You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3902017 05.12 Product Information<br />

<strong>Inline</strong> <strong>Power</strong> <strong>Venter</strong><br />

<strong>IPVB</strong><br />

Use<br />

The <strong>IPVB</strong> <strong>Power</strong> <strong>Venter</strong> is intended for use as a true<br />

in-line draft inducer. It can be installed in-line in the<br />

vertical or horizontal section of a chimney or stack.<br />

It is specifically designed for applications where<br />

reliable and efficient operation, low noise level, low<br />

energy consumption, variable speed and compact<br />

design are of utmost importance.<br />

The <strong>IPVB</strong> is for use with condensing and noncondensing<br />

appliances at flue gas temperatures of<br />

575 o F (302 o C).<br />

Typical uses are: mechanical venting of gas-fired<br />

or oil-fired boilers and water heaters. For indoor or<br />

outdoor installation.<br />

Description<br />

The <strong>IPVB</strong> <strong>Power</strong> <strong>Venter</strong> is an efficient, hightemperature<br />

ventilator with backward-inclined<br />

impeller. The ventilator housing is made of stainless<br />

steel and equipped with an energy-efficient, totally<br />

enclosed, variable speed motor, which is mounted<br />

outside the air stream. The design is a Type B, Spark<br />

Resistant Construction. The motor and impeller is a<br />

complete assembly (drive unit) that can be removed<br />

from the fan housing without removing the fan from<br />

the stack system. The stack connections are of the<br />

flanged connection type and fit most commercial<br />

pre-fabricated chimney systems. Slip connection<br />

fittings are available. The fan is typically installed<br />

hung from ceiling mounting brackets to support the<br />

weight. The <strong>IPVB</strong> is a component in the ENERVEX<br />

CASI, Chimney Automation System.<br />

Material<br />

The housing is made of 316L stainless steel. The<br />

impeller is of the backward inclined type made of<br />

cast aluminum.<br />

Specifications are subject to change without notice.<br />

Motor<br />

Commercial grade, totally enclosed (TEFC), variable<br />

speed, Class A insulated motor with sealed and<br />

permanently lubricated bearings. Thermal overload<br />

protection.<br />

Accessories<br />

EBC 30 or EBC 12 Modulating Fan Control, Variable<br />

Frequency Drive (VFD), PDS, ECO Economizer<br />

(integrated)<br />

Listings<br />

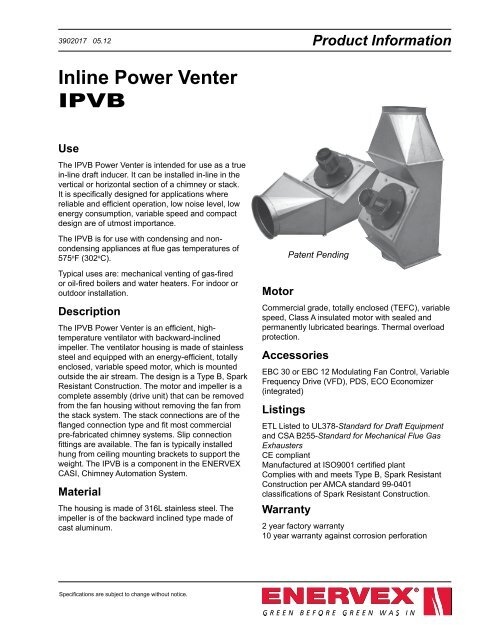

Patent Pending<br />

ETL Listed to UL378-Standard for Draft Equipment<br />

and CSA B255-Standard for Mechanical Flue Gas<br />

Exhausters<br />

CE compliant<br />

Manufactured at ISO9001 certified plant<br />

Complies with and meets Type B, Spark Resistant<br />

Construction per AMCA standard 99-0401<br />

classifications of Spark Resistant Construction.<br />

Warranty<br />

2 year factory warranty<br />

10 year warranty against corrosion perforation

3902017 05.12 Product Information<br />

Specifications<br />

Model <strong>IPVB</strong> 300 <strong>IPVB</strong> 350 <strong>IPVB</strong> 400 <strong>IPVB</strong> 500<br />

Fan Type Centrifugal Impeller (B-wheel)<br />

Motor Type TEFC<br />

Voltage VAC 1 x 120 3 x 200-240 / 3 x 440-480<br />

Amperage Amps 5.8 2.6 / 1.5 5.5 / 2.9 7.8 / 4.1<br />

Motor Output HP 0.5 1.0 2.0 3.0<br />

Removal of drive unit Fan without drive unit<br />

ENERVEX Inc.<br />

1685 Bluegrass Lakes Pkwy.<br />

Alpharetta, GA 30004<br />

kW 0.35 0.75 1.5 2.2<br />

Max. RPM 1600 1740<br />

Duct Connection<br />

in 12 14 16 20<br />

(Nominal)<br />

mm 300 350 400 500<br />

Dimensions A in 19.3 22.4 26.4 29.5<br />

mm 490 569 671 749<br />

B in 13.0 14.6 17.0 21.3<br />

mm 330 371 432 541<br />

C in 13.9 15.5 17.8 22.1<br />

mm 353 394 452 561<br />

D in 12.1 14.0 16.0 20<br />

mm 306 356 406 508<br />

E in 11.1 12.7 14.6 16.2<br />

mm 282 322 370 411<br />

F in 6.9 7.8 8.9 11.1<br />

mm 175 198 226 282<br />

G in 15.8 15.8 16.2 20.1<br />

mm 401 401 411 511<br />

H in 21.6 24.6 26.3 30.0<br />

mm 549 625 668 762<br />

J in 2.5 2.5 2.6 2.7<br />

mm 64 64 66 69<br />

L in 47.1 51.2 56.8 66.9<br />

mm 1199 1300 1443 1699<br />

W in 22.2 25.3 29.2 32.4<br />

mm 564 643 742 823<br />

Weight lbs 75 94 128 182<br />

kg 34 42.5 58 82.5<br />

Max. Temperature 575oF (302oC) Continuous<br />

P: 770.587.3238<br />

F: 770.587.4731<br />

T: 800.255.2923<br />

info@enervex.com<br />

www.enervex.com<br />

Capacity:<br />

Pt (inW.C.)<br />

5.0<br />

4.5<br />

4.0<br />

3.5<br />

3.0<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

<strong>IPVB</strong> 300<br />

<strong>IPVB</strong> 350<br />

<strong>IPVB</strong> 400<br />

<strong>IPVB</strong> 500<br />

0.0<br />

0 1000 2000 3000<br />

Volume (cfm)<br />

4000 5000<br />

NOTE:<br />

The capacity data above is tested in accordance<br />

with ISO Standard 5801-Industial Fans Performance<br />

Testing Using Standardized Airways.<br />

6000