Industrial Power Transmission Products - Bando USA

Industrial Power Transmission Products - Bando USA

Industrial Power Transmission Products - Bando USA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

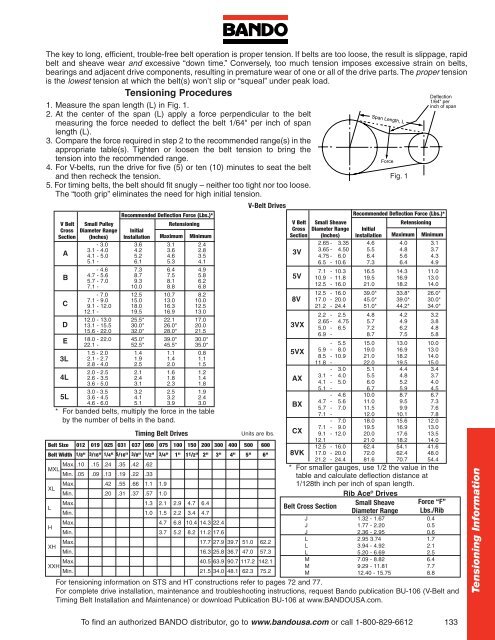

The key to long, efficient, trouble-free belt operation is proper tension. If belts are too loose, the result is slippage, rapid<br />

belt and sheave wear and excessive “down time.” Conversely, too much tension imposes excessive strain on belts,<br />

bearings and adjacent drive components, resulting in premature wear of one or all of the drive parts. The proper tension<br />

is the lowest tension at which the belt(s) won’t slip or “squeal” under peak load.<br />

