors who, in turn, collect the specific input from<br />

the spare part dealers, who have a more direct contact<br />

with the end users. This is why the spare part dealer is<br />

often the one who organises the meetings, informing his<br />

own territorial customers and inviting them to<br />

participate». The distributors’ cooperation also helped<br />

organise various co-marketing operations at local level,<br />

where <strong>Dayco</strong> was present mainly as a brand rather than<br />

a direct interlocutor, as well as some interesting<br />

merchandising and sponsoring initiatives, including an<br />

activity aimed at involving the historical Abarth brand,<br />

through one of its most renowned engineers: «This is<br />

just a glimpse – concludes Pierobon – of an event<br />

calendar that will be undoubtedly very intense and<br />

demanding throughout 2012».<br />

MAY 2012<br />

7

8 POWER WORLD<br />

Communication and Promotion<br />

Different strategic choices<br />

Being flexible and listening to<br />

the market are two of the<br />

main elements of <strong>Dayco</strong>’s<br />

model, starting from a<br />

common strategic base then adapting it<br />

to the various market needs. Therefore it<br />

is of no real surprise that this its<br />

localisation formula also worked in<br />

countries with such varying<br />

requirements.<br />

«When we talk about Eastern Europe we<br />

tend to think of a sort of uniform macroarea,<br />

but on the contrary they are unique<br />

and characterised by local differences.<br />

– observes Taverna. – Therefore it is<br />

also necessary to modify the<br />

communication activity according to the<br />

requirements of the markets, focusing in<br />

some cases on an institutional brand<br />

communication, in other cases on a more<br />

focused promotional strategy, through<br />

activities such as, shows, exhibitions and<br />

events on the premises of our partners.<br />

In Poland for instance, the very unique<br />

distribution situation which is very<br />

structured, even more than in some<br />

mature markets of Western Europe,<br />

requires the ability to support the market<br />

locally in a more targeted manor.<br />

The situation is different in Russia where,<br />

due to the geographical extension, <strong>Dayco</strong><br />

decided to maintain it’s core business in<br />

Moscow and, from there, to move to<br />

other big cities like Saint Petersburg.<br />

The case of the Lada, the Russian car par<br />

excellence is emblematic in this sense;<br />

«For <strong>Dayco</strong>, entering the Lada market<br />

provided automatically a strong<br />

advertising arm, that allowed the brand<br />

awareness to grow from the bottom<br />

much more quickly than what would<br />

have been the case using the classic<br />

advertising channels, without waiting for<br />

the brand value to move from the top of<br />

the chain to the bottom». The strategy<br />

consisted of identifying the distributors<br />

specialising in the Lada <strong>Aftermarket</strong> who,<br />

even though small in number, handle<br />

important volumes, particularly outside<br />

the Moscow area, where the vehicle parc<br />

is more similar to that of Western Europe.<br />

A choice that clearly worked, as <strong>Dayco</strong><br />

quickly became the leader in the Russian<br />

market, and thus proving the strength of<br />

a model that does not merely intends to<br />

“talk” to the customers, but wants to<br />

involve them in a real dialogue, to learn<br />

their language and to adapt it to its own.<br />

From this point of view, the presence at<br />

the Moscow MIMS Fair is of fundamental<br />

importance in this country.<br />

«Over the years, this fair has developed<br />

from a national event mainly attracting<br />

the former Soviet countries of the<br />

Russian Federation, to an international<br />

event in all respects, in terms of visitors<br />

and exhibitors, who are now coming from<br />

all European countries». Most of all, given<br />

the huge extent of the Russian territory,<br />

MIMS represents a unique opportunity to<br />

know and meet customers from every<br />

corner of the country, from cities that are<br />

as remote as Vladivostok.<br />

«We can say – adds Taverna – that while<br />

the approach to the Lada market enabled<br />

us to make ourselves known from the<br />

bottom, through the repair shops and<br />

spare parts dealers, the Moscow Fair<br />

helped us to push our brand at an<br />

institutional level, introducing it in the<br />

local competition framework. In addition<br />

it has also allowed us to reach new<br />

customers, to consolidate those already<br />

acquired»

