PDF, 13Mb - Dayco

PDF, 13Mb - Dayco

PDF, 13Mb - Dayco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

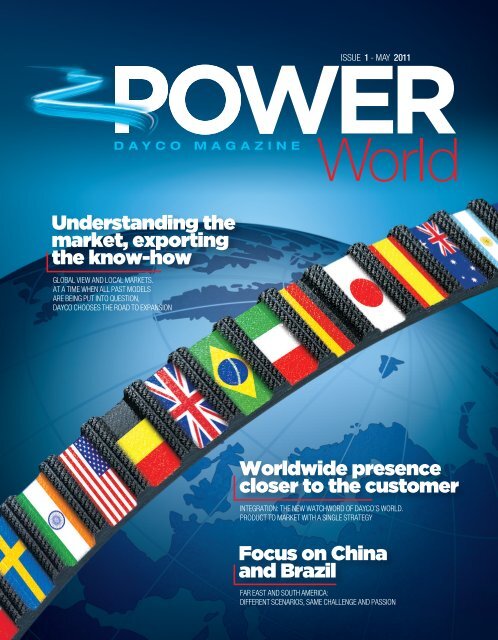

ISSUE 1 - MAY 2011

<strong>Dayco</strong>.<br />

The original power in motion<br />

www.dayco.com

Editorial<br />

®<br />

Going against the trend<br />

David Martínez<br />

President EU/SAO/Asia<br />

Localize instead of delocalize.<br />

Invest instead of disinvest.<br />

Continual growth rather than<br />

reductions. Three imperatives,<br />

three objectives and three alternatives<br />

which <strong>Dayco</strong> has chosen without<br />

hesitation, because we believe that the<br />

identity of a company is defined above all,<br />

through the choices it makes and the<br />

strategies it follows – especially when a<br />

sector is experiencing tough times.<br />

And the last few years have seen <strong>Dayco</strong><br />

going distinctly “against the trend” through<br />

our focus on expansion of productivity,<br />

sales and logistics combined with steady<br />

progress on the international stage,<br />

making <strong>Dayco</strong> today an ever more “global”<br />

company but at the same time, able to<br />

operate “locally” in each individual market.<br />

Undoubtedly, demanding directions to take<br />

but also highly rewarding ones. Indeed,<br />

through these choices, <strong>Dayco</strong> has<br />

managed to respond positively to the<br />

economic crisis that has hit the automotive<br />

industry so profoundly, by transforming<br />

difficulties into new stimulus and<br />

recognizing this situation as a call for<br />

change.<br />

A change that for us has involved major<br />

restructuring of our operations and<br />

strategies and the creation of a completely<br />

renewed organization of which I have the<br />

personal honor of being president. A more<br />

complex and international company,<br />

including three distinct geographical areas<br />

with their respective resources,<br />

opportunities and challenges, three<br />

perspectives and three general managers<br />

- (Ronald Teffeha for South America, Bruno<br />

Vallillo for Europe and Riccardo Bosco for<br />

Asia), but connected by a single basic<br />

identity.<br />

With our recent opening of facilities in<br />

China and India we have firmly begun our<br />

“venture” into the Asian market, an area<br />

which though clearly offers great potential,<br />

needs to be approached with respect and<br />

caution. We have also just launched our<br />

second factory in San Paolo, Brazil, which<br />

will enable us to fully respond to the<br />

specific requirements of South America<br />

and in Europe we are continuing to expand<br />

both our range of products and services.<br />

This is how we are responding to the<br />

delicate issue of globalization. A reality<br />

which we strongly believe does not mean<br />

a standardizing of the business<br />

relationship or the company offer, but on<br />

the contrary, a tailored and personalized<br />

approach to each market. However, we<br />

also believe that this type of approach is<br />

only possible through a consistent,<br />

regulated and interconnected<br />

organization.<br />

From this viewpoint, one of the most<br />

significant steps we have made has been<br />

to recognize the importance of the sharing<br />

of experience and methodology amongst<br />

the various internal departments and the<br />

understanding that this common<br />

knowledge is the essential factor which<br />

links the needs of the market with those of<br />

the company and provides improved<br />

efficiency.<br />

Therefore, the key objective of this phase<br />

has been global integration and<br />

specifically, the desire to create a unified<br />

network of principles and operative<br />

strategies which can be applied to the<br />

whole <strong>Dayco</strong> structure. Principles which<br />

can then be adapted to meet the needs of<br />

each particular area or sector. In fact, the<br />

concept of integration will continue to be<br />

crucial in our plans for the near future as<br />

we follow our goal of moving ever closer to<br />

the “voice of the market”…or more<br />

precisely to the voices of the diverse<br />

markets and diverse contexts in which<br />

<strong>Dayco</strong> operates, with the same passion<br />

day after day.<br />

MAY 2011<br />

1

®<br />

ISSUE 1<br />

Periodical<br />

Registered at the Ordinary Court of Pescara<br />

N. 488/2011 V.G.<br />

N. 07/2011 Print Reg.<br />

N. 72/2011 Cron.<br />

Editor<br />

Daniela Panosetti<br />

Editorial coordination<br />

Franca Pierobon<br />

Graphics<br />

Pomilio Blumm srl<br />

Via Venezia, 4 - 65121 Pescara<br />

Printing<br />

Ivrea Grafica, Ivrea - To<br />

Index<br />

4Understanding<br />

the market, exporting<br />

the know-how<br />

6<br />

Worldwide<br />

presence - closer<br />

to the customer<br />

10<br />

Range and quality for<br />

professional repair shops<br />

14<br />

Focus on China<br />

and Brazil<br />

7<br />

Growing in line with<br />

the environment<br />

How companies respond<br />

to a society aiming at a more<br />

sustainable development<br />

18 R&D aftermarket<br />

Some months ago, <strong>Dayco</strong> started collaborating<br />

with the Research & Development department<br />

on some special projects intended for the<br />

Aftermarket.<br />

31 A valuable<br />

feedback<br />

A bridge between the company<br />

and the end customer.<br />

2 POWER WORLD

D A Y C O M A G A Z I N E<br />

World<br />

May<br />

2011<br />

19 Focus 28<br />

The web,<br />

a gate<br />

to the world<br />

24<br />

The mechanic’s<br />

advice<br />

30<br />

Technical<br />

Information: an<br />

additional resource<br />

Editorial<br />

Marketing<br />

Communication and Promotion<br />

Product<br />

Zoom<br />

Research & Development<br />

Garage<br />

Abstract of new products<br />

Auto catalogue 2012<br />

1<br />

4<br />

6<br />

10<br />

14<br />

18<br />

22<br />

32<br />

MAY 2011<br />

3

Marketing<br />

Understanding the<br />

market, exporting<br />

the know-how<br />

interview to Bruno Vallillo<br />

Global view and local markets.<br />

At a time when all past models are being put into<br />

question, <strong>Dayco</strong> chooses the road to expansion<br />

Bruno Vallillo<br />

Vice President<br />

General Manager Europe<br />

Acrisis<br />

is<br />

an<br />

opportunity to<br />

reconsider and<br />

modify all past<br />

e c o n o m i c<br />

models –<br />

s a y s<br />

Bruno<br />

Vallillo, Vice President – General Manager<br />

Europe. «Provided of course, that we<br />

understand and interpret it rightly. This<br />

means, first and foremost, the capacity to<br />

understand the needs of the market».<br />

And the market – in particular the<br />

Aftermarket sector – is showing an ever<br />

increasing quality and variety in terms of<br />

products and services. «Quality and range<br />

have always been the pillars of our model<br />

- explains Vallillo - and we intend to<br />

continue in this direction, offering the<br />

utmost in terms of information,<br />

applications and support. The aim is to<br />

give all our customers, from the spare part<br />

dealer to the mechanic, the ability to<br />

respond simply and efficiently to all<br />

possible repair scenarios».<br />

BETWEEN PRESENT AND FUTURE<br />

The figures from the last two years<br />

indicate that this objective has already<br />

been reached to a great extent. In<br />

Europe the results have been excellent,<br />

