Simulink® Modeling for Vehicle Simulator Design - Delphi

Simulink® Modeling for Vehicle Simulator Design - Delphi

Simulink® Modeling for Vehicle Simulator Design - Delphi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Figure 8. Rolling Count on Simulation<br />

Figure 9. Radar Scan Index on Simulation<br />

2. DECODING OF CAN MESSAGES<br />

FROM THE ECU<br />

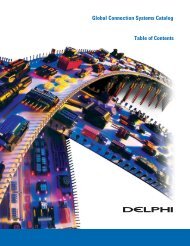

Decoding of CAN messages is automated in the model with<br />

the help of CAN database.<br />

3. INSTRUMENTATION SUPPORT FOR<br />

READING AND WRITING MEMORY<br />

THROUGH CAN CALIBRATION<br />

PROTOCOL (CCP) AND UNIVERSAL<br />

CALIBRATION PROTOCOL (XCP)<br />

CAN calibration protocol (CCP) provide a set of commands<br />

<strong>for</strong> instrumentation. Read- and-write memory operations are<br />

achieved using UPLOAD and DOWNLOAD commands<br />

respectively.<br />

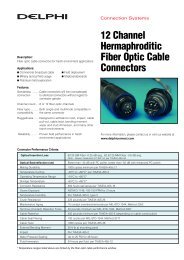

Universal measurement and calibration protocol (XCP) offers<br />

synchronous data transfer in both directions, from master<br />

(simulator) to slave (ECU) and from slave to master. XCP<br />

protocol uses transportation layers like CAN, TCP/IP, UDP/<br />

IP and USB.<br />

This Simulink ® model uses TCP/IP as a transport layer <strong>for</strong><br />

XCP to verify ACC algorithms which involves processing of<br />

huge amount of data.<br />

Figure 10. CCP Architecture<br />

Figure 11. XCP Architecture<br />

4. SUPPORT FOR PERIODIC DATA<br />

ACQUISITION (DAQ) AND PERIODIC<br />

DATA STIMULATION (STIM) USING<br />

CCP AND XCP<br />

Data acquisition (DAQ) is used to read non-contiguous<br />

memory locations periodically.