Communication and Promotion<br />

Quality as<br />

security<br />

Amechanic is working in his<br />

workshop. Suddenly, a dark and<br />

threatening figure walks by: it is<br />

a roaming shadow, death looming over,<br />

waiting for the mechanic to make a<br />

mistake and fit a second-rate or faulty<br />

part on a car. But the mechanic keeps his<br />

composure and, unperturbed and<br />

smiling, shows the unusual guest how a<br />

job well done leaves nothing to fear, until<br />

an ironic conclusion that leaves the<br />

audience amused, but also more aware.<br />

This is the video that was shown in Spain<br />

and Portugal in recent months, as part of<br />

an awareness campaign “recambioletal”,<br />

promoted by a group of component<br />

producers operating in the area, among<br />

which <strong>Dayco</strong>. Launched with the catch<br />

line “elegir calidad es elegir seguridad”<br />

(choosing quality means choosing<br />

safety”), the campaign intends to<br />

emphasize with strength the importance<br />

for the end customer to choose OEM<br />

quality brands for their spare parts.<br />

As Bruno Padierna, Sales manager for<br />

Spain and Portugal explains, the project<br />

was developed as the result of a fact<br />

observed on the market. «Over the past<br />

few years, there has been an increasing<br />

number of customers requesting<br />

products that cost less, but offer a quality<br />

that repair shops consider insufficient to<br />

guarantee not only a job well done but,<br />

above all, a safe result».<br />

For this reason we decided to join forces<br />

to send a strong message to the market,<br />

explaining that choosing quality is not an<br />

accessory choice but a necessary one.<br />

«Initially, the group was rather small but<br />

the number of members grew quickly».<br />

The objective is to explain, not only to the<br />

end customer but also to distributors and<br />

repair shops, a simple yet extremely<br />

important principle, i.e. «the price cannot<br />

and should not be the first and sole<br />

parameter in the choice of a component,<br />

because before the cost, the quality of<br />

the repair is and remains the most<br />

important factor». Fitting a part that is not<br />

certified implies fitting a part that has<br />

probably not received correct approval<br />

and may therefore create serious<br />

problems in the long term.<br />

The channel chosen to communicate this<br />

message is deliberately “strong”,<br />

although clearly sarcastic. A choice that,<br />

even though it drew inevitable criticism,<br />

turned out to be rewarding, as the video<br />

was viewed nearly 15 million times on the<br />

related website.<br />

«The second stage of the campaign<br />

should be launched soon – concludes<br />

Padierna –; it is aimed at opening a direct<br />

dialogue with the main local interlocutors<br />

of the industry: purchasing groups,<br />

distributors, major producers, in order to<br />

create a single front, united by the<br />

conscious choice of quality».<br />

MAY 2012<br />

9

Product<br />

Milestones<br />

of a leadership<br />

Corrado Bisegna<br />

Senior Product Manager<br />

Collaboration with all major vehicle manufacturers improving<br />

product technology and range. One result of this is the extension<br />

of the automatic tensioners with a range of over 1000 parts,<br />

covering 93% of the European vehicle car parc.<br />

Together with the belt,<br />

automatic tensioners are<br />

actually the leading product of<br />

<strong>Dayco</strong>’s offer. They represent<br />

the most technologically advanced line,<br />

both for the primary timing system and<br />

for the accessory system. The tensioner<br />

function is to absorb constantly, for the<br />

whole life of the belt, the tension and<br />

vibration peaks generated by the<br />

movement of the belt itself, ensuring a<br />

constant tension. This objective can be<br />

reached with various methods and<br />

devices having different structural characteristics<br />

and different advantages.<br />

In detail, the <strong>Dayco</strong> catalogue offers two<br />

types of tensioners; i.e. automatic and<br />

fixed. “Active spring” or hydraulic<br />

FROM THE UNITED<br />

STATES TO EUROPE<br />

For many years, <strong>Dayco</strong> has been a<br />

