Manual - Delta Electronics

Manual - Delta Electronics

Manual - Delta Electronics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Preface<br />

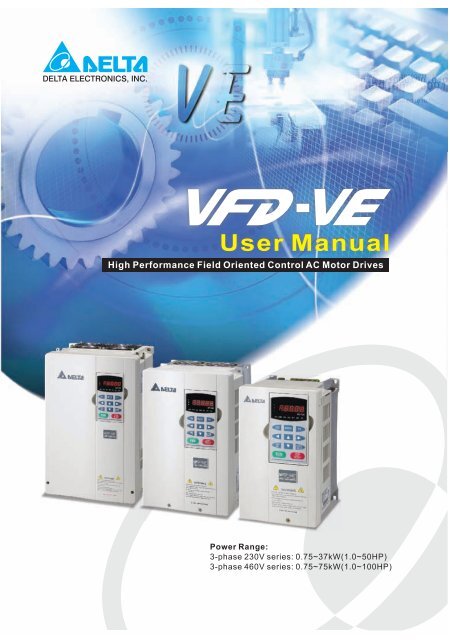

Thank you for choosing DELTA’s high-performance VFD-VE Series. The VFD-VE Series is<br />

manufactured with high-quality components and materials and incorporates the latest microprocessor<br />

technology available.<br />

This manual is to be used for the installation, parameter setting, troubleshooting, and daily<br />

maintenance of the AC motor drive. To guarantee safe operation of the equipment, read the following<br />

safety guidelines before connecting power to the AC motor drive. Keep this operating manual at hand<br />

and distribute to all users for reference.<br />

To ensure the safety of operators and equipment, only qualified personnel familiar with AC motor<br />

drive are to do installation, start-up and maintenance. Always read this manual thoroughly before<br />

using VFD-VE series AC Motor Drive, especially the WARNING, DANGER and CAUTION notes.<br />

Failure to comply may result in personal injury and equipment damage. If you have any questions,<br />

please contact your dealer.<br />

PLEASE READ PRIOR TO INSTALLATION FOR SAFETY.<br />

DANGER!<br />

1. AC input power must be disconnected before any wiring to the AC motor drive is made.<br />

2. A charge may still remain in the DC-link capacitors with hazardous voltages, even if the power<br />

has been turned off. To prevent personal injury, please ensure that power has turned off before<br />

opening the AC motor drive and wait ten minutes for the capacitors to discharge to safe voltage<br />

levels.<br />

3. Never reassemble internal components or wiring.<br />

4. The AC motor drive may be destroyed beyond repair if incorrect cables are connected to the<br />

input/output terminals. Never connect the AC motor drive output terminals U/T1, V/T2, and<br />

W/T3 directly to the AC mains circuit power supply.<br />

5. Ground the VFD-VE using the ground terminal. The grounding method must comply with the<br />

laws of the country where the AC motor drive is to be installed. Refer to the Basic Wiring<br />

Diagram.<br />

6. VFD-VE series is used only to control variable speed of 3-phase induction motors, NOT for 1phase<br />

motors or other purpose.<br />

7. VFD-VE series shall NOT be used for life support equipment or any life safety situation.

WARNING!<br />

1. DO NOT use Hi-pot test for internal components. The semi-conductor used in AC motor drive<br />

easily damage by high-voltage.<br />

2. There are highly sensitive MOS components on the printed circuit boards. These components<br />

are especially sensitive to static electricity. To prevent damage to these components, do not<br />

touch these components or the circuit boards with metal objects or your bare hands.<br />

3. Only qualified persons are allowed to install, wire and maintain AC motor drives.<br />

CAUTION!<br />

1. Some parameters settings can cause the motor to run immediately after applying power.<br />

2. DO NOT install the AC motor drive in a place subjected to high temperature, direct sunlight,<br />

high humidity, excessive vibration, corrosive gases or liquids, or airborne dust or metallic<br />

particles.<br />

3. Only use AC motor drives within specification. Failure to comply may result in fire, explosion or<br />

electric shock.<br />

4. To prevent personal injury, please keep children and unqualified people away from the<br />

equipment.<br />

5. When the motor cable between AC motor drive and motor is too long, the layer insulation of the<br />

motor may be damaged. Please use a frequency inverter duty motor or add an AC output<br />

reactor to prevent damage to the motor. Refer to appendix B Reactor for details.<br />

6. The rated voltage for AC motor drive must be ≤ 240V (≤ 480V for 460V models) and the mains<br />

supply current capacity must be ≤ 5000A RMS (≤10000A RMS for the ≥ 40hp (30kW) models).

Table of Contents<br />

Preface ............................................................................................................. i<br />

Table of Contents .......................................................................................... iii<br />

Chapter 1 Introduction................................................................................ 1-1<br />

1.1 Receiving and Inspection ................................................................... 1-2<br />

1.1.1 Nameplate Information................................................................ 1-2<br />

1.1.2 Model Explanation ...................................................................... 1-2<br />

1.1.3 Series Number Explanation ........................................................ 1-3<br />

1.1.4 Drive Frames and Appearances ................................................. 1-3<br />

1.2 Preparation for Installation and Wiring ............................................... 1-4<br />

1.2.1 Ambient Conditions..................................................................... 1-4<br />

1.2.2 Remove Keypad ......................................................................... 1-6<br />

1.2.3 Remove Front Cover................................................................... 1-7<br />

1.2.4 Lifting .......................................................................................... 1-8<br />

1.3 Dimensions......................................................................................... 1-9<br />

Chapter 2 Installation and Wiring .............................................................. 2-1<br />

2.1 Wiring ................................................................................................. 2-2<br />

2.2 External Wiring ................................................................................... 2-4<br />

2.3 Main Circuit ........................................................................................ 2-5<br />

2.3.1 Main Circuit Connection.............................................................. 2-5<br />

2.3.2 Main Circuit Terminals ................................................................ 2-9

2.4 Control Terminals .............................................................................2-10<br />

Chapter 3 Digital Keypad Operation and Start Up ....................................3-1<br />

3.1 Digital Keypad KPV-CE01 ..................................................................3-1<br />

3.1.1 Description of the Digital Keypad KPV-CE01 ..............................3-1<br />

3.1.2 How to Operate the Digital Keypad KPV-CE01...........................3-3<br />

3.1.3 Dimension of the Digital Keypad .................................................3-5<br />

3.1.4 Reference Table for the LCD Display of the Digital Keypad........3-5<br />

3.1.5 Operation Method........................................................................3-6<br />

3.2 Tuning Operations ..............................................................................3-7<br />

3.2.1 Flow Chart...................................................................................3-7<br />

3.2.2 Explanations for the Tuning Steps.............................................3-10<br />

3.3.2.1 Step 1 ................................................................................3-10<br />

3.3.2.2 Step 2 ................................................................................3-11<br />

3.3.2.3 Step 3 ................................................................................3-12<br />

3.3.2.4 Step 4 ................................................................................3-13<br />

Chapter 4 Parameters..................................................................................4-1<br />

4.1 Summary of Parameter Settings.........................................................4-2<br />

4.2 Version Differences ..........................................................................4-26<br />

4.2.1 Version 2.02 ..............................................................................4-26<br />

4.2.2 Version 2.04 ..............................................................................4-29<br />

4.2.3 Version 2.05 ..............................................................................4-38<br />

4.3 Description of Parameter Settings ....................................................4-47<br />

Chapter 5 Troubleshooting .........................................................................5-1<br />

5.1 Over Current (OC) ..............................................................................5-1<br />

5.2 Ground Fault.......................................................................................5-2

5.3 Over Voltage (OV).............................................................................. 5-2<br />

5.4 Low Voltage (Lv) ................................................................................ 5-3<br />

5.5 Over Heat (oH1, oH2, oH3) ................................................................ 5-4<br />

5.6 Overload............................................................................................. 5-4<br />

5.7 Display of KPV-CE01 is Abnormal ..................................................... 5-5<br />

5.8 Phase Loss (PHL) .............................................................................. 5-5<br />

5.9 Motor cannot Run............................................................................... 5-6<br />

5.10 Motor Speed cannot be Changed..................................................... 5-7<br />

5.11 Motor Stalls during Acceleration....................................................... 5-8<br />

5.12 The Motor does not Run as Expected .............................................. 5-8<br />

5.13 Electromagnetic/Induction Noise ...................................................... 5-9<br />

5.14 Environmental Condition .................................................................. 5-9<br />

5.15 Affecting Other Machines ............................................................... 5-10<br />

Chapter 6 Fault Code Information and Maintenance................................ 6-1<br />

6.1 Fault Code Information....................................................................... 6-1<br />

6.1.1 Common Problems and Solutions............................................... 6-1<br />

6.1.2 Reset .......................................................................................... 6-6<br />

6.2 Maintenance and Inspections............................................................. 6-7<br />

Appendix A Specifications ........................................................................ A-1<br />

Appendix B Accessories ........................................................................... B-1<br />

B.1 All Brake Resistors & Brake Units Used in AC Motor Drives..............B-1<br />

B.1.1 Dimensions and Weights for Brake Resistors ............................B-4<br />

B.1.2 Specifications for Brake Unit ......................................................B-6<br />