both in terms of turnover, market<br />

response and development of customer<br />

loyalty.<br />

«Experience has taught us not only the<br />

importance of understanding the<br />

market - which products to develop<br />

and when and how to put them on<br />

the market – but also to give the<br />

customer the maximum confidence in<br />

their use as well as in our support».<br />

Quality therefore, refers not only to the<br />

quality of the product but also to the<br />

service provided. And if we guarantee<br />

this, we manage to make the customer<br />

feel part of the company – a difficult<br />

challenge but of the greatest importance.<br />

In <strong>Dayco</strong>’s vision, objectives which are<br />

reached are not simply points of arrival,<br />

but rather stepping stones for the next<br />

stage. In fact, all our future projects<br />

involve new investments not only<br />

consolidation - in terms of production and<br />

distribution, but also in terms of<br />

communication and marketing. «We are<br />

continuing to open regional warehouses<br />

in our areas of interest – explains Vallillo<br />

– with the aim of reducing the reaction<br />

time to the market and responding to local<br />

demand as rapidly and efficiently as<br />

possible – and this demand can vary<br />

greatly according to the different contexts<br />

in which we operate».<br />

This particularly refers to the emerging<br />

markets, where the rising number of<br />

customers requires a parallel and<br />

constant improvement of local<br />

communication strategies, to achieve an<br />

ever increasing “personalisation”. «We<br />

must not forget – emphasizes the Vice<br />

President – that our sector embraces<br />

many languages, many messages and a<br />

great number of structures. It is therefore<br />

4 POWER WORLD

necessary to know how to use different<br />

approaches, in the belief that personalisation<br />

means moving closer to the<br />

customer: it is up to us to understand their<br />

needs and not up to them to comply with<br />

our standard».<br />

STANDARDIZING<br />

AND PERSONALISING<br />

But how can these two apparently<br />

opposing principles, i.e. standardisation<br />

and personalisation, be combined In<br />

reality the globalisation of some aspects<br />

does not exclude the diversification of<br />

others. <strong>Dayco</strong> has always focused on this<br />

approach: “Standardisation of internal<br />

processes (production, logistics and<br />

information technology) on which the<br />

international brand identity is based, and<br />

personalisation of products and services,<br />

i.e. those aspects which the final user<br />

receives. Therefore, sums up Vallillo,<br />

«globalisation of the brand identity<br />

through the internal exchange of<br />

experience and models, but not the standardization<br />

of the relationship with the<br />

market. We must use the same “internal<br />

language” all over the world, whilst<br />

recognizing the need for different<br />

“external languages” in each country in<br />

order to adapt to the diverse contexts, car<br />

parcs, customs and practices».<br />

A model which seems a return to the<br />

original marketing vision where<br />

production meets the demand and<br />

“speaks” to the customer without the<br />

need to “pressurize” or impose the<br />

purchase of a product. «We can influence,<br />

but we cannot condition a market»,<br />

confirms Vallillo. It is in this sense, he<br />

adds, that we must understand the<br />

concept of “flexibility” which has always<br />

been central to the <strong>Dayco</strong> model.<br />

Essentially, this signifies «aiming at the<br />

expansion of the range rather than the<br />

quantity produced per item» and above all,<br />

localising production according to specific<br />

markets – a process we are<br />

implementing in China for the Asian<br />

market, as was done in the past for<br />

Europe, i.e. «exporting to other areas that<br />

important bank of knowledge that<br />

represents our added value».<br />

EXCHANGE OF EXPERIENCES<br />

Consistent with the strategy of exporting<br />

knowledge acquired from past experience<br />

to new contexts, the company is investing<br />

extensively in the Aftermarket sector. In<br />

this case, it is the valuable experience<br />

gained in the Original Equipment sector<br />

and in particular the European market,<br />

(much more complex than it first appears),<br />

which is being “transferred” and adapted.<br />

«It is important to stress that when we<br />

speak about know-how, we are not only<br />

referring to knowledge of the product, but<br />

also of the system, logistics, marketing<br />

and communication – specifies Vallillo –<br />

Most of all, the ability to acquire this<br />

knowledge through analysis and research<br />

and to adapt our global structures to local<br />

requirements as quickly as possible, as<br />

mentioned earlier».<br />

The Original Equipment sector is also<br />

beginning a process of exchanging<br />

experience - a trend illustrated by the<br />

increasing number of mergers, joint<br />

ventures and takeovers. In this respect,<br />

<strong>Dayco</strong> has even anticipated this<br />

movement: «An unavoidable choice, as<br />

the approach to the Aftermarket is<br />

generally less rapid due to the fact that we<br />

“arrive” on the market after the vehicle is<br />

sold. We must consider everything –<br />

communications, logistics, equipment,<br />

market analysis – which all takes time;<br />

Therefore, if we don’t want to fall behind,<br />

we must think ahead».<br />

Furthermore, a specific consequence of<br />

personalisation that must be taken into<br />

account is the decreasing number of<br />

engine types, which are becoming more<br />

standardised due to the economies of<br />

scale. At the same time the number of<br />

actual vehicles is increasing and the<br />

proportion of diesel and petrol engines is<br />

changing. «In the European market, for<br />

instance, we are the leaders in diesel<br />

applications and we are continuing to<br />

invest. Following the enormous sales<br />

boom of a couple of years ago, this is a<br />

sector which requires sophisticated<br />

solutions and a quality guarantee<br />

equivalent to that of Original Equipment».<br />

There is also the second-hand car market<br />

which is experiencing a significant growth<br />

in some countries, as occurred in the past<br />

in Eastern Europe, and which naturally<br />

stimulates the replacement sector; Also<br />

here, the crisis is an opportunity because<br />

reduced spending power has increased<br />

the tendency to buy second-hand cars<br />

and to make them last as long as possible.<br />

«In this sense it is very important to<br />

anticipate the changes of trends in the<br />

“flow” of vehicles. In the past, for instance,<br />

following generous government scrapage<br />

schemes, there was a massive transfer of<br />

used cars to other countries».<br />

Today, a vehicle remains longer in the<br />

country where it is sold: this change of<br />

trend must be taken into account and<br />

faced. Keeping in mind the principle that<br />

has always been the guideline for <strong>Dayco</strong>’s<br />

development - «Understanding the<br />

product and understanding the market»<br />

– concludes Vallillo – «It is the synergy of<br />

these two objectives which provides the<br />

firm model from which each new<br />

experience and each change can be<br />

developed».