leader on the European market of<br />

automatic tensioners. This objective<br />

was reached after a long route that<br />

started some thirty years ago. «It was<br />

at the end of the 80’s that the<br />

American multinational “landed” on<br />

the old continent, introducing the<br />

automatic tensioner production<br />

technology» explains Corrado<br />

Bisegna, Senior Product Manager.<br />

«Here, the know-how already<br />

developed in the United States was<br />

improved and adapted to suit the<br />

different operating and<br />

manufacturing procedures of local<br />

engines, and resulted in the timing<br />

belt product, which was and remains<br />

a typically European production».<br />

The intense cooperation between<br />

<strong>Dayco</strong> and the major car<br />

manufacturers and heavy duty (HD)<br />

producers started at that time, and led<br />

to an increasingly complete and<br />

specialised range of products, both<br />

for the primary and secondary timing<br />

systems. In particular, the offer of<br />

solutions for automatic tensioners<br />

was strongly developed, as these<br />

components have become absolutely<br />

necessary for some types of engines.<br />

«This cooperation has also allowed<br />

the accurate fulfilment of the quality<br />

standards required by the various<br />

producers – adds Bisegna – and<br />

from the 90’s on, <strong>Dayco</strong> has become<br />

the market leader for this line of<br />

product: a record that is still holding».<br />

automatic tensioners are – explains<br />

Bisegna – «intelligent“ tensioners: when<br />

installed correctly, they are actually<br />

capable of optimising the tension<br />

according to the engine load.<br />

On the other hand, fixed tensioners are<br />

components that help the operator<br />

adjust the belt tension at the same time<br />

as the fastening operation.<br />

Consequently, once it is set, this type of<br />

tensioner cannot be adapted to possible<br />

variations of external tension. Therefore,<br />

<strong>Dayco</strong> invites the installer to use the<br />

<strong>Dayco</strong> tensiometer in order to check the<br />

correct tensioning of the belt. Tensioners<br />

are components of a more complex<br />

system, which requires a number of<br />

accessory components that are essential<br />

to optimise the performance of the whole<br />

belt route system. These components,<br />

which must have the same operative life<br />

as the tensioner, include for example the<br />

dampers (see special box), but also the<br />

idlers, which follow the route of the belt<br />

to facilitate its movement inside the<br />

transmission, interrupting the so-called<br />

“free span”. «If there is no idler or pulley<br />

to govern it, the longer the belt section is<br />

and the more likely it is to resonate»,<br />

explains Bisegna.<br />

PRODUCERS AND INSTALLERS:<br />

FULL RIGHT PARTNERS<br />

Tensioners and dampers perform a<br />

highly important function for the correct

Focus on DAMPERS<br />

In a transmission system, the main circuit is supported by the so-called<br />

auxiliary circuit, which governs elements such as the alternator, the air<br />

conditioning compressor and, in some cases, the water pump.<br />

Among the internal accessories of this transmission, one of the most important<br />

is the damper. It is usually a pulley fitted with rubber components,<br />

capable of absorbing and damping the<br />

crankshaft vibrations, preventing them<br />

from reaching other parts of the system.<br />

Besides the traditional dampers, <strong>Dayco</strong><br />

also produces much more complex variants<br />

called DDS (double damping system),<br />

designed to be fitted on more<br />

powerful and efficient engines.<br />

An example is the series<br />

of Fiat Multijet<br />

1.9/2.0 engines:<br />

these new-generation<br />

diesel engines<br />

are extremely<br />

efficient and<br />

therefore require a<br />

double damping system. All this implies the capacity to<br />

face a number of significant technological difficulties, from<br />

the need to join and “merge” rubber and metal components, to the formulation<br />

of specific compounds capable of reacting immediately to the intense<br />

vibrations transmitted to the system by these types of engines. Finally, it<br />

