You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ISSN 1862-2879<br />

Issue 1/2011 Vol. 7<br />

<strong>EDI</strong> Journal<br />

European Journal for<br />

Dental Implantologists<br />

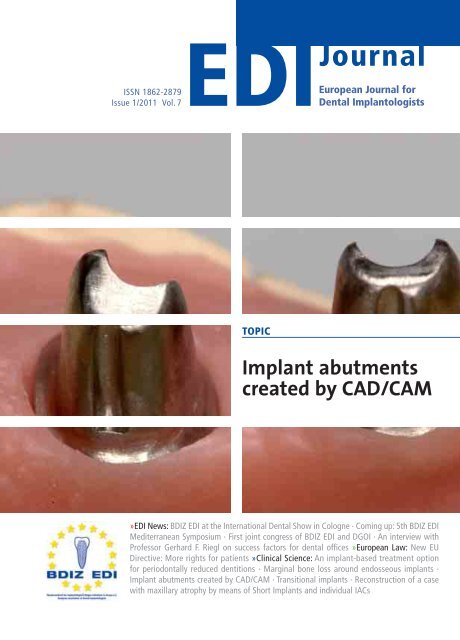

TOPIC<br />

Implant abutments<br />

created by CAD/CAM<br />

»<strong>EDI</strong> News: BDIZ <strong>EDI</strong> at the International Dental Show in Cologne · Coming up: 5th BDIZ <strong>EDI</strong><br />

Mediterranean Symposium · First joint congress of BDIZ <strong>EDI</strong> and DGOI · An interview with<br />

Professor Gerhard F. Riegl on success factors for dental offices »European Law: New EU<br />

Directive: More rights for patients »Clinical Science: An implant-based treatment option<br />

for periodontally reduced dentitions · Marginal bone loss around endosseous implants ·<br />

Implant abutments created by CAD/CAM · Transitional implants · Reconstruction of a case<br />

with maxillary atrophy by means of Short Implants and individual IACs

The Exacone implant is included in the libraries<br />

of the most common implant planning softwares<br />

(SimPlant® Materialise, Implant3D Medialab, Sicat-<br />

Galileos Sirona) to permit an accurate treatment<br />

plan and offer the possibility of fabricating surgical<br />

guides for a computer-assisted surgery.<br />

MultiTech is the new abutment specifi cally created<br />

for CAD/CAM technology used in restorative<br />

implantology. Its distinctive design favours its<br />

capturing through dental laboratory or intra-oral<br />

scanners and the customizing of its emergence<br />

profi le and angulation.<br />

Thanks to the absence of a screw hole and its<br />

consequently high mechanical strength, the geometry<br />

and specifi c surface of its bonding portion, MultiTech<br />

allows the realization of a fully patient-customized<br />

abutment. MultiTech offers the option to choose<br />

without any restriction among the several CAD/CAM<br />

methods using aesthetic materials like zirconium<br />

oxide and lithium disilicate.<br />

Orthodontics and Implantology<br />

LEONE S.p.a ��� �� � ���������� �� � ����� ����� ���������� ������� ������� � ����� ������������ ��� ������������� � ������������� � www.leone.it

The 34rd International Dental Show (IDS) in Cologne will again<br />

offer many surprises in terms of products and procedures. We<br />

are anxious to learn whether one of the major implant manufacturers<br />

will dare to embark on the zirconia implant “adventure”<br />

at IDS. Manufacturers have long been announcing<br />

ceramic implants, but they have yet to present them in the<br />

form of products ready for the market. Their presumed excellent<br />

biocompatibility and aesthetic shade would make these<br />

implants highly desirable for use in aesthetic dentistry, provided<br />

they can withstand continuous functional loads and feature<br />

abutments that are prefabricated but customizable.<br />

Innovative implant surfaces and treatment concepts based<br />

on angulated abutments definitely deserve mention. Without<br />

constant innovation and ongoing improvements to medicinal<br />

products, we would have fewer implant systems, implant surfaces<br />

and bone replacement materials today. As it is, however,<br />

implant dentistry has a large number of highly specific surgical<br />

techniques and materials available for a broad range of indications.<br />

But treatment providers and patients alike ask questions<br />

about the right choice of products and, especially, product safety.<br />

For example, the promotion of conditioned surfaces hydroxylated<br />

with hydroxide ions shortly before insertion to achieve<br />

better primary stability and improved osseointegration during<br />

the healing phase begs the question of whether reliable clinical<br />

studies are available to show that these specially conditioned<br />

surfaces actually result in shortened healing times.<br />

Another focus at IDS 2011 will be on biotechnological strategies<br />

for osteogenesis. We are facing an almost endless proliferation<br />

of synthetic bone replacement materials today. Some<br />

materials serve as placeholders for natural bone formation,<br />

while other types of materials are designed to replace autologous<br />

bone grafts. How well-proven and how successful are<br />

products such as porcine collagen matrix “straight from the<br />

blister pack”, designed to replace autologous connective-tissue<br />

grafts in covering recessions and augmented soft tissue?<br />

In addition to these developments in dental materials, new<br />

digital devices are coming more and more into focus with<br />

dental practitioners – in diagnostics and therapy alike.<br />

Products range from three-dimensional x-ray units and<br />

computer-guided implant placement all the way to optical<br />

scanners replacing conventional impression-taking and even<br />

automated dental technology procedures.<br />

In terms of diagnostics, many companies now offer software<br />

for computer-assisted treatment planning based on CBCT<br />

images. Oral implantologists will take the opportunity to scan<br />

IDS for software solutions capable of processing data for as<br />

many popular implant systems as possible.<br />

CAD/CAM procedures for manufacturing implant-supported<br />

restorations include opto-digital processes that dispense with<br />

plaster casts altogether. Single-session chairside restorations<br />

using scanner technology could be unveiled at IDS. Automated<br />

processes in dental technology are supposed to reduce cost.<br />

The industry has promised that custom components, e.g. for<br />

the aesthetic zone – which now require manual fabrication –<br />

could be produced in this way.<br />

Doubtlessly, recent innovation within oral implantology has<br />

been driven in large part by scientific progress and by the products<br />

developed by the dental industry. Prompted by an everincreasing<br />

demand by dentists and their patients, new products,<br />

new processes and improved therapeutic methods have<br />

been brought to market for many indications – from new<br />

approaches to bone augmentation and novel procedures in<br />

laser technology to newer materials, not least the now already<br />

familiar zirconia. Coming from a high level of achievement and<br />

extremely high success rates compared with other medical procedures,<br />

ever better results and shorter treatment times are<br />

not easy to attain. There are limits to what nature will allow us<br />

to do. In the light of this realization, it is all the more important<br />

for oral implantologists to avail themselves of opportunities<br />

for continuing education – to keep up with technical innovations<br />

and new materials, for the benefit of the patients and<br />

their own.<br />

Sincerely,<br />

Christian Berger, Kempten/Germany<br />

President of BDIZ <strong>EDI</strong><br />

<strong>EDI</strong><br />

Editorial<br />

Training and<br />

education<br />

must keep up<br />

with progress<br />

3

4 <strong>EDI</strong><br />

Table of Content<br />

<strong>EDI</strong> News<br />

The dental world assembles in Cologne<br />

Kicking off IDS 2011 8<br />

CAD/CAM developments at breathtaking speed<br />

Interview with Professor Joachim E. Zöller 10<br />

Meeting Point Implantology 2011<br />

BDIZ <strong>EDI</strong> at the International Dental Show<br />

in Cologne 14<br />

Implantology guide 16<br />

Implantological challenges on Portugal’s coast<br />

5th BDIZ <strong>EDI</strong> Mediterranean Symposium,<br />

10–17 June 2011 20<br />

Implantology and the dental team<br />

15th BDIZ <strong>EDI</strong> Symposium · 8th International<br />

Annual Congress of the DGOI 24<br />

PrintStar 2010 nomination for BDIZ <strong>EDI</strong> konkret<br />

“Academy Award” of the German printing world 30<br />

BDIZ <strong>EDI</strong> Administrator, Bonn office<br />

Career notes: Dr Dirk U. Duddeck 31<br />

Biomaterials under scrutiny<br />

20th International Expert Symposium for<br />

Regenerative Methods in Medicine and Dentistry 32<br />

Haemophilia’s little sister<br />

Third anniversary of the von Willebrand<br />

syndrome (vWS) network 34<br />

Finding the right patients<br />

An interview with Professor Gerhard F. Riegl on<br />

success factors for dental offices 36<br />

Europe Ticker 40<br />

European Law<br />

New EU Directive: More rights for patients 44<br />

On the legality of prior authorization requirements<br />

for outpatient treatment requiring the use of<br />

major medical devices in a different member state 48<br />

Clinical Science<br />

A new therapeutic approach<br />

An implant-based treatment option for<br />

periodontally reduced dentitions 50<br />

Marginal bone loss around endosseous implants<br />

Comparison of the bone response to dental<br />

implants with threaded and non-threaded necks 54<br />

Roads to implant abutments<br />

Implant abutments created by CAD/CAM 64<br />

Clinical Science<br />

Transitional implants<br />

A new approach to ridge restoration in cases of<br />

severe horizontal resorption 78<br />

A perfect fit<br />

Reconstruction of a case with maxillary atrophy<br />

by means of Short Implants and individual IACs<br />

(Integrated Abutment Crowns) 86<br />

Business & Events<br />

Innovations by Dentsply Friadent at IDS 2011 94<br />

An interview with Frank Bartsch,<br />

Trade Marketing Manager at Carestream Health 96<br />

An interview with Professor Daniel Buser and<br />

Professor Mariano Sanz on the International<br />

Osteology Symposium in Cannes 98<br />

MIS Global Conference, Cancun, Mexico,<br />

19 to 21 May 2011 100<br />

Thommen Connecting Science Workshop<br />

during the International Osteology Symposium 101<br />

TV-Wartezimmer’s market share on the rise 102<br />

H&H Webranking survey: Nobel Biocare’s<br />

website breaks top 5 103<br />

News and Views<br />

Editorial 3<br />

Imprint 6<br />

Product Reports 104<br />

Product News 107<br />

Calendar of Events/Publishers Corner 122<br />

Page 82:<br />

Inserting a<br />

transitional<br />

implant<br />

with a<br />

square tip.