B.1.3 Dimensions for Brake Unit..........................................................B-7

B.2 No-fuse Circuit Breaker Chart ........................................................... B-9<br />

B.3 Fuse Specification Chart ................................................................. B-10<br />

B.4 AC Reactor...................................................................................... B-11<br />

B.4.1 AC Input Reactor Recommended Value ...................................B-11<br />

B.4.2 AC Output Reactor Recommended Value ................................B-11<br />

B.4.3 Applications for AC Reactor......................................................B-13<br />

B.5 Zero Phase Reactor (RF220X00A) ................................................. B-15<br />

B.6 DC Choke Recommended Values................................................... B-16<br />

B.7 Remote Controller RC-01................................................................ B-17<br />

B.8 PG Card (for Encoder) .................................................................... B-18<br />

B.8.1 EMV-PG01X .............................................................................B-18<br />

B.8.2 EMV-PG01O.............................................................................B-22<br />

B.8.3 EMV-PG01L..............................................................................B-26<br />

B.9 AMD-EMI Filter Cross Reference .................................................... B-30<br />

B.9.1 Dimensions ...............................................................................B-33<br />

B.10 Multi-function I/O Extension Card.................................................. B-40<br />

B.10.1 Functions ................................................................................B-40<br />

B.10.2 Dimensions .............................................................................B-42<br />

B.10.3 Wiring......................................................................................B-42<br />

Appendix C How to Select the Right AC Motor Drive.............................. C-1<br />

C.1 Capacity Formulas ............................................................................ C-1<br />

C.2 General Precaution ........................................................................... C-3<br />

C.3 How to Choose a Suitable Motor....................................................... C-5

Chapter 1 Introduction<br />

The AC motor drive should be kept in the shipping carton or crate before installation. In order to retain<br />

the warranty coverage, the AC motor drive should be stored properly when it is not to be used for an<br />

extended period of time. Storage conditions are:<br />

CAUTION!<br />

1. Store in a clean and dry location free from direct sunlight or corrosive fumes.<br />

2. Store within an ambient temperature range of -10 ° C to +40 ° C.<br />

3. Store within a relative humidity range of 0% to 90% and non-condensing environment.<br />

4. Store within an air pressure range of 86 kPA to 106kPA.<br />

5. DO NOT place on the ground directly. It should be stored properly. Moreover, if the surrounding<br />

environment is humid, you should put exsiccator in the package.<br />

6. DO NOT store in an area with rapid changes in temperature. It may cause condensation and<br />

frost.<br />

7. If the AC motor drive is stored for more than 3 months, the temperature should not be higher<br />

than 30 °C. Storage longer than one year is not recommended, it could result in the degradation<br />

of the electrolytic capacitors.<br />

8. When the AC motor drive is not used for longer time after installation on building sites or places<br />

with humidity and dust, it’s best to move the AC motor drive to an environment as stated above.<br />

Revision Dec. 2008, 04VE, SW V2.05 1-1

Chapter 1 Introduction|<br />

1.1 Receiving and Inspection<br />

This VFD-VE AC motor drive has gone through rigorous quality control tests at the factory before<br />

shipment. After receiving the AC motor drive, please check for the following:<br />

� Check to make sure that the package includes an AC motor drive, the User <strong>Manual</strong>/Quick<br />

Start and CD.<br />

� Inspect the unit to assure it was not damaged during shipment.<br />

� Make sure that the part number indicated on the nameplate corresponds with the part<br />

number of your order.<br />

1.1.1 Nameplate Information<br />

Example for 5HP/3.7kW 3-phase 230V AC motor drive<br />

AC Drive Model<br />

Input Spec.<br />

Output Spec.<br />

Output Frequency Range<br />

Enclosure type<br />

Serial Number & Bar Code<br />

1.1.2 Model Explanation<br />

MODE : VFD037V23A-2<br />

INPUT : 3PH 200-240V 50/60Hz 19.6A<br />

OUTPUT : 3PH 0-240V 17A 6.5kVA 5HP<br />

Freq. Range : 0.00~600.00Hz<br />

ENCLOSURE: TYPE 1<br />

037V23A2T6360001<br />

VFD 037 V 23 A-2<br />

VFD-VE Series<br />

Version Type<br />

Mains Input Voltage<br />

23: 230V Three phase 43: 460V Three phase<br />

Vector Series<br />

Applicable motor capacity<br />

007: 1 HP(0.7kW) 150: 20HP(15kW)<br />

022: 3 HP(2.2kW) 220: 30 HP(22kW)<br />

037: 5 HP(3.7kW) 300: 40HP(30kW)<br />

055: 7.5HP(5.5kW) 370: 50 HP(37kW)<br />

075: 10 HP(7.5kW) 450: 60HP(45kW)<br />

110: 15 HP(11kW) 550: 75HP(55kW)<br />

750: 100HP(75kW)<br />

Series Name ( Variable Frequency Drive)<br />

1-2 Revision Dec. 2008, 04VE, SW V2.05

1.1.3 Series Number Explanation<br />

037V23A2 T 7 36<br />

230V 3-phase 5HP(3.7kW)<br />

Chapter 1 Introduction|<br />

Production number<br />

Production week<br />

Production year 2007<br />

Production factory<br />

(T: Taoyuan, W: Wujian)<br />

Model<br />

If the nameplate information does not correspond to your purchase order or if there are<br />

any problems, please contact your distributor.<br />

1.1.4 Drive Frames and Appearances<br />

1-5HP/0.75-3.7kW (Frame B) 7.5-15HP/5.5-11kW (Frame C)<br />

Revision Dec. 2008, 04VE, SW V2.05 1-3

Chapter 1 Introduction|<br />

15-30HP/11-22kW (Frame D) 40-100HP/30-75kW (Frame E)<br />

Frame Power range Models<br />

B (B1) 1-3hp (0.75-2.2kW)<br />

VFD007V23A/43A-2, VFD015V23A/43A-2,<br />

VFD022V23A/43A-2<br />

B (B2) 5hp (3.7kW) VFD037V23A/43A-2<br />

C 7.5-15hp (5.5-11kW) VFD055V23A/43A-2, VFD075V23A/43A-2, VFD110V43B-2<br />

D 15-30hp (11-22kW)<br />

VFD110V23A/43A-2, VFD150V23A/43A-2,<br />

VFD185V23A/43A-2, VFD220V23A/43A-2<br />

E (E1) 40-60hp (30-45kW) VFD300V43A-2, VFD370V43A-2, VFD450V43A-2<br />

E (E2) 40-100hp (30-75kW)<br />

VFD300V23A-2, VFD370V23A-2, VFD550V43C-2,<br />

VFD750V43C-2<br />

Please refer to Chapter 1.3 for exact dimensions.<br />

1.2 Preparation for Installation and Wiring<br />

1.2.1 Ambient Conditions<br />

Install the AC motor drive in an environment with the following conditions:<br />

1-4 Revision Dec. 2008, 04VE, SW V2.05

Operation<br />

Air Temperature: -10 ~ +40°C (14 ~ 122°F)<br />

Relative Humidity:

Chapter 1 Introduction|<br />

CAUTION!<br />

1. Operating, storing or transporting the AC motor drive outside these conditions may cause<br />

damage to the AC motor drive.<br />

2. Failure to observe these precautions may void the warranty!<br />

3. Mount the AC motor drive vertically on a flat vertical surface object by screws. Other directions<br />

are not allowed.<br />

4. The AC motor drive will generate heat during operation. Allow sufficient space around the unit<br />

for heat dissipation.<br />

5. The heat sink temperature may rise to 90°C when running. The material on which the AC motor<br />

drive is mounted must be noncombustible and be able to withstand this high temperature.<br />

6. When AC motor drive is installed in a confined space (e.g. cabinet), the surrounding<br />

temperature must be within -10 ~ 40°C with good ventilation. DO NOT install the AC motor<br />

drive in a space with bad ventilation.<br />

7. When installing multiple AC more drives in the same cabinet, they should be adjacent in a row<br />

with enough space in-between. When installing one AC motor drive below another one, use a<br />

metal separation between the AC motor drives to prevent mutual heating.<br />

8. Prevent fiber particles, scraps of paper, saw dust, metal particles, etc. from adhering to the<br />

heatsink.<br />

1.2.2 Remove Keypad<br />

1-5HP/0.75-3.7kW (Frame B) 7.5-15HP/5.5-11kW (Frame C)<br />

1-6 Revision Dec. 2008, 04VE, SW V2.05

Chapter 1 Introduction|<br />

15-30HP/11-22kW (Frame D) 40-100HP/30-75kW (Frame E)<br />

1.2.3 Remove Front Cover<br />

1-5HP/0.75-3.7kW (Frame B) 7.5-15HP/5.5-11kW (Frame C)<br />

Revision Dec. 2008, 04VE, SW V2.05 1-7

Chapter 1 Introduction|<br />

15-30HP/11-22kW (Frame D) 40-100HP/30-75kW (Frame E)<br />

1.2.4 Lifting<br />

Please carry only fully assembled AC motor drives as shown in the following.<br />