should be noted that each engine requires a specific damper with the wide<br />

range of applications, currently including some 110 models.<br />

and efficient operation of the transmission<br />

system. This function is reflected in the<br />

structural complexity of the product: each<br />

tensioner actually consists of a rather<br />

articulated system of components, the<br />

design and implementation of which<br />

require significant commitment in terms<br />

of technical knowledge and research<br />

investments.<br />

For this reason, says Gianluca Fantozzi,<br />

Technical department, <strong>Dayco</strong> pays<br />

particular attention to the constant and<br />

progressive technological development:<br />

«This requirement is directly related to the<br />

direct relation we have with the car<br />

manufacturers, who express<br />

their precise and advanced<br />

requirements, for products<br />

that are increasingly efficient<br />

and effective in terms of<br />

weight, performance and<br />

reliability. In line with this approach –<br />

adds Fantozzi – we have<br />

established with some<br />

OEM producers strong<br />

relations of design<br />

synergies, for<br />

example with Fiat,<br />

Psa, Ford,<br />

Volkswagen for the<br />

a u t o m o t i v e<br />

segment and<br />

with Scania,<br />

Volvo, Iveco, Mercedes for<br />

the heavy duty segment».<br />

The relation with the<br />

producers and with the new<br />

technologies introduced on the<br />

market is the first and most specific<br />

parameter followed by <strong>Dayco</strong><br />

when drafting its OEM<br />

development<br />

plans. Another element that<br />

is just as important, if not more, for the<br />

<strong>Aftermarket</strong> Division is the direct and<br />

ongoing contact with the end user, i.e. the<br />

installer who is considered a full right<br />

partner of the company, as he is capable<br />

of indicating in the most precise and<br />

specific manner the various requirements<br />

and problems of the engines.<br />

In line with this approach,<br />

with particular<br />

reference to the<br />

automatic tensioner range,<br />

for which <strong>Dayco</strong> is already<br />

the European leader,<br />

the company has<br />

decided to produce<br />

real “monographs”<br />

dedicated to some<br />

selected engines which, due<br />

to their complex architecture,<br />

generate some management and<br />

maintenance criticalities. The increased<br />

diffusion of automatic tensioners, which<br />

are already fitted to modern engines at<br />

design level, actually carries, together<br />

with many benefits, a collateral risk, that<br />

is a tendency for the installer to think that,<br />

in many engines, the tensioner “does<br />

everything by itself” so to speak. In reality,<br />

although these engines are equipped with<br />

automatic tensioners with<br />

an extremely simple<br />

layout, their<br />

i n s t a l l a t i o n<br />

requires specific<br />

attention and<br />

skills that must be<br />

implemented to avoid a<br />

series of rather frequent<br />

issues, from the skipping<br />

of a tooth to more serious<br />

problems, such as the<br />

failure of the tensioner. It is<br />

therefore essential that the<br />

installers are given all the necessary<br />

information to carry out the assembly<br />

correctly.<br />

«Among the engines that <strong>Dayco</strong> is treating<br />

MAY 2012<br />

11

with particular attention – explains<br />

Fantozzi – the 1.7 TD model by General<br />

Motors is one of the most widespread at<br />

the European level in the Opel and<br />

Vauxhall range».<br />

AN OFFER<br />

IN CONTINUOUS EXPANSION<br />

The ongoing search for new technological<br />

solutions, constant dialogue with the<br />

OEM producers, as<br />

well as direct and organised contacts<br />

with the end customers: these are the<br />

three pillars of <strong>Dayco</strong>`s product strategy,<br />

which have allowed, over the years, to<br />

achieve an extensive range coverage for<br />

all products, in<br />

12 POWER WORLD<br />

Product<br />

particular rigid components. As explained<br />

in detailed by Corrado Bisegna, «<strong>Dayco</strong>’s<br />

range of automatic tensioners currently<br />

includes over 500 items for each of the<br />

two product families, i.e. primary timing<br />

and accessory timing, reaching in both<br />

cases a coverage exceeding 93% of the<br />

European circulating fleet of vehicles,<br />

and therefore all the major manufacturers».<br />

As a whole, we are talking about<br />

over 1000 “single” codes that are subsequently<br />

combined within the kits according<br />

to the different engine layouts.<br />

On the other hand, the expansion of<br />

the range is an ongoing and<br />

constant process:<br />

the catalogue is<br />

updated and<br />

completed on<br />

a daily basis,<br />

in an attempt<br />

to follow as<br />

closely as<br />

possible the<br />

continuous evolution of<br />

the product on the OE market. In this<br />

respect, the horizontal integration<br />

model adopted by <strong>Dayco</strong> proves to<br />

be highly efficient. «The OE and<br />

<strong>Aftermarket</strong> Divisions – explains<br />

Bisegna – actually operate<br />

on a continuous<br />

basis: the addition<br />

of new applications<br />

is<br />

always implemented<br />

in<br />

agreement with<br />

the producer in<br />

the first place to<br />

achieve the best<br />

quality, before<br />

being transferred<br />

to the <strong>Aftermarket</strong><br />

segment, with virtually<br />

no continuity solution.<br />

In this way, we can<br />

guarantee a coverage that<br />

is not only vast, but also effective<br />

and highly functional,<br />

or guarantee products equivalent to<br />

the original at every stage of the vehicle<br />

life and in various combinations of offers,<br />

thus achieving, as we claim, “infinite<br />

possibilities”: infinite solutions for the infinite<br />

situations and requirements<br />

that may arise».

Prodotti<br />

MAY 2012<br />

13

14 POWER WORLD<br />

Prodotti

Product<br />

TB SET: solutions<br />

for every situation<br />

Researched by <strong>Dayco</strong>, one successful product line to<br />

the range are timing belt sets in one box. When a<br />

complete substitution of the transmission is not<br />

required this is the perfect solution to the garage.<br />

<strong>Dayco</strong>`s mission is to provide quality products to offer the garage every solution in the substitution<br />

of the components within the transmission, whether it be a partial or complete substitution.<br />

This is precisely the idea behind the recent introduction in the <strong>Dayco</strong> catalogue of a new product<br />

line: the TB SET. The purpose is to provide, in a single solution, the combination of two belts that<br />

are usually found in more complex timing kits, but that could be replaced, in specific situations,<br />

without involving the rest of the system.<br />

«For example on some diesel engines, the injection pump is controlled by the belt, therefore<br />

when the pump is faulty, it is sufficient to replace the flexible part of the timing system without<br />

touching the rest – explains Gianluca Fantozzi –.<br />

In other cases, a complete replacement has just been made and an additional service is required<br />

on a single part, for example the water pump». In this way, <strong>Dayco</strong> can provide the installer with<br />

specific solutions for all types of services on the engine: from the replacement (always<br />

recommended) of the whole system, including the water pump, to the fitting of the basic kit<br />

