Cutting cylinder oil costs without a break in service - Wärtsilä

Cutting cylinder oil costs without a break in service - Wärtsilä

Cutting cylinder oil costs without a break in service - Wärtsilä

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

p [ MARINE / IN DETAIL ]<br />

[ MARINE / IN DETAIL ]<br />

vessel. <strong>Wärtsilä</strong>’s two-stroke center and the<br />

<strong>Wärtsilä</strong> <strong>service</strong>s network are thus work<strong>in</strong>g<br />

<strong>in</strong> close co-operation to m<strong>in</strong>imize the<br />

required <strong>in</strong>stallation time so that RPLS can<br />

be retrofitted <strong>in</strong> a ship while on passage and<br />

dur<strong>in</strong>g a normal port stay. For example,<br />

<strong>Wärtsilä</strong> <strong>in</strong> Korea is manufactur<strong>in</strong>g all<br />

pipework and other mechanical parts.<br />

Before dispatch<strong>in</strong>g the material to the<br />

vessel, it is prefitted on a dummy <strong>in</strong> the<br />

<strong>Wärtsilä</strong> workshop <strong>in</strong> Noksan, South<br />

Korea, to verify that the work is correct.<br />

RPLS is an <strong>in</strong>dependent system with few<br />

connections or <strong>in</strong>terfaces to other systems,<br />

and utilizes the eng<strong>in</strong>e’s exist<strong>in</strong>g <strong>cyl<strong>in</strong>der</strong><br />

l<strong>in</strong>ers. Thus preparation and <strong>in</strong>stallation<br />

are easy and fast. All equipment, <strong>in</strong>clud<strong>in</strong>g<br />

prefabricated pip<strong>in</strong>g, is supplied with<br />

<strong>in</strong>stallation and commission<strong>in</strong>g work be<strong>in</strong>g<br />

undertaken by <strong>Wärtsilä</strong> <strong>service</strong> eng<strong>in</strong>eers.<br />

To a substantial extent this material<br />

can be <strong>in</strong>stalled dur<strong>in</strong>g the voyage,<br />

thereby considerably reduc<strong>in</strong>g the<br />

port time required for fi nish<strong>in</strong>g the<br />

<strong>in</strong>stallation and for the commission<strong>in</strong>g.<br />

Installation of controls, pumps, wir<strong>in</strong>g,<br />

and <strong>in</strong>terface connections to remote and<br />

alarm monitor<strong>in</strong>g systems, is executed<br />

dur<strong>in</strong>g the voyage. Ample attention is<br />

paid to commission<strong>in</strong>g, fi ne adjustment<br />

and the runn<strong>in</strong>g-<strong>in</strong> of the RPLS <strong>in</strong> port<br />

and dur<strong>in</strong>g a confi rmation voyage.<br />

The whole retrofit and commission<strong>in</strong>g<br />

on the first vessel, the 7500 TEU conta<strong>in</strong>er<br />

ship “COSCO SHENZHEN” with a 12<strong>cyl<strong>in</strong>der</strong><br />

<strong>Wärtsilä</strong> RTA96C ma<strong>in</strong> eng<strong>in</strong>e,<br />

could be completed <strong>in</strong> five steps <strong>without</strong><br />

<strong>in</strong>terrupt<strong>in</strong>g the vessel’s schedule:<br />

1. Pre-<strong>in</strong>spection <strong>in</strong> Hong Kong<br />

on 22 June 2006.<br />

2. First <strong>in</strong>stallation trip from Hong<br />

Kong to Yantian dur<strong>in</strong>g 26–27<br />

August. Installation work cont<strong>in</strong>ued<br />

<strong>in</strong> Yantian and dur<strong>in</strong>g the Pacifi c<br />

cross<strong>in</strong>g to Long Beach (USA),<br />

arriv<strong>in</strong>g there on 9 September.<br />

3. The second and fi nal <strong>in</strong>stallation<br />

period <strong>in</strong> Long Beach dur<strong>in</strong>g 9–<br />

11 September, <strong>in</strong>cluded pistonrunn<strong>in</strong>g<br />

related modifi cations.<br />

4. The commission<strong>in</strong>g was carried-out<br />

while on passage from Long Beach to<br />

Oakland, where on 13 September the<br />

f<strong>in</strong>al <strong>in</strong>spection was also carried out.<br />

5. F<strong>in</strong>ally, on her ‘maiden’ passage<br />

to Ch<strong>in</strong>a, measurements and<br />

documentation of the RPLS<br />

performance were carried out.<br />

52 <strong>in</strong>detail<br />