Communication and Promotion<br />

Worldwide presence -<br />

closer to the customer<br />

“A single, uniform image showcasing its main aspects. But at the same<br />

time tailored and suited to the single markets in which <strong>Dayco</strong> operates.”<br />

This is how Franca Pierobon, Communication Manager, summarises the<br />

integration strategy that the brand is developing.<br />

Starting from a Fair Plan that is increasingly end-user oriented<br />

Franca Pierobon<br />

Communication Manager<br />

Integration: if one could sum up in a<br />

single objective the totality of the<br />

strategies and organizational models<br />

implemented by <strong>Dayco</strong> in all the main<br />

business sectors – from production to<br />

logistics, from marketing to product<br />

management – this would be precisely<br />

the “strong” concept that comes to mind.<br />

Integration intended as an internal organisational<br />

model capable of fostering<br />

shared exchanges of skills between the<br />

various departments, as well as an<br />

external expansion strategy, enabling to<br />

export and adapt the acquired<br />

experiences to new contexts.<br />

In this framework, it is natural that the<br />

communication activities, internal as well<br />

as external, adopt the same vision, under<br />

the sign of transversality and flexibility.<br />

«The first step – explains Franca<br />

Pierobon, in charge of Communications<br />

– was to create a coherent and unitary<br />

communication format at the European<br />

macro area level, which so far has proven<br />

to be very functional». This was achieved<br />

through the constant optimisation of<br />

some key concepts such as innovation,<br />

dynamism, continuous development,<br />

technology. Today, the challenge consists<br />

in “exporting” this model to the other two<br />

macro areas, i.e. Asia and South<br />

America.<br />

In line with the more general trend, that<br />

tends to reconcile standardisation and<br />

personalisation, «the communication<br />

strategy is planned to present first of all<br />

a unique and uniform image in its main<br />

aspects – starting with the “quality and<br />

range” dual theme – but all the same<br />

time personalised to the single markets».<br />

This applies to external communications,<br />

addressing different customers, from the<br />

spare parts dealer to the car repair shop.<br />

But the same principle also governs<br />

internal communications, with an impact<br />

on various aspects of everyday business,<br />

for instance in the relations between the<br />

European marketing and the Chinese or<br />

South American marketing, which still<br />

speak very different languages. «The<br />

prospect – continues Pierobon – is to<br />

standardise these different approaches,<br />

whilst adapting them to the local<br />

requirements».<br />

“This is a communication strategy<br />

running on two parallel tracks: «On the<br />

one hand, the institutional<br />

communication purely concerned with<br />

the brand positioning, that will gradually<br />

tend to convey a single message with the<br />

same language: the brand identity. On<br />

the other hand, the product and<br />

marketing communication, which will<br />

produce more specific and localised<br />

messages, whilst fully adopting the<br />

concept of our corporate vision. ».<br />

NEW MARKETS, SAME TARGET<br />

This is exactly what was done, for<br />

instance, at the last Shanghai Exhibition<br />

6 POWER WORLD

Communication and Promotion<br />

in December: «In China, we have<br />

concentrated on <strong>Dayco</strong>’s brand<br />

positioning, explains Pierobon – mainly<br />

focused on Brand communication and, at<br />

the same time, on the introduction of<br />

product communication, limited for now<br />

to a single line: the timing belts. Talking<br />

about more complex applications in that<br />

context would be premature at the<br />

moment».<br />

In fact, whilst in mature markets –<br />

essentially those of the original Europe,<br />

i.e. Italy, Spain, France, Great Britain,<br />

Germany – the kit culture has been<br />

widely assimilated, in all the emerging<br />

markets, including Eastern Europe,<br />

product communication must be<br />

calibrated according to the different<br />

contexts.<br />

Besides China, the other area of great<br />

interest is South America for which,<br />

however we anticipate faster and easier<br />

integration times and procedures<br />

considering the many cultural analogies,<br />

not forgetting the “language” analogy<br />

with the other Latin countries.<br />

Another basic principle of <strong>Dayco</strong>’s<br />

communication strategy is the capacity of<br />

addressing its targets, i.e. spare parts<br />

dealers and car repair shops in an<br />

increasingly direct and efficient way.<br />

«And – explains Pierobon – the multifunctional<br />

virtual garage space created on<br />

the website which will be further<br />

implemented and complemented with<br />

technical information and other tools, is<br />

designed just for them».<br />

The main purpose of this and other tools<br />

is to support the customer in his daily<br />

work, offering him a concrete and<br />

functional help in his various activities. It<br />

is therefore extremely important to use all<br />

types of communication tools, from<br />

traditional tools to online tools, leaving<br />

behind the classical business to business<br />

model. In addition, the use of the Internet<br />

offers to the mechanics a means to keep<br />

up to date, not only in real time, but also<br />

in a targeted and personalised manner,<br />

according to their current needs.<br />

Constant updating, especially on purely<br />

technical aspects, is clearly essential in<br />

this field. However these new tools will<br />

continue to be supported by the direct<br />

training service through our technicians<br />

who will still operate directly in the field,<br />

giving specific courses that <strong>Dayco</strong><br />

organises free of charge, usually in<br />

coordination with the resellers. In Italy,<br />

these courses are experiencing a<br />

constant growth both in terms of<br />

attendance and participation.<br />

ENTERING THE TERRITORY:<br />

THE FAIR PLAN<br />

Mechanics and spare part dealers are<br />

currently the company’s main<br />

interlocutors. The aim is to complement<br />

Growing in line<br />

with the environment<br />

How companies respond<br />

to a society aiming at a more<br />

sustainable development<br />

All the contradictions of our<br />

economic and social<br />

development model are<br />

ever so convincingly<br />

highlighted by the global crisis and the<br />

unrelenting thrust imposed by<br />

technological development. Financial<br />

crises, energy crises, natural<br />

disasters, emphasize the fragility of the<br />

world we have built. These issues have<br />

been investigated for many years by<br />

eminent experts, from Bauman to<br />

Giddens to name a few, who<br />

attempted, through their vision, to<br />

outline a profile of what we are and<br />

what possible alternative routes we<br />

can follow.<br />