and the fitting of the belt-belt set or single “loose” component. «The mechanic can therefore<br />

choose independently, on the basis of his experience and the various situations that may<br />

occur, the most suitable tool for each application», concludes Fantozzi.<br />

In this sense, the launching of the TB SET is<br />

in perfect keeping with the mutual trust and<br />

cooperation relation between producer and<br />

spare part dealer, which <strong>Dayco</strong> focused on<br />

from the start. In no way does the TB-SET<br />

association imply a weakening of the kit<br />

solution, which remains the most<br />

recommended solution and is widely<br />

expanding on the whole European market<br />

but, on the contrary, its extension: a ‘plus’,<br />

a further facility designed for the customer<br />

who carries out partial replacements.<br />

MAY 2012<br />

15

Zoom<br />

From Moscow to Warsaw:<br />

a fast growing horizon<br />

Very different, promising and unique markets.<br />

Central-Eastern Europe proves to be one<br />

of the most strategic scenarios of the <strong>Dayco</strong>’s<br />

globalisation process<br />

From Russia to Poland, from the Czech<br />

Republic to the former Soviet Republics<br />

of Central Asia: these country’s express<br />

the extent and vastness of the market area<br />

that is generally known as Central-Eastern<br />

Europe.<br />

A region with very different requirements,<br />

cultures and vehicle parcs that <strong>Dayco</strong> started<br />

exploring about six years ago as a new<br />

territory. Initially with a limited presence<br />

that gradually expanded and eventually<br />

led to <strong>Dayco</strong> creating an important distribution<br />

network and to develop the awareness<br />

of a brand that was at the time almost<br />

totally unknown in the area. A goal<br />

achieved above all else through to the implementation<br />

in the different countries of<br />

<strong>Dayco</strong>’s core principle of cooperation and<br />

partnership between the company and<br />

it’s customer.<br />

MARKETS TO BE EXPLORED<br />

«The gradual penetration in Central-Eastern<br />

Europe was probably the most difficult<br />

challenge we had to face – explains<br />

Andrea Taverna, Regional Sales Manager<br />

Central Eastern Europe – Today we can<br />

state that even though the brand awareness<br />

has grown considerably, we need to<br />

continue to support it with targeted marketing<br />

and promotional activities in all the<br />

different areas.<br />

Within this area, Russia certainly represents<br />

the main market due to it’s size and<br />

vehicle parc. Russia is also the country<br />

where the turnover grew most significantly.<br />

«Hence – continues Taverna – the<br />

need to be present in loco. In fact, three<br />

years ago we opened an office in Moscow,<br />

in order to serve our customers more closely.<br />

The customer service, now available<br />

in Russian, was established with this purpose<br />

in mind. Furthermore, <strong>Dayco</strong> has<br />

now been present at the Moscow MIMS<br />

Fair for five years with its own stand; our<br />

presences at the show growing in proportion<br />

to <strong>Dayco</strong>’s presence within the<br />

market. Again with the aim of consolidating<br />

and strengthening the customer-partner<br />

relationship, a requirement that is<br />

even more important in a territory as large<br />

as Russia.<br />

Poland is certainly another important market<br />

and is seen to have the greatest potenial<br />

of all the countries in the. Central-Eastern<br />

Europe area. In fact it is very similar<br />

to the Italian and German markets, both<br />

for its vehicle parc size and age. In this<br />

case, the strategy being implemented is<br />

therefore slightly different to the other<br />

countries of the area. «<strong>Dayco</strong>’s activity in<br />

Poland is predominantly based on marketing<br />

and advertising activities aimed at<br />

supporting sales. Here too, we can also<br />

rely on a local team to provide customer<br />

service and maintain good daily contact<br />

and support for the customers.