© MIS Corporation. All rights Reserved.<br />

Explore<br />

360° Implantology

6<br />

<strong>EDI</strong><br />

Imprint<br />

<strong>EDI</strong><br />

European Journal for Dental Implantologists<br />

a BDIZ <strong>EDI</strong> publication<br />

published by teamwork media GmbH, Fuchstal<br />

Association: The European Journal for Dental Implantologists (<strong>EDI</strong>)<br />

is published in cooperation with BDIZ <strong>EDI</strong>.<br />

Publisher Board<br />

Members:<br />

Christian Berger<br />

Professor Joachim E. Zöller<br />

Dr Detlef Hildebrand, Dr Thomas Ratajczak<br />

Editor in Chief: Ralf Suckert, r.suckert@teamwork-media.de<br />

Editors: Anita Wuttke, Phone: +49 89 72069-888, wuttke@bdizedi.org<br />

Simone Stark, Phone: +49 8243 9692-34, s.stark@teamwork-media.de<br />

Scientific Board: Professor Alberico Benedicenti, Genoa Dr Marco Degidi, Bologna<br />

Dr Eric van Dooren, Antwerp Professor Rolf Ewers, Vienna<br />

Professor Antonio Felino, Porto Dr Jens Fischer, Bern<br />

Dr Roland Glauser, Zurich Professor Ingrid Grunert, Innsbruck<br />

Dr Detlef Hildebrand, Berlin Dr Axel Kirsch, Filderstadt<br />

Professor Ulrich Lotzmann, Marburg Professor Edward Lynch, Belfast<br />

Dr Konrad Meyenberg, Zurich Professor Georg Nentwig, Frankfurt<br />

Dr Jörg Neugebauer, Landsberg Professor Hakan Özyuvaci, Istanbul<br />

Professor Georgios Romanos, Rochester Luc and Patrick Rutten, MDT, Tessenderlo<br />

Dr Henry and Maurice Salama, Atlanta Dr Ashok Sethi, London<br />

Ralf Suckert, Fuchstal Professor Joachim E. Zöller, Cologne<br />

All case reports and scientific documentations are peer reviewed by the international editorial board<br />

of “teamwork – Journal of Multidisciplinary Collaboration in Restorative Dentistry“.<br />

Project Management<br />

& Advertising:<br />

Marianne Steinbeck, MS Media Service, Badstraße 5, D-83714 Miesbach<br />

Phone: +49 8025 5785, Fax: +49 8025 5583, ms@msmedia.de, www.msmedia.de<br />

Publishers: teamwork media Verlags GmbH, Hauptstr. 1, D-86925 Fuchstal<br />

Phone: +49 8243 9692-11, Fax: +49 8243 9692-22<br />

service@teamwork-media.de, www.teamwork-media.de<br />

Layout: Sigrid Eisenlauer; teamwork media GmbH<br />

Printing: J. Gotteswinter GmbH; Munich<br />

Publication Dates: March, June, September, December<br />

Subscription Rates: Annual subscription: Germany € 40 including shipping and VAT. All other countries € 58 including shipping. Subscription<br />

payments must be made in advance. Ordering: in written form only to the publisher. Cancellation deadlines: in<br />

written form only, eight weeks prior to end of subscription year. Subscription is governed by German law. Past issues<br />

are available. Complaints regarding nonreceipt of issues will be accepted up to three months after date of publication.<br />

Current advertising rate list from 1/1/2011.<br />

ISSN 1862-2879<br />

Payments: to teamwork media GmbH;<br />

Raiffeisenbank Fuchstal BRC 733 698 54 Account No.100 416746<br />

Copyright and<br />

Publishing Rights:<br />

All rights reserved. The magazine and all articles and illustrations therein are protected by copyright. Any utilization<br />

without the prior consent of editor and publisher is inadmissible and liable to prosecution. No part of this publication<br />

may be produced or transmitted in any form or by any means, electronic or mechanical including by photocopy, recording,<br />

or information storage and retrieval system without permission in writing from the publisher. With acceptance of<br />

manuscripts the publisher has the right to publish, translate, permit reproduction, electronically store in databases, produce<br />

reprints, photocopies and microcopies. No responsibility shall be taken for unsolicited books and manuscripts. Articles<br />

bearing symbols other than of the editorial department or which are distinguished by the name of the authors represent<br />

the opinion of the afore-mentioned, and do not have to comply with the views of BDIZ <strong>EDI</strong> or teamwork media<br />

GmbH. Responsibility for such articles shall be borne by the author. All information, results etc. contained in this publication<br />

are produced by the authors with best intentions and are carefully checked by the authors and the publisher. All<br />

cases of liability arising from inaccurate or faulty information are excluded. Responsibility for advertisements and other<br />

specially labeled items shall not be borne by the editorial department.<br />

Copyright: teamwork media GmbH . Legal Venue: Munich

© MIS Corporation. All rights Reserved.<br />

Enjoy<br />

The Best Cancun Has To Offer...

8<br />

<strong>EDI</strong><br />

<strong>EDI</strong> News<br />

IDS will be held in Halls 2, 3, 4, 10 and 11 this year.<br />

As in 2009, BDIZ <strong>EDI</strong> can be found in Hall 11.2, Aisle O,<br />

Stand 059 – again jointly with the legal offices of<br />

Ratajczak & Partners.<br />

The organizers – the Society for the Promotion of the<br />

Dental Industry (GDFI), the commercial arm of the<br />

Association of German Dental Manufacturers (VDDI),<br />

in cooperation with Koelnmesse, Cologne – expect<br />

approximately 1,900 exhibitors from 56 countries,<br />

with international exhibitors taking a 65 per cent<br />

share. This year, IDS will additionally utilize Hall 2 of<br />

the Cologne fairgrounds, for a gross exhibition area<br />

of 143,000 square metres or about 20 football fields.<br />

“Given the tremendous response on the part of our<br />

exhibitors, we hope to repeat the performance of<br />

2009, when more than 100,000 visitors attended.<br />

This will further consolidate and expand the position<br />

of IDS as a global beacon of the dental industry, not<br />

only with regard to the number of exhibitors, floor<br />

space or international attendance, but also with<br />

regard to the number of visitors”, as the organizers<br />

said in a joint statement.<br />

In addition to Germany, the most well-represented<br />

countries include Italy, the U.S., South Korea and<br />

Switzerland. In addition, there has been sizable<br />

growth in terms of international cooperation stands<br />

under the auspices of public or private export-promoting<br />

organizations or associations. Fourteen such<br />

cooperations have been registered so far, from<br />

Argentina, Australia, Brazil, Bulgaria, China, Japan,<br />

Israel, Italy, Pakistan, Russia, South Korea, Spain, Taiwan<br />

and the U.S. For 185 exhibitors this will be the<br />

first time they are represented in Cologne.<br />

One well-established feature of the IDS program is<br />

Speaker’s Corner in Hall 3.1, right next to the south<br />

entrance, where IDS exhibitors will be presenting<br />

Kicking off IDS 2011<br />

The dental world<br />

assembles in<br />

Cologne<br />

What is new at IDS 2011? Visitors to the International Dental Show in<br />

Cologne are looking forward to finding out. On 22 March 2011, the<br />

gates will open for the world’s largest fair for dentistry and dental<br />

technology. The first day is reserved for professional visitors. From<br />

23 to 26 March, Halls 2, 3, 4, 10 and 11 will be open to the general public.<br />