For 40-100HP (Frame E and E1)<br />

Step 1 Step 2<br />

1-8 Revision Dec. 2008, 04VE, SW V2.05

Step 3 Step 4<br />

1.3 Dimensions<br />

Chapter 1 Introduction|<br />

Revision Dec. 2008, 04VE, SW V2.05 1-9

Chapter 1 Introduction|<br />

Frame B<br />

W<br />

W1<br />

H1<br />

H<br />

1-10 Revision Dec. 2008, 04VE, SW V2.05<br />

S1<br />

D<br />

S2<br />

D1<br />

D2<br />

Unit: mm[inch]<br />

Frame W W1 H H1 D D1 D2 S1 S2<br />

B1<br />

B2<br />

150.0<br />

[5.91]<br />

150.0<br />

[5.91]<br />

NOTE<br />

135.0<br />

[5.32]<br />

135.0<br />

[5.32]<br />

260.0<br />

[10.24]<br />

272.1<br />

[10.72]<br />

244.3<br />

[9.63]<br />

244.3<br />

[9.63]<br />

160.2<br />

[6.31]<br />

183.7<br />

[7.24]<br />

67.0<br />

[2.64]<br />

67.0<br />

[2.64]<br />

4.0<br />

[0.16]<br />

4.0<br />

[0.16]<br />

Frame B1: VFD007V23A/43A-2, VFD015V23A/43A-2, VFD022V23A/43A-2<br />

Frame B2: VFD037V23A/43A-2<br />

8.0<br />

[0.32]<br />

8.0<br />

[0.32]<br />

6.5<br />

[0.26]<br />

6.5<br />

[0.26]

Frame C<br />

W<br />

W1<br />

H1<br />

H<br />

Chapter 1 Introduction|<br />

Revision Dec. 2008, 04VE, SW V2.05 1-11<br />

D<br />

S1 S2<br />

Unit: mm[inch]<br />

Frame W W1 H H1 D - - S1 S2<br />

C<br />

200.0<br />

[7.88]<br />

NOTE<br />

185.6<br />

[7.31]<br />

323.0<br />

[12.73]<br />

244.3<br />

[9.63]<br />

160.2<br />

[6.31]<br />

- -<br />

Frame C: VFD055V23A/43A-2, VFD075V23A/43A-2, VFD110V43B-2<br />

7.0<br />

[0.28]<br />

7.0<br />

[0.28]

Chapter 1 Introduction|<br />

Frame D<br />

W<br />

W1<br />

H1<br />

H<br />

1-12 Revision Dec. 2008, 04VE, SW V2.05<br />

D<br />

S1<br />

D1<br />

D2<br />

Unit: mm[inch]<br />

Frame W W1 H H1 D D1 D2 S1 -<br />

D<br />

250.0<br />

[9.85]<br />

NOTE<br />

226.0<br />

[8.90]<br />

408.2<br />

[16.07]<br />

384.0<br />

[15.13]<br />

205.4<br />

[8.08]<br />

110.0<br />

[4.33]<br />

10.0<br />

[0.39]<br />

10.0<br />

[0.39]<br />

Frame D: VFD110V23A/43A-2, VFD150V23A/43A-2, VFD185V23A/43A-2, VFD220V23A/43A-2<br />

-

Frame E<br />

H<br />

W D<br />

W1<br />

H2<br />

H1<br />

Chapter 1 Introduction|<br />

Revision Dec. 2008, 04VE, SW V2.05 1-13<br />

S1<br />

S3<br />

D1<br />

S2<br />

D2<br />

Unit: mm[inch]<br />

Frame W W1 H H1 H2 D D1 D2 S1 S2 S3<br />

E1<br />

370.0<br />

[14.57]<br />

335.0<br />

[13.19]<br />

-<br />

589.0<br />

[23.19]<br />

560.0<br />

[22.05]<br />

260.0<br />

[10.24]<br />

370.0 335.0 595.0 589.0 560.0 260.0<br />

E2<br />

[14.57] [13.19] [23.43] [23.19] [22.05] [10.24]<br />

NOTE<br />

132.5<br />

[5.22]<br />

132.5<br />

[5.22]<br />

18.0<br />

[0.71]<br />

18.0<br />

[0.71]<br />

Frame E1: VFD300V43A-2, VFD370V43A-2, VFD450V43A-2<br />

Frame E2: VFD300V23A-2, VFD370V23A-2, VFD550V43C-2, VFD750V43C-2<br />

13.0<br />

[0.51]<br />

13.0<br />

[0.51]<br />

13.0<br />

[0.51]<br />

13.0<br />

[0.51]<br />

18.0<br />

[0.71]<br />

18.0<br />

[0.71]

Chapter 1 Introduction|<br />

This page intentionally left blank<br />

1-14 Revision Dec. 2008, 04VE, SW V2.05

Chapter 2 Installation and Wiring<br />

After removing the front cover (see chapter 1.2.3 for details), check if the power and control terminals<br />

are clear. Be sure to observe the following precautions when wiring.<br />

� General Wiring Information<br />

Applicable Codes<br />

All VFD-VE series are Underwriters Laboratories, Inc. (UL) and Canadian Underwriters<br />

Laboratories (cUL) listed, and therefore comply with the requirements of the National<br />

Electrical Code (NEC) and the Canadian Electrical Code (CEC).<br />

Installation intended to meet the UL and cUL requirements must follow the instructions<br />

provided in “Wiring Notes” as a minimum standard. Follow all local codes that exceed UL<br />

and cUL requirements. Refer to the technical data label affixed to the AC motor drive and<br />

the motor nameplate for electrical data.<br />

The "Line Fuse Specification" in Appendix B, lists the recommended fuse part number for<br />

each VFD-VE Series part number. These fuses (or equivalent) must be used on all<br />

installations where compliance with U.L. standards is a required.<br />

CAUTION!<br />

1. Make sure that power is only applied to the R/L1, S/L2, T/L3 terminals. Failure to comply may<br />

result in damage to the equipment. The voltage and current should lie within the range as<br />

indicated on the nameplate.<br />

2. Check following items after finishing the wiring:<br />

A. Are all connections correct?<br />

B. No loose wires?<br />

C. No short-circuits between terminals or to ground?<br />

DANGER!<br />

1. A charge may still remain in the DC bus capacitors with hazardous voltages even if the power<br />

has been turned off. To prevent personal injury, please ensure that the power is turned off and<br />

wait ten minutes for the capacitors to discharge to safe voltage levels before opening the AC<br />

motor drive.<br />

2. All the units must be grounded directly to a common ground terminal to prevent lightning strike<br />

or electric shock.<br />

3. Only qualified personnel familiar with AC motor drives is allowed to perform installation, wiring<br />

and commissioning.<br />

4. Make sure that the power is off before doing any wiring to prevent electric shock.<br />

Revision Dec. 2008, 04VE, SW V2.05 2-1

Chapter 2 Installation and Wiring|<br />

2.1 Wiring<br />

Users must connect wires according to the circuit diagrams on the following pages. Do not plug a<br />

modem or telephone line to the RS-485 communication port or permanent damage may result. The<br />

pins 1 & 2 are the power supply for the optional copy keypad KPV-CE01 only and should not be used<br />

