HiTeC & Yokogawa - emitec-industrial.ch

HiTeC & Yokogawa - emitec-industrial.ch

HiTeC & Yokogawa - emitec-industrial.ch

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

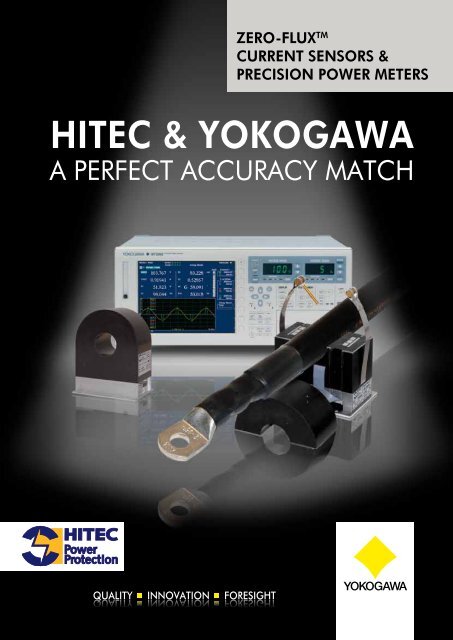

zero-flux TM<br />

CurrenT SenSorS &<br />

PreCiSion Power MeTerS<br />

<strong>HiTeC</strong> & <strong>Yokogawa</strong><br />

A perfect AccUrAcY mAt<strong>ch</strong>

contents<br />

Accuracy the perfect mat<strong>ch</strong> 3<br />

Electronic current sensors 4<br />

Zero-flux TM current sensors 5<br />

Power Meters & Analysers 6/7<br />

Added Value of Zero-flux TM current sensors 8/9<br />

Large Hadron Collider at Cern, Switzerland 10<br />

The basic principle 11<br />

aCCuraCY:<br />

THe PerfeCT MaTCH<br />

Hitec Power Protection and <strong>Yokogawa</strong> are global companies, both active in the high<br />

te<strong>ch</strong>nology segment of the electrical energy generation and conversion industry. Where<br />

Hitec focuses on UPS and highly accurate current sensors, <strong>Yokogawa</strong> concentrates on the<br />

pure high accuracy power measurements. As the values <strong>ch</strong>ange from kilowatt to megawatt<br />

the companies understand professionally how to complement ea<strong>ch</strong> other based on a long<br />