Today, the corporate world still<br />

develops on two levels with, on the one<br />

hand, companies that are seriously<br />

committed to developing innovation<br />

and corporate social responsibility,<br />

including the themes of environmental<br />

responsibility and, on the other hand,<br />

companies that, for a number of<br />

reasons, not all of them dependent on<br />

their own responsibility, find it difficult<br />

to understand the value of<br />

environmental protection as a strategic<br />

factor of development of their<br />

products.<br />

Over twenty-five years ago, Freeman<br />

exposed for the first time the concept<br />

of Corporate Social Responsibility.<br />

Since then, owing to the significant<br />

contribution of the European Union, a<br />

new course was taken which, with the<br />

introduction of certification processes,<br />

helped stimulate the growing<br />

awareness of the company’s social<br />

and ethic role towards all stakeholders<br />

(employees, suppliers, citizens,<br />

institutions, consumers, etc.) and the<br />

territory where they operate.<br />

It is undeniable that the role of Europe<br />

was a driving force for research and<br />

Francesco Pira<br />

Sociologist, National Adviser<br />

of the Italian Association<br />

of Public Communication<br />

innovation, and many Italian<br />

companies adopted and followed the<br />

trend. This is proved by the increased<br />

attention to production processes,<br />

ongoing research on new materials<br />

and the fact that Italian companies<br />

have become leaders in Europe in the<br />

field of renewable energy and related<br />

technologies. This trend also results<br />

from the 2009 MAE Award experience<br />

(the award for Environmental and<br />

Ethical Marketing sponsored by the<br />

Italian Association of Public and<br />

Institutional Communication and by<br />

GUS - Press Agency Group), intended<br />

to call attention to the commitment of<br />

some companies such as <strong>Dayco</strong>,<br />

capable of making changes. The jury<br />

decided to reward this particular<br />

company for its ability to communicate<br />

in a consistent and efficient way, both<br />

formally and linguistically, the<br />

importance of product technical<br />

innovation.<br />

MAY 2011<br />

7

Communication and Promotion<br />

the communication directed to the trade,<br />

the distributors who have always played<br />

the part of intermediaries between the<br />

producer and the purchaser, with a<br />

communication expressly designed for<br />

the so called “end user”.<br />

For this reason, taking part in international<br />

and local fairs has become more and<br />

more important.<br />

The major appointments in the shortmedium<br />

term are the Bologna<br />

Autopromotec and the Automechanika<br />

Fair in Frankfurt, by far the main event at<br />

international level in the sector. These<br />

events are particularly strategic for <strong>Dayco</strong>:<br />

Automechanika, attended by all the main<br />

brands, weighs greatly in terms of image<br />

and public relations; Autopromotec,<br />

focused on mechanics, is fundamental to<br />

reach this specific target and to open a<br />

direct dialogue, not a business dialogue<br />

but a promotion and information<br />

dialogue.<br />

For the Bologna Fair in particular, many<br />

novelties are planned. First of all, the new<br />

Auto and Scooter catalogues will be<br />

presented, with reviewed contents and<br />

restyled graphic design, in order to further<br />

facilitate the choice of products and the<br />

information presentation. An important<br />

space will be dedicated to the complete<br />

water pump range and, first of all, to the<br />

Long Life +1 project, already presented<br />

with success on other markets, for<br />

example at the Frankfurt Fair, but that will<br />

find its more natural environment at<br />

Autopromotec.<br />

Obviously, <strong>Dayco</strong>’s presence at fairs is<br />

closely related to its presence on the<br />

various markets. For this reason, outside<br />

the European context, a key event was<br />

first singled out for each of the two<br />

reference macro areas: this year, for the<br />

Asian market, the main reference will<br />

naturally be the International<br />

Automechanika Fair in Shanghai, while<br />

for the South American market, the main<br />

appointment will take place in San Paolo,<br />

Brazil.<br />

Once again, in line with the strategy<br />

combining global presence and local<br />

roots, the idea is to be present at<br />

exhibition events on two levels: obviously<br />

taking part in the main international fairs<br />

of the sector, but also working on the<br />

specific target of local events, which are<br />

numerous in Europe and are continuously<br />

spreading, in particular in the emerging<br />

markets, such as Poland, Bulgaria,<br />

Russia, Uzbekistan, Azerbaijan.<br />

As Franca Pierobon anticipates: «Specific<br />

events will be organised for the various<br />

markets and will be designed and<br />

“tailored” according to the actual<br />

requirements of our targets.<br />

I am thinking of ideas such as evening<br />

conventions or road shows, that may<br />

depart from the traditional B2B model,<br />

but are more efficient than fairs in<br />

creating dialogue opportunities and direct<br />

exchanges with our target. In this way, the<br />

target will not have to come and look for<br />

us at the various fairs to get to know our<br />

products and services, because it will be<br />

us who will go and talk to them directly on<br />

their working place”.<br />

Let DAYCO show you the way<br />

Welcome to <strong>Dayco</strong> world:<br />

games, mini-courses and plenty<br />

of gadgets to stimulate your passion.<br />

Torque wrenches, overalls, <strong>Dayco</strong><br />

Tool 6, USB keys.<br />

These are just some of the prizes<br />

<strong>Dayco</strong> has decided to offer for the<br />

launch of its new virtual game “Test<br />

your ability”, soon available online<br />

on our Web site. How can you win<br />

You just have to give the correct<br />

answer, as fast as possible, to five<br />

easy questions on <strong>Dayco</strong>’s world.<br />

But as it is the taking part that counts,<br />

anyone giving a wrong answer will not<br />

leave empty-handed.<br />

The first players will be able to<br />

measure themselves against the<br />

virtual “prize contest” before<br />

everybody else at the next<br />

Autopromotec Fair in Bologna.<br />

<strong>Dayco</strong> is inviting you to a unique<br />

opportunity to meet, get information<br />

and have fun together.<br />

Fiera di Bologna<br />

25 - 29 maggio 2011<br />

8 POWER WORLD

Product<br />

Range and quality<br />

for professional<br />

repair shops<br />

Product alignment, development of the Asian range and extension of the HD pump offering,<br />

whilst the “kit culture” is developing, particularly in Europe, and the basic concept of<br />

transmission system is getting increasingly successful at all levels.<br />

Corrado Bisegna, <strong>Dayco</strong> Product Manager, details the main technical and productive innovations,<br />