for RS-485 communication.<br />

Figure 1 for models of VFD-VE Series (15 HP/11kW and below)<br />

VFD007V23A/43A-2, VFD015V23A/43A-2, VFD022V23A/43A-2, VFD037V23A/43A-2,<br />

VFD055V23A/43A-2, VFD075V23A/43A-2, VFD110V43B-2, VFD110V23A/43A-2<br />

DC choke<br />

(optional)<br />

Brake resistor<br />

(optional)<br />

Fuse/NFB(No Fuse Breaker)<br />

R(L1)<br />

S(L2)<br />

T(L3)<br />

Recommended Circuit<br />

when power supply<br />

is turned OFF by a<br />

Jumper<br />

+1 +2/B1<br />

R(L1)<br />

S(L2)<br />

T(L3)<br />

E<br />

SA<br />

MC RB<br />

B2 -<br />

U(T1)<br />

V(T2)<br />

W(T3)<br />

E<br />

RA<br />

Motor<br />

IM<br />

3~<br />

fault output.<br />

If the fault occurs, the OFF ON<br />

contact will be ON to turn<br />

MC<br />

off the power and protect the power system.<br />

Factory setting:<br />

FWD/STOP<br />

SINK Mode<br />

REV/STOP<br />

Sink<br />

Sw1<br />

Multi-step 1<br />

Factory<br />

Source<br />

setting<br />

Multi-step 2<br />

Please refer to<br />

Figure 3 for wiring<br />

Multi-step 3<br />

of SINK mode and Multi-step 4<br />

SOURCEmode.<br />

No function<br />

No function<br />

Digital Signal Common<br />

* Don't apply the mains voltage directly<br />

to above terminals.<br />

ACI current/voltage selection<br />

ACI Switch<br />

3<br />

Make sure that power is OFF<br />

before changing the switch 5K 2<br />

setting.<br />

1<br />

0-20mA 0-10V<br />

RC<br />

RB<br />

RC<br />

+24V<br />

MRA<br />

FWD<br />

REV<br />

MRC<br />

MI1<br />

MI2 MO1<br />

MI3<br />

MI4<br />

MI5<br />

MO2<br />

MI6<br />

DCM<br />

MCM<br />

E<br />

DFM<br />

+10V<br />

Power supply<br />

+10V 20mA<br />

AVI<br />

Master Frequency DCM<br />

0 to 10V 47k<br />

ACI<br />

4~20mA/0~10V<br />

AUI<br />

-10~+10V<br />

ACM<br />

Analog Signal Common<br />

Multi-function contact output 1<br />

(relay)<br />

factory setting: fault indication<br />

Multi-function contact output 2<br />

(relay)<br />

48VDC 50mA<br />

factory setting:<br />

indicates that it is running<br />

Multi-function contact output 3<br />

(photocoupler)<br />

Multi-function contact output 4<br />

(photocoupler)<br />

Multi-function<br />

Photocoupler Output<br />

Digital Frequency Output<br />

Ter minal<br />

factory setting: 1:1<br />

Duty=50%, 10VDC<br />

Digital Signal Common<br />

DFM output signal selection<br />

DFM Switch<br />

Make sure that power is OFF<br />

before changing the switch<br />

setting.<br />

OC TP<br />

Analog Multi-function Output Terminal<br />

E<br />

AFM analog output selection<br />

AFM Switch<br />

Make sure that power is OFF<br />

before changing the switch<br />

setting.<br />

0-10V 0-20mA<br />

AFM 0~10VDC/2mA<br />

ACM<br />

Analog Signal common<br />

E<br />

RS-485 serial communication<br />

1: +EV<br />

2: GND For communication,<br />

3: SG- it needs to use<br />

4: SG+ VFD-USB01/IFD8500<br />

5: NC to connect to PC.<br />

6: NC<br />

Main circuit (power) terminals Control circuit terminals Shielded leads & Cable<br />

NOTE<br />

The brake resistor is built-in to model VFD110V43B.<br />

2-2 Revision Dec. 2008, 04VE, SW V2.05

Chapter 2 Installation and Wiring|<br />

Figure 2 for models of VFD-VE Series (20HP/15kW and above)<br />

VFD150V23A/43A-2, VFD185V23A/43A-2, VFD220V23A/43A-2, VFD300V43A-2, VFD370V43A-2,<br />

VFD450V43A-2, VFD300V23A-2, VFD370V23A-2, VFD550V43C-2, VFD750V43C-2<br />

DC choke brake unit<br />

(optional) (optional)<br />

VFDB<br />

brake resistor<br />

(optional)<br />

Fuse/NFB(No Fuse Breaker)<br />

Jumper<br />

-(minus sign)<br />

R(L1)<br />

S(L2)<br />

T(L3)<br />

+1<br />

R(L1)<br />

S(L2)<br />

T(L3)<br />

+2<br />

U(T1)<br />

V(T2)<br />

W(T3)<br />

Motor<br />

IM<br />

3~<br />

Recommended Circuit<br />

when power s upply<br />

is turned OFF by a<br />

SA<br />

MC<br />

E<br />

RB<br />

E<br />

RA<br />

fault output.<br />

If the fault occurs, the OFF ON<br />

contact will be ON to turn<br />

MC<br />

off the power and protect the power system.<br />

Factory setting:<br />

FWD/STOP<br />

SINK Mode<br />

REV/STOP<br />

Sink<br />

Sw1<br />

Multi-step 1<br />

Factory<br />

Source<br />

setting<br />

Multi-step 2<br />

Please refer to<br />

Multi-step 3<br />

Figure 3 for wiring<br />

of SINK mode and Multi-step 4<br />

SOURCEmode.<br />

No function<br />

No function<br />

Digital Signal Common<br />

* Don't apply the mains voltage directly<br />

to above terminals.<br />

ACI current/voltage selection<br />

ACI Switch<br />

3<br />

Make sure that power is OFF<br />

before changing the switch 5K 2<br />

setting.<br />

1<br />

0-20mA 0-10V<br />

RC<br />

RB<br />

RC<br />

+24V<br />

MRA<br />

FWD<br />

REV<br />

MRC<br />

MI1<br />

MI2 MO1<br />

MI3<br />

MI4<br />

MI5<br />

MO2<br />

MI6<br />

DCM<br />

MCM<br />

E<br />

DFM<br />

+10V<br />

Power supply<br />

+10V 20mA<br />

AVI<br />

Master Frequency DCM<br />

0 to 10V 47k<br />

ACI<br />

4~20mA/0~10V<br />

AUI<br />

-10~+10V<br />

ACM<br />

Analog Signal Common<br />

Multi-function contact output 1<br />

(relay)<br />

factory setting: fault indication<br />

Multi-function contact output 2<br />

(relay)<br />

48VDC 50mA<br />

factory setting:<br />

indicates that it is running<br />

Multi-function contact output 3<br />

(photocoupler)<br />

Multi-function contact output 4<br />

(photocoupler)<br />

Multi-function<br />

Photocoupler Output<br />

Digital Frequency Output<br />

Terminal<br />

factory setting: 1:1<br />

Duty=50%, 10VDC<br />

Digital Signal Common<br />

DFM output signal selection<br />

DFM Switch<br />

Make sure that power is OFF<br />

before changing the switch<br />

setting.<br />

OC TP<br />

Analog Multi-function Output Terminal<br />

E<br />

AFM analog output selection<br />

AFM Switch<br />

Make sure that power is OFF<br />

before changing the switch<br />

setting.<br />

0-10V 0-20mA<br />

AFM 0~10VDC/2mA<br />

ACM<br />

Analog Signal common<br />

E<br />

RS-485 serial communication<br />

1: +EV<br />

2: GND For communication,<br />

3: SG- it needs to use<br />

4: SG+ VFD-USB01/IFD8500<br />

5: NC to connect to PC.<br />

6: NC<br />

Main circuit (power) terminals Control circuit terminals Shielded leads & Cable<br />