history and experience to keep the uncertainties to a minimum.<br />

The name Hitec Power Protection stands for more<br />

than 50 years of experience in power electronics,<br />

product innovation and dedication to zero downtime<br />

of mission critical processes. The result is high quality,<br />

cost efficient and reliable UPS te<strong>ch</strong>nology with minimal<br />

maintenance requirements. The Special Measuring<br />

Systems division of Hitec Power Protection offers<br />

solutions where accurate measurement of currents is<br />

required. You can rely on high quality products and a<br />

global operating organization.<br />

Features & Benefits:<br />

■ Te<strong>ch</strong>nology leader in high precision current<br />

measurement<br />

■ Accurate measurements based on Zero-flux TM<br />

principle<br />

■ High quality engineering and production<br />

■ Tailor-made solutions<br />

■ Over 35 years of experience in DCCT’s<br />

Hitec is specialised in high current measuring systems<br />

with high precision and stability for science, HVDC,<br />

healthcare and industry.<br />

Hitec Power Protections is a global te<strong>ch</strong>nology leader<br />

in rotary UPS systems for supply of uninterruptible,<br />

continuous and conditioned power to mission critical<br />

applications.<br />

Since its founding in 1915, quality, innovation and<br />

foresight have laid the foundations for <strong>Yokogawa</strong> to<br />

grow into the global multi-billion Euro organisation it<br />

is today. Providing high quality, highly reliable test and<br />

measurement solutions, we enable our customers to<br />

design, build and deploy next generation products that<br />

increase the quality of life, productivity and the efficient<br />

use of the world’s resources.<br />

Being engaged in cutting-edge resear<strong>ch</strong> and innovation<br />

has secured more than 7000 patents and registrations.<br />

This strong commitment to invest in R&D will continue<br />

long into the future, allowing us to extend our already<br />

comprehensive product range of digital oscilloscopes,<br />

power analysers and optical test equipment as well as<br />

data acquisition systems.<br />

<strong>Yokogawa</strong> is a global organisation and has over 1200<br />

employees spread throughout Europe and Africa in a<br />

network of strategic locations that are complemented<br />

by our partners in a distributor network. From Finland<br />

to Portugal and from Ireland to South Africa, every<br />

customer receives the local assistance to support their<br />

investment in our test and measurement solutions to<br />

enable them to be pioneers and innovators in their<br />

fields.<br />

Zero-flux TM current sensor wiring diagrams 12/13<br />

General Specifications<br />

MACC plus 14<br />

SC1000 14<br />

CURACC/STACC 15<br />

Contact 16<br />

3

eleCTroniC CurrenT<br />

SenSorS<br />

Measuring aC<br />

including DC Current<br />

the preferred current<br />

connection for power meters is<br />

the power meter direct current<br />

input. Up to 50Arms this is no<br />

problem but higher currents<br />

generate mu<strong>ch</strong> heat in the<br />

internal shunt, making the<br />

measurement inaccurate, due<br />

to temperature drift.<br />

■ measures Ac + Dc currents<br />

at the same time<br />

■ Isolated from the primary<br />

circuits<br />

■ Very high stability and<br />

accuracy<br />

■ high bandwidth<br />

■ Also available in clamp type<br />

■ Saturation detection circuit<br />

with automatic reset after<br />

over current<br />

■ can be swit<strong>ch</strong>ed on with<br />

current already present when<br />

connected<br />

External current<br />

sensors<br />

For higher currents the only<br />

solution is to make use of external<br />

current sensors. Current sensors<br />

are widely available, but current<br />

sensors for accurate energy and<br />

power measurements are scare. A<br />

current sensor for electrical power<br />

measurements needs to have<br />

specifications for its internal phase<br />

shifts at different frequencies.

zero-flux TM CurrenT<br />

SenSor TYPeS<br />

MaCC plus - external current sensor<br />

This is the most popular current sensor available, with a<br />

1000:1 current transfer ratio for maximal 850Apk (600Arms).<br />

In case of DC currents, max. 600Adc can be measured<br />

continuously. Also types with voltage outputs are available;<br />

■ 100Apk/10Vpk and 200Apk/10Vpk & 500Apk/10Vpk.<br />

■ With overload capacity of 20%, sinusoidal currents can be<br />

measured of respectively 85Arms, 170Arms and 430Arms.<br />

■ Maximum continuous DC currents are the same as the ACpeak<br />

limits.<br />

Can be used with the junction unit HUB4MACC to minimize<br />

wiring. The “current-in/current-out” type has preference over the<br />

“current in/voltage out” type, mainly because of better noise<br />

behaviour of the signals between the junction unit and the low<br />

impedance of the power meter current shunt.<br />

SC1000 - Split Core zero-flux TM current measuring<br />

system<br />

Often it is not possible or allowed to swit<strong>ch</strong>-off a motor used<br />

in a production facility or in a critical safety environment like<br />

a nuclear power plant. Also it can be inconvenient and costly<br />

to remove and replace eyelets of thick power cables in order<br />

to run them through the sensor hole. The new SC1000 high<br />

precision split-core current sensor solves these issues.<br />

■ Measures primary currents up to 1000Apk (700Arms).<br />

■ Transfer ratio is 1000Apk/0.5Apk or 1000Apk/10Vpk in<br />

case of a voltage output.<br />

■ The SC1000 can be used with the junction unit<br />

HUB4MACC to minimize wiring.<br />

CuraCC - zero-flux TM current measuring system<br />

If 1000Apk (700Arms) is not enough, then there is the<br />

CURACC-series, up to 6000Apk (4240Arms) for “current-in<br />

current-out”. Up to and including 2000Apk (1400Arms) we<br />

advise the head model B encapsulated, a resin encapsulated<br />

head that is more robust for industry applications. Between<br />

2000Apk (1400Arms) and 6000Apk (4240Arms) the head<br />

model E with side plates is advised for easy mounting and<br />

robustness.<br />

■ Output current always 1Apk at the primary peak current<br />

level as defined by the customer.<br />

■ In case of DC currents, max. 2000Adc (model B) resp.<br />

6000Adc (model E) can be measured continuously.<br />

■ Can be used with the junction unit SUM3 or SUM4 to<br />

minimize wiring.<br />

for every application there is a solution. please contact your local<br />

<strong>Yokogawa</strong> or hitec representative if you have even more demanding<br />

applications.<br />

The input current producing the specified output signal (1A or 10V) can be <strong>ch</strong>osen between<br />