This year’s focus will be on endodontics and oral implantology.<br />

information on new products, services and procedures<br />

throughout the fair. Expert speakers will report<br />

on recent results and breakthroughs in science and<br />

technology.<br />

To make the most of their time at IDS 2011, visitors<br />

are recommended to plan their visit ahead of time.<br />

For this purpose, IDS now offers a separate app for<br />

iPhones, Blackberries, Android and other mobile systems<br />

comprising the IDS catalogue and an innovative<br />

navigation system for mobile devices guiding visitors<br />

safely through the halls and to the stands they wish<br />

to see.<br />

Arrival<br />

Both your trip and your stay can be easily arranged<br />

online ahead of time, the same is true of registration<br />

and ticketing at the IDS online shop. The IDS e-ticket<br />

not only gives you access to the IDS but doubles as<br />

your ticket for local transportation. The official IDS<br />

2011 airline is Lufthansa, offering visitors departing<br />

from more than 250 international<br />

cities in 100 countries special airfare<br />

rates. You may also obtain<br />

reduced-price train tickets on<br />

Deutsche Bahn to take you to IDS.<br />

The www.hotelzimmerbuchung.com<br />

website offers reservation of facilities<br />

for hotel rooms in Cologne<br />

and vicinity. For more information,<br />

please visit the IDS 2011 website at<br />

www.ids-cologne.de AWU<br />

IDS at a glance<br />

Getting started p. 8<br />

In depth p. 10<br />

The BDIZ <strong>EDI</strong> stand p. 14<br />

Implantology guide p. 16<br />

Opening hours<br />

23 to 26 March 2011<br />

Visitors: 9 am to 6 pm daily

© MIS Corporation. All rights Reserved.<br />

Three Days of 360° Implantology. lantology. Explore 360°<br />

Implantology: A complete world ld of dental implant resources<br />

from MIS. An up to date range e of researches, technologies<br />

and knowledge. And... Enjoy oy the full spectrum of the<br />

luxurious Cancun fun.<br />

MIS offers a wide range of implants, innovative e kits and<br />

accessories that provide creative and simple solutions<br />

for the varied challenges of implant dentistry. y.<br />

Make it Simple<br />

®<br />

For further information please visit:<br />

www.mis-events.com/cancun Or visit us at the<br />

IDS - International Dental Show, Cologne 22-26.03.2011<br />

Hall 4 Level 2 Booth Number 10L/19N

10<br />

<strong>EDI</strong><br />

<strong>EDI</strong> News<br />

Interview with Professor Joachim E. Zöller<br />

CAD/CAM developments<br />

at breathtaking speed<br />

What expectations do implant dentists have of IDS 2011? What innovations make sense, and where would healthy scepticism<br />

be indicated? Professor Joachim E. Zöller, Vice President of BDIZ <strong>EDI</strong> and scientific director of its symposia, answered the<br />

editorial team’s questions on the future of oral implantology as seen from the perspectives of the user and the scientist.<br />