and announces a new benefit: the Agri catalogue<br />

Reading the market<br />

requirements. Reacting as<br />

quickly as possible. At times<br />

even anticipating them. These<br />

are the pillars of the product management<br />

activity for <strong>Dayco</strong>. And today, this mission<br />

of “listening to the market” is strengthened<br />

and diversified by the primary objective of<br />

product and process integration, the<br />

watchword of the current expansion phase<br />

of <strong>Dayco</strong> in new commercial and<br />

productive sectors.<br />

Besides, the synergy between the various<br />

sectors of product management has<br />

always been a primary guideline in this<br />

sector, but today, faced with the double<br />

challenge from the Asian and South<br />

American markets, the creation of a single<br />

integrated system has become crucial.<br />

Obviously, the distribution of the different<br />

product lines in the various contexts<br />

necessarily follows different timings – for<br />

the Asian market, for instance, this applies<br />

only to belts; rigid components will come<br />

later. But it is precisely why it is important<br />

at this stage to carry out a systematic<br />

alignment of the products, that is to<br />

guarantee “upstream”, for each line, the<br />

same coding system that will be<br />

subsequently managed according to the<br />

different requirements and timings of the<br />

single markets.<br />

ALIGNING THE PRODUCTS,<br />

DIFFERENTIATING THE MARKETS<br />

In technical terms, this is called “product<br />

alignment”, and it is already under way in<br />

South America. «In substance, it consists<br />

in identifying the coexistence of the same<br />

item in different markets and verifying its<br />

code, which is then different for each micro<br />

area – explains Corrado Bisegna. The aim<br />

for the near future, is to be able to trace<br />

back the common parts, i.e. those<br />

circulating in Europe as well as in South<br />

America and Asia, to a single code so that<br />

they can be treated by the various business<br />

units through the same management<br />

database. This will also guarantee the<br />

markets specificities; which remain distinct<br />

“upstream” ».<br />

For this purpose, the European codifying<br />

system will be used as a reference, thus<br />

enabling <strong>Dayco</strong> to “cover” with a single and<br />

same “glance” approximately three<br />

quarters of the world market. Even better,<br />

this will allow to “anticipate” the integration<br />

of new products, which will be immediately<br />

inserted in the new <strong>Dayco</strong> catalogues with<br />

the same code as soon as the system is<br />

finished and implemented, with significant<br />

benefits in terms of “response” immediacy<br />

to the market.<br />

«It is clear – underlines Bisegna – that all<br />

this will require a certain period of<br />

adjustment for the customer. Afterwards,<br />

it will be up to the units of the various areas<br />

to support the customer in this transition<br />

phase, helping him to “get used” to the<br />

new codes”.<br />

HD PUMPS: ANTICIPATING<br />

THE MARKET REQUIREMENTS<br />

This general integration and globalisation<br />

framework will also include the single<br />

actions for each line of product. Among<br />

these, the growing attention dedicated to<br />

the water pump range, recently included<br />

in the HD catalogue (Industrial vehicles) is<br />

striking. «This decision – explains Corrado<br />

Bisegna, Product Manager, – was<br />

motivated by the leadership position that<br />

<strong>Dayco</strong> already occupies in the HD segment<br />

as far as belts and tensioners are<br />

concerned. This is why it appeared obvious<br />

to us to complete the offer with the water<br />

pumps ».<br />

On the other hand, the water pump needs<br />

replacement with more or less the same<br />

frequency as the other components. «As<br />

part of the system – continues Bisegna –<br />

the water pump must be considered as a<br />

transmission component just like the<br />

others, and therefore equally subject to<br />

acceleration stress, thermal expansion,<br />

10 POWER WORLD

Product<br />

dust, etc.». Consequently, in case of failure,<br />

the collapse of the pump can affect the<br />

entire system, thus the importance of<br />

preventive maintenance.<br />

PRODUCERS OF SYSTEMS<br />

Increasing the water pumps offering, both<br />

as single components (HD) and in the kits<br />

(Auto), is aimed at covering the<br />

transmission system concept in its totality<br />

and giving the customer the possibility to<br />

carry out a complete replacement, if<br />

needed. With all the implied benefits in<br />

terms of safety and quality. In fact, it should<br />

be stressed that these pumps are not<br />

“reconditioned” pumps”, but brand new<br />

products manufactured by carefully<br />

selected suppliers that are covered by<br />

<strong>Dayco</strong>’s guarantee.<br />

Some 70 HD pumps and more than 100<br />

Auto pumps are currently available in the<br />

catalogue, but the range is increasing<br />

constantly, with the objective of covering<br />

about 70-80% of the market.<br />

Within the HD market, <strong>Dayco</strong> plays a pilot<br />

role, relying on the positive experience<br />

already acquired in the motorcar sector,<br />

where the “kit culture” is increasingly<br />

spreading, together with the importance of<br />

preventive maintenance, which is<br />

particularly important when it comes to<br />

working vehicles: «In fact, a stationary<br />

truck, or a stationary bus, for example, can<br />

cause considerable problems, including<br />

from an economic point of view. To prevent<br />

these problems, we feel that giving the<br />

customer the possibility to get a<br />

guaranteed and selected product directly<br />

from <strong>Dayco</strong> is a new and important<br />

system».<br />

If we consider that the part production is<br />

supported by a capillary network of<br />

suburban stores, in Europe as well as in the<br />

other areas, it becomes possible to fulfil all<br />

requests in an extremely short time,<br />

reducing at the same time the costs<br />

resulting from the vehicle downtime. The<br />

savings in terms of time are obvious, and<br />

the workshop intervention is also<br />

facilitated: In fact, the repair shop does not<br />

have to look for the most suitable product,<br />

as a complete offer of specific products is<br />

immediately available for this given vehicle<br />

in the catalogue.<br />

KITS AND COMPONENTS: ENDLESS<br />

SOLUTIONS<br />

<strong>Dayco</strong>’s competitive “strength” lies in the<br />

innovative choice of presenting itself first<br />

of all as a producer of systems and not only<br />

of single components. Bisegna adds: «This<br />

is also what makes us different from the<br />

simple trader, behind each product, there<br />

is the will to make life easier for our<br />

customers, calling for an in-depth study of<br />

the requirements and needs on which our<br />

offer is “tailored” ». A positioning and<br />

service choice perfectly in line with the<br />

transmission system concept, which<br />

springs from the idea that, for a<br />

transmission to operate at its best, it must<br />

be considered as part of a system.<br />

The entire kit offer is actually based on this:<br />

anticipating as much as possible the<br />

customer’s needs and giving him, in a<br />

single solution, everything he may need to<br />

solve a specific repair situation – from the<br />

bolt to the belt, to the washer – avoiding<br />

movements, searching and a waste of time<br />

and energy: «And offering at the same time<br />

the thorough quality guaranteed by <strong>Dayco</strong>,<br />

which is not always available in other split<br />

product offers, as well as a careful rationalisation<br />

of the contents, presentation<br />

and packaging of the kit, which is<br />

designed to be as functional and orderly<br />

as possible».<br />

To achieve this, the kits have been<br />

designed in various “sizes”: from the<br />

single pack including a belt and a<br />

tensioner, to the complete pack which also<br />

includes the water pump.<br />

Even though the advice is to always carry<br />

out a complete replacement, we want to<br />

give the customer the opportunity to<br />

choose the degree of intervention that is<br />

actually necessary. «The aim is to always<br />

give the customer exactly what he needs,<br />

to install exactly what is needed for each<br />

single situation. This is what the catalogue<br />

is intended to be: an offer of solutions,<br />

endless solutions.”<br />

This is made possible by the extensive<br />

product range which, in Europe, covers<br />

approximately 97% of the circulating fleet.<br />

The increase of the kits sales proves that<br />

the customers did perceive the message<br />

very well: it is better to think in terms of<br />

system rather than in terms of single<br />

component.<br />

FROM CUSTOMER<br />

TO PRODUCER AND BACK<br />

But what<br />

does the<br />

w o r k<br />

of “anticipation” of the customer’s needs<br />

consist in In which manner is <strong>Dayco</strong><br />

capable of “intercepting” the market’s<br />

needs, interpret them and finally translate<br />