±150Apk and ±6000Apk.<br />

Example: A CURACC ordered with a transfer ratio 500A/1A can measure currents from -500Apk<br />

to +500Apk, producing -1Apk to +1Apk at the output.<br />

5

Power MeTerS<br />

& analYSerS<br />

reliable measurements<br />

for all applications<br />

Meet the world’s most stable<br />

and accurate power analysers,<br />

with more bandwidth and<br />

more features. Supreme<br />

accuracy makes them ideal<br />

for transformer applications.<br />

Cos j measurements close to<br />

zero are normally difficult to<br />

make, but not for the WT series.<br />

They support up to 50/60 Hz<br />

(10/12 cycles) harmonic and<br />

inter-harmonic measurement<br />

and analysis, as required by the<br />

IEC61000 standards. It can also<br />

measure and analyse voltage<br />

fluctuation/flicker according to<br />

IEC61000-3-3/ -3-11.<br />

A powerful motor testing version<br />

is also available, allowing<br />

evaluation of motors, inverters,<br />

and both electrical efficiency<br />

and electrical/me<strong>ch</strong>anical<br />

efficiency measurements..<br />

■ large 8.4-in<strong>ch</strong> LcD<br />

supporting user-configurable<br />

screens<br />

■ USB and ethernet interfaces<br />

■ bandwidth: Dc, 0.1 hz<br />

to 1 mhz<br />

More accurate power<br />

measurements<br />

Transient and low power standby<br />

behaviour, transformers and<br />

highly distorted waveforms caused<br />

by inverters, motors, lighting<br />

circuits, power supplies, etc, all<br />

require stable and trustworthy<br />

measurements. <strong>Yokogawa</strong>, the<br />

world’s largest manufacturer of<br />

energy and power analysers and<br />

meters, provides a broad <strong>ch</strong>oice to<br />

satisfy all requirements.

software and accessories<br />

761922 Current Harmonic<br />

and Voltage fluctuation and<br />

flicker measurements<br />

Conform IEC-EN 61000-3-2/3/11/12 and<br />

IEC-EN 61000-4-7/15<br />

760122 wTViewer<br />

for wT-Power Meters<br />

Applications software downloads<br />

numerical & waveform data onto a PC<br />

and offers Remote- Control, GPIB, RS-<br />

232 or Ethernet.<br />

Power MeTerS<br />

& analYSerS<br />

wT3000 - power analyser<br />

Meet the world’s most stable and accurate power analyser,<br />

with more bandwidth and more features. Precise cos j<br />

measurements, close to zero, makes the WT3000 different<br />

from conventional power meters.<br />

■ Precise low cos j capabilities as required in transformer<br />

loss measurements<br />

■ IEC-EN61000-3-2/3/11/12 compliancy test<br />

■ IEC-EN61000-4-7/15<br />

■ Motor version, Bandwidth DC, 0,1Hz to 1MHz<br />

wT500 - compact power analyser<br />

The WT500 offers features for efficiency measurements<br />

of power conditioners in the field of renewable energy<br />

with high-speed data updating (100 ms) and display<br />

of numerical values, waveforms and trends. It can also<br />

measure bought and sold watt hours separately.<br />

■ Current range: 0.5 to 40 A, Voltage range: 15 to 1000 V.<br />

■ Easy setup and operation<br />

■ Frequency range: DC and 0.5 Hz to 100 kHz<br />

wT210 (1-phase) & wT230 (2-3 phase) series<br />

One compact instrument to measure voltage,<br />

current, phase angle, power factor, harmonics etc. The most<br />

widely used power meter in production facilities.<br />

■ Extremely good price/performance ratio<br />

■ Ranges down to 5 mA (WT210) to measure standby/<br />

sleep mode power with 25 µA resolution<br />

■ Go-NoGo test output for production testing<br />

wT1600/wT1600S - digital power meter<br />

Offers electrical pump and motor testers a free selection of<br />

input elements and a wide <strong>ch</strong>oice of measurement ranges<br />

for a higher accuracy.<br />

■ Standard master-slave function allows syn<strong>ch</strong>ronised<br />

operation of 4 WT1600 meters or 24 power elements<br />

■ Input frequency range DC, 0.5 Hz to 1 MHz (DC, 0.5<br />

Hz to 300 kHz for WT1600S)<br />

■ Highest accuracy energy measurements via 200 kS/s<br />

continuous sample speed<br />

■ Up to the 100th order harmonic<br />

Pz4000 - Single shot power analyser<br />

By combining our high precision power measurement and<br />

deep-memory oscilloscope te<strong>ch</strong>nology, <strong>Yokogawa</strong> has<br />