Professor Joachim E. Zöller<br />

Professor Zöller, what innovations do you expect to<br />

see at IDS 2011?<br />

I would think that true innovation can be expected<br />

in the area of CAD/CAM-supported fabrication of<br />

implant-supported dentures, and here especially in<br />

digital impressions. This is where development progresses<br />

rapidly, and we can soon expect these procedures<br />

to become a standard adjunct in state-of-theart<br />

dentistry. We will also see some new developments<br />

in implant surfaces and bone replacement<br />

materials, but these I would not go so far as to call<br />

true innovations. Furthermore, I believe that we will<br />

be seeing the beginnings of a restructuring of the<br />

implant market. The roster of exhibitors has changed<br />

significantly since 2009. A recently published analytical<br />

study by Morgan Stanley on the dental implant<br />

market in Germany is highly interesting in this context.<br />

This study re-evaluates the major players and<br />

points out the changes that are taking place.<br />

There have been rumours that one of the big players<br />

among implant manufacturers might present a zirconia<br />

implant. Would not this represent a breakthrough<br />

for ceramic implants?<br />

At this point, ceramic implants have less than a five<br />

per cent market share, so they only play a minor role.<br />

The main reason is that ceramic implants – especially<br />

in cantilever situations – still have disadvantages<br />

compared to titanium. A breakthrough could occur<br />

if we saw significant progress in surface treatments<br />

and if the stability of the connection between two<br />

segmented ceramic implants was similar to that<br />

between titanium implants.<br />

Speaking of implant surfaces: What is your take on<br />

surface conditioning, where surfaces are hydroxylated<br />

with hydroxide ions shortly before placement to<br />

achieve extra stability and better osseointegration<br />

during the healing phase?<br />

Healing rates in healthy patients exceed 95 per<br />

cent. In other words, current hydrophilic surfaces<br />

based on the acid-etching technology can be considered<br />

very mature products. Not least for statistical<br />

reasons, further optimization would be possible only<br />

if someone invented a completely new surface offering<br />

very significant extra benefits. The current “innovations”,<br />

in my opinion, do not fit this bill. Rather,<br />

what we hear is mostly the industry’s sales arguments.<br />

As far as the healing phase is concerned, we<br />

are actually very familiar with the processes governing<br />

physiological bone healing. Thinking that we can<br />

cheat nature is a mistaken belief.<br />

But are there any reliable studies showing that shorter<br />

healing times can be achieved only with specially<br />

conditioned surfaces?<br />

Consolidating bone fractures will be tentatively<br />

stable after six weeks and functionally stable after

Cone-beam<br />

computed<br />

tomography<br />

(CBCT) is making<br />

further advances.<br />

<strong>EDI</strong><br />

<strong>EDI</strong> News<br />

eight to ten weeks. If we allow for a safety margin of<br />

two weeks, we have arrived at today’s healing times.<br />

My question is: Who is actually interested in shortened<br />

healing times? Does shortening the healing<br />

times by two to four weeks really help the patient?<br />

Or is this a phenomenon similar to the immediateplacement<br />

fad? Here, too, we have seen that this only<br />

works reliably in certain situations.<br />

Can we expect anything revolutionary at IDS regarding<br />

abutments and superstructures? What are you<br />

personally on the lookout for?<br />

I think we will see the trend toward custom abutments<br />

continue. We have already seen a lot of developments<br />

in this field in recent years. But here, too,<br />

ceramic abutments will be accepted only in the aesthetic<br />

zone. We continue to experience massive problems<br />

with these abutments in the posterior region.<br />

CAD/CAM procedures for manufacturing implant-supported<br />

restorations now include opto-digital processes<br />

that dispense with plaster casts altogether. Automated<br />

processes are supposed to reduce cost. The industry<br />

has promised that custom components, e.g. for the<br />

aesthetic zone, which now require manual fabrication,<br />

could be produced in this way. Single-session<br />

chairside restorations using scanner technology could<br />

be unveiled at IDS. Does that not sound promising?<br />

The important breakthrough for CAD/CAM procedures<br />

for manufacturing implant-supported restorations<br />

will come once intraoral digital impressions are<br />

ready for use in clinical practice. Here I expect digital<br />

images to be available in a matter of milliseconds,<br />

just as with present-day impression trays. Once this<br />

problem has been solved, and solved in a practical<br />

manner, I am sure that this impression technique will<br />

replace all conventional laboratory procedures, with<br />

very few exceptions. This will not only mark the end<br />

of all outsourcing of laboratory services to far-away<br />

countries – domestic laboratories, too, will have to<br />

completely revamp their processes in order to survive.<br />

11<br />

����������������<br />

�����������<br />

�����������������������<br />

�������������������������<br />

�������������������������<br />

�������������<br />

����������������������<br />

������������������<br />

�������������<br />

�����������������<br />

����������������<br />

���������������������<br />

���<br />

���<br />

���<br />

���<br />

�<br />

���������<br />

��������<br />

��������������������������<br />

������������������������������������������<br />

��������������������������������������<br />

���������������������������������<br />

����������� ����<br />

���������������<br />

�������������������������������������<br />

��������������������������������������<br />

��������������

12<br />

<strong>EDI</strong><br />

<strong>EDI</strong> News<br />

Just imagine: In the future you can have a scan taken<br />

of your adult daughter, and if she really should lose<br />

a tooth later on, she will simply have one milled. I<br />

am certain that we will see new possibilities evolve<br />

with tremendous speed.<br />

In diagnostics, the three-dimensional planning system<br />

hype appears to be subsiding. Although CBCT units<br />

have significantly come down in price, they still cost<br />

twice as much as conventional radiography. What circumstances,<br />

in your opinion, would justify the higher<br />

cost, extra time and the extra training needed to evaluate<br />

the results?<br />

I am sure clinical reality will provide the answer for<br />

that. Whether we like it or not: implantological diagnostics<br />

will increasingly be three-dimensional, with<br />

two-dimensional procedures restricted to very clearcut<br />

clinical situations. So CBCT will definitely not be<br />

reserved for particularly severe or complicated cases,<br />

as we thought not too long ago; time has passed us<br />

by. And once we have precision diagnostics available<br />

anyway, we will want to transfer the treatment planning<br />

data to the result as well. Over the long haul,<br />

the patients themselves will expect this. I believe<br />

that navigated template-guided implant insertion<br />

will become standard in the foreseeable future, a<br />

development that will be driven not least by cheap<br />

CAD/CAM-produced templates.<br />

I am sure you have been looking particularly closely at<br />

biotech strategies for osteogenesis. There is an almost<br />

endless proliferation of synthetic bone replacement<br />

materials. How well-proven and how successful are<br />

products such as porcine collagen matrix “straight<br />

from the blister pack” designed to replace autologous<br />

connective-tissue grafts in covering recessions and<br />

augmented soft tissue?<br />

It is true that “new” bone replacement materials<br />

are marketed at a rapid pace, but many allegedly new<br />

products are simply old wine in new bottles. For<br />

many of these materials, there has been hardly any<br />

clinical testing, or at least not at a higher level of evidence.<br />

Here the industry benefits from a tendency on<br />

the part of many dentists to try something “new” in<br />

order to chase the potential benefit rather than opting<br />

for well-proven products.<br />

When do you think that bone cultivated from bonemarrow<br />

stem cells will be ready for the market?<br />

Billions are being invested in stem cell research<br />

every year, all over the world. This field of research<br />

receives the most support. Ultimately, I believe that<br />

we will be seeing entirely new ways of practicing<br />

medicine opening up. Take diabetes mellitus or<br />

myocardial infarction. Here we will be able to effec-<br />

tively treat the causes rather than<br />

prescribing drugs to treat the<br />

symptoms. Compared to that, producing<br />

bone for various medical<br />

applications will be a minor problem.<br />

We will be able to generate<br />

bone tissue, not only complete<br />

with cortical and spongious bone<br />

but also complete with all other<br />

components such as blood vessels.<br />

This so-called tissue printing is<br />

the objective of massive research<br />

efforts. But we will probably see<br />

another five to ten years go by<br />

before we can proceed to clinical<br />

testing of initial applications. Even<br />

though stem-cell products are<br />

introduced every now and then,<br />

we are still a long way from any<br />

mature clinically products.<br />

What does the future hold for<br />

bone augmentation? Could laser<br />

technology offer new impulses?<br />

Industry protagonists hope to<br />

develop consistently porous<br />

moulded bodies to replace autolo-<br />

Bone replacement materials:<br />

gous grafts. They could improve<br />

The familiar and the new.<br />

the success rates in lateral-access<br />

augmentation procedures using bone replacement<br />

materials. I do not believe that bony integration of<br />

these moulded bodies will be good enough in the<br />

case of vertical augmentation. Overall, these products<br />

might constitute an interim solution until viable<br />

stem-cell products are available.<br />

Our last question will prompt you to take a peek at<br />

the future: Can we expect to see new treatment concepts<br />

in oral implantology?<br />

I think that we will see new treatment concepts<br />

related to CAD/CAM-produced implant-supported<br />

restorations. Here we will see an avalanche of new<br />

technologies, with considerably falling costs as a<br />

consequence, making laboratory products significantly<br />

cheaper. With regard to the surgical aspects of<br />

oral implantology, we would be well advised to continue<br />

standardizing current treatment concepts and<br />

their variants so that patients can be offered low-risk<br />

treatment and high success rates. This level of quality,<br />

however, will always have to have its price.<br />

Professor Zöller, thank you very much for this insightful<br />

look into the future of oral implantology.<br />

AWU

© Nobel Biocare Services AG, 2011. All rights reserved. Nobel Biocare, the Nobel Biocare logotype and all other trademarks are, if nothing else is stated or is evident from the context<br />

in a certain case, trademarks of Nobel Biocare<br />

Dual-function prosthetic<br />

connection.<br />

Bone-condensing property.<br />

NobelActive TM<br />

A new direction for implants.<br />

Adjustable implant orientation<br />

for optimal final placement.<br />

Meet us<br />

in Hall 4,<br />

A090/091<br />

NobelActive equally satisfies<br />

surgical and restorative clinical<br />

goals. NobelActive thread design<br />

progressively condenses bone<br />

with each turn during insertion,<br />

which is designed to enhance<br />

initial stability. The sharp apex<br />

and cutting blades allow surgical<br />

clinicians to adjust implant orientation<br />

for optimal positioning of the<br />

prosthetic connection. Restorative<br />

clinicians benefit by a versatile and<br />

secure internal conical prosthetic<br />

connection with built-in platform<br />

shifting upon which they can<br />

produce excellent esthetic results.<br />

Based on customer feedback and<br />

market demands for NobelActive,<br />

the product assortment has been<br />

expanded – dental professionals<br />

Built-in platform shifting.<br />

High initial stability,<br />

even in compromised<br />

bone situations.<br />

will now enjoy even greater flexi -<br />

bility in prosthetic and implant<br />

selection.<br />

Nobel Biocare is the world leader<br />

in innovative and evidence-based<br />

dental solutions.<br />

For more information, visit our<br />

website<br />

www.nobelbiocare.com<br />

Disclaimer: Some products may not be regulatory cleared/released for sale in all markets. Please contact the local Nobel Biocare sales office for current product<br />

assortment and availability.<br />

NobelActive A4 IDS <strong>EDI</strong> JOURNAL.indd 1 11-02-10 16.20.08

14<br />

<strong>EDI</strong><br />

<strong>EDI</strong> News<br />

BDIZ <strong>EDI</strong> at the International Dental Show in Cologne<br />

Meeting Point Implantology 2011<br />

We offer high-profile continuing education and training. Our support for dentists when it comes to private-patient billing issues<br />

in Germany is second to none. Like a well-trained rescue dog, BDIZ <strong>EDI</strong> sniffs out what implantological clinics are missing in terms<br />

of education and legal and accounting advice. The main beneficiaries of these efforts are BDIZ <strong>EDI</strong>’s members, whom we would<br />

like to welcome to the BDIZ <strong>EDI</strong> stand at IDS 2011 in Cologne (Hall 11.2, Aisle O, Stand 059) to meet the people behind the scenes.<br />