them into single product projects<br />

In this process, a crucial role is played by<br />

internal communication which, as a result<br />

of the ongoing exchange between areas<br />

and departments, allows us to transmit to<br />

the various sections all the information and<br />

motivation “gathered” in the field by the<br />

trade, through dialogue and exchange with<br />

the customers.<br />

To this effect, the role of the technician is<br />

particularly important as he can gather and<br />

interpret this information in the best<br />

possible way, and report it to the company.<br />

A highly technical channel is also available,<br />

based on the information sent by the official<br />

support network and backed by<br />

external services of information<br />

supply and market analysis,<br />

resulting from sector<br />

surveys. « We also<br />

receive crucial<br />

indications<br />

from our<br />

o w n<br />

MAY 2011<br />

11

Product<br />

WATER PUMPS: OPERATION<br />

The water pump used in motor vehicle engines is<br />

usually of the centrifugal type and generally consists<br />

of an impeller that can be in metal<br />

or thermoplastic material; its<br />

duty is to guarantee the<br />

forced and pressurised<br />

movement of the coolant -<br />

a mixture of water and<br />

antifreeze providing a high<br />

boiling point - inside the<br />

engine cooling system.<br />

The impeller is operated by a<br />

pulley to which it is connected by a rigid shaft that<br />

rotates on bearings, and the pulley is usually<br />

departments, in<br />

particular from the R&D<br />

department and, through to<br />

testing and direct contact with the<br />

manufacturers, they can guarantee and<br />

communicate the continuous product<br />

improvements».<br />

operated in turn by<br />

the timing belt.<br />

The purpose<br />

of the pump is to<br />

help eliminate the heat<br />

created by the engine operation and to<br />

maintain the heat balance within the range<br />

defined by the design engineers<br />

thus contributing to its<br />

correct functioning,<br />

limiting power losses and<br />

reducing fuel consumption<br />

and pollution.<br />

important line of products and, in<br />

general, of the number of applications, in<br />

particular on the Asian market, mainly<br />

from Japan and Korea, that are<br />

increasingly present on the European<br />

market.<br />

This important step toward the completion<br />

of the range offer<br />

has actually already reached 97% and<br />

covers all the world manufacturers. As<br />

Bisegna points out, «the completion<br />

process proceeds by saturation of very<br />

small uncovered “islands”. In general,<br />

however, we start from the belt and then<br />

add the tensioner and finally the kit». The<br />

catalogue is a product in continuous<br />

evolution, intended to “take a snapshot” of<br />

the market as a whole in any given<br />

moment, but also to include new products<br />

as new vehicles are launched on the<br />

market”.<br />

In addition to the quantitative increase of<br />

the range, a good catalogue also requires<br />

a qualitative evaluation of the different<br />

markets. As, for instance, the HD<br />

catalogue that includes – the first one in<br />

Europe for this product – a certain number<br />

of applications for heavy vehicles produced<br />

in the USA, designed to fulfil specific<br />

market indications, mostly coming from<br />

Eastern countries. It should be also kept in<br />

mind that, in the case of Europe, among<br />

the three main markets – France, Italy and<br />

Spain – the latter registers an increasing<br />

diffusion of the Asian range.<br />

THE NEW CATALOGUE:<br />

RICHER, MORE FUNCTIONAL<br />

The new Auto catalogue,<br />

Edition 2012 was designed<br />

and prepared on the<br />

basis of all this<br />

information. Richer,<br />

more functional,<br />

more userfriendly.<br />

Unlike<br />

the previous<br />

edition, the<br />

new catalogue<br />

will allow users to check the<br />

generation of each vehicle and to look for<br />

the corresponding component.<br />

Altogether, the number of the indexed<br />

codes has increased from 3.000 to 4.000.<br />

As mentioned before, there has also<br />

been an increase of the percentage of<br />

kits, which have become the most<br />

The most<br />

recent analyses<br />

show that the<br />

Asian vehicles<br />

account for<br />

approximately 15%<br />

of the European<br />

circulating fleet and<br />

<strong>Dayco</strong> continues to<br />

12 POWER WORLD

Product<br />

guarantee the coverage of 80 to 90% of<br />

this share.<br />

The Scooter catalogue, on the other hand,<br />

has been increased with about 150 new<br />

applications, to meet an ever increasing<br />

demand, in particular for Kevlar belts,<br />

which can provide maximum power<br />

transmission of the engine and reduce<br />

skidding, even in high stress conditions.<br />

TOOLS FOR ALL TYPES<br />

OF REQUIREMENTS<br />

Supporting and helping the end-customer<br />

as much as possible in the direct work on<br />

the engine has always been one of the<br />

principles of <strong>Dayco</strong>’s Aftermarket service.<br />

It is for this purpose, for example, that the<br />

offer of <strong>Dayco</strong> tools was created and is<br />

rapidly developing.<br />

This offer includes a series of tools required<br />

to assemble products with specific<br />

replacement features, such as the<br />

alternator free wheel, which must be<br />

replaced using special wrenches (Tool 4,<br />

Tool5 and Tool 7: the complete set of<br />

wrenches).<br />

The <strong>Dayco</strong> TOOLS range also includes a<br />

set of tools designed to facilitate the<br />

installation of elastic belts.<br />

These wrenches are supplied as<br />

“disposable” products in the elastic belt<br />

kits PVE001 and PVE002, specific for Ford<br />

applications, whilst for all other<br />

applications, <strong>Dayco</strong> supplies a universal kit<br />

of tools (TOOL6) ready and easy to use.<br />

Lastly <strong>Dayco</strong> proposes a sophisticated tool,<br />

the tensiometer, which allows to check the<br />

correct installation of the timing belts.<br />

Together with its computer software, the<br />

tensiometer checks the correct tension of<br />

the belt, which is a very important<br />

parameter to guarantee the mileage<br />

indicated by the car manufacturers. The<br />

Tools availability shows how <strong>Dayco</strong> is<br />

concerned not only by the quality of the<br />

product, but also by the simplicity of use,<br />

making the repair activity easier for the<br />

repair shops.<br />

DISCOVERING<br />

THE WORLD OF AGRICULTURE<br />

<strong>Dayco</strong> has now been working for some<br />

time on the development of a catalogue for<br />

a new line of products, dedicated to<br />

agricultural machinery: this world is much<br />

more complex than one might think, as it<br />

ranges from the small grass cutter up to<br />

the enormous combine, with systems that,<br />

in some cases, include dozens of belts. «In<br />

many cases, however, these machines are<br />

fitted with engines that are identical to<br />

those fitted on the HD line. <strong>Dayco</strong> will focus<br />

its attention on the tractors, including a<br />

range from 70 to 390 hp».<br />

The agricultural machine sector represents<br />

the typical niche market, extremely limited:<br />

approximately 8 million units in all of<br />

Europe, that are highly fragmented into a<br />

huge quantity of models: from special<br />

tractors to crawlers, from double traction<br />

tractors to those specific for orchards and<br />

so on .<br />

This market is also very peculiar from a<br />

competitive point of view, as it is essentially<br />

controlled by a few large groups of<br />

producers, starting from New Holland<br />

which, for example, fits mostly Iveco<br />

engines and for which it usually supplies<br />

directly the spare parts. «With this new line,<br />

<strong>Dayco</strong> will be among the first actors in the<br />

sector to propose a specific Aftermarket<br />

range of products for tractors».<br />

It should also be kept in mind that an<br />

agricultural vehicle has an extremely long<br />

life cycle; it is built to last for several<br />

decades and this represents both an<br />

advantage and a drawback for the spare<br />

parts dealer: «On the one hand, it is in the<br />

interest of those buying an agricultural<br />

machine to carry out a constant, accurate<br />

and preventive maintenance. In fact, even<br />

if they are used only for a few months a<br />

year, these machines work in extreme<br />

conditions, under the rain or on uneven<br />

grounds which highly stress the<br />

transmission components. On the other<br />

hand, however, the type of activity implies<br />

that it is often the machine’s user who<br />

replaces the parts, without going through<br />

the mechanic». The objective of the<br />

catalogue is to offer to the end-customer<br />

the opportunity to choose the spare part<br />

independently, in line with the still<br />

“traditional” tendency that characterizes<br />

maintenance in this sector.<br />

MAY 2011<br />

13

Zoom<br />

Focus on China and Brazil<br />

Different countries, same challenge and passion. <strong>Dayco</strong>’s expansion<br />