Tensioning Procedures<br />

1. Measure the span length (L) in Fig. 1.<br />

2. At the center of the span (L) apply a force perpendicular to the belt<br />

measuring the force needed to deflect the belt 1/64" per inch of span<br />

length (L).<br />

3. Compare the force required in step 2 to the recommended range(s) in the<br />

appropriate table(s). Tighten or loosen the belt tension to bring the<br />

tension into the recommended range.<br />

4. For V-belts, run the drive for five (5) or ten (10) minutes to seat the belt<br />

and then recheck the tension.<br />

5. For timing belts, the belt should fit snugly – neither too tight nor too loose.<br />

The “tooth grip” eliminates the need for high initial tension.<br />

Span Length, L<br />

V-Belt Drives<br />

Recommended Deflection Force (Lbs.)*<br />

Recommended Deflection Force (Lbs.)*<br />

V Belt<br />

Cross<br />

Section<br />

Small Pulley<br />

Diameter Range<br />

(Inches)<br />

Initial<br />

Installation<br />

Retensioning<br />

Maximum Minimum<br />

V Belt<br />

Cross<br />

Section<br />

Small Sheave<br />

Diameter Range<br />

(Inches)<br />

Initial<br />

Installation<br />

Retensioning<br />

Maximum Minimum<br />

2.65 - 3.35<br />

3.65 - 4.50<br />

4.75 - 6.0<br />

6.5 - 10.6<br />

4.6<br />

5.5<br />

6.4<br />

7.3<br />

4.0<br />

4.8<br />

5.6<br />

6.4<br />

3.1<br />

3.7<br />

4.3<br />

4.9<br />

7.1 - 10.3<br />

10.9 - 11.8<br />

12.5 - 16.0<br />

16.5<br />

19.5<br />

21.0<br />

14.3<br />

16.9<br />

18.2<br />

11.0<br />

13.0<br />

14.0<br />

12.5 - 16.0<br />

17.0 - 20.0<br />

21.2 - 24.4<br />

39.0*<br />

45.0*<br />

51.0*<br />

33.8*<br />

39.0*<br />

44.2*<br />

26.0*<br />

30.0*<br />

34.0*<br />

2.2 - 2.5<br />

2.65 - 4.75<br />

5.0 - 6.5<br />

6.9 -<br />

- 5.5<br />

5.9 - 8.0<br />

8.5 - 10.9<br />

11.8 -<br />

- 3.0<br />

3.1 - 4.0<br />

4.1 - 5.0<br />

5.1 -<br />

- 4.6<br />

4.7 - 5.6<br />

5.7 - 7.0<br />

7.1 -<br />

- 7.0<br />

4.8<br />

5.7<br />

7.2<br />

8.7<br />

15.0<br />

19.0<br />

21.0<br />

22.0<br />

5.1<br />

5.5<br />

6.0<br />

6.7<br />

10.0<br />

11.0<br />

11.5<br />

12.0<br />

18.0<br />

4.2<br />

4.9<br />

6.2<br />

7.5<br />

13.0<br />

16.9<br />

18.2<br />

19.5<br />

4.4<br />

4.8<br />

5.2<br />

5.9<br />

8.7<br />

9.5<br />

9.9<br />

10.1<br />

15.6<br />

3.2<br />

3.8<br />

4.8<br />

5.8<br />

10.0<br />

13.0<br />

14.0<br />

15.0<br />

3.4<br />

3.7<br />

4.0<br />

4.5<br />

6.7<br />

7.3<br />

7.6<br />

7.8<br />

12.0<br />

7.1 - 9.0<br />

9.1 - 12.0<br />

19.5<br />

20.0<br />

16.9<br />

17.6<br />

13.0<br />

13.5<br />

Belt Size 012 019 025 031 037 050<br />

Belt Width 1/8" 3/16" 1/4" 5/16" 3/8" 1/2"<br />

Max. .10 .15 .24 .35 .42 .62<br />

MXL<br />

Min. .05 .09 .13 .19 .22 .33<br />

075<br />

3/4"<br />

100<br />

1"<br />

150 200 300<br />

11/2" 2" 3"<br />

400<br />

4"<br />

500<br />

5"<br />

600<br />

6"<br />

12.1 21.0 18.2 14.0<br />

12.5 - 16.0 62.4 54.1 41.6<br />

17.0 - 20.0 72.0 62.4 48.0<br />

21.2 - 24.4 81.6 70.7 54.4<br />

XL<br />

Max.<br />

Min.<br />

.42<br />

.20<br />

.55<br />

.31<br />

.66<br />

.37<br />

1.1<br />

.57<br />

1.9<br />

1.0<br />

Rib Ace<br />

L<br />

H<br />

Max.<br />

Min.<br />

Max.<br />

Min.<br />

1.3<br />

1.0<br />

2.1<br />

1.5<br />

4.7<br />

3.7<br />

2.9<br />

2.2<br />

6.8<br />

5.2<br />

4.7 6.4<br />

3.4 4.7<br />

10.4 14.3 22.4<br />

8.2 11.2 17.6<br />

Belt Cross Section<br />

Small Sheave<br />

Diameter Range<br />

Force “F”<br />

Lbs./Rib<br />

XH<br />

Max.<br />

Min.<br />

17.7 27.9 39.7 51.0<br />

16.3 25.8 36.7 47.0<br />

62.2<br />

57.3<br />

Max.<br />

XXH<br />

Min.<br />

40.5 63.9 90.7 117.2 142.1<br />

21.5 34.0 48.1 62.3 75.2<br />

For tensioning information on STS and HT constructions refer to pages 72 and 77.<br />

For complete drive installation, maintenance and troubleshooting instructions, request <strong>Bando</strong> publication BU-106 (V-Belt and<br />

Timing Belt Installation and Maintenance) or download Publication BU-106 at www.BANDO<strong>USA</strong>.com.<br />

® A<br />

- 3.0<br />

3.1 - 4.0<br />

4.1 - 5.0<br />

5.1 -<br />

3.6<br />

4.2<br />

5.2<br />

6.1<br />

3.1<br />

3.6<br />

4.6<br />

5.3<br />

2.4<br />

2.8<br />

3.5<br />

4.1<br />

3V<br />

B<br />

- 4.6<br />

4.7 - 5.6<br />

5.7 - 7.0<br />

7.1 -<br />

7.3<br />

8.7<br />

9.3<br />

10.0<br />

6.4<br />

7.5<br />

8.1<br />

8.8<br />

4.9<br />

5.8<br />

6.2<br />

6.8<br />

5V<br />

C<br />

- 7.0<br />

7.1 - 9.0<br />

9.1 - 12.0<br />

12.5<br />

15.0<br />

18.0<br />

10.7<br />

13.0<br />

16.3<br />

8.2<br />

10.0<br />

12.5<br />

8V<br />

12.1 - 19.5 16.9 13.0<br />

12.0 - 13.0 25.5* 22.1 17.0<br />

D 13.1 - 15.5 30.0* 26.0* 20.0<br />

15.6 - 22.0 32.0* 28.0* 21.5<br />

E 18.0 - 22.0 45.0* 39.0* 30.0*<br />

22.1 - 52.5* 45.5* 35.0*<br />

1.5 - 2.0 1.4 1.1 0.8<br />

3L 2.1 - 2.7 1.9 1.4 1.1<br />

2.8 - 4.0 2.5 2.0 1.5<br />

2.0 - 2.5 2.1 1.6 1.2<br />

4L 2.6 - 3.5 2.4 1.8 1.4<br />

3.6 - 5.0 3.1 2.3 1.8<br />

3.0 - 3.5 3.2 2.5 1.9<br />

5L 3.6 - 4.5 4.1 3.2 2.4<br />

4.6 - 6.0 5.1 3.9 3.0<br />

* For banded belts, multiply the force in the table<br />

by the number of belts in the band.<br />

3VX<br />

5VX<br />

AX<br />

BX<br />

Timing Belt Drives<br />

Units are lbs. CX<br />

8VK<br />

* For smaller gauges, use 1/2 the value in the<br />

table and calculate deflection distance at<br />

1/128th inch per inch of span length.<br />

Drives<br />

J<br />

J<br />

J<br />

1.32 - 1.67<br />

1.77 - 2.20<br />

2.36 - 2.95<br />

0.4<br />

0.5<br />

0.6<br />

L<br />

L<br />

L<br />

2.95 3.74<br />

3.94 - 4.92<br />

5.20 - 6.69<br />

1.7<br />

2.1<br />

2.5<br />

M<br />

M<br />

M<br />

7.09 - 8.82<br />

9.29 - 11.81<br />

12.40 - 15.75<br />

6.4<br />

7.7<br />

8.8<br />

Force<br />

Fig. 1<br />

To find an authorized BANDO distributor, go to www.bandousa.com or call 1-800-829-6612<br />

Deflection<br />

1/64" per<br />

inch of span<br />

133<br />

Tensioning Information