GREAT POTENTIAL<br />

Zoom<br />

Continuing south of Poland, the <strong>Dayco</strong><br />

brand was introduced to the Czech<br />

Republic, to Hungary and Rumania.<br />

Rumania in particular has provided many<br />

opportunities and has enabled <strong>Dayco</strong> to<br />

establish a strong presence in the market<br />

which has resulted in new customers,<br />

brand awareness growth and sales.<br />

There are also the various former Soviet<br />

Republics, characterised by rather<br />

different economic contexts: some of<br />

which are already significant, as in<br />

Byelorussia and Ukraine, who are<br />

As well as the participation in fairs<br />

one of most efficient methods to<br />

increase and consolidate the company’s<br />

presence in a new market is to organize<br />

training activities in loco, managed<br />

by the <strong>Aftermarket</strong> staff but often organized<br />

by the customer’s themselves. Customer’s<br />

who, even if they are new, are receptive to<br />

the updating process and, in general, to the<br />

use of highly advanced technologies, in<br />

terms of logistics and supporting data processing<br />

systems.<br />

In this context, the training service offered<br />

by <strong>Dayco</strong>, in many cases part of an “academy”<br />

formula, also works as an instrument<br />

to gain the customer’s loyalty. Therefore,<br />

the aim for the future is to intensify this type<br />

of activity, transferring more and more knowhow<br />

from the company to the customer,<br />

thus stimulating as much as possible a sort<br />

of “requirement from the bottom”.<br />

In Poland, as already pointed out, the distribution<br />

situation is rather different each distributor<br />

works on the national scale, with<br />

their own regional warehouse network and<br />

owned or franchised workshops with which<br />

they maintain a direct relation. Consequently,<br />

there are no intermediaries between the distributor<br />

and the customer. As a result knowledge<br />

and information provided to the distributor<br />

is automatically cascaded down to<br />

the workshops explains Taverna. The situation<br />

is different in the Balkan region, Slovenia,<br />

Macedonia, Croatia, Bosnia, Serbia and<br />

Montenegro. «In this case – continues Taverna<br />

– there are organized distribution net-<br />

supported by the Moscow office, others<br />

are still developing, like Kazakhstan,<br />

Uzbekistan, Kyrgyzstan, Tajikistan,<br />

Turkmenistan Republics. «However, these<br />

countries have great potentials that has<br />

not yet been fully exploited.<br />

And it is this potential we are aiming at –<br />

intervenes Taverna. –We are present in<br />

each of these markets with at least one<br />

distributor, and in some cases these<br />

distributors have pre-existing customers<br />

structures that are growing rapidly. In both<br />

cases, creating a relationship of<br />

cooperation with the distribution operators<br />

becomes crucial, with the common<br />

Objective:<br />

customer loyalty<br />

works similar to the Italian or the Polish ones,<br />

but smaller in terms of numbers. In fact,<br />

these markets can be considered as immature<br />

where new structures still coexist with<br />

those of the past, like the old-style mechanic<br />

who might try to import the component directly<br />

from abroad and who only contacts<br />

the distributor when he finds himself in trouble.<br />

To conclude, as far as Eastern Europe<br />

is concerned, <strong>Dayco</strong>’s strategy of listening<br />

to the market seems to be even more important.<br />

Each market presents its own unique<br />

challenges and requirements and must<br />

be understood and translated into strategic<br />

objective of reaching, satisfying and<br />

retaining the end customer».<br />

These emerging countries have huge<br />

potentials that provides great<br />

opportunities for for the automotive sector<br />

but is characterised by a rather structured<br />

and deep-rooted competitive framework.<br />

In this context, the main challenge for<br />

<strong>Dayco</strong> is to make its brand known. When<br />

this goal is achieved, we can start working<br />

on the commercial growth.<br />

commitments. But they must also be adaptable<br />

to specific elements common to the<br />

whole area, i.e. the seasonal trends of the<br />

demand, which undergoes a considerable<br />

drop during the winter period, because of<br />

the extremely low temperatures and then<br />

followed by an explosion during the spring<br />

period . «Seasonal trend is definitely a rare<br />

characteristic in the automotive sector as it<br />

is usually not affected by the climate factor<br />

– concludes Taverna – but it is also a further<br />

confirmation of how important it is for a company<br />

like <strong>Dayco</strong>, to look at the market without<br />

prejudices or preconception, but to use all<br />

means available to understand it and to respond<br />

in the best possible manner».<br />

MAY 2012<br />

17

Anew <strong>Aftermarket</strong> production<br />

plant in the Suzhou industrial<br />

area is the most important in<br />

the Shanghai region and<br />

represents a further step forward in<br />

<strong>Dayco</strong>’s expansion in the Far East. This<br />

plant will support and complement a<br />

presence already established at a<br />

distribution and commercial level .<br />

It will also offer significant opportunities<br />

to the local community with promises of<br />

future developments and job<br />

18 POWER WORLD<br />

Zoom<br />

The eastern frontier<br />