strategy in the Far East and in Latin America takes a further step<br />

forward. Riccardo Bosco, Vice president Asia, explains why knowing<br />

the market is essential when operating in such different contexts<br />

LOOKING EAST<br />

The Far East and South America, two very<br />

different worlds, but two extremely<br />

important markets. These are the two<br />

“new frontiers” where <strong>Dayco</strong> is investing<br />

with increasing determination,<br />

implementing targeted strategies, both<br />

at organisation and production level.<br />

Identifying, for each of the two macro<br />

areas, a lead market in which to invest in<br />

this first phase: China for the Far East and<br />

Brazil for Latin America.<br />

In this respect, China represents a<br />

particularly stimulating challenge, owing<br />

to its major cultural differences with<br />

Europe and the extremely high growth<br />

rate of the market, and this is where we<br />

intend to invest significant economic and<br />

human resources in the years to come<br />

“Our aim, explains Riccardo Bosco, Vice<br />

President – General Manager Asia – is<br />

to guarantee a sufficient production<br />

capacity to cover the market, as well as<br />

the organisation of the Aftermarket sector<br />

and, from there, to possibly serve the<br />

other markets of the region. After all - he<br />

adds – at this point, <strong>Dayco</strong> can count on<br />

a presence and integration capacity that<br />

allows to establish a continuous product<br />

and information exchange among the<br />

different markets.”<br />

within a few months, a complete customer<br />

service will be implemented».<br />

Distribution has been entrusted to<br />

distributors selected according to their<br />

professional skills and geographic location<br />

so as to guarantee the coverage of the<br />

whole territory and the best service to spare<br />

parts dealers and workshops. «The<br />

objective is actually to distribute <strong>Dayco</strong><br />

products in all the Chinese provinces, giving<br />

priority to the areas with greater potential».<br />

After all, the Chinese market is undoubtedly<br />

the most significant of the entire Asian area<br />

at the moment.<br />

The circulating fleet is developing at<br />

exceptional rates: today there are more than<br />

50 million light vehicles in circulation and 13<br />

million registrations were made in 2010. «To<br />

be quite clear - continues Bosco – this is<br />

approximately the number of registrations<br />

made in 25 countries of the European Union<br />

in the same period». Furthermore, the<br />

vehicle fleet is getting younger, more<br />

diversified and modern: scrapping is on the<br />

increase as well as the presence of<br />

international brands (the current leader is<br />

Volkswagen).<br />

A STAGGERING GROWTH<br />

Any expansion requires a certain number<br />

of steps, each of them delicate and<br />

important. The “Chinese adventure” is<br />

therefore clearly aimed at both Original<br />

Equipment and the Aftermarket «The<br />

prospect is to acquire a relevant position<br />

in the aftermarket and OE sectors within<br />

3 years or so. By then, based on these<br />

growth rates, the fleet could reach 90<br />

million vehicles», concludes Bosco.<br />

On the other hand, the composition of the<br />

circulating fleet requires a two-front<br />

approach: on the one hand, the presence<br />

in China of the major world<br />

manufacturers allows the company to<br />

“export” technology and pre-existing<br />

supply relations to Asia; on the other<br />

hand, however, specific strategies must<br />

be implemented to acquire the greatest<br />

number of relations with the local car<br />

manufacturers.<br />

Without forgetting another fastdeveloping<br />

market in the area, i.e. the<br />

Indian market, with its 1,8 million car<br />

registrations per year: few compared with<br />

China, but still many considering the<br />

Indian context and significant if compared<br />

with the average of the European<br />

countries. India will be the next step of the<br />

Chinese adventure, followed by other<br />

markets of the Asian area, such as<br />

Taiwan, South Korea, the Philippines and<br />

Malaysia.<br />

EXPORTING THE KNOW-HOW<br />

But how is this “export” of experiences<br />

and know-how carried out concretely As<br />

Bosco explains «what is being transferred<br />

is substantially the <strong>Dayco</strong> standard<br />

THE CHINESE ADVENTURE<br />

The gradual conquest of the Chinese market<br />

is therefore going on: «We have just started<br />

the production of timing belts and<br />

accessories in the Shanghai plant, with the<br />

prospect of a progressive increase of the<br />

range and products», explains Bosco. «We<br />

have already started building up a local<br />

commercial and logistic organisation, and<br />

14 POWER WORLD

Zoom<br />

developed in Europe: as far as the<br />

Aftermarket is concerned for instance,<br />

there is a single database which provides<br />

the necessary information for a given<br />

market, and this information is then<br />

adapted and localised. But this also<br />

applies to the logistic and commercial<br />

strategies strictly speaking».<br />

Obviously, from this point of view, China<br />

calls for a greater work of adaptation<br />

compared to the South American market:<br />

in fact, beside the European models,<br />

some applications are exclusive for this<br />

market and must naturally be included in<br />

the offering and in the specific catalogue<br />

for this area. And if the range currently<br />

consists of flexible components for the<br />

most part, it is clear that it will expand<br />

more and more. «For example, it is still<br />

too early to promote the kit culture as the<br />

consumer is still rather wary of the repair<br />

costs, but the distribution of vehicles with<br />

high technological contents leads us to<br />

believe that a more developed “repair<br />

culture”, similar to the European one, will<br />

gradually spread - asserts Bosco –.<br />

Fifteen years ago, in Europe, nobody<br />

wanted the kit; today, in most markets it<br />

is the top selling product».<br />

OBJECTIVE: VISIBILITY<br />

The first presence of <strong>Dayco</strong>’s “new era”<br />

at the Automechanika Fair of Shanghai<br />

last December, was extremely important,<br />

both from a commercial and<br />

communication point of view “It seems<br />

that the event efficiently borrowed from<br />

the German formula, leading to an<br />

improvement of the organisation and<br />

better effectiveness of the exhibition”<br />

says Bosco. And he adds: «<strong>Dayco</strong>’s<br />

presence in this context was a strong<br />

signal. It was not only a question of<br />

visibility, to have a stand, to introduce our<br />

catalogue and products, but also to have<br />

the opportunity to present ourselves with<br />

a structure and management that are<br />

almost exclusively Chinese, selected on<br />

site. In other words, to give the customers<br />

the possibility of concretely perceiving<br />

our presence on this market». The<br />

visitors’ interest clearly confirmed that<br />

the brand has a good positioning and that<br />

the customer recognizes and appreciates<br />

<strong>Dayco</strong>’s quality guarantee.<br />

Before attending the next edition of<br />

Automechanika in April 2011, <strong>Dayco</strong> was<br />

present at the AutoShow China in<br />

Shanghai: «This event of great<br />

international value is mainly dedicated to<br />

motorcars, and a vast section is reserved<br />

to the Aftermarket, where the visitors can<br />

have a clear proof of the actual mass of<br />

investments made by all car<br />

manufacturers. And it is important for the<br />

customer to see <strong>Dayco</strong> side by side with<br />

the producers, immediately identifying us<br />

as Original Equipment suppliers and<br />

leaders in the Aftermarket ».<br />

<strong>Dayco</strong> will also take part in a series of<br />

local fairs at regional and provincial level,<br />

obviously meaning the Chinese Province,<br />

together with the local distributors, with<br />

the objective, as is the case in Europe, of<br />

addressing first and foremost the final<br />

consumer, i.e. the mechanic. However,<br />

we have to consider that China’s<br />

commercial model is extremely different:<br />

«Spare parts dealers – explains Bosco –<br />

are usually concentrated in great<br />

organised complexes, the auto-centres,<br />

where all the sector’s brands are present<br />

side by side. In other words, the customer<br />

Where the sun never sets: <strong>Dayco</strong>, sponsor of the Swedish Rally<br />