NOTE The brake resistor is built-in to model VFD110V43B.<br />

Revision Dec. 2008, 04VE, SW V2.05 2-3

Chapter 2 Installation and Wiring|<br />

Figure 3 Wiring for SINK(NPN) mode and SOURCE(PNP) mode<br />

CAUTION!<br />

SINK/NPN Mode<br />

Sink<br />

SW1<br />

Source<br />

Factory<br />

setting<br />

FWD/STOP<br />

REV/STOP<br />

Multi-step1<br />

Multi-step2<br />

Multi-step3<br />

Multi-step4<br />

No Function<br />

No Function<br />

Digital Signal Common<br />

*Don't apply the mains voltage directly<br />

to above terminals.<br />

SOURCE/PNP Mode<br />

Sink<br />

FWD/STOP<br />

SW1<br />

REV/STOP<br />

Source<br />

Multi-step1<br />

Multi-step2<br />

Multi-step3<br />

Factory<br />

setting Multi-step4<br />

No Function<br />

No Function<br />

*Don't apply the mains voltage directly<br />

to above terminals.<br />

+24V<br />

FWD<br />

REV<br />

MI1<br />

MI2<br />

MI3<br />

MI4<br />

MI5<br />

MI6<br />

DCM<br />

E<br />

+24V<br />

FWD<br />

REV<br />

MI1<br />

MI2<br />

MI3<br />

MI4<br />

MI5<br />

MI6<br />

DCM<br />

E<br />

1. The wiring of main circuit and control circuit should be separated to prevent erroneous actions.<br />

2. Please use shield wire for the control wiring and not to expose the peeled-off net in front of the<br />

terminal.<br />

3. Please use the shield wire or tube for the power wiring and ground the two ends of the shield<br />

wire or tube.<br />

2.2 External Wiring<br />

2-4 Revision Dec. 2008, 04VE, SW V2.05

Power Supply<br />

EMI Filter<br />

R/L1 S/L2 T/L3<br />

U/T1 V/T2 W/T3<br />

Motor<br />

2.3 Main Circuit<br />

FUSE/NFB<br />

Magnetic<br />

contactor<br />

Input AC<br />

Line Reactor<br />

+/B1<br />

B2<br />

-<br />

Zero-phase<br />

Reactor<br />

E<br />

Break resistor<br />

(optional)<br />

Zero-phase<br />

Reactor<br />

Output AC<br />

Line Reactor<br />

Break unit (optional)<br />

BR<br />

Break resistor<br />

(optional)<br />

2.3.1 Main Circuit Connection<br />

Power<br />

supply<br />

Chapter 2 Installation and Wiring|<br />

Items Explanations<br />

Fuse/NFB<br />

(Optional)<br />

Magnetic<br />

contactor<br />

(Optional)<br />

Input AC<br />

Line Reactor<br />

(Optional)<br />

Zero-phase<br />

Reactor<br />

(Ferrite Core<br />

Common<br />

Choke)<br />

(Optional)<br />

EMI filter<br />

(Optional)<br />

Brake<br />

Resistor<br />

(Optional)<br />

Output AC<br />

Line Reactor<br />

(Optional)<br />

Please follow the specific power<br />

supply requirements shown in<br />

Appendix A.<br />

There may be an inrush current<br />

during power up. Please check the<br />

chart of Appendix B and select the<br />

correct fuse with rated current. Use of<br />

an NFB is optional.<br />

Please do not use a Magnetic<br />

contactor as the I/O switch of the AC<br />

motor drive, as it will reduce the<br />

operating life cycle of the AC drive.<br />

Used to improve the input power<br />

factor, to reduce harmonics and<br />

provide protection from AC line<br />

disturbances (surges, switching<br />

spikes, short interruptions, etc.). AC<br />

line reactor should be installed when<br />

the power supply capacity is 500kVA<br />

or more or advanced capacity is<br />

activated .The wiring distance should<br />

be ≤ 10m. Refer to appendix B for<br />

details.<br />

Zero phase reactors are used to<br />

reduce radio noise especially when<br />

audio equipment is installed near the<br />

inverter. Effective for noise reduction<br />

on both the input and output sides.<br />

Attenuation quality is good for a wide<br />

range from AM band to 10MHz.<br />

Appendix B specifies the zero phase<br />

reactor. (RF220X00A)<br />

To reduce electromagnetic<br />

interference, please refer to Appendix<br />

B for more details.<br />

Used to reduce the deceleration time<br />

of the motor. Please refer to the chart<br />

in Appendix B for specific Brake<br />

Resistors.<br />

Motor surge voltage amplitude<br />

depends on motor cable length. For<br />

applications with long motor cable<br />

(>20m), it is necessary to install a<br />

reactor at the inverter output side<br />

Revision Dec. 2008, 04VE, SW V2.05 2-5

Chapter 2 Installation and Wiring|<br />

Figure 1 for the main terminals<br />

No-fuse breaker<br />

(NFB)<br />

R<br />

S<br />

T<br />

Figure 2 for the main terminals<br />

R<br />

S<br />

T<br />

No-fuse breaker<br />

(NFB)<br />

MC<br />

MC<br />

Br ak e res istor(O pti onal)<br />

+1 +2/B1 B2 -<br />

R(L1)<br />

U(T1)<br />

S(L2)<br />

V(T2)<br />

T(L3)<br />

W(T3)<br />

E<br />

E<br />

VFDB<br />

+1 +2 -<br />

R(L1)<br />

U(T1)<br />

S(L2)<br />

V(T2)<br />

T(L3)<br />

W(T3)<br />

E<br />

E<br />

Brak e res istor<br />

(optional)<br />

Terminal Symbol Explanation of Terminal Function<br />

R/L1, S/L2, T/L3 AC line input terminals (1-phase/3-phase)<br />

U/T1, V/T2, W/T3<br />

Motor<br />

IM<br />

3~<br />

Motor<br />

IM<br />

3~<br />

AC drive output terminals for connecting 3-phase<br />

induction motor<br />

+1, +2 Connections for DC Choke (optional)<br />

+2/B1, B2 Connections for Brake Resistor (optional)<br />

+2~(-), +2/B1~(-) Connections for External Brake Unit (VFDB series)<br />

Earth connection, please comply with local regulations.<br />

2-6 Revision Dec. 2008, 04VE, SW V2.05

Mains power terminals (R/L1, S/L2, T/L3)<br />

Chapter 2 Installation and Wiring|<br />

� Connect these terminals (R/L1, S/L2, T/L3) via a no-fuse breaker or earth leakage breaker to<br />

3-phase AC power (some models to 1-phase AC power) for circuit protection. It is<br />

unnecessary to consider phase-sequence.<br />

� It is recommended to add a magnetic contactor (MC) in the power input wiring to cut off<br />

power quickly and reduce malfunction when activating the protection function of AC motor<br />

drives. Both ends of the MC should have an R-C surge absorber.<br />

� Please make sure to fasten the screw of the main circuit terminals to prevent sparks which is<br />

made by the loose screws due to vibration.<br />

� Please use voltage and current within the regulation shown in Appendix A.<br />

� When using leakage-current breaker to prevent leakage current,<br />

� Do NOT run/stop AC motor drives by turning the power ON/OFF. Run/stop AC motor drives<br />

by RUN/STOP command via control terminals or keypad. If you still need to run/stop AC<br />

drives by turning power ON/OFF, it is recommended to do so only ONCE per hour.<br />

� Do NOT connect 3-phase models to a 1-phase power source.<br />

Output terminals for main circuit (U, V, W)<br />

� When the AC drive output terminals U/T1, V/T2, and W/T3 are connected to the motor<br />

terminals U/T1, V/T2, and W/T3, respectively, the motor will rotate counterclockwise (as<br />

viewed on the shaft end of the motor) when a forward operation command is received. To<br />

permanently reverse the direction of motor rotation, switch over any of the two motor leads.<br />

Forward<br />

running<br />

� DO NOT connect phase-compensation capacitors or surge absorbers at the output terminals<br />

of AC motor drives.<br />

� With long motor cables, high capacitive switching current peaks can cause over-current, high<br />

leakage current or lower current readout accuracy. To prevent this, the motor cable should<br />

be less than 20m for 3.7kW models and below. And the cable should be less than 50m for<br />

5.5kW models and above. For longer motor cables use an AC output reactor.<br />

� Use well-insulated motor, suitable for inverter operation.<br />

Terminals [+1, +2] for connecting DC reactor<br />

DC reactor<br />

Jumper<br />

+1<br />

Revision Dec. 2008, 04VE, SW V2.05 2-7

Chapter 2 Installation and Wiring|<br />

� To improve power factor and reduce harmonics connect a DC reactor between terminals [+1,<br />

+2]. Please remove the jumper before connecting the DC reactor.<br />

NOTE Models of 15kW and above have a built-in DC reactor.<br />

Terminals [+2/B1, B2] for connecting brake resistor and terminals [+1, +2/B1] for<br />

connecting external brake unit<br />

Brake resistor(optional)<br />

BR<br />

Brake unit(optional)<br />

VFDB<br />

Refer to Appendix B for the use of<br />

BR<br />

spec ial braking resis tor/unit<br />

+2/B1 B2<br />

+2/B1<br />

-<br />

� Connect a brake resistor or brake unit in applications with frequent deceleration ramps, short<br />

deceleration time, too low brake torque or requiring increased brake torque.<br />

� If the AC motor drive has a built-in brake chopper (all models of 11kW and below), connect<br />

the external brake resistor to the terminals [+2/B1, B2].<br />

� Models of 15kW and above don’t have a built-in brake chopper. Please connect an external<br />

optional brake unit (VFDB-series) and brake resistor. Refer to VFDB series user manual for<br />

details.<br />

� Connect the terminals [+(P), -(N)] of the brake unit to the AC motor drive terminals<br />

[+2(+2/B1), (-)]. The length of wiring should be less than 5m with twisted cable.<br />

� When not used, please leave the terminals [+2/B1, -] open.<br />

WARNING!<br />

1. Short-circuiting [B2] or [-] to [+2/B1] can damage the AC motor drive.<br />

Grounding terminals ( )<br />

� Make sure that the leads are connected correctly and the AC drive is properly grounded.<br />

(Ground resistance should not exceed 0.1Ω.)<br />

� Use ground leads that comply with local regulations and keep them as short as possible.<br />

� Multiple VFD-VE units can be installed in one location. All the units should be grounded<br />

directly to a common ground terminal, as shown in the figure below. Ensure there are no<br />

