Industrial Power Transmission Products - Bando USA

Industrial Power Transmission Products - Bando USA

Industrial Power Transmission Products - Bando USA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

V-Belt Installation<br />

Proper installation techniques will assure that you get full service life and minimum downtime from your belt<br />

drives.<br />

1. Turn machine OFF and lock out power source. 5. Install new belts.<br />

2. Remove belt guard, loosen motor mounts, and short-<br />

Loosen the drive take up and place the new belts on<br />

en center distance between sheaves. Remove old<br />

the sheaves. Press the belts with your hand to posi-<br />

belts.<br />

tion the slack of each belt on the same side of the<br />

drive. If the slack is on different sides, start up loads<br />

can break belt tensile cords.<br />

Do not pry or force belts on the sheave. This can<br />

break the load carrying tensile “muscle” of the belt,<br />

and the belts will break or turn over shortly after<br />

installation.<br />

Take up slack until the belts fit snugly.<br />

3. Inspect, repair, or replace drive components.<br />

Clean oil, grease, and debris from sheaves; remove<br />

rust with a wire brush.<br />

Inspect and replace damaged sheaves.<br />

Get your money’s worth from a new set of belts by<br />

checking and replacing worn or damaged sheaves. In<br />

the long run, replacement sheave cost will more than<br />

be recovered in increased belt life, reduced downtime,<br />

and lower maintenance expense. Check the following:<br />

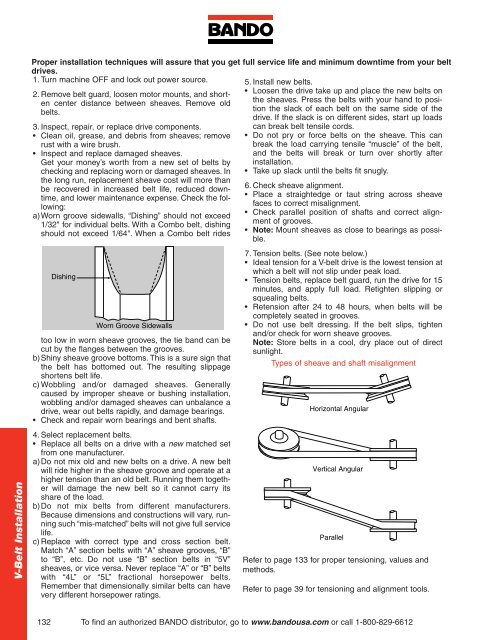

a)Worn groove sidewalls, “Dishing” should not exceed<br />

1/32" for individual belts. With a Combo belt, dishing<br />

should not exceed 1/64". When a Combo belt rides<br />

too low in worn sheave grooves, the tie band can be<br />

cut by the flanges between the grooves.<br />

b)Shiny sheave groove bottoms. This is a sure sign that<br />

the belt has bottomed out. The resulting slippage<br />

shortens belt life.<br />

c) Wobbling and/or damaged sheaves. Generally<br />

caused by improper sheave or bushing installation,<br />

wobbling and/or damaged sheaves can unbalance a<br />

drive, wear out belts rapidly, and damage bearings.<br />

Check and repair worn bearings and bent shafts.<br />

4. Select replacement belts.<br />

Replace all belts on a drive with a new matched set<br />

from one manufacturer.<br />

a)Do not mix old and new belts on a drive. A new belt<br />

will ride higher in the sheave groove and operate at a<br />

higher tension than an old belt. Running them together<br />

will damage the new belt so it cannot carry its<br />

share of the load.<br />

b)Do not mix belts from different manufacturers.<br />

Because dimensions and constructions will vary, running<br />

such “mis-matched” belts will not give full service<br />

life.<br />

c) Replace with correct type and cross section belt.<br />

Match “A” section belts with “A” sheave grooves, “B”<br />

to “B”, etc. Do not use “B” section belts in “5V”<br />

sheaves, or vice versa. Never replace “A” or “B” belts<br />

with “4L” or “5L” fractional horsepower belts.<br />

Remember that dimensionally similar belts can have<br />

very different horsepower ratings.<br />

132<br />

Dishing<br />

Worn Groove Sidewalls<br />

6. Check sheave alignment.<br />

Place a straightedge or taut string across sheave<br />

faces to correct misalignment.<br />

Check parallel position of shafts and correct alignment<br />

of grooves.<br />

Note: Mount sheaves as close to bearings as possible.<br />

7. Tension belts. (See note below.)<br />

Ideal tension for a V-belt drive is the lowest tension at<br />

which a belt will not slip under peak load.<br />

Tension belts, replace belt guard, run the drive for 15<br />

minutes, and apply full load. Retighten slipping or<br />

squealing belts.<br />

Retension after 24 to 48 hours, when belts will be<br />

completely seated in grooves.<br />

Do not use belt dressing. If the belt slips, tighten<br />

and/or check for worn sheave grooves.<br />

Note: Store belts in a cool, dry place out of direct<br />

sunlight.<br />

Types of sheave and shaft misalignment<br />

Horizontal Angular<br />

Vertical Angular<br />

Parallel<br />

Refer to page 133 for proper tensioning, values and<br />

methods.<br />

Refer to page 39 for tensioning and alignment tools.<br />

To find an authorized BANDO distributor, go to www.bandousa.com or call 1-800-829-6612