At the 34th IDS, BDIZ <strong>EDI</strong> will have a joint stand with<br />

the legal offices of Ratajczak & Partners. As an expert in<br />

medical law, Dr Thomas Ratajczak has been a knowledgeable<br />

partner of the BDIZ <strong>EDI</strong> Board and members<br />

for many years and provided legal counsel. “Our<br />

Meeting Point Implantology is meant to assemble<br />

and focus all the available expertise and to demonstrate<br />

the support that BDIZ <strong>EDI</strong> can offer implant<br />

dentists”, says BDIZ <strong>EDI</strong> President Christian Berger.<br />

New: Implantological guideline<br />

“Implants without augmentation”<br />

In early March, the European Consensus Conference<br />

(EuCC) held a meeting in Cologne under the auspices<br />

of BDIZ <strong>EDI</strong>. The result was a new implantological<br />

guideline, the sixth to be issued so far. At IDS, the<br />

guideline, which addresses the issue of implants<br />

without augmentation, will be available fresh off the<br />

press. The other five guidelines published to date, on<br />

immediate loading (2006), ceramics (2007), periimplantitis<br />

(2008), 3-D imaging (2009) and complications<br />

(2010) can be downloaded from the BDIZ <strong>EDI</strong><br />

website at www.bdizedi.org (change to English,<br />

select Professionals, choose the desired guidelines<br />

from the menu on the left).<br />

New: Testing implant surface materials<br />

The second qualitative and quantitative elemental<br />

analysis of the surfaces of more than 40 different<br />

makes of sterile-wrapped implants, presumably one<br />

of the most comprehensive worldwide, was conducted<br />

by BDIZ <strong>EDI</strong> jointly with the University of Cologne<br />

in 2010. Its findings, made possible only by the use of<br />

the scanning electron microscope, included improperly<br />

milled threads, implants with remarkably high<br />

levels of sandblasting residue and even implants<br />

with systematic organic contaminants. Significant<br />

improvements to a number of implants had already<br />

BDIZ <strong>EDI</strong> will be at Hall 11.2, Aisle O, Stand 059.<br />

followed the first publications of the results by BDIZ<br />

<strong>EDI</strong>. In a comprehensive follow-up study, numerous<br />

implants by other manufacturers are currently being<br />

examined using the same study protocol. The objective<br />

is to obtain an overview of the surface characteristics<br />

of as many implants on the market as feasible.<br />

For the first time, this research will also include zirconia<br />

implants, mini-implants and intermediate structures<br />

in the SEM analyses. If you are curious to find<br />

out how “your” implant has fared in this study, just<br />

visit us at the BDIZ <strong>EDI</strong> stand.<br />

Learn more at the BDIZ <strong>EDI</strong> stand!<br />

Any questions? We will be happy to provide answers.<br />

Of course, the BDIZ <strong>EDI</strong> Board will be present on-site:<br />

Presidents Christian Berger and Professor Joachim E.<br />

Zöller, Treasurer Dr Heimo Mangelsdorf, Secretary<br />

General Dr Detlef Hildebrand, Managing Director and<br />

Secretary Dr Stefan Liepe, as well as the Administrator<br />

of the BDIZ <strong>EDI</strong> Bonn office, Dr Dirk U. Duddeck. We<br />

will be happy to try to answer any questions you may<br />

have – whether on BDIZ <strong>EDI</strong> symposia, on curricula or<br />

on material testing procedures.<br />

AWU

110301_WH_AD_ELCOMED_A4_AEN_IDS:Layout 1 01.03.11 12:20 Seite 1<br />

80 Ncm<br />

Powerful for surgery<br />

120 Years W&H.<br />

Help us support SOS Children’s Villages!<br />

The new Elcomed from W&H: logical and easy to use. Uncompromising<br />

in performance: with a torque of up to 80 Ncm on the rotating instrument,<br />

the surgical drive unit guarantees smooth usage, which can be completely<br />

documented at no further cost thanks to an inte grated USB interface.<br />

These are just three of the many advantages of the new W&H Elcomed.<br />

Captivation and precision

16<br />

<strong>EDI</strong><br />

<strong>EDI</strong> News<br />

Implantology guide<br />

Company Hall Aisle Stand<br />

3M Espe AG 4.2 G + J 090 + 099<br />

+ 091<br />

ACTEON Germany GmbH 10.2 N + O 060 + 069<br />

Advanced Technology Research ATR s.r.l. 11.2 R 051<br />

AESCULAP AG 10.1 C + D 020 + 029<br />

Alpha-Bio tec. 4.2 G 020<br />

ANTHOGYR 11.1 C + D 040 + 041<br />

Aseptico, Inc. 10.2 T 015<br />

Astra Tech AB 3.2 A + C<br />

C + E<br />

010 + 019<br />

AVINENT IMPLANT SYSTEM, S.L. 4.1 D 040<br />

B.T.I. Deutschland GmbH 3.2 E + F 020 + 029<br />

Bego Implant Systems 10.2 M + N 018 + 029<br />

020 + 029<br />

N + O 028 + 029<br />

Bien Air 10.1 H + J 050 + 059<br />

BioHorizons GmbH 4.1 A 039<br />

BIOMET 3i 4.2 J + G 039 + 030<br />

BIOTECK s.r.l. 11.1 J 017<br />

Bontempi Medizintechnik GmbH 4.1 C 100<br />

BPI Biologisch Physikalische Implantate<br />

GmbH & Co. KG<br />

4.2 K 040<br />

B-Productions GmbH 10.2 R 068<br />

bredent medical GmbH & Co. KG 11.1 B + C 010 + 019<br />

BTI Biotechnology Institute, S.L. 3.2 E + F 020 + 029<br />

BTLock s.r.l. 11.1 F 038<br />

C. Hafner GmbH + Co. KG Goldund<br />

Silberscheideanstalt<br />

CAMLOG Biotechnologies AG 11.3 A + B<br />

+ C<br />

10.2 R 011<br />

010 + 019<br />

018 + 019<br />

Carestream 10.2 T + U 040 + 041<br />

+ 043<br />

Carl Martin GmbH 10.2 N + O 020 + 021<br />

Carlo de Giorgi SRL. 11.2 L 049<br />

Champions Implants 11.1 B 008<br />

Clinical House Europe GmbH 2.2 D + E 010 + 011<br />

Curasan 4.2 L + M 038 + 039<br />

Degradable Solutions 10.1 J 064<br />

DENTATUS AB 10.1 K 050<br />

DENTAURUM IMPLANTS GmbH 10.1 F 014<br />

DENTECH CORPORATION 10.2 V 023<br />

Dentech Dental Instruments<br />

Manufacturer & Trade<br />

4.2 G 008<br />

Dentegris Deutschland GmbH 11.2 K 051<br />

Dentium USA 4.2 K + L 060 + 061<br />

DENTSPLY Friadent GmbH 11.2 K + L 018 + 019<br />

020 + 021<br />

018 + 019<br />

020 + 021<br />

Company Hall Aisle Stand<br />

DEPPELER S.A. 10.2 T 025<br />

DIO Corporation 4.1 A 030<br />

DOT GmbH 11.2 N 063<br />

Dr. Ihde Dental GmbH 10.2 O 059<br />

Dyna Dental Engineering b.v. 10.2 S + T 068 + 069<br />

DZR 3.2 A 015<br />

EQUINOX M<strong>EDI</strong>CAL TECHNOLOGIES BV 10.1 B 048<br />

FairImplant 4.1 F 101<br />

Gebrüder Martin GmbH & Co. KG 4.2 G 028<br />

Geistlich 4.2 G 031<br />

General Implants GmbH 11.1 G 011<br />

Ghimas S.p.A. 4.1 B + C 070 + 071<br />

GlaxoSmithKline 11.3 K + L 020 + 029<br />

HADER SA 10.1 G + H 048 + 049<br />

Hager & Meisinger GmbH 10.1 G + H 019 + 028<br />

+ 029 +<br />

030 + 039<br />

Hager & Werken 4.1 A + B 070 + 079<br />

Hauschild & Co. KG 10.2 S + T 068 + 069<br />

Helmut Zepf Medizintechnik GmbH 10.1 C 041<br />

Henry Schein 10.2 L + M 040 + 049<br />

+ 048<br />

Heraeus Kulzer GmbH & Co KG 10.1 A + B<br />

+ C<br />

010 + 019<br />

010 + 019<br />

HI-TEC IMPLANTS LTD 3.2 F + G 028 + 029<br />

Hu-Friedy Mfg. Co., Inc. 10.1 D + E 040 + 041<br />

IDI SYSTEM (IMPLANTS DIFFUSION<br />

INTERNATIONAL)<br />

4.1 D 041<br />

Implant Direct 4.1 C 012<br />

Imtegra OHG 4.1 C 018<br />

Institut Straumann AG 4.2 G + K 080 + 089<br />

Intra-Lock International, Inc. 4.2 N 048<br />

J+K Chirurgische Instrumente GmbH 10.1 K 061<br />

Jakobi Dental Instruments 11.3 F 060<br />

KaVo 10.1 J + K<br />

H + J<br />

J + K<br />

J + K<br />

H + J<br />

Keystone 11.1 A 050<br />

K.S.I.-Bauer-Schraube GmbH 10.2 S 048<br />

Karl Hammacher GmbH 10.1 C 031<br />

KOHLER Medizintechnik GmbH & Co. KG 10.2 L 029<br />

030 + 031<br />

040 + 041<br />

010 + 019 +<br />

020 + 021<br />

028 + 029<br />

018 + 019<br />

Komet Gebr. Brasseler GmbH & Co. KG 10.2 U + V 010 + 019<br />

LEADER ITALIA SRL 10.2 U 019<br />

LEONE s.p.a. 4.1 A 068

The<br />

nnew<br />

e ew<br />

kkit<br />

it<br />

fo for or<br />

s ssuccess.<br />

uccess.<br />

Geistlich Combi-Kit Collagen –<br />

the best kit for successful<br />

and predictable results in<br />

ridge preservation and minor<br />

augmentations.<br />

Geistlich<br />

Bio-Oss ® Collagen and<br />

Geistlich Bio-Gide ®<br />

NEW<br />

combined in Geistlich<br />

Combi-Kit Collagen<br />

www.geistlich-pharma.com<br />

Visit us at the<br />

IDS in Cologne,<br />

Germany<br />

��March 22–26, 2011<br />

�����������<br />

���������������<br />

LEADING RE REGENERATION<br />

GGENERATION

18<br />

<strong>EDI</strong><br />

<strong>EDI</strong> News<br />

Company Hall Aisle Stand<br />

MATERIALISE DENTAL NV 4.2 J 019<br />

MECTRON S.P.A. 10.2 O + P 040 + 041<br />

med3D GmbH Implantology 10.2 R 011<br />

medentis medical GmbH 3.2 C + E 030 + 039<br />

Medizintechnik Gulden 11.3 B 014<br />

Medical Instinct 3.2 E + F 058 + 059<br />

MegaGen Implant Co., Ltd. 3.1 H 051<br />

Merz Dental GmbH 10.2 T + U 038 + 039<br />

Metoxit AG 4.1 B 006<br />

MIS 4.2 N + L 019 + 010<br />

MK1 Dental-Attachment GmbH 11.1 A 057<br />

J. Morita 10.2 R + S 040 + 049<br />

+ 042<br />

MOZO-GRAU, S.L. 4.1 D 078<br />

Nemris GmbH & Co. KG 4.1 B 029<br />

NEOSS GmbH 4.2 K + L 090 + 099<br />

Nobel Biocare Deutschland GmbH 10.1 D + E 010 + 019<br />

NOUVAG AG 11.1 F 059<br />

OMNIA S.p.A. 4.1 C + D 088 + 089<br />

Orangedental 11.2 M + N 040 + 049<br />

OSSTELL AB 3.2 E 070<br />

OSSTEM IMPLANT Co., Ltd. 4.1 A + B 010 + 019<br />