ground loops.<br />

excellent good not allowed<br />

2-8 Revision Dec. 2008, 04VE, SW V2.05

2.3.2 Main Circuit Terminals<br />

Frame B<br />

Frame C<br />

+1 +2 B1 - B2 U/T1 V/T2 W/T3<br />

Screw Torque :<br />

18Kgf-cm<br />

Wire Gauge :<br />

18~10AWG<br />

POWER<br />

R/L1 S/L2 T/L3<br />

IM MOTOR<br />

3<br />

Chapter 2 Installation and Wiring|<br />

Main circuit terminals<br />

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, , +1, +2/B1, -, B2<br />

Models<br />

VFD007V23A-2<br />

VFD007V43A-2<br />

VFD015V23A-2<br />

Wire Torque Wire Type<br />

VFD015V43A-2<br />

VFD022V23A-2<br />

VFD022V43A-2<br />

VFD037V23A-2<br />

VFD037V43A-2<br />

14-10 AWG<br />

(2.1-5.3mm 2 )<br />

18kgf-cm<br />

(15.6in-lbf)<br />

Stranded<br />

copper only,<br />

75 o C<br />

Main circuit terminals<br />

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, , +1, +2/B1, -, B2<br />

Models<br />

VFD055V23A-2<br />

Wire Torque Wire Type<br />

VFD075V23A-2<br />

VFD110V43B-2<br />

VFD055V43A-2<br />

VFD075V43A-2<br />

12-8 AWG<br />

(3.3-8.4mm 2 )<br />

30kgf-cm<br />

(26in-lbf)<br />

Stranded<br />

copper only,<br />

75 o C<br />

Revision Dec. 2008, 04VE, SW V2.05 2-9

Chapter 2 Installation and Wiring|<br />

Frame D<br />

R/L1 S/L2 T/L3 +1 +2 - V/T2 W/T3<br />

POWER DC ( + ) DC ( - ) IM<br />

3 MOTOR<br />

Frame E<br />

CHARGE<br />

POWER<br />

ALARM<br />

R/L1 S/L2 T/L3 +1 +2 U/T1 V/T2 W/T3<br />

Screw Torque:<br />

IM POWER 200kgf-cm (173in-lbf)<br />

3 MOTOR<br />

NOTE<br />

Main circuit terminals<br />

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, , +1, +2, -<br />

Models<br />

VFD110V23A-2<br />

VFD110V43A-2<br />

VFD150V43A-2<br />

Wire Torque Wire Type<br />

VFD150V23A-2<br />

VFD185V23A-2<br />

VFD185V43A-2<br />

VFD220V43A-2<br />

VFD220V23A-2<br />

8-2 AWG<br />

(8.4-33.6mm 2 )<br />

30kgf-cm<br />

(26in-lbf)<br />

Stranded<br />

copper only,<br />

75 o C<br />

Main circuit terminals<br />

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, , +1, +2, -<br />

Models Wire Torque Wire Type<br />

VFD300V43A-2<br />

VFD370V43A-2<br />

VFD450V43A-2<br />

4-2 AWG<br />

VFD300V23A-2<br />

(21.2-33.6mm<br />

VFD370V23A-2<br />

2 )<br />

VFD550V43C-2<br />

VFD750V43C-2<br />

# To connect 6 AWG (13.3 mm 2 ) wires, use Recognized Ring Terminals<br />

2.4 Control Terminals<br />

57kgf-cm<br />

(49in-lbf)<br />

200kgf-cm<br />

(173in-lbf)<br />

Stranded<br />

copper<br />

only, 75 o C<br />

2-10 Revision Dec. 2008, 04VE, SW V2.05

Chapter 2 Installation and Wiring|<br />

Circuit diagram for digital inputs (SINK current 16mA.)<br />

SINK Mode<br />

SOURCE Mode<br />

multi-input<br />

terminal<br />

MRA<br />

DCM<br />

RA<br />

MRC RB<br />

+24<br />

Internal Circuit<br />

Multi-Input<br />

Terminal<br />

Revision Dec. 2008, 04VE, SW V2.05 2-11<br />

+24V<br />

The Position of the Control Terminals<br />

DCM<br />

Internal Circuit<br />

RC<br />

MCM +24V FWD MI1 MI3 MI5 DFM +10V AVI ACM<br />

MO1 MO2 DCM REV MI2 MI4 MI6 AFM AUI<br />

ACI

Chapter 2 Installation and Wiring|<br />

Terminal symbols and functions<br />

Terminal<br />

Symbol<br />

Terminal Function<br />

FWD Forward-Stop Command<br />

REV Reverse-Stop Command<br />

Factory Settings (SINK)<br />

ON: Connect to DCM<br />

ON: Run in FWD direction<br />

OFF: Stop acc. to Stop Method<br />

ON: Run in REV direction<br />

OFF: Stop acc. to Stop Method<br />

+24V DC Voltage Source +24VDC, 80mA, used for SOURCE mode.<br />

MI1 Multi-function Input 1<br />

MI2 Multi-function Input 2<br />

MI3 Multi-function Input 3<br />

MI4 Multi-function Input 4<br />

MI5 Multi-function Input 5<br />

MI6 Multi-function Input 6<br />

DFM<br />

Digital Frequency Meter<br />

(Open Collector Output)<br />

DFM-DCM<br />

Max: 48V<br />

50mA<br />

J5<br />

50%<br />

internal circuit<br />

DCM Digital Signal Common<br />

RA<br />

RB<br />

100%<br />

Multi-function Relay Output 1<br />

(N.O.) a<br />

Multi-function Relay Output 1<br />

(N.C.) b<br />

RC Multi-function Relay Common<br />

MRA<br />

Multi-function Relay Output 2<br />

(N.O.) a<br />

MRC Multi-function Relay Common<br />

Refer to Pr.02-01 to Pr.02-06 for programming<br />

the Multi-function Inputs.<br />

ON: the activation current is 6.5mA. OFF:<br />

leakage current tolerance is 10μA.<br />

Pulse voltage output monitor signal,<br />

proportional to output frequency<br />

Duty-cycle: 50%<br />

Ratio: Pr.02-18<br />

Min. load: 4.7kΩ<br />

Max. current: 50mA<br />

Max. voltage: 48Vdc<br />

Jumper: DFM jumper, factory<br />

setting is OC<br />

Common for digital inputs and used for SINK<br />

mode.<br />

Resistive Load:<br />

5A(N.O.)/3A(N.C.) 240VAC<br />

5A(N.O.)/3A(N.C.) 24VDC<br />

Inductive Load:<br />

1.5A(N.O.)/0.5A(N.C.) 240VAC<br />

1.5A(N.O.)/0.5A(N.C.) 24VDC<br />

To output monitor signal, including in operation,<br />

frequency arrival, overload and etc.<br />

Refer to Pr.02-11~02-12 for programming<br />

2-12 Revision Dec. 2008, 04VE, SW V2.05

Terminal<br />

Symbol<br />

Terminal Function<br />

Chapter 2 Installation and Wiring|<br />

Factory Settings (SINK)<br />

ON: Connect to DCM<br />

+10V Potentiometer Power Supply +10VDC 20mA (variable resistor 3-5kohm)<br />

MCM<br />

MO1<br />

MO2<br />

AVI<br />

ACI<br />

AUI<br />

Multi-function Output<br />

Common (Photocoupler)<br />

Multi-function Output 1<br />

(Photocoupler)<br />

Multi-function Output 2<br />

(Photocoupler)<br />

Analog voltage Input<br />

+10V<br />

AVI<br />

ACM<br />

AVI circuit<br />

internal circuit<br />

Analog current Input<br />

ACI circuit<br />

ACI<br />

ACM<br />

internal circuit<br />

Max. 48VDC 50mA<br />

Maximum 48VDC, 50mA<br />

Refer to Pr.02-13 to Pr.02-14 for programming<br />

MO1~MO2-DCM<br />

MO1~MO2<br />

Revision Dec. 2008, 04VE, SW V2.05 2-13<br />

MCM<br />

Internal Circuit<br />

Impedance: 200kΩ<br />

Max: 48Vdc<br />

50mA<br />

Resolution: 12 bits<br />

Range: 0 ~ 10VDC = 0 ~ Max. Output<br />

Frequency (Pr.01-00)<br />

Set-up: Pr.03-00 ~ Pr.03-02<br />

Impedance: 250Ω<br />

Resolution: 12 bits<br />

Range: 4 ~ 20mA/0~10V =<br />

0 ~ Max. Output Frequency<br />

(Pr.01-00)<br />

Set-up: Pr.03-00 ~ Pr.03-02<br />

Jumper: ACI jumper, factory setting is<br />

4-20mA<br />

Auxiliary analog voltage input<br />

+10<br />

~ AUI circuit<br />

-10V<br />

Impedance:<br />

Resolution:<br />

Range:<br />

200kΩ<br />

12 bits<br />

-10 ~ +10VDC =<br />

0 ~ Max. Output Frequency<br />

AUI<br />

(Pr.01-00)<br />

ACM<br />

internal circuit<br />

Set-up: Pr.03-00 ~ Pr.03-02

Chapter 2 Installation and Wiring|<br />

Terminal<br />

Symbol<br />

AFM<br />

ACM<br />

Terminal Function<br />

Analog output meter<br />

AFM<br />

ACM<br />

Analog control signal<br />

(common)<br />

0~20mA<br />

Factory Settings (SINK)<br />

ON: Connect to DCM<br />

Impedance: 18.5kΩ (voltage output)<br />

1.1mΩ (current output)<br />

Output current 20mA max<br />

Resolution: max. frequency corresponds to<br />

0-10V<br />

Range: 0 ~ 10V/0 ~ 20mA<br />

Function: Pr.03-18<br />

Switch: AFM switch, factory setting is 0-<br />

10V<br />

Common for AVI, ACI, AUI, AFM<br />

*Control signal wiring size: 18 AWG (0.75 mm 2 ) with shielded wire.<br />

Analog input terminals (AVI, ACI, AUI, ACM)<br />

� Analog input signals are easily affected by external noise. Use shielded wiring and keep it as<br />

short as possible (

General<br />

Chapter 2 Installation and Wiring|<br />

� Keep control wiring as far as possible from the power wiring and in separate conduits to<br />

avoid interference. If necessary let them cross only at 90º angle.<br />

� The AC motor drive control wiring should be properly installed and not touch any live power<br />

wiring or terminals.<br />

NOTE<br />

� If a filter is required for reducing EMI (Electro Magnetic Interference), install it as close as<br />

possible to AC drive. EMI can also be reduced by lowering the Carrier Frequency.<br />

� When using a GFCI (Ground Fault Circuit Interrupter), select a current sensor with sensitivity<br />

of 200mA, and not less than 0.1-second detection time to avoid nuisance tripping.<br />