created a unique instrument suitable for analysing power in<br />

linear motors, unstable loads, and fast transients.<br />

■ Scope style triggering<br />

■ High speed sampling to 5 MS/s<br />

■ Cursor measurements on original data<br />

■ Power frequency input range DC to 2 MHz<br />

253734 Power viewer<br />

for Pz4000<br />

Communicates and offers Remote-<br />

Control to the PZ4000. Allows<br />

MATH functions on the PC for full<br />

PZ4000 memory extentions.<br />

7

why an external Zeroflux<br />

tm current sensor?<br />

To maintain the unique features of<br />

the <strong>Yokogawa</strong> power meters, su<strong>ch</strong><br />

as measuring accurately current<br />

and power from DC up to several<br />

kHz, it is necessary to connect<br />

special current sensors with the same<br />

features. This is of great importance<br />

for measuring conversion efficiency<br />

in situations where DC power is<br />

converted to AC power as for solar<br />

power or variable frequency drives.<br />

temPerature & Phase shift<br />

The normal connection for measuring<br />

current with power meters is the<br />

“direct current input”, whi<strong>ch</strong> consists<br />

of a special resistor with very good<br />

AC properties, the shunt. Up to<br />

50Arms for <strong>Yokogawa</strong>’s WT1600<br />

(33Arms for WT3000) is no<br />

problem. Higher currents however<br />

generate too mu<strong>ch</strong> heat in this shunt<br />

to maintain accurate measurements<br />

due to temperature drift.<br />

For this reason, measuring higher<br />

currents requires external current<br />

sensors. Current sensors (most for<br />

50–60Hz only) are widely available,<br />

but current sensors for accurate<br />

energy and power measurements are<br />

scarce. A current sensor for electrical<br />

power measurements needs to have<br />

specifications, not only for its transfer<br />

ratio, but also for its internal phase shifts<br />

at several frequencies and it’s stability.<br />

ct anD Dcct<br />

Conventional AC measurement<br />

Current Transformers (CT’s) lack the<br />

capability to measure current at low<br />

frequencies (for example 5Hz, as<br />

found in frequency inverter drives).<br />

DC current will not be transformed<br />

at all, as it saturates the transformer.<br />

8<br />

Output<br />

AC with some DC might saturate a<br />

conventional transformer, or at least<br />

strongly distort the current shape.<br />

The Hitec Direct-Current Current<br />

Transformer (DCCT), based on<br />

the Zero-flux TM principle, is able<br />

to measure currents in a wide<br />

bandwidth from DC to several kHz<br />

with a very high accuracy.<br />

Hitec DCCT’s eliminate measuring<br />

errors whi<strong>ch</strong> may arise with<br />

conventional AC-sensors.<br />

Galvanic isolation<br />

More and more users in the Industry<br />

start to appreciate the performance<br />

of the Hitec Zero-flux TM CT’s for<br />

precise current measurements related<br />

to electrical power and energy. A<br />

Zero-flux TM CT consists of a special<br />

multi-core toroidal measuring head<br />

and an electronics module. The<br />

high accuracy and stability of the<br />

Hitec Zero-flux TM CT is based on<br />

the Zero-flux TM principle that actively<br />

maintains a perfect balance between<br />

the magnetic fields of the primary<br />

and secondary windings down to<br />

the parts-per-million (ppm) level. The<br />

Zero-flux TM CT sensors are galvanic<br />

isolated from the primary circuits,<br />

similar to conventional AC-current<br />

transformers.<br />

Powerloss Dc-comPonent<br />

As most AC clamps and sensors<br />

today ignore DC current by not being<br />

able to measure DC, the Zero-flux TM<br />

CT measures the true wave shape,<br />

including the DC component. This<br />

is a great improvement for PWM<br />

inverters measurements, where any<br />

DC component at the output creates<br />

a power-loss in the drive and motor<br />

windings and therefore should be<br />

measured.<br />

aDDeD Value of zero-fl<br />

Power loss measurements on big transformers require an<br />

equals 1 MW uncertainty.<br />

Zero-flux TM sensors used in the 500 kV High Voltage Dire<br />

current measuring systems in the NORNED converter sta<br />

of 700 MW.<br />

Transfer ratio of<br />

isolated current<br />

sensor types and<br />

the <strong>Yokogawa</strong><br />

power meter<br />

direct input.