China being one of the most important regions in the Asian market is where<br />

<strong>Dayco</strong> are focusing expansion in development and coverage.<br />

Already implemented are the sales, communication and logistics and most<br />

recently production is well under way in Suzhou.<br />

opportunities. According to Riccardo<br />

Bosco, VP General Manager <strong>Dayco</strong><br />

<strong>Aftermarket</strong> Asia, these are the main<br />

reasons that have led to <strong>Dayco</strong>’s decision<br />

to establish a production facilities a long<br />

side its existing distribution facilities – in<br />

the Chinese area.<br />

«Asia is an essential element of the<br />

globalisation and localisation strategy<br />

that <strong>Dayco</strong> is developing. And China is<br />

probably the most important market in<br />

this part of the world».<br />

PRODUCTION EXPANSION<br />

Launched in May 2011, the Suzhou plant<br />

houses two production lines, which are<br />

the most important, i.e. timing belts and<br />

accessory belts. However, due to the<br />

promising market conditions, <strong>Dayco</strong> is<br />

planning to extend this range in the near<br />

future. Currently, <strong>Dayco</strong>’s local<br />

production supports about 80% of the<br />

<strong>Aftermarket</strong> demand of the Chinese<br />

market, the remaining 20% is imported<br />

from Europe and Argentina: «This is a<br />

significant figure, which shows the<br />

company’s growing level of autonomy in<br />

this region» comments Bosco. « In<br />

addition to the aftermarket sector, the<br />

plant will also supply all the major world<br />

car manufacturers present in China, for<br />

example Volkswagen, Ford and General<br />

Motors, As well as local OE<br />

manufacturers who will also be supplied<br />

with product, particularly in the<br />

passenger car and heavy duty sectors,

Zoom<br />

with the aim of achieving a strong<br />

strategic position within the this Asian<br />

sector ». The last objective was made<br />

easier by recent acquisition from a local<br />

company in the South-East of China<br />

which specialised in the production of<br />

transmission belts for the heavy duty<br />

sector. These plants are currently<br />

undergoing, a technical-production<br />

restructuring to bring their procedures<br />

and processes in line with the standard<br />

<strong>Dayco</strong> model. While the aftermarket<br />

sector is moving with greater agility and<br />

speed, expansion in the OE sector<br />

requires more time. This is why the<br />

creation of a local production site<br />

represents a significant strategic asset,<br />

capable of bringing positive effects in the<br />

medium and long term.<br />

Furthermore, the opening of a local plant<br />

in loco, means significant improvements<br />

in terms of logistics due to the fact that<br />

transport costs are reduced and greater<br />

quantities can be handled over greater<br />

distances. The rapidly expanding<br />

Chinese market is thus provided with an<br />

improved service, at competitive prices<br />

and products that are in full compliance<br />

with the <strong>Dayco</strong> quality assurance. Bosco<br />

explains: «The production processes are<br />

the same in all our plants, from the<br />

material inspection to the quality control<br />

on the production line».<br />

A GROWING TEAM<br />

The growing production effort in the<br />

Chinese territory is obviously supported<br />

by the strengthening of the managerial<br />

and commercial activities. «The<br />

aftermarket organisation has been<br />

developed and consolidated – explains<br />

Bosco – and currently consists of a team<br />

of seven people: a sales manager, three<br />

area managers with various geographic<br />

responsibilities (North, Centre and South<br />

of the country), a person in charge of<br />

logistic planning and a product manager<br />

and a marketing manager for the<br />

customer service ». The OE organisation<br />

is also developing at the same rate, with<br />

the objective of bringing new supply<br />

opportunities for the local market, that<br />

will be made possible by the newly<br />

opened plant. «To this aim, an extremely<br />

interesting project is being undertaken in<br />

the current months, – declares Bosco –<br />

that will help <strong>Dayco</strong> develop its approach<br />

to the other aftermarket sectors of the<br />

Asian region, where two production<br />

plants already exist and where an<br />

increase in demand, would further<br />

increase their output. The distribution<br />

network that is growing in parallel is<br />

becoming increasingly diverse and<br />

widespread. Over a year, it increased<br />

from 4-5 independent distributors to the<br />

current 15, most of which are of<br />

significant size, with the aim of reaching<br />

20-25 distributors in a near future. «The<br />

covering of such a large territory requires<br />

a wide presence, capable of supporting<br />

all the major areas of demand: we are<br />

planning to start with business<br />

agreements in the areas with the highest<br />

demand potential, and expand gradually<br />

to all Chinese provinces», explains Bosco.<br />

As far as the spare parts dealers are<br />

concerned, the <strong>Dayco</strong> network currently<br />

includes approximately 30,000 people;<br />

a more accurate figure will be available<br />

when the results of specific market investigations<br />

which are still in progress are<br />

known.<br />

A PECULIAR MARKET<br />

«The Chinese market is a market that is<br />

growing at a extremely high rates –<br />