OT medical 3.2 F + G 030 + 039<br />

Otto Leibinger GmbH 4.2 G 100<br />

POLYDENTIA SA 10.2 R 050<br />

Promedia 10.2 V 029<br />

RESISTA Ing. Carlo Alberto Issoglio<br />

& C. S.R.L.<br />

10.2 T 049<br />

Resorba 3.2 A 048<br />

Riemser 3.2 C 040<br />

SAE DENTAL VERTRIEBS GmbH -<br />

INTERNATIONAL<br />

10.2 V 058<br />

Schlumbohm GmbH & Co. KG 10.2 U 030<br />

Schütz-Dental GmbH 10.1 G + H 010 + 019<br />

SICAT 10.2 O + P 010 + 029<br />

SIC invent AG 4.2 N + L 089 + 080<br />

Sirona Dental Systems GmbH 10.2 N + O<br />

+ P<br />

Si-tec GmbH 4.1 B 020<br />

Southern Implants GmbH 3.2 A 008<br />

steco-system-technik GmbH & Co. KG 11.1 D 008<br />

Stoma Dentalsysteme GmbH & Co. KG 10.2 U 011<br />

010 + 019<br />

+ 029 + 009<br />

Straumann GmbH 4.2 G + K 080 + 089<br />

Sybron Implant Solutions GmbH 10.1 J 029<br />

Talladium International 10.2 T 037<br />

T.B.R. GROUP SUDIMPLANT SA 11.2 N + O 030 + 031<br />

Tecnoss Dental s.r.l. 10.1 A 031<br />

Thommen Medical AG 4.2 N + L 091 + 090<br />

Company Hall Aisle Stand<br />

TRI dental 11.1 G 011<br />

Trinon Titanium GmbH 11.3 G 038<br />

Ustomed Instrumente Ulrich Storz<br />

GmbH & Co. KG<br />

10.1 A + B 048 + 049<br />

Wegold Edelmetalle AG 4.1 B + D 020 + 030<br />

+ 039<br />

Wieland Dental + Technik GmbH<br />

& Co. KG<br />

10.1 F + G 018 + 020<br />

+ 029<br />

W & H 10.1 C + D 018 + 019<br />

YDM CORPORATION 4.1 D + C 071 + 070<br />

ziterion GmbH 4.2 G 040<br />

ZL Microdent-Attachment GmbH<br />

& Co. KG<br />

10.1 P + Q 038 + 039<br />

Z-Systems AG 4.1 E 013<br />

Zimmer Dental 3.2 C + E 020 + 029<br />

Important addresses<br />

Company Hall Aisle Stand<br />

BDIZ <strong>EDI</strong> 11.2 O 059<br />

BZÄK/DGZMK/KZBV 11.2 O + P 050 + 059<br />

DAISY – Akademie und Verlag 11.2 S 009<br />

Deutscher Ärzte-Verlag 11.1 E + F 008 + 009<br />

DGOI 2.2 A 011a + 011<br />

DGZI 4.1 C 063<br />

Quintessenz Verlags-GmbH 11.2 N + O<br />

+ P<br />

008 + 009<br />

Spitta Verlag 11.2 P + Q 020/029<br />

teamwork media Verlag 11.1 F 008<br />

Zahnärztlicher Fachverlag/DZW 11.2 N + O 049 + 049

Zimmer Dental is evolving implant dentistry with the introduction<br />

of Trabecular Metal Material. With over a decade of clinical use in<br />

orthopaedics, Trabecular Metal Material’s highly biocompatible<br />

tantalum and 3D porous cellular structure have been clinically proven<br />

to create the potential for clinical ingrowth, or osseoincorporation. 1-3<br />

Bone’s ability to not only grow into the pores and around the struts,<br />

but also to interconnect, is what makes Trabecular Metal Material<br />

The Best Thing Next To Bone.<br />

To learn more, talk to a Zimmer sales representative or visit<br />

http://TrabecularMetal.zimmerdental.com.<br />

1. Bobyn JD, Poggie RA, Krygier JJ, Lewallen DF, Hanssen AD, Lewis RJ, Unger AS, O’Keefe TJ, Christie MH, Nasser S, Wood JE,<br />

Stulberg SD, Tanzer M. Clinical validation of a structural porous tantalum biomaterial for adult reconstruction. J Bone Joint<br />

Surg. 2004;86-A(Suppl 2):123-129. 2. Black J. Biological performance of tantalum. Clin Mater. 1994;16:167-173. 3. Bobyn JD.<br />

UHMWPE: the good, bad, & ugly. Fixation and bearing surfaces for the next millennium. Orthop. 1999;22(9):810-812.<br />

The Best Thing Next To Bone. <br />

Introducing Trabecular Metal TM<br />

Material to implant dentistry.<br />

Trabecular Metal Material<br />

Osseoincorporation<br />

The process of ingrowth<br />

Artistic Rendering<br />

www.zimmerdental.com<br />

©2010 Zimmer Dental Inc.<br />

Trabecular bone<br />

���������������������������������� ����������������

20<br />

<strong>EDI</strong><br />

<strong>EDI</strong> News<br />

5th BDIZ <strong>EDI</strong> Mediterranean Symposium, 10–17 June 2011<br />

Implantological challenges<br />

on Portugal’s coast<br />

In 2011, as in previous years, BDIZ <strong>EDI</strong> will continue its proven concept of holding continuing education<br />

courses outside Germany. This year’s Mediterranean Symposium will be held in Portugal.<br />

If you are looking for a high-class continuing education event and a relaxing environment for<br />

the whole family, the 5th BDIZ <strong>EDI</strong> Mediterranean Symposium will be the right choice for you.<br />

Together with its Portuguese partner organization,<br />

the Sociedade Portuguesa de Cirurgia Oral (SPCO),<br />

BDIZ <strong>EDI</strong> will be holding an international congress<br />

at Lisbon, the Portuguese capital, followed<br />

by a week of lectures and workshops – and quality<br />

time for you to unwind together with your family<br />

– in the Atlantic resort of Estoril, next to larger<br />

Cascais.<br />

The all-day symposium will take place at the<br />

Pestana Hotel in Lisbon on Saturday, 11 June 2011.<br />

The topic of the 5th Mediterranean Symposium<br />

will be ”Clinical Challenges in Oral Implantology.”<br />

Simultaneous interpretation will be available for<br />

the presentations of the Portuguese speakers; the<br />

German speakers will present in English. The scientific<br />

program has been compiled jointly by Professor<br />

Jo achim E. Zöller, Cologne, and Professor Antonio<br />

Felino, Porto.<br />

The venue for the continuing-education week will<br />

be the Atlantic Coast, a place of spectacular beauty.<br />

Cascais/Estoril offers sunshine, beach life and an<br />

attractive coastscape, sailing and golfing opportunities<br />

– and the area also has a lot to offer for those<br />

interested in history. Many buildings go back to the<br />

heydays of the Portuguese seafarers. Once again<br />

this year, symposium attendees can learn something<br />

where others spend their holidays.<br />

Lisbon yesterday and today<br />

Lisbon, the Portuguese capital, has 560,000 inhabitants<br />

within its administrative limits (more than<br />

2 million overall) and is known as the City of the<br />

Seven Hills. From its commercial port in the bay of<br />

the Tejo River, Portuguese sailors set out to conquer<br />

the world starting in the late 15th century. The<br />

city has many sights worth seeing – starting with<br />

the Belem Tower, the widely visible defence tower<br />

dating back to the 16th century and certainly not<br />

ending with the fascinating “azulejos”, the blue tiles<br />

that still adorn many houses in the old city, originally<br />

introduced to Portugal by the Moors.<br />

Portugal’s Estoril coast<br />

An exclusive resort long frequented by the local<br />

nobility, Estoril is less than 30 km away from Lisbon –<br />

about half an hour by car. Given this short distance, it<br />

is probably a good idea to spend the entire time at<br />

the Palácio Estoril Golf & Spa, riding in to Lisbon only<br />

for the symposium itself. The Palácio is probably the<br />

most well-known and certainly the most beautiful<br />

hotel in town and has a five-star rating. The rooms<br />

with their marble bathrooms are lavishly and comfortably<br />

furnished. The hotel itself was built in 1930 and

Elegance and<br />

refinement<br />

in the most<br />

beautiful hotel<br />

in Estoril: The<br />

Palácio Estoril.<br />

radiates elegance and refinement. It was the refuge<br />

for many eminent personalities during World War II.<br />

Famous films were shot here as well, including a James<br />

Bond film, “On Her Majesty’s Secret Service”. The beach<br />

is only 200 m away from the hotel with its 161 rooms<br />

and its renowned restaurants featuring local specialties<br />

and international cuisine, a gourmet grill, piano<br />

bar, ocean water swimming pool and sun terrace. During<br />

World War II, Bar Estoril was a popular meeting<br />

point for spies. Today the place offers an atmosphere<br />

of classical charm and a view of the poolside gardens.<br />

The hotel’s own golf course, the Parcour Golf do<br />

Estoril, is located only 5 km northeast of the hotel.<br />

One of Europe’s largest casinos is within walking distance,<br />

with one of the most beautiful beaches, Praia<br />

do Tamariz, directly adjacent.<br />

Schedule of events<br />

<strong>EDI</strong> 21<br />

Participants and their families can enjoy a one-week<br />

stay in rooms with a highly exclusive ambience<br />

(breakfast included) at the Palácio Estoril Golf & Spa<br />

in Estoril or, alternatively, two nights (10 – 12 June) at<br />

the Real Palácio in Lisbon and then move to the<br />

Palácio Estoril. The arrival date is 10 June. The international<br />

symposium and dental exhibition will take<br />

place at the Pestana in Lisbon on Saturday, 11 June.<br />

An interactive week of continuing education begins<br />

at the Palácio Estoril Golf & Spa on Monday, 13 June,<br />

and continues through Thursday, 16 June. Friday,<br />

17 June, will be the day of departure.<br />

AWU

22<br />

<strong>EDI</strong><br />

<strong>EDI</strong> News<br />

Symposium Saturday, 11 June 2011; Pestana Hotel, Lisbon<br />

08:45 – 09:00 am Professor Antonio Felino, Porto<br />

Christian Berger, Kempten<br />

✁<br />

Fax your registration to:<br />

+49 89 72069023<br />

or send an e-mail to:<br />

office-munich@bdizedi.org<br />

or send to<br />

BDIZ <strong>EDI</strong><br />

Lipowskystr. 12<br />

81373 Munich<br />

Germany<br />

Welcoming address<br />

09:00 – 09:25 am Professor João Carames, Lisbon Rehabilitation of the atrophic maxilla: New strategies<br />