ux TM CurrenT SenSorS<br />

extreme high accuracy: 0,1% of a 1 GW transformer<br />

ct Current transmission. Shown here are the three-phase<br />

tion in Eemshaven (NL) with a total power transmission<br />

accuracy<br />

The accuracy of the Hitec Zero-flux TM<br />

CT sensors mat<strong>ch</strong>es perfectly with<br />

the high accuracy of the power<br />

meters from <strong>Yokogawa</strong>. The typical<br />

accuracy of a Zero-flux TM CT with a<br />

closed type sensor head is 0.01%<br />

of the rated current (50Hz). Closed<br />

AC/DC-type sensors equipped with<br />

Hall-elements do have an uncertainty<br />

of approximately 0.1% of the rated<br />

current.<br />

sPlit-core<br />

A disadvantage in using closed type<br />

current sensors is that the primary<br />

conductors temporarily have to be<br />

disconnected from the load. The<br />

load has to be swit<strong>ch</strong>ed off, eyelets<br />

of the cable connection need to<br />

be replaced if they don’t fit through<br />

the sensor hole etc. This is not<br />

always allowed and at least timeconsuming,<br />

inconvenient and costly.<br />

Often it requires the assistance of an<br />

installation engineer<br />

Therefore Hitec developed the<br />

SC1000 high precision split-core<br />

Zero-flux TM CT, with an overall<br />

accuracy of 0.1% of the rated current<br />

(for DC and AC), where<br />

as traditional clamp type<br />

accuracy normally starts<br />

with a 1% uncertainty.<br />

The SC1000 reduces the<br />

measurement uncertainty<br />

on a 4 MW motor/<br />

generator from 40 kW to<br />

4kW.<br />

multi-Phase anD easy<br />

connection<br />

The Hitec current sensors can be<br />

delivered as a single unit to measure<br />

single-phase current or as a multiphase<br />

system with 3 or 4 Zero-flux TM<br />

CT’s together with a junction unit,<br />

powering all Zero-flux TM CT’s. The<br />

junction unit interconnects the current<br />

sensors and directs all measuring<br />

signals to one output connector to<br />

whi<strong>ch</strong> the <strong>Yokogawa</strong> power meter is<br />

connected.<br />

In case of multiple primary cables per<br />

phase (power generators, distribution<br />

transformers etc.) it is even possible to<br />

parallel the Zero-flux TM current sensors<br />

to measure higher currents.<br />

The standard cable length between<br />

the sensor head and the junction unit<br />

is 3 meter. Up to 50 meter of cable<br />

length is possible on request, more<br />

than 50 meter, depends on the local<br />

noise environment.<br />

The same flexibility applies for the<br />

cable length between the junction<br />

unit and power meter.<br />

measurinG ac-current incluDinG Dc-current; the Zero-flux tm current transformer<br />

■ Measures AC + DC currents at<br />

the same time<br />

■ Isolated from the primary circuits<br />

■ Current output or voltage output<br />

■ Wide bandwidth<br />

■ Also a clamp type is available<br />

■ Can be swit<strong>ch</strong>ed on with primary<br />

current already present<br />

■ Long cables possible for remote<br />

operation<br />

Electrical motors easily draw 300 A or more.<br />

■ Saturation detection circuit with<br />

automatic reset after over current<br />

■ Very high stability and accuracy<br />

9

large HaDron ColliDer aT Cern,<br />

SwiTzerlanD<br />

The first manufacturer<br />

The Zero-flux TM principle is by<br />

far the best way to measure<br />

Direct Currents. Galvanic<br />

separation, extremely high<br />

accuracy and stability are<br />

the foremost advantages of<br />

this principle. The Zero-flux TM<br />

principle was already known at<br />

the turn of the 20th century, but<br />

was never put into practice.<br />

It found its revival in the mid<br />

sixties when a scientist at<br />

Cern in Geneva, developed<br />

te<strong>ch</strong>niques to use it for very<br />

accurate measurements of<br />

current. Soon a commercial<br />

version became available for<br />

general use when Hitec Power<br />

Protection became the first to<br />

manufacture a product based<br />

on this zero-flux principle.<br />

The Large Hadron Collider (Photo CERN © Geneva)<br />

The Zero-flux TM<br />

current sensors<br />

the Zero-flux tm current sensors are<br />

well-liked in high-energy physics<br />

resear<strong>ch</strong> centers for rectification<br />

systems supplying the current<br />

that generate the magnetic fields<br />

for the focusing and deflection<br />

of elementary particles or for the<br />

containment of plasma.