The month of July is a special period in<br />

Sweden: days are very long and the<br />

darkness of the night lasts just a few<br />

hours. For this reason, July is also the<br />

month that the Swedes choose for their<br />

holidays.<br />

It is also the time of the Midnattsolsrallyt,<br />

the “Midnight Sun Rally”, the most<br />

important date of the traditional<br />

Swedish Rally, one of the most popular<br />

car races in the country.<br />

This year <strong>Dayco</strong> will be attending the<br />

main race as the sponsor of one of the<br />

competitors, the PAS Motorsport team.<br />

Pilot Per-Arne Sjöstedt and co-pilot<br />

Robin Sjöstedt will race in a splendid<br />

vintage car: a 1964 Two-Stroke Saab<br />

96. This choice is in perfect agreement<br />

with the “historical” spirit of the race,<br />

and it is no coincidence that the finish<br />

line will be the Saab Museum of<br />

Trollhättan, birth place of the Saab cars.<br />

wants to have the choice between a great<br />

number of alternatives». For this reason,<br />

the marketing strategy is significantly<br />

different and must mainly focus on<br />

greater visibility, in a material sense:<br />

“Neon signs, posters, carefully prepared<br />

show-cases. In other words – concludes<br />

Bosco – a competitive, communicative<br />

and even “aesthetic” model that is totally<br />

different”.<br />

An important<br />

step forward:<br />

the warehouse<br />

in Germany<br />

A few months of activity were<br />

enough to confirm that the recent<br />

opening of the Neunkirchen<br />

warehouse in Germany (already<br />

mentioned in the previous issue) was<br />

a successful strategic choice. In fact,<br />

if <strong>Dayco</strong>’s primary goal is to be as<br />

close as possible to their customers,<br />

the new structure allows us to<br />

achieve this in the best way possible.<br />

First of all, the presence of a logistic<br />

base in Germany allows us to work<br />

with distribution second-level<br />

customers at national level, making<br />

urgent “over-night” shipments if<br />

necessary.<br />

In addition, the favourable position of<br />

the warehouse – in the centre of<br />

continental Europe – greatly<br />

reduces transportation times for<br />

shipments to neighbouring<br />

countries, which are thus supplied<br />

directly from Neunkirchen.<br />

Following the strong growth of last<br />

year, the German structure has now<br />

entered a new development stage,<br />

with about 500 new locations.<br />

The objective for this year is to<br />

optimise the processes and perfect<br />

the planning, in order to give the<br />

customer an increasingly efficient<br />

service level, further strengthening<br />

the presence of <strong>Dayco</strong>’s brand in<br />

Central and Northern Europe.<br />

MAY 2011<br />

15

Zoom<br />

<strong>Dayco</strong> Brazil opens its first plant<br />

for the Aftermarket organisation<br />

in South America<br />

Two important events are taking<br />

place in South America: the<br />

new plant in San Paolo and the<br />

opening of the Aftermarket<br />

headquarters.<br />

With the inauguration of the San Paolo<br />

site, <strong>Dayco</strong> celebrates the opening of its<br />

second plant in Brazil in less than three<br />

months. Like the Minas Gerais plant,<br />

which started operating last November,<br />

with the production of tensioners, pulleys<br />

and dampers, the new <strong>Dayco</strong> plant of San<br />

Paolo, based near Mooca, will be<br />

dedicated to the manufacturing of rigid<br />

components.<br />

According to the Vice President & General<br />

Manager South America, Ronaldo<br />

Teffeha, «the group’s objective is to further<br />

invest in the country and the inauguration<br />

of this industrial production facility only<br />

confirms the work achieved by our team».<br />

With this new Aftermarket site, <strong>Dayco</strong><br />

intends to gather and coordinate all the<br />

main activities in South America,<br />

optimizing the response times to the<br />

market. Specifically designed to serve the<br />

new & emerging markets, this new<br />

structure already allows <strong>Dayco</strong> to consider<br />

further ambitious expansions in the near<br />

future. «In the beginning, we will cover the<br />

aftermarket in the Brazilian area. The<br />

second stage will involve the South<br />

American market and the third stage the<br />

European market», explains Ronaldo<br />

Teffeha.<br />

The first step of the Brazilian production<br />

will be dedicated to the local market,<br />

before spreading to other markets. The<br />

aim is to develop highly flexible productive<br />

capacities that can be adapted to meet the<br />

varied market demands, ensuring at the<br />

same time the same level of service,<br />

quality and customers’ satisfaction in<br />

terms of the product & service<br />

offered.<br />

16 POWER WORLD

Zoom<br />

D. Martinez, President EU/SAO/Asia<br />

R. Teffeha, Vice President, General Manager South America<br />

J. Orchard, CO-CEO MarK IV<br />

MAY 2011<br />

17

R&D - Research & Development<br />

R&D for the Aftermarket<br />

Special Projects<br />

The technical know-how is a precious resource for any<br />

company. Even more so for companies like <strong>Dayco</strong>,<br />

constantly investing in process and product innovation<br />

Some months ago, <strong>Dayco</strong><br />

started collaborating with<br />

the Research &<br />

Development department on<br />

some special projects intended for the<br />

Aftermarket. This decision was based<br />

on the clear conviction that a worldwide<br />

company such as <strong>Dayco</strong>, operating in<br />

a sector with high technological impact,<br />

must keep on dedicating to research<br />

and innovation in the replacement<br />

sector, the same attention as that<br />

dedicated to original equipment.<br />

The objective is to give the end<br />

customer the maximum level of<br />

product quality, assembly simplicity<br />

and information to support the<br />

professional repair shops. Particularly<br />

important is the supply of spare parts<br />

for older vehicles, especially in the<br />

emerging markets, where a car is not<br />

just a commodity but an investment.<br />

We must therefore develop suitable<br />

technologies for this investment to last<br />

over the years.<br />

Working in synergy with the OE sector,<br />

cooperation projects can be developed,<br />

in direct contact with the producers,<br />

thus leading to a significant reversal of<br />

trend: indeed, it is not only the producer<br />

who must deal with the relation with the<br />

customer, it is <strong>Dayco</strong> itself that<br />

complete the OE product with the<br />

know-how required by professional<br />

repair shops in an increasingly<br />

important market.<br />

In other words, innovation and flexibility<br />

must be combined.<br />

The expansion strategy basically<br />

involves two “stages”: In the first place,<br />

the single markets and their respective<br />

requirements must be accurately<br />

surveyed then, based on this survey,<br />

the best practices already developed<br />

for original equipment are evaluated to<br />

decide which of them can be suitable<br />

for the new sector and adapted to<br />

the new context.<br />

<strong>Dayco</strong> has developed a number of<br />

activities in the R&D field. It is now<br />

time to select the best experiences<br />

and to use them in the most fruitful way<br />

in the various markets. But this can only<br />

take place after the requirements have<br />

been fully understood. For this<br />

reason, we have carried out in-depth<br />

analyses in the markets concerned,<br />

highlighting the customers’<br />

expectations in the various<br />

applications. The objective is to offer<br />

the best level of quality, life and<br />

efficiency. With our experience, knowhow<br />

and technical skills, we are in an<br />

ideal position to do it, to export this<br />

technology to new contexts, both in<br />

emerging country and mature<br />

markets.<br />

This general framework also<br />

includes some specific projects.<br />

For each line of products,<br />

priorities have been established,<br />

which obviously depend on the<br />

investment choices.<br />

The initial decisions concern the Raw<br />

Edge line: for this product, investments<br />

in new structures are being planned<br />

with the use and improvement of<br />

existing resources. As for the Poly-V<br />

belts, timing belts and tensioners, new<br />

investments are<br />

under way in the Asian area - China,<br />

India - and in the South American area,<br />

in particular Brazil.<br />

18 POWER WORLD

APPOINTMENT IN BOLOGNA<br />

This year again, <strong>Dayco</strong> will be in the<br />

front line at the Autopromotec Fair of<br />

Bologna, the most important event of<br />

this sector. This fair definitely<br />

represents a valuable opportunity for<br />

contact and direct dialogue with the<br />

mechanics, end-users of <strong>Dayco</strong>’s<br />

offering. An offering that keeps on<br />

expanding, as the already wide range of<br />

products is being completed with a<br />

growing variety of services, both face to<br />

face and through IT instruments.<br />

Particular emphasis will be placed on<br />

the Long Life +1 project, launched a<br />

few months ago and already rewarded<br />

by excellent results. The new auto and<br />

scooter catalogues will also be<br />

available, following their recent graphic<br />

restyling and improved contents.<br />

This edition will focus on two events: the<br />

<strong>Dayco</strong> stand will be organised, as usual,<br />

inside the pavilion, where the visitors<br />

will be given all technical and<br />

commercial information and will have<br />

the opportunity to examine the<br />

products, receive gadgets and try a<br />

useful and entertaining interactive<br />

game before its release on the Web site.<br />

To increase the user- and trainingoriented<br />

approach, the stand can be<br />

transformed into a “mini-classroom”, to<br />

organise short course specimens,<br />

seminars, individual or group meetings<br />

with the customers.<br />

In addition, a temporary exhibition<br />

space will be set up outside the pavilion,<br />

where everyone will have the<br />

opportunity to admire closely a splendid<br />

race car: a Lancia Martini 037, a<br />

historical rally model from the Eighties.<br />

MAY 2011<br />

19

Focus Autopromotec<br />

Let DAYCO<br />

show you<br />

the way<br />

Enter <strong>Dayco</strong>’s world:<br />

Games, mini-courses and plenty of gadgets<br />

to stimulate your passion.<br />

Bologna Fair<br />

25 - 29 may 2011<br />

Visit <strong>Dayco</strong>’s stand - Pav. 16 - Stand C50<br />

2 0 POWER WORLD

Focus Autopromotec<br />

MAI 2011<br />

21

From the<br />

distributor to<br />

the mechanic<br />

Authorised technicians, independent<br />

technicians, mechanics and, in parallel, the<br />

spare part and component dealers segment<br />

as well as a number of distribution platforms<br />

a complex Italian sector that requires<br />

particular care and attention.<br />

In particular the benefit of <strong>Dayco</strong>’s<br />

development of increasingly user-oriented<br />

services and real-time updating facilities, as<br />

Diego Grigoletto explains<br />

In Italy, the global financial crisis was<br />

only slightly felt in the Aftermarket<br />

sector, apart from some<br />

market/press paranoia & some local<br />

invoice payment issues. We can<br />

therefore say that we obtained and<br />

confirmed significant results in terms of<br />

market. However, in spite of this, Italy<br />

remains an extremely complicated<br />

market for the Aftermarket sector even<br />

more complicated than it may appear at<br />