DANGER!<br />

Damaged insulation of wiring may cause personal injury or damage to circuits/equipment if it comes<br />

in contact with high voltage.<br />

The specification for the control terminals<br />

The Position of the Control Terminals<br />

MRA RA<br />

MRC RB<br />

NOTE<br />

RC<br />

MCM +24V FWD MI1 MI3 MI5 DFM +10V AVI ACM<br />

MO1 MO2 DCM REV MI2 MI4 MI6 AFM AUI<br />

Frame Torque Wire<br />

Revision Dec. 2008, 04VE, SW V2.05 2-15<br />

ACI<br />

B, C, D, E, E1 8 kgf-cm (6.9 in-lbf) 22-14 AWG (0.3-2.1mm 2 )<br />

Frame B: VFD007V23A/43A-2, VFD015V23A/43A-2, VFD022V23A/43A-2, VFD037V23A/43A-2;<br />

Frame C: VFD055V23A/43A-2, VFD075V23A/43A-2, VFD110V43B-2,<br />

Frame D: VFD110V23A/43A-2, VFD150V23A/43A-2, VFD185V23A/43A-2, VFD220V23A/43A-2<br />

Frame E: VFD300V43A-2, VFD370V43A-2, VFD450V43A-2<br />

Frame E1: VFD300V23A-2, VFD370V23A-2, VFD550V43C-2, VFD750V43C-2

Chapter 3 Digital Keypad Operation and Start Up<br />

3.1 Digital Keypad KPV-CE01<br />

3.1.1 Description of the Digital Keypad KPV-CE01<br />

MODE Selection Key<br />

Press this key to view different<br />

operating values<br />

Left Key<br />

moves cursor to the left<br />

FWD/REV Direction Key<br />

RUN key<br />

F<br />

H<br />

U<br />

JOG<br />

KPV-CE01<br />

EXTPU<br />

STOP<br />

RUN RESET<br />

LED Display<br />

Display frequency, current, voltage<br />

and error, etc.<br />

Part Number<br />

Status Display<br />

Display of driver status<br />

STOP/RESET<br />

Revision Dec. 2008, 04VE, SW V2.05 3-1<br />

PU<br />

Display Message Descriptions<br />

Displays the AC drive Master Frequency.<br />

Right Key<br />

Moves the cursor right<br />

Displays the actual output frequency present at terminals U/T1, V/T2, and<br />

W/T3.<br />

User defined unit (where U = F x Pr.00-05)<br />

Displays the output current present at terminals U/T1, V/T2, and W/T3.<br />

The counter value (C).

Chapter 3 Digital Keypad Operation and Start Up|<br />

Display Message Descriptions<br />

Displays the selected parameter.<br />

Displays the actual stored value of the selected parameter.<br />

External Fault.<br />

Display “End” for approximately 1 second if input has been accepted by<br />

pressing key. After a parameter value has been set, the new<br />

value is automatically stored in memory. To modify an entry, use the<br />

, and keys.<br />

Display “Err”, if the input is invalid.<br />

3-2 Revision Dec. 2008, 04VE, SW V2.05

F<br />

H<br />

U<br />

Chapter 3 Digital Keypad Operation and Start Up|<br />

3.1.2 How to Operate the Digital Keypad KPV-CE01<br />

START<br />

F<br />

H<br />

U<br />

Selection mode<br />

To set parameters<br />

F<br />

H<br />

U<br />

To shift cursor<br />

START<br />

To modify data<br />

START<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

NOTE: In the selection mode, press<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

MODE<br />

MODE<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

NOTE: In the parameter setting mode, you can press<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

START<br />

MODE<br />

To switch display mode<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

MODE MODE<br />

F<br />

H<br />

U<br />

MODE<br />

Revision Dec. 2008, 04VE, SW V2.05 3-3<br />

MODE<br />

to set the parameters.<br />

move to previous display<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

MODE<br />

F<br />

H<br />

U<br />

parameter set successfully<br />

to return to the selection mode.<br />

F<br />

H<br />

U<br />

parameter set error<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

MODE<br />

GO START<br />

F<br />

H<br />

U

Chapter 3 Digital Keypad Operation and Start Up|<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

To copy parameters 1<br />

Copy parameters from the AC Motor Drive to the KPV-CE01<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

start blinking It will display "End" to indicate that<br />

the first parameter is saved, then<br />

return to "rEAd0".<br />

To copy parameters 2<br />

F<br />

H<br />

U<br />

3-4 Revision Dec. 2008, 04VE, SW V2.05<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

start blinking It will display "End" to indicate that<br />

about 2-3 seconds<br />

the second parameter is saved, then<br />

return to "rEAd1".<br />

Copy parameters from the KPV-CE01 to the AC Motor Drive<br />

about 2-3 seconds<br />

F<br />

H<br />

U<br />

start blinking<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

H<br />

U<br />

F<br />

F<br />

H<br />

H<br />

U<br />

U<br />

It will display "End" to indicate that<br />

the first parameter is saved, then<br />

return to "SAvEv".<br />

F<br />

H<br />

U<br />

F<br />

F<br />

H<br />

H<br />

U<br />

U<br />

start blinking<br />

about 2-3 seconds<br />

F<br />

H<br />

U<br />

about 2-3 seconds<br />

F<br />

H<br />

U<br />

F<br />

F<br />

H<br />

H<br />

U<br />

U<br />

It will display "End" to indicate that<br />

the second parameter is saved, then<br />

return to "SAvEv".

3.1.3 Dimension of the Digital Keypad<br />

F<br />

H<br />

U<br />

JOG<br />

FWD<br />

REV<br />

RUN<br />

MODE<br />

KPV-CEO1<br />

RUN STOP JOGFWD REV EXT PU<br />

PU<br />

PROG<br />

DATA<br />

STOP<br />

RESET<br />

Chapter 3 Digital Keypad Operation and Start Up|<br />

3.1.4 Reference Table for the LCD Display of the Digital Keypad<br />

Digital 0 1 2 3 4 5 6 7 8 9<br />

LCD<br />

English<br />

alphabet<br />

LCD<br />

English<br />

alphabet<br />

LCD<br />

English<br />

alphabet<br />

LCD<br />

A b Cc d E F G Hh I Jj<br />

K L n Oo P q r S Tt U<br />

v Y Z<br />

Unit: mm [inch]<br />

Revision Dec. 2008, 04VE, SW V2.05 3-5<br />

LABEL 1

Chapter 3 Digital Keypad Operation and Start Up|<br />

3.1.5 Operation Method<br />

Refer to 3.1.2 How to operate the digital keypad KPV-CE01 and chapter 4 parameters for<br />

setting. Please choose a suitable method depending on application and operation rule. The<br />

operation is usually used as shown in the following table.<br />

Operation Method Frequency Source<br />

KPV-CE01 keypad<br />

Operate from<br />

external signal<br />

Operate from<br />

communication<br />

Factory setting:<br />

SINK Mode<br />

Sink<br />

Sw1<br />

Factory<br />

Source setting<br />

Please refer to<br />

Figure 3 for wiring<br />

of SINK mode and<br />

SOURCEmode.<br />

FWD/STOP<br />

REV/STOP<br />

Multi-step 1<br />

Multi-step 2<br />

Multi-step 3<br />

Multi-step 4<br />

No function<br />

No function<br />

Digital Signal Common<br />

* Don't apply the mains voltage directly<br />

to abov e terminals.<br />

ACI current/voltage selection<br />

ACI Switch<br />

3<br />

Make sure that power is OFF<br />

before changing the switch 5K 2<br />

setting.<br />

0-20mA 0-10V<br />

1<br />

Analog Multi-function Output Terminal<br />

AFM analog output selection<br />

AFM Switch<br />

Make sure that power is OFF<br />

before changing the switch<br />

setting.<br />

0-10V 0-20mA<br />

Main circuit (power) terminals<br />

Operation Command<br />

Source<br />

STOP<br />

RUN RESET<br />

+24V<br />

FWD<br />

REV<br />

MI1<br />

MI2<br />

MI3<br />

MI4<br />

MI5<br />

MI6<br />

DCM<br />

E<br />

+10V<br />

Power supply<br />

+10V 20mA<br />

AVI<br />

Master Frequency<br />

0 to 10V 47k<br />

ACI<br />

4~20mA/0~10V<br />

AUI<br />

-10~+10V<br />

ACM<br />

Analog Signal Common<br />

E<br />

AFM 0~10VDC/2mA<br />

ACM<br />

Analog Signal common<br />

E<br />

Control circuit terminals Shielded leads & Cable<br />

Please refer to the communication address 2000H and 2119H settings in the<br />

communication address definition.<br />

3-6 Revision Dec. 2008, 04VE, SW V2.05

3.2 Tuning Operations<br />

3.2.1 Flow Chart<br />

Take motor 1 as example<br />

Step 1<br />

Basic parameters settings<br />

Reset all parameters<br />

to factory setting<br />

Pr.00-02<br />

Setting the related<br />

information of IM motor<br />

Pr.01-00~01-02<br />

Pr.05-01~05-04<br />

If the motor and<br />

load can be<br />

separated<br />

YES<br />

run in low speed<br />

Check if output current<br />

is within (20~50%) of<br />

rated current<br />

YES<br />

Stop running<br />

Motor auto tuning<br />

Pr.05-00=1<br />

NO<br />

NO<br />

Chapter 3 Digital Keypad Operation and Start Up|<br />

Step 2 Motor tuning<br />

No-load current of motor<br />

Pr.05-05<br />

Motor auto tuning<br />

Pr.05-00=2<br />

If it displays "tun"<br />

during trial run<br />

Please contact<br />

motor supplier<br />

Revision Dec. 2008, 04VE, SW V2.05 3-7<br />

YES<br />

The motor tuning is<br />

finished after motor<br />

is stopped.<br />

Check if the value<br />

has been written<br />

into Pr.05-05~05-09<br />

NO<br />

If it displays "AUE",<br />

please check the<br />

wiring and parameter<br />

settings.