Basic diagram of a Zero-flux TM<br />

CT with voltage output<br />

the basic PrinciPle<br />

The primary current Ip generates a magnetic flux that<br />

will be counteracted by the current Is in the secondary<br />

winding (Ns) of the measuring head. Any remaining flux<br />

is sensed by three toroidal-wound ring cores located<br />

within the secondary winding volume.<br />

Two of them (N1, N2) are used to sense the DC part of<br />

the remaining flux. N3 senses the AC part.<br />

An oscillator drives the two DC flux-sensing cores into<br />

saturation in opposite directions. The resulting current<br />

peaks are equal in both directions if the remaining DC<br />

flux is zero. If not zero, their difference is proportional<br />

to the residual DC flux. The Zero-flux TM CT has a double<br />

peak detector to find this DC flux. After adding the AC<br />

component (N3), a control loop is set up to generate<br />

the secondary current that makes the flux zero. A power<br />

amplifier provides this current Is to the secondary winding<br />

Ns. The secondary current, whi<strong>ch</strong> is a scaled image<br />

(1/Ns) of the primary current, is fed to the burden resistor<br />

to convert the signal into a voltage. The signal across<br />

the burden is amplified to make the signal available<br />

for further use. The unique design of the Zero-flux TM CT<br />

system provides high accuracy and stability without the<br />

need for temperature control devices.<br />

Above several kHz, the power amplifier no longer has<br />

active control over its output current, but merely forms<br />

a short circuit. The Zero-flux TM CT still performs as a<br />

wideband current measuring device, but now with the<br />

measuring head as a passive current transformer. The<br />

final bandwidth is only limited by the stray reactance<br />

and capacitance in the head and interconnecting cable.<br />

THe baSiC PrinCiPle<br />

In case of a Zero-flux TM CT with current output, the<br />

secondary current is the output, omitting in that case the<br />

burden resistor and precision amplifier.<br />

If the core saturates due to primary overload, the zero<br />

flux condition is lost, and a sear<strong>ch</strong> cycle is started<br />

automatically. This means the secondary current is swept<br />

between the minus and plus current limits in a slow<br />

triangle until zero flux is detected, and normal tracking<br />

continues. The same happens when the auxiliary power<br />

is swit<strong>ch</strong>ed-on with primary current present.<br />

the burDen resistor<br />

In view of required measurement precision a four-wire<br />

resistor is the best. The power dissipation is kept very<br />

low, because the voltage drop across the resistor (usually<br />

0.5V at rated current) is low. The thermal stability of the<br />

burden resistor, under normal load conditions, is ensured<br />

even over the long time.<br />

the Precision amPlifier<br />

The precision amplifier is a very stable differential<br />

amplifier, whi<strong>ch</strong> delivers a highly accurate output<br />

voltage, proportional with the secondary current through<br />

the burden resistor. To ensure that the gain factor remains<br />

constant, the temperature coefficients of the gain-setting<br />

resistors are mat<strong>ch</strong>ed (TC tracking). The offset error<br />

is minimized by careful selection of the operational<br />

amplifier and fine-tuned during adjustment. The gain,<br />

usually 20x, is factory adjusted in order to compensate<br />

for tolerances in burden and gain-setting resistors. The<br />

output usually delivers 10V at the rated current and may<br />

be loaded by up to 5mA.<br />

11

zero-flux TM CurrenT<br />

SenSor DiagraMS<br />

a tyPical Zero-flux tm ct set-uP consists of the followinG comPonents:<br />

■ Sensor head(s)<br />

■ Cable between ea<strong>ch</strong> measuring<br />

head and the junction unit<br />

■ Junction unit with built-in wiring<br />

and power supply<br />

■ Cable between the junction unit<br />

and the power meter<br />

■ Power supply cable<br />

■ Power meter<br />

MACC plus with current output<br />

Ratio: 1000:1 Maximum primary current 1000Apk (600Arms)<br />

Current<br />

Current sensor MACC plus<br />

(up to 4), ea<strong>ch</strong> with<br />

control electronics<br />

Mains supply<br />

MACC plus with voltage output<br />

12<br />

Current<br />

Current sensor MACC plus<br />

(up to 4), ea<strong>ch</strong> with<br />

control electronics<br />

Mains supply<br />

Wiring<br />

Power Supply<br />

Junction unit HUB4MACC<br />

Power Supply<br />

Junction unit HUB4MACC<br />

Current<br />

4<br />

Voltage<br />

4<br />

Power Meter<br />

(Current Input)<br />

Power meter shunt =<br />

burden resistor<br />

Ratio: 10Vpk at a maximum primary current of 100Apk (70Arms), 200Apk (140Arms) or<br />

500Apk (350Arms)<br />

Wiring<br />

Burden resistors<br />

with precision<br />

amplifier<br />

Power Meter<br />

(Sensor Input)

SC1000 with current output<br />

Current<br />

Current sensor SC1000<br />

(up to 4), ea<strong>ch</strong> with<br />

control electronics<br />

Power Supply<br />

zero-flux TM CurrenT<br />

SenSor DiagraMS<br />

Ratio 2000:1 (=1000A : 0.5A) Maximum primary current 1000Apk (700Arms)<br />

Current<br />

Current sensor SC1000<br />

(up to 4), ea<strong>ch</strong> with<br />

control electronics<br />

Mains supply<br />

SC1000 with voltage output<br />

Ratio: 10Vpk at a maximum primary current of 1000Apk (700Arms), 1V/100A<br />

Mains supply<br />

Current<br />

Current sensor<br />

model B or E<br />

(up to 4)<br />

Mains supply<br />

Wiring<br />

Power Supply<br />

Junction unit HUB4MACC<br />

Wiring<br />

Burden resistors<br />

with precision<br />

amplifier<br />

Junction unit HUB4MACC<br />

Wiring<br />

Control electronics<br />

Power Supply<br />

Junction unit SUM3 or SUM4 (3U/19”)<br />

Current<br />

Voltage<br />

CURACC with current output (all electronics centralized in the junction unit)<br />