09:30 – 09:55 am Dr Nuno Braz de Oliveira, Sesimbra Management of complex cases<br />

10:00 – 10:25 am Dr Roque Braz de Oliveira, Sesimbra Multi-detail management of the anterior maxillary segment – clinical cases and<br />

science<br />

10:30 – 11:00 am Coffee break · Exhibition visit<br />

11:00 – 11:25 am Dr Ricardo Faria Almeida, Porto Immediate implants and immediate function in the aesthetic zone – new challenges<br />

11:30 – 11:55 am Dr Francisco Salvado, Lisbon Bone regeneration: Bone, biomaterials and tissue engineering<br />

12:00noon–12:25 pm Professor Hakan Özyuvaci, Istanbul Reflections on 3D imaging in oral surgery and implantology<br />

12:30 – 12:55 pm Professor Joachim E. Zöller, Cologne Augmentation: Different techniques and different materials – high risk, low risk<br />

1:00 – 2:30 pm Lunch · Exhibition visit<br />

2:30 – 2:55 pm Dr Detlef Hildebrand, Berlin The TEAM-BERLIN-CONCEPT: Planning and implementation of implants<br />

in complex cases – a team approach<br />

3:00 – 3:25 pm Professor Antonio Felino, Porto The importance of bone-preserving surgical techniques for subsequent<br />

implantation procedures – clinical practice<br />

3:30 – 3:55 pm Coffee break · Exhibition visit<br />

3:55 – 4:20 pm Dr Dirk U. Duddeck, Cologne Comparative investigation of various implant surfaces by SEM analysis –<br />

a surprise in the land of microns<br />

4:25 – 4:55 pm Professor João Carlos Ramos, Coimbra Immediate implants: From investigation to clinical practice<br />

5:00 – 5:30 pm Professor Antonio Felino<br />

Professor Joachim E. Zöller<br />

Final Discussion<br />

Interactive education at the Palácio Estoril in Estoril: Monday, 13 June to Thursday, 16 June.<br />

Registration<br />

5th BDIZ <strong>EDI</strong> Mediterranean Symposium (11 June 2011), Pestana Hotel, Lisbon<br />

Continuing-education week, Palácio Estoril Golf & Spa Hotel, Estoril, 13 to 16 June<br />

Travel and accommodation:<br />

10–12 June Lisbon: Hotel Real Palácio ***** / with breakfast<br />

Doubles: € 78 per person per night, Singles: € 139 per person per night<br />

12–17 June Estoril: Hotel Palácio Estoril ***** / with breakfast<br />

Doubles: € 130 per person per night, Singles: €230 per person per night<br />

For reduced rates for children and prices for extension days, please inquire.<br />

Event charge<br />

Until 15 April € 480, after 16 April € 680<br />

(including the symposium and one week of interactive continuing education)<br />

Booking through a different travel agency or registering for the continuing-education course only<br />

is subject to a € 500 surcharge.<br />

For travel and course details please visit www.bdizedi.org (Events).<br />

I want to attend the 5th BDIZ <strong>EDI</strong> Mediterranean Symposium (10–17 June 2011). Please contact me.<br />

Surname, Firstname<br />

Street, Number<br />

Postal Code, City<br />

Contact, Phone, E-Mail<br />

Signature<br />

Each participant will be awarded 8 CE points per day.

Planmeca sets new standards with<br />

world’s fi rst dental unit integrated intraoral scanner<br />

for open connectivity to various CAD/CAM systems.<br />

We would like to invite you to explore the dentistry in new dimensions – see the perfect combination of digital<br />

intraoral scan, CBVT and 3D facial photo datasets in one 3D image. This digital perfection enables you to study<br />

patient’s complete anatomy in detail, plan and utilise open interface with modern CAD/CAM systems according<br />

to your needs. Now you can be one of the pioneering specialists, whether you are an implantologist, endodontist,<br />

periodontist, orthodontist or maxillofacial surgeon. The new era of dentistry is reality. It’s your decision.<br />

Planmeca Oy, Asentajankatu 6, 00880 Helsinki, Finland<br />

tel. +358 20 7795 500, fax +358 20 7795 555, sales@planmeca.com, www.planmeca.com<br />

1971 - 2011

24<br />

<strong>EDI</strong><br />

<strong>EDI</strong> News<br />

Teamwork and collaboration will be the central issue<br />

at this congress – collaboration between the two<br />

organizing associations, of course, but mainly collaboration<br />

between the patient, dental nurses and assistants,<br />

dental technicians and dentists. Professor<br />

Joachim E. Zöller, Professor Georg-H. Nentwig, Dr Georg<br />

Bayer and Christian Berger have also collaborated – on<br />

creating the schedule of events and on selecting the<br />

speakers. The result is a top-notch program with international<br />

contributions that neither dentists nor their<br />

teams nor dental technicians should miss.<br />

The presentations during the two congress days<br />

include the entire range of what is important for oral<br />

implantologists and their teams. The congress will<br />

be kicked off on Friday by the Young Implantologists<br />

Forum and the first industry workshop session. The<br />

main podium for all attendees will feature Professor<br />

Wilfried Wagner discussing serious risks that can be<br />

present in the oral cavity, e.g. in osteoporosis patients,<br />

and the treatment providers must beware of. Dr Jörg<br />

Neugebauer will present information about the<br />

application, cost and benefits of CBCT in the dental<br />

practice. Marketing professional Professor Gerhard F.<br />

Riegl will speak about the factors that make a dental<br />

office or clinic a success. Dr Gerd Körner and Dr Josef<br />

Diemer will report on periodontal treatment prior to<br />

implant placement and on tooth preservation from<br />

the endodontist’s point of view. BDIZ <strong>EDI</strong> legal advisor<br />

Dr Thomas Ratajczak will inform the audience on<br />

issues to keep in mind when informing patients of<br />

available treatment alternatives. After a final discussion<br />

on this set of topics, a second industry workshop<br />

session will conclude Friday’s business.<br />

15th BDIZ <strong>EDI</strong> Symposium · 8th International<br />

Annual Congress of the DGOI<br />

Implantology and<br />

the dental team<br />

Two organizers, one event: All systems are go for the joint congress of BDIZ <strong>EDI</strong> and DGOI in Munich on 16/17 September 2011.<br />

All spotlights are highlighting “Implantology and the dental team”. The five-star Hotel Sofitel Munich Bayerpost – next to the<br />

central railway station – has once again been selected as the pivotal point for dentists, dental nurses and assistants, dental<br />

technicians, the dental industry and of course the speakers at this two-day continuing-education event. In anticipation of<br />

Oktoberfest, scheduled to start the same weekend, BDIZ <strong>EDI</strong> and DGOI would love to see all attendees visit the special<br />

pre-Oktoberfest held in the Löwenbräukeller’s Oktoberfest “marquee”.<br />

Oktoberfest marquee<br />

The evening will be rustic: In anticipation of Oktoberfest,<br />

scheduled to start the same weekend, BDIZ <strong>EDI</strong><br />

and DGOI would love to see all attendees visit the<br />

Oktoberfest “marquee“ at Löwenbräukeller on centrally<br />

located Stigelmaierplatz. Pre-Oktoberfest means<br />

that we will be getting a head start by one day –<br />

the day before the traditional tapping of the barrel<br />

by Munich’s mayor. Many Oktoberfest aficionados can<br />

hardly wait to celebrate in the traditional manner<br />

and to savour the classic Oktoberfest atmosphere –<br />

enjoying Bavarian music and cabaret artists, and not<br />

least hearty food and drink.<br />

The implantological world<br />

assembles in Munich<br />

The entire world – it is said – will assemble in Munich<br />

at Oktoberfest. The implantological world, too, will<br />

assemble in Munich that weekend – with global<br />

speakers adding international flair: Speakers Dr Carl<br />

Misch (USA), Dr Eduardo Anitua (Spain) and Dr Maurice<br />

Salama (USA) will kick off Saturday’s program by<br />

discussing immediate vs. delayed implant placement,<br />

results achieved with short implants and orthodontic<br />

treatment before and after implant placement.<br />

Hard-tissue and soft-tissue aspects will be highlighted<br />

by Professor Joachim E. Zöller and Dr Stefan<br />

Reinhardt in their presentations on differential indications<br />

of augmentation techniques and materials and<br />

on new aspects in soft-tissue management, respectively.<br />

The presentations after lunch will once again

Looking For<br />

Efficiency?<br />

Encode is a registered trademark and Providing Solutions - One Patient At A Time and design<br />

are trademarks of BIOMET 3i LLC. BIOMET 3i and design are trademarks of BIOMET, Inc.<br />

©2011 BIOMET 3i LLC. All rights reserved.<br />

Enhanced<br />

Knowledge<br />

Comprehensive<br />

Treatment<br />

Business<br />

Excellence<br />

Introducing ’s Encode ® Impression on System For Improved Efficiency<br />

The Patient Friendly Solution:<br />

�� �����������������������������������������������<br />

For Implant Level Impressions<br />

�� ������������������<br />

�� �����������������������������������������<br />

Preserve The Soft Tissue<br />

Providing Clinicians��������������������������������������� ® Impression System<br />