underlines Bosco – therefore it is very<br />

difficult to obtain accurate data: to obtain<br />

reliable information, we need to cross<br />

check various sources and various<br />

parameters, which complicates any<br />

analysis. Suffice it to think that, out of 14<br />

million registrations, statistics show that<br />

approximately 5-6 million vehicles<br />

produced in China evade registration».<br />

This situation is obviously worsened by<br />

the complexity of the cultural context,<br />

which requires highly specific marketing<br />

and communication strategies, mainly<br />

aimed, at this stage, at introducing the<br />

brand and making it familiar, increasing<br />

<strong>Dayco</strong>s’s brand awareness among the<br />

Chinese public, as a worldwide OE and<br />

aftermarket leader. Considering the<br />

specific features of the Chinese market,<br />

this strategic process intends to prioritise<br />

channels such as advertising billposting<br />

in large specialised automotive centres,<br />

the so-called autocenters and autoparks,<br />

and the participation in dedicated fairs<br />

and shows. «Furthering this approach,<br />

we have also planned a strong<br />

advertising presence in some of the most<br />

widespread magazines dedicated to the<br />

automotive sector, focusing first of all on<br />

the offer of a complete range of products<br />

for the production of belts, and then<br />

progressing to the promotion of other<br />

families of products», concludes Bosco.<br />

This is yet another stage of <strong>Dayco</strong>’s<br />

expansion process, that is as complex as<br />

it is stimulating and rich in diversity.<br />

MAY 2012<br />

19

R&D - Research & Development<br />

Sustainability and innovation:<br />

a team work<br />

20 POWER WORLD<br />

Reduction in emissions and increase in<br />

consumption is the potential to improve the overall<br />

performance of the engine. Not just from a<br />

supplier level on product innovation but also from<br />

vehicle manufacturers to end users. Carlo<br />

Trappolini explains from <strong>Dayco</strong>`s point of view our<br />

innovation and advanced technology of products<br />

we have collaborated with vehicle manufacturers.<br />

The continuous contact with car manufacturers<br />

for the production of original equipment<br />

has been a strategic pillar of <strong>Dayco</strong>’s<br />

philosophy, from the very beginning of its<br />

European experience. This type of cooperation<br />

has allowed <strong>Dayco</strong> to become the<br />

supplier of all the major world manufacturers<br />

in the European area: from PSA and<br />

Renault to Ford (England), from Volvo Car<br />

to Volkswagen, Daimler, Opel and BMW<br />

in Germany, as well as Fiat for Italy and,<br />

through a common platform, also Chrysler.<br />

A significant commitment that has allowed<br />

<strong>Dayco</strong> to reach a world leading position in<br />

the OEM sector.<br />

OEM<br />

<strong>Dayco</strong>’s cooperation with the producers<br />

covers, on the one hand, a specific sector<br />

of activity dedicated to the application and<br />

management of customer-centred projects<br />

and, on the other hand, a kind of special<br />

task force dealing more specifically with<br />

the HD sector. Discussed with Carlo Trappolini,<br />

[Project Manager], who is currently<br />

in charge of the management of specific<br />

development projects for the <strong>Aftermarket</strong>,<br />

after working at <strong>Dayco</strong> at first in the testing<br />

division (dynamic simulation of transmissions),<br />

then as Product Engineer, Technical<br />

Account Manager for the German market<br />

and finally as Project Manager. «All the<br />

above groups – explains Trappolini – are<br />

currently adopting massive production localisation<br />

strategies in the BRIC countries<br />

(Brazil, Russia, India and China), and we<br />

are compelled to adapt to this trend by<br />

opening new plants or developing the production<br />

plants already existing in these<br />

areas. Not only for economical reasons,<br />

but also for sustainability reasons related<br />

to the so-called “Global Footprint”».<br />

<strong>Dayco</strong> is already present in Asia and South<br />

America. «We have a plant for the production<br />

of flexible components in Argentina<br />

and a plant for rigid components in Brazil<br />

– adds Trappolini –. In China, the plant<br />

producing flexible components is already<br />

operational, whilst the rigid components<br />

are produced in India».<br />

However, the benefits of this cooperation<br />

model are best perceived in Europe, where<br />

it has reached full maturity. In fact, as a<br />

general rule, the local centres must strictly<br />

follow the instructions of the European parent<br />

company.<br />

Trappolini explains: “As a result of our will<br />

to discuss and exchange with the producers<br />

on an ongoing basis, especially as far<br />

as the most widespread engines are concerned,<br />

our OE technology, in line with the<br />

“<strong>Dayco</strong> model” i.e. the constant adjustment<br />

to the needs of the market, does not stem<br />

from “simple” observations, but from an<br />

effective cooperation, and thus from the<br />

direct experience with the producers and<br />

a thorough knowledge of the respective<br />

market requirements».

R&D - Research & Development<br />

REDUCED CONSUMPTION,<br />

REDUCED EMISSIONS<br />

Among the most pressing requests from<br />

the market in recent years, those related<br />

to the reduction of fuel consumption clearly<br />