Chapter 3 Digital Keypad Operation and Start Up|<br />

Step 3 Trial run for FOCPG feedback control<br />

Selection of speed<br />

feedback card<br />

E MV-P G01X<br />

E MV-P G01O<br />

E MV-P G01L<br />

Encoder pulse<br />

Pr.10-00<br />

Encoder input type setting<br />

Pr.10-01<br />

Pr.00-10=3<br />

FOCPG control mode<br />

If the motor can run YES<br />

NO<br />

Stop trial run<br />

Check if PG card<br />

is nor mal<br />

3-8 Revision Dec. 2008, 04VE, SW V2.05<br />

NO<br />

Check if output<br />

current is normal<br />

YES<br />

Change the operation<br />

direction of motor<br />

Increase the<br />

frequency command<br />

Finish trial run<br />

YES<br />

NO<br />

Refer to chapter 6<br />

for fault c ode<br />

Check the setting<br />

of Pr.10-00<br />

If there is<br />

mechanical<br />

gear<br />

YES<br />

Check the setting of<br />

gear ratio (Pr.10-27~<br />

10-28)

Step 4 Inertia estimation<br />

Connect the load and motor<br />

Adjust accel./decel. time<br />

Pr.01-12~01-13<br />

Pr.11-00=2<br />

If it allows the motor<br />

to forward/reverse<br />

running<br />

YES<br />

Set the operation frequency<br />

to 2/3 of motor rated<br />

frequency<br />

operate the motor<br />

observe Pr.11-01<br />

and adjust the<br />

operation direction<br />

NO<br />

Chapter 3 Digital Keypad Operation and Start Up|<br />

adjust multi-step speed<br />

MI1=1, set Pr.04-00 to 1/5 of<br />

rated frequency and operation<br />

frequency to 4/5 of rated frequency<br />

operate the motor<br />

observe Pr.11-01 and<br />

set Pr.02-10 to 4 or 0<br />

Check if Pr.11-01<br />

setti ng is<br />

convergence<br />

Revision Dec. 2008, 04VE, SW V2.05 3-9<br />

YES<br />

Stop motor running<br />

record Pr.11-01<br />

Pr.11-00=0<br />

Finish trial run<br />

NO<br />

Check accel./decel. time<br />

and operation frequency<br />

setting

Chapter 3 Digital Keypad Operation and Start Up|<br />

3.2.2 Explanations for the Tuning Steps<br />

3.3.2.1 Step 1<br />

Basic parameters settings for the motor<br />

� Make sure that Pr.00-00 (identity code of the AC motor drive) corresponds with the<br />

nameplate indicated on the AC motor drive.<br />

� Make sure that all parameters are reset to factory setting (Pr.00-02 is set to 9 or 10).<br />

Pr.00-02<br />

Parameter Reset<br />

0: No function<br />

1: Read only<br />

2: Enable group 11 parameters setting<br />

8: Keypad lock<br />

9: All parameters are reset to factory settings (50Hz,<br />

220V/380V)<br />

10: All parameters are reset to factory settings (60Hz,<br />

220V/440V)<br />

� Enter the related information of the motor into Pr.01-00~01-02 and Pr.05-01~05-04<br />

Pr.01-00<br />

50.00 ~ 600.00Hz<br />

Max. Output Frequency<br />

Pr.01-01<br />

1st Output Frequency<br />

Setting 1<br />

Pr.01-02<br />

1st Output Voltage<br />

Setting 1<br />

Pr.05-01<br />

Full-load Current of<br />

Motor 1 (A)<br />

0.00~600.00Hz<br />

230V: 0.1V~255.0V<br />

460V: 0.1V~510.0V<br />

40~120% of drive’s rated current<br />

NOTE: This value should be set according to the rated frequency of the motor as indicated on the<br />

motor nameplate. The factory setting is 90% of the rated current.<br />

Pr.05-02<br />

Rated Power of Motor 1<br />

(kW)<br />

0~655.35<br />

NOTE: It is used to set rated power of the motor 1. The factory setting is the power of the drive.<br />

3-10 Revision Dec. 2008, 04VE, SW V2.05

Pr.05-03<br />

Rated Speed of Motor 1<br />

(rpm)<br />

Chapter 3 Digital Keypad Operation and Start Up|<br />

0~65535<br />

NOTE: It is used to set the rated speed of the motor and needs to set according to the value indicated<br />

on the motor nameplate.<br />

Pr.05-04<br />

Number of Motor<br />

Poles 1<br />

2~20<br />

NOTE: it is used to set the number of motor poles (must be an even number).<br />

� Check if the motor and load can be separated. If yes, please set by the following steps. If not,<br />

please jump to step 2 for static test of the motor auto tuning.<br />

� If the above steps are normal, please trial run in low speed and check if the motor runs<br />

steadily without abnormal noise and vibration. If yes, please stop running and check if the<br />

wiring is correct or contact the motor supplier.<br />

� After ensure that the output current displayed on the digital keypad is within 20~50% of the<br />

motor rated current when trial run in low speed, please go to step 2. If the output current is<br />

out of the range, please check the motor wiring, parameter settings or contact the motor<br />

supplier.<br />

3.3.2.2 Step 2<br />

Motor tuning<br />

� Make sure that Pr.00-00 (identity code of the AC motor drive) corresponds to the nameplate<br />

of the AC motor drive.<br />

� Check if the motor and load can be disconnected.<br />

If yes: set Pr.05-00 to 1 (rolling test)<br />

If not: it needs to input value into Pr.05-05 and set Pr.05-00 to 2 (static test)<br />

� Motor auto tuning<br />

Pr.05-00<br />

0: No function<br />

Motor Auto Tuning 1: Rolling test<br />

2: Static Test<br />

3: Reserved<br />

� It will display on the digital keypad until the tuning is finished. Then the motor<br />

will stop automatically and save the value into Pr.05-06~Pr.05-09. If it displays<br />

, please check if the wiring and parameters settings are correct.<br />

Revision Dec. 2008, 04VE, SW V2.05 3-11

Chapter 3 Digital Keypad Operation and Start Up|<br />

3.3.2.3 Step 3<br />

Trial run for FOCPG feedback control<br />

� Selection for speed feedback card<br />

Please refer to Appendix B PG card for selection. <strong>Delta</strong> provides 3 PG cards, including EMV-<br />

PG01X, EMV-PG01O and EMV-PG01L, for your selection.<br />

� Encoder pulse<br />

Pr.10-00<br />

1~20000<br />

Encoder Pulse<br />

� Selection for encoder input type<br />

Pr.10-01<br />

Encoder Input Type<br />

Setting<br />

� Set it to FOCPG mode<br />

Pr.00-10<br />

Control Method<br />

0: Disable<br />

1: Phase A leads in a forward run command and phase B<br />

leads in a reverse run command<br />

2: Phase B leads in a forward run command and phase A<br />

leads in a reverse run command<br />

3: Phase A is a pulse input and phase B is a direction<br />

input. (low input=reverse direction, high input=forward<br />

direction)<br />

4: Phase A is a pulse input and phase B is a direction<br />

input. (low input=forward direction, high input=reverse<br />

direction)<br />

5: Single-phase input<br />

0: V/f Control<br />

1: V/f Control + Encoder (VFPG)<br />

2: Sensorless vector control (SVC)<br />

3: FOC vector control + Encoder (FOCPG)<br />

4: Torque control + Encoder (TQCPG)<br />

� Check if the PG feedback card is normal<br />

1. check if the actual output frequency reaches the frequency command<br />

2. When the PG feedback card is abnormal, the fault code.<br />

Check if Pr.10-01 is set to 0<br />

Check if the wiring of the feedback card is correct<br />

Check if the wiring of the feedback card, PI gain parameter<br />

is correct or adjust decel./accel. time<br />

Check if the wiring of the feedback card, PI gain parameter<br />

is correct or adjust decel./accel. time<br />

� After the fault is cleared, please trial run again.<br />

� Check if the output current is normal<br />

When changing frequency command, check if the output current is increased or decreased<br />

abnormally. If it is abnormal, please check if Pr.10-00 and Pr.10-27~Pr.10-28 are correct.<br />

� Changing the rotation direction of the motor<br />

Adjust the rotation direction of the motor to ensure that it can run in all the rotation directions.<br />

� Increase the frequency command<br />

Check if the output current/frequency and motor actual speed(it can set Pr.00-04=7 during<br />

operation) is normal in different commands.<br />

� Finish trial run<br />

If the results of trial run are normal, the trial run in FOCPG mode is completed.<br />

3-12 Revision Dec. 2008, 04VE, SW V2.05

3.3.2.4 Step 4<br />

Chapter 3 Digital Keypad Operation and Start Up|<br />

Inertia estimate<br />

� Check if the load and motor are connected correctly<br />