Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

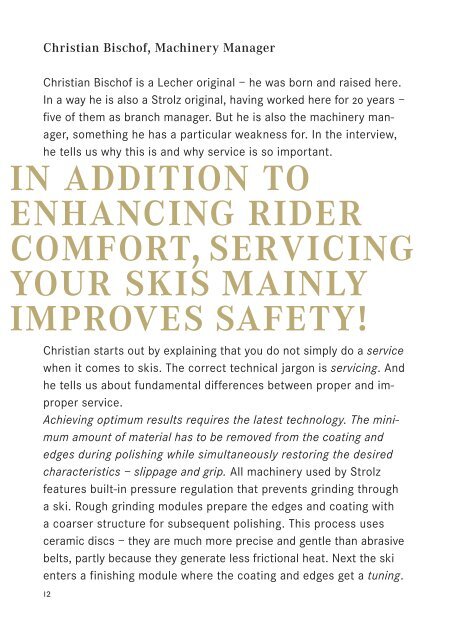

Christian Bischof, Machinery Manager<br />

Christian Bischof is a Lecher original – he was born and raised here.<br />

In a way he is also a Strolz original, having worked here for 20 years –<br />

fi ve of them as branch manager. But he is also the machinery manager,<br />

something he has a particular weakness for. In the interview,<br />

he tells us why this is and why service is so important.<br />

IN ADDITION TO<br />

ENHANCING RIDER<br />

COMFORT, SERVICING<br />

YOUR SKIS MAINLY<br />

IMPROVES SAFETY!<br />

Christian starts out by explaining that you do not simply do a service<br />

wh<strong>en</strong> it comes to skis. The correct technical jargon is servicing. And<br />

he tells us about fundam<strong>en</strong>tal differ<strong>en</strong>ces betwe<strong>en</strong> proper and improper<br />

service.<br />

Achieving optimum results requires the latest technology. The minimum<br />

amount of material has to be removed from the coating and<br />

edges during polishing while simultaneously restoring the desired<br />

characteristics – slippage and grip. All machinery used by Strolz<br />

features built-in pressure regulation that prev<strong>en</strong>ts grinding through<br />

a ski. Rough grinding modules prepare the edges and coating with<br />

a coarser structure for subsequ<strong>en</strong>t polishing. This process uses<br />

ceramic discs – they are much more precise and g<strong>en</strong>tle than abrasive<br />

belts, partly because they g<strong>en</strong>erate less frictional heat. Next the ski<br />

<strong>en</strong>ters a finishing module where the coating and edges get a tuning.<br />

12