4<br />

Current<br />

4<br />

Power Meter<br />

(Current Input)<br />

Power meter shunt =<br />

burden resistor<br />

Power Meter<br />

(Sensor Input)<br />

Ratio: User defined,1Apk at requested rated primary current up to 6kApk (4240 Arms)<br />

4<br />

Power Meter<br />

(Current Input)<br />

Power meter shunt =<br />

burden resistor<br />

13

general<br />

SPeCifiCaTionS<br />

hitec current sensors as useD with yokoGawa Power meters<br />

macc plus <strong>ch</strong>aracteristic specification<br />

current output type<br />

Input range DC ±600A (±850Apk)<br />

Input range AC ±850Apk (600Arms)<br />

Transfer ratio 1000:1<br />

External burden 0…1Ω (at max. current)<br />

Accuracy DC 0.005% of reading + 0.002% of range<br />

Accuracy AC<br />

voltage output type<br />

0.010% of reading + 0.002% of range<br />

Input range DC ±100, 200 or 500A<br />

Input range AC ±100, 200 or 500Apk (70, 140 or 350Arms)<br />

Transfer ratio 10, 20 or 50A/V<br />

Output voltage 12Vmax with ≥2kΩ load<br />

Accuracy DC 0.020% of reading + 0.005% of range<br />

Accuracy AC<br />

General<br />

0.025% of reading + 0.005% of range<br />

Bandwidth DC … 100kHz (-3dB)<br />

Overload 120% (DC / AC)<br />

Supply voltage ±15Vdc (max. 1Apk)<br />

Dimensions 112x82x45mm<br />

Hole diameter 25mm<br />

sc1000 (split core) <strong>ch</strong>aracteristic specification<br />

current output type<br />

Input range DC ±1000A<br />

Input range AC ±1000Apk (700Arms)<br />

Transfer ratio 2000:1<br />

External burden 0…2Ω (at max. current)<br />

Accuracy DC / AC<br />

voltage output type<br />

0.01% of reading + 0.08% of range<br />

Input range DC ±400 or 1000A<br />

Input range AC ±400 or 1000Apk (280 or 700Arms)<br />

Transfer ratio 40 or 100A/V<br />

Output voltage 12Vmax with ≥2kΩ load<br />

Accuracy DC / AC<br />

General<br />

0.02% of reading + 0.08% of range<br />

Bandwidth DC … 100kHz (-3dB)<br />

Overload 110% (DC / AC)<br />

Supply voltage ±15Vdc (max. 0.6Apk)<br />

Dimensions 163x130x70mm<br />

Hole diameter 45mm<br />

Notes:<br />

Specification for ambient 25±10°C, humidity ≤90% (non condensing) and sinusoidal AC-currents. Junction unit system HUB4MACC available<br />

for supplying up to four MACC plus or four SC1000 with “current-in/current-out” or “current-in/voltage-out” option.<br />

Input currents with f > 1kHz must be de-rated according to the graph on the next page.<br />

14

curacc/stacc <strong>ch</strong>aracteristic specification<br />

general<br />

SPeCifiCaTionS<br />

current output type (curacc)<br />

Input range DC, up to ±2000A model B, ±6000A model E<br />

Input range AC, up to ±2000Apk (1400Arms), ±6000Apk (4200Arms)<br />

Transfer ratio user defined 1Apk at requested primary peak current<br />

External burden 0…1Ω (at 1Apk)<br />

Accuracy DC 0.002% of reading + 0.001% of range<br />

Accuracy AC<br />

voltage output type (stacc)<br />

0.010% of reading + 0.002% of range<br />

Input range DC, up to ±2000A model B, ±6000A model E<br />

Input range AC, up to ±2000Apk (1400Arms), ±6000Apk (4200Arms)<br />

Transfer ratio 10Vpk at requested primary peak current 2000:1 or 6000:1<br />

Output voltage 12Vmax with ≥2kΩ load<br />

Accuracy DC 0.010% of reading + 0.005% of range<br />

Accuracy AC<br />

General<br />

0.015% of reading + 0.005% of range<br />

Bandwidth DC … 100kHz (-3dB)<br />

Overload 110% (DC / AC)<br />

Supply voltage ±24, ±32 or ±40Vdc (max. 1Apk)<br />

Dimensions head B: 170x130x70mm, E: 225x225x180mm<br />

Hole diameter B: 45mm, E: 56mm<br />

Notes:<br />

Specification for ambient 25±10°C, humidity ≤90% (non condensing) and sinusoidal AC-currents. Junction unit system SUM3 resp. SUM4<br />

available for supplying three resp. four CURACCs “current-in/current-out” or STACCs “current-in/voltage-out”.<br />

