Evaluation of hastelloy N alloys after nine years exposure to both a ...

Evaluation of hastelloy N alloys after nine years exposure to both a ...

Evaluation of hastelloy N alloys after nine years exposure to both a ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

10<br />

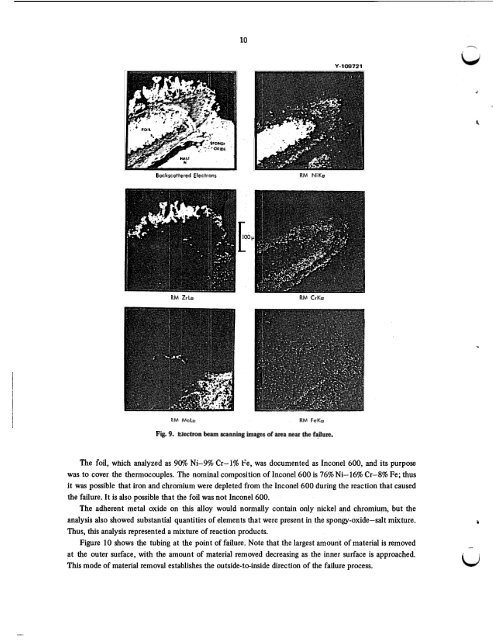

Backscattered Electrons RM NiKa<br />

RM Zrla RM CrKa<br />

RM MoLo RM FeKo<br />

Fig. 9. mctron beam scanning images <strong>of</strong> area near the feure.<br />

Y-109721<br />

The foil, which analyzed as 90% Ni-9% Cr-1% Fe, was documented as Inconel 600, and its purpose<br />

was <strong>to</strong> cover the thermocouples. The nominal composition <strong>of</strong> Inconel 600 is 76%Ni-16% Cr-8% Fe; thus<br />

it was possible that iron and chromium were depleted from the Inconel 600 during the reaction that caused<br />

the failure. It is also possible that the foil was not Inconel 600.<br />

The adherent metal oxide on this alloy would normally contain only nickel and chromium, but the<br />

analysis also showed substantial quantities <strong>of</strong> elements that were present in the spongy-oxide-salt mixture.<br />

Thus, this analysis represented a mixture <strong>of</strong> reaction products.<br />

Figure 10 shows the tubing at the point <strong>of</strong> failure. Note that the largest amount <strong>of</strong> material is removed<br />

at the outer surface, with the amount <strong>of</strong> material removed decreasing as the inner surface is approached.<br />

This mode <strong>of</strong> material removal establishes the outside-<strong>to</strong>-inside direction <strong>of</strong> the failure process.<br />

.<br />

i<br />

L,

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)