�� �����������������������������������<br />

����������3i�����������������<br />

�����������������������������������������������<br />

�����������������������������������������<br />

��������������������������������������<br />

In Titanium or Zirconia<br />

Follow us on:<br />

�������������<br />

The Encode ®<br />

Impression<br />

System!<br />

Come and visit us at<br />

the 2011 IDS<br />

March 22-26, 2011<br />

Koelnmesse<br />

Hall 4.2<br />

Aisle J Nº039 - Aisle G Nº030<br />

To Improve Your Efficiency With The Encode® Impression System,<br />

Contact Your Local Sales Representative Today.<br />

Europe, Middle East, Africa Headquarters: +34-93-470-55-00<br />

Or visit us online at www.biomet3i.com<br />

���������������<br />

Smartphone!<br />

���������������������������<br />

������������������������<br />

���������������<br />

reader installed.<br />

ENCODE_ADV_B3I_EMEA(A4).indd 1 03/02/11 16:50

26<br />

<strong>EDI</strong><br />

<strong>EDI</strong> News<br />

Pre-Oktoberfest<br />

A contiguous section of seats has been reserved<br />

for BDIZ <strong>EDI</strong> and DGOI in the “Wiesn Marquee” at<br />

Löwenbräukeller on 16 September 2011. The ticket<br />

price of €38 p.p. includes a voucher for food and<br />

drink worth €16. While you may expect to see<br />

some guests in traditional Bavarian attire, there is<br />

no specific dress code. Sturdy clothing is recommended.<br />

address the entire team. Dr Fred Bergmann will shed<br />

some light on the interaction between surgical and<br />

prosthetic issues and discuss patient management.<br />

Professor Daniel Edelhoff will discuss whether CAD/<br />

CAM is ready to replace conventional impressions.<br />

Implantologists and dental technicians alike are also<br />

the presumptive audience of the presentation by<br />

Peter Finke on potential laboratory and prosthodontic<br />

complications.<br />

Late Saturday afternoon also has something in<br />

store for everyone: managing complications in<br />

referred patients (Dr Michael Stiller), “correct” billing<br />

for implantological treatments (Dr Hans-Joachim<br />

Friday, 16 September 2011<br />

Scientific program<br />

Implantology and the dental team<br />

08:00 – 10:00 am Young Implantologists Podium<br />

10:00 – 10:15 am Discussion<br />

10:15 – 10:30 am Coffee break · Exhibition visit<br />

10:30 am – 12:00 noon Workshop Session I<br />

12:00 noon – 1:00 pm Buffet lunch · Exhibition visit<br />

1:00 – 1:15 pm Welcome and introduction<br />

Dr Georg Bayer, President of DGOI, and<br />

Christian Berger, President of BDIZ <strong>EDI</strong><br />

1:15 – 2:00 pm Risk factors in the oral cavity<br />

(HIV, bisphosphonates)<br />

Professor Wilfried Wagner, Mainz<br />

2:00 – 2:30 pm CBCT – when, which, why, how much?<br />

Dr Jörg Neugebauer, Landsberg am Lech<br />

2:30 – 3:00 pm Teamwork at the successful<br />

dental office<br />

Professor Gerhard F. Riegl, Augsburg<br />

3:00 – 3:15 pm Discussion<br />

Nickenig) and aesthetic issues to be addressed by<br />

dentists in the laboratory (Dr Paul Weigl). The final<br />

discussion, too, is something to look forward to,<br />

because it will almost certainly address some questions<br />

related to the German fee schedule, GOZ.<br />

With this joint congress, BDIZ <strong>EDI</strong> and DGOI wish<br />

to send a signal in favour of deceleration, given the<br />

madly spinning carousel of implantological congresses<br />

and events in Germany. Dentists have long<br />

since lost track of the multitude of dates and offerings;<br />

the industry, too, has been complaining about<br />

the excessive number of events.<br />

AWU<br />

3:15 – 3:45 pm Coffee break · Exhibition visit<br />

BDIZ <strong>EDI</strong> and<br />

DGOI would<br />

love to see all<br />

attendees visit<br />

the special<br />

pre-Oktoberfest.<br />

3:45 – 4:15 pm Pre-implantological periodontics<br />

Dr Gerd Körner, Bielefeld<br />

4:15 – 4:45 pm Informing patients about treatment<br />

alternatives<br />

Dr Thomas Ratajczak, Sindelfingen<br />

4:45 – 5:15 pm Tooth preservation from an<br />

endodontist’s point of view<br />

Dr Josef Diemer, Meckenbeuren<br />

5:15 – 5:30 pm Final discussion<br />

Professor Georg-Hubertus Nentwig,<br />

Frankfurt, Professor Joachim E. Zöller,<br />

Cologne<br />

5:30 – 7:00 pm Workshop Session II<br />

Evening<br />

8:00 pm Kicking off Oktoberfest:<br />

Bavarian night at Löwenbräukeller<br />

Bavarian food and drink, music<br />

and comedy at the 13th “Wiesnzelt”<br />

marquee

Let’s get to work.<br />

True working results with the true all-in-one<br />

Orthopantomograph ®<br />

Orthopantomograph ®<br />

OC200 D VT<br />

The only original Orthopantomograph ®<br />

with new Core Lateral Ceph imaging<br />

program. Same proven superb image quality as before with up to 68% less radiation.<br />

All the important imaging tools you need in one unit – including Volumetric Tomography.<br />

Learn more at www.instrumentariumdental.com<br />

IDS Cologne 2011, Our stand in Hall 11.2, Aisle P, 050<br />

www.instrumentariumdental.com<br />

ID_OC200_D_add_<strong>EDI</strong>_2011.indd 1 24.2.2011 16:51:53

28<br />

✁<br />

<strong>EDI</strong><br />

<strong>EDI</strong> News<br />

Saturday, 17 September 2011<br />

Scientific program<br />

Implantology and the dental team<br />

08:30 – 08:45 am Welcome and introduction<br />

Professor Georg-Hubertus Nentwig,<br />

Professor Joachim E. Zöller<br />

08:45 – 09:30 am Immediate vs. delayed implant<br />

placement<br />

Dr Carl Misch, Beverly Hills/USA<br />

09:30 – 10:15 am Performance of short implants –<br />

evidence-based?<br />

Dr Eduardo Anitua, Vitoria/Spain<br />

10:15 – 11:00 am Orthodontic treatment before and<br />

after implant placement<br />

Dr Maurice Salama, Atlanta/USA<br />

11:00 – 11:15 am Discussion<br />

11:15 – 11:45 am Coffee break · Exhibition visit<br />

11:45 am – 12:30 pm Differential indications of augmentation<br />

techniques and materials<br />

Professor Joachim E. Zöller, Cologne<br />

12:30 – 12:45 pm New aspects of soft-tissue<br />

management<br />

Dr Stefan Reinhardt, Münster<br />

12:45 – 1:00 pm Discussion<br />

Please register via fax:<br />

+49 8243 9692-55<br />

or online: www.bdiz.dgoi.teamwork-media.de<br />

or by mail<br />

teamwork media GmbH<br />

Hauptstraße 1<br />

86925 Fuchstal<br />

Germany<br />

Registration<br />

1:00 – 2:00 pm Lunch break · Exhibition visit<br />

2:00 – 2:30 pm Surgery and prosthetics as team<br />

players: Patient management<br />

Dr Fred Bergmann, Viernheim<br />

2:30 – 3:00 pm Will CAD/CAM replace conventional<br />

impressions?<br />

Professor Daniel Edelhoff, Munich<br />

3:00 – 3:30 pm Laboratory and prosthodontic<br />

complications and liability issues<br />

Peter Finke, Erlangen<br />

3:30 – 3:45 pm Discussion<br />

3:45 – 4:15 pm Coffee break · Exhibition visit<br />

4:15 – 4:45 pm Managing complications in referred<br />

patients<br />

Dr Michael Stiller, Berlin<br />

4:45 – 5:15 pm “Correct” billing for implantological<br />

treatments<br />

Dr Hans-Joachim Nickenig, Cologne<br />

5:15 – 5:45 pm Laboratory-office teamwork:<br />

Aesthetics<br />

Dr Paul Weigl, Frankfurt<br />

5:45 – 6:00 pm Final discussion<br />

Dr Georg Bayer, Christian Berger<br />

Symposium<br />

Members of BDIZ <strong>EDI</strong>: € 350 (after 1 July: € 420)<br />

Non-members: € 450 (after 1 July: € 520)<br />

Assistant dentists: € 280 (after 1 July: € 350)<br />

Dental students: € 200 (after 1 July: € 270)<br />

Program for dental assistants<br />

Nurses, assistants: € 150 (after 1 July: € 180)<br />

Pre-Oktoberfest night: ______ tickets @ € 38 p.p. = € __________<br />

(subject to availability)<br />

Family name and given name<br />

Street address<br />

Postal code and city<br />

Contact/Phone/E-Mail<br />

Date and signature

Diagnostic<br />

performance!<br />

Versatile. Easy. Eff ective.<br />

Come to visit us at IDS Cologne<br />

Hall 11.2. Aisle N Booth 050<br />

Digital imaging made easy<br />

www.soredex.com<br />

SCANORA® 3D low dose digital cone<br />

beam unit featuring real panoramic<br />

imaging.<br />

The SCANORA® 3D contains the newest<br />