Input currents with f > 1kHz must be de-rated according to the graph below.<br />

Amplitude of continuous current<br />

De-rating curve for input signals with f > 1 kHz<br />

inPut current anD crest factor<br />

The Zero-flux TM CT specifies the maximum waveform peak current, rather than the maximum rms-current, as done for the<br />

direct current input of the <strong>Yokogawa</strong> power meters. For example to measure 1000Arms with a Zero-flux TM CT you need a<br />

type suitable for 1400Apk, whi<strong>ch</strong> is the peak value of the sinusoidal current.<br />

Currents having high crest factors also can be measured properly, as long as the waveform “fits” within the peak current<br />

capabilities of the Zero-flux TM CT.<br />

This means you can measure currents up to 280Arms having a crest factor of 5.<br />

15

euroPean HeaDQuarTerS<br />

<strong>Yokogawa</strong> euroPe b.V.<br />

Euroweg 2,<br />

3825 HD, Amersfoort<br />

The Netherlands<br />

Tel. +31 88 464 1000<br />

Fax +31 88 464 1111<br />

info@yokogawa.nl<br />

http://tmi.yokogawa.com<br />

http://www.hitecsms.com<br />

<strong>HiTeC</strong> Power ProTeCTion<br />

HeaDQuarTerS<br />

<strong>HiTeC</strong> Power ProTeCTion b.V<br />

Bedrijvenpark Twente 40<br />

7602 KB Almelo<br />

The Netherlands<br />

Tel. +31 546 589 589<br />

Fax +31 546 589 489<br />

E-Mail: info@hitec-ups.com<br />

www.hitecsms.com<br />

euroPe<br />

TeST anD MeaSureMenT SaleS neTwork<br />

THe neTHerlanDS<br />

<strong>Yokogawa</strong> Europe B.V.<br />

T&M Division -<br />

Sales Netherlands & Belgium<br />

Euroweg 2,<br />

3825 HD, Amersfoort<br />

The Netherlands<br />

Tel. +31 88 464 1000<br />

Fax +31 88 464 1111<br />

iTalY<br />

<strong>Yokogawa</strong> Italia S.r.l.<br />

Via Pelizza da Volpedo 53<br />

20092 Cinisello Balsamo (MI)<br />

Italy<br />

Tel. +39 02 66 055 1<br />

Fax +39 02 66 011 415<br />

uniTeD kingDoM<br />

<strong>Yokogawa</strong> Measurement<br />

Te<strong>ch</strong>nologies Ltd<br />

Stuart Road, Manor Park<br />

Runcorn, Cheshire<br />

WA7 1TR<br />

United Kingdom<br />

Tel. +44 1928 597200<br />

Fax +44 1928 597201<br />

T&M DiSTribuTor neTwork<br />

<strong>Yokogawa</strong> has an extensive distribution<br />

network. To find the representative in<br />

your country or close to you,<br />

go to http://tmi.yokogawa.com<br />

or call +31 88 464 1000<br />

or email to t&m@nl.yokogawa.com<br />

BU-H-Y09 Subject to <strong>ch</strong>ange without notice. Copyright © <strong>Yokogawa</strong>, 2009. Printed in The Netherlands, 01-909.<br />

gerManY<br />

<strong>Yokogawa</strong> Measurement<br />

Te<strong>ch</strong>nologies GmbH<br />

Gewerbestrasse 17<br />

D-82211 Herrs<strong>ch</strong>ing<br />

Germany<br />

Tel. +49 815293 100<br />

Fax +49 815293 1060<br />

SPain iberia<br />

<strong>Yokogawa</strong> Iberia S.A.<br />

c/Lezama, Nº22<br />

28034 Madrid<br />

Spain<br />

Tel. +34 91 771 31 50<br />

Fax +34 91 771 31 80<br />

norDiC<br />

<strong>Yokogawa</strong> Measurement<br />

Te<strong>ch</strong>nologies A.B.<br />

Finlandsgatan 52, 2fl<br />

SE-164 74 Kista<br />

Stockholm<br />

Sweden<br />

Tel. +46 8 477 1900<br />

Fax +46 8 477 1999