Industrial Power Transmission Products - Bando USA

Industrial Power Transmission Products - Bando USA

Industrial Power Transmission Products - Bando USA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

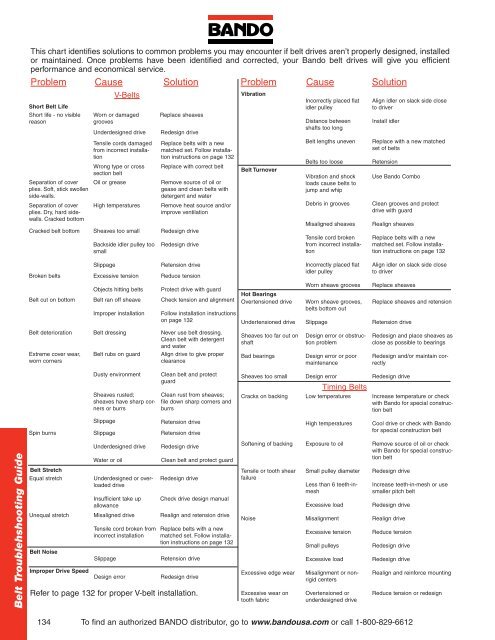

Belt Belt Troublehshooting Guide<br />

This chart identifies solutions to common problems you may encounter if belt drives aren’t properly designed, installed<br />

or maintained. Once problems have been identified and corrected, your <strong>Bando</strong> belt drives will give you efficient<br />

performance and economical service.<br />

Problem Cause Solution Problem Cause Solution<br />

Short Belt Life<br />

Short life - no visible<br />

reason<br />

134<br />

V-Belts<br />

Worn or damaged<br />

grooves<br />

Underdesigned drive<br />

Tensile cords damaged<br />

from incorrect installation<br />

Wrong type or cross<br />

section belt<br />

Separation of cover Oil or grease<br />

plies. Soft, stick swollen<br />

side-walls.<br />

Separation of cover<br />

plies. Dry, hard sidewalls.<br />

Cracked bottom<br />

High temperatures<br />

Replace sheaves<br />

Redesign drive<br />

Replace belts with a new<br />

matched set. Follow installation<br />

instructions on page 132<br />

Replace with correct belt<br />

Remove source of oil or<br />

gease and clean belts with<br />

detergent and water<br />

Remove heat source and/or<br />

improve ventilation<br />

Cracked belt bottom Sheaves too small Redesign drive<br />

Backside idler pulley too<br />

small<br />

Redesign drive<br />

Slippage<br />

Retension drive<br />

Broken belts Excessive tension Reduce tension<br />

Objects hitting belts Protect drive with guard<br />

Belt cut on bottom Belt ran off sheave Check tension and alignment<br />

Improper installation<br />

Follow installation instructions<br />

on page 132<br />

Belt deterioration Belt dressing<br />

Never use belt dressing.<br />

Clean belt with detergent<br />

and water<br />

Extreme cover wear, Belt rubs on guard Align drive to give proper<br />

worn corners<br />

clearance<br />

Dusty environment<br />

Sheaves rusted;<br />

sheaves have sharp corners<br />

or burrs<br />

Clean belt and protect<br />

guard<br />

Clean rust from sheaves;<br />

file down sharp corners and<br />

burrs<br />

Slippage<br />

Retension drive<br />

Spin burns Slippage<br />

Retension drive<br />

Underdesigned drive<br />

Water or oil<br />

Redesign drive<br />

Clean belt and protect guard<br />

Belt Stretch<br />

Equal stretch Underdesigned or overloaded<br />

drive<br />

Redesign drive<br />

Insufficient take up<br />

allowance<br />

Check drive design manual<br />

Unequal stretch Misaligned drive Realign and retension drive<br />

Belt Noise<br />

Improper Drive Speed<br />

Tensile cord broken from<br />

incorrect installation<br />

Slippage<br />

Design error<br />

Replace belts with a new<br />

matched set. Follow installation<br />

instructions on page 132<br />

Retension drive<br />

Redesign drive<br />

Refer to page 132 for proper V-belt installation.<br />

Vibration<br />

Belt Turnover<br />

Hot Bearings<br />

Overtensioned drive<br />

Undertensioned drive<br />

Sheaves too far out on<br />

shaft<br />

Bad bearings<br />

Sheaves too small<br />

Cracks on backing<br />

Softening of backing<br />

Tensile or tooth shear<br />

failure<br />

Noise<br />

Excessive edge wear<br />

Excessive wear on<br />

tooth fabric<br />

Incorrectly placed flat<br />

idler pulley<br />

Distance between<br />

shafts too long<br />

Belt lengths uneven<br />

Belts too loose<br />

Vibration and shock<br />

loads cause belts to<br />

jump and whip<br />

Debris in grooves<br />

Misaligned sheaves<br />

Tensile cord broken<br />

from incorrect installation<br />

Incorrectly placed flat<br />

idler pulley<br />

Worn sheave grooves<br />

Worn sheave grooves,<br />

belts bottom out<br />

Slippage<br />

Design error or obstruction<br />

problem<br />

Design error or poor<br />

maintenance<br />

Design error<br />

Timing Belts<br />

Low temperatures<br />

High temperatures<br />

Exposure to oil<br />

Small pulley diameter<br />

Less than 6 teeth-inmesh<br />

Excessive load<br />

Misalignment<br />

Excessive tension<br />

Small pulleys<br />

Excessive load<br />

Misalignment or nonrigid<br />

centers<br />

Overtensioned or<br />

underdesigned drive<br />

Align idler on slack side close<br />

to driver<br />

Install idler<br />

Replace with a new matched<br />

set of belts<br />

Retension<br />

Use <strong>Bando</strong> Combo<br />

Clean grooves and protect<br />

drive with guard<br />

Realign sheaves<br />

Replace belts with a new<br />

matched set. Follow installation<br />

instructions on page 132<br />

Align idler on slack side close<br />

to driver<br />

Replace sheaves<br />

Replace sheaves and retension<br />

Retension drive<br />

Redesign and place sheaves as<br />

close as possible to bearings<br />

Redesign and/or maintain correctly<br />

Redesign drive<br />

Increase temperature or check<br />

with <strong>Bando</strong> for special construction<br />

belt<br />

Cool drive or check with <strong>Bando</strong><br />

for special construction belt<br />

Remove source of oil or check<br />

with <strong>Bando</strong> for special construction<br />

belt<br />

Redesign drive<br />

Increase teeth-in-mesh or use<br />

smaller pitch belt<br />

Redesign drive<br />

Realign drive<br />

Reduce tension<br />

Redesign drive<br />

Redesign drive<br />

Realign and reinforce mounting<br />

Reduce tension or redesign<br />

To find an authorized BANDO distributor, go to www.bandousa.com or call 1-800-829-6612