Robotic/Automatic Tool Changer - ATI Industrial Automation

Robotic/Automatic Tool Changer - ATI Industrial Automation

Robotic/Automatic Tool Changer - ATI Industrial Automation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TOOL CHANGERS FOR HEAVY AUTOM<strong>ATI</strong>ON<br />

<strong>Robotic</strong> <strong>Tool</strong> <strong>Changer</strong>s for Heavy<br />

<strong>Automation</strong><br />

The Heavy <strong>Automation</strong> <strong>Robotic</strong> <strong>Tool</strong> <strong>Changer</strong> line has<br />

been developed for the resistance welding market and<br />

medium- to heavy-duty material handling. Because<br />

these <strong>Tool</strong> <strong>Changer</strong>s use modules to pass utilities (e.g.,<br />

water, electrical, pneumatic, etc.), they are able to<br />

handle numerous applications by simply selecting the<br />

appropriate modules. These <strong>Tool</strong> <strong>Changer</strong>s have<br />

extremely high moment capacity for use in demanding<br />

applications.<br />

Product Advantages<br />

Modular Design: Power, coolant, servo, and control/<br />

signal features are built into separate modules making<br />

maintenance easy. Module housings use a common<br />

mounting design for use on the QC-210, QC-310, QC-<br />

510, and QC-1210, increasing flexibility in configuring the<br />

<strong>Tool</strong> <strong>Changer</strong>.<br />

Extremely High Moment Capacity: Many <strong>Tool</strong><br />

<strong>Changer</strong>s with high moment loads gap (separate<br />

between the Master and <strong>Tool</strong> plates) during high-speed<br />

moves, causing disruption to utilities such as Fieldbus<br />

networks and servo lines. The Heavy <strong>Automation</strong> series<br />

from <strong>ATI</strong> can take on dynamic moment loads and<br />

maintain utility functions during full range of motion.<br />

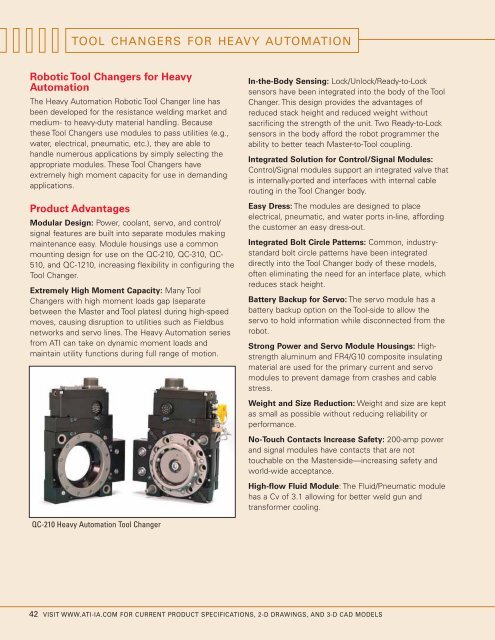

QC-210 Heavy <strong>Automation</strong> <strong>Tool</strong> <strong>Changer</strong><br />

In-the-Body Sensing: Lock/Unlock/Ready-to-Lock<br />

sensors have been integrated into the body of the <strong>Tool</strong><br />

<strong>Changer</strong>. This design provides the advantages of<br />

reduced stack height and reduced weight without<br />

sacrificing the strength of the unit. Two Ready-to-Lock<br />

sensors in the body afford the robot programmer the<br />

ability to better teach Master-to-<strong>Tool</strong> coupling.<br />

Integrated Solution for Control/Signal Modules:<br />

Control/Signal modules support an integrated valve that<br />

is internally-ported and interfaces with internal cable<br />

routing in the <strong>Tool</strong> <strong>Changer</strong> body.<br />

Easy Dress: The modules are designed to place<br />

electrical, pneumatic, and water ports in-line, affording<br />

the customer an easy dress-out.<br />

Integrated Bolt Circle Patterns: Common, industrystandard<br />

bolt circle patterns have been integrated<br />

directly into the <strong>Tool</strong> <strong>Changer</strong> body of these models,<br />

often eliminating the need for an interface plate, which<br />

reduces stack height.<br />

Battery Backup for Servo: The servo module has a<br />

battery backup option on the <strong>Tool</strong>-side to allow the<br />

servo to hold information while disconnected from the<br />

robot.<br />

Strong Power and Servo Module Housings: Highstrength<br />

aluminum and FR4/G10 composite insulating<br />

material are used for the primary current and servo<br />

modules to prevent damage from crashes and cable<br />

stress.<br />

Weight and Size Reduction: Weight and size are kept<br />

as small as possible without reducing reliability or<br />

performance.<br />

No-Touch Contacts Increase Safety: 200-amp power<br />

and signal modules have contacts that are not<br />

touchable on the Master-side—increasing safety and<br />

world-wide acceptance.<br />

High-flow Fluid Module: The Fluid/Pneumatic module<br />

has a Cv of 3.1 allowing for better weld gun and<br />

transformer cooling.<br />

42 VISIT WWW.<strong>ATI</strong>-IA.COM FOR CURRENT PRODUCT SPECIFIC<strong>ATI</strong>ONS, 2-D DRAWINGS, AND 3-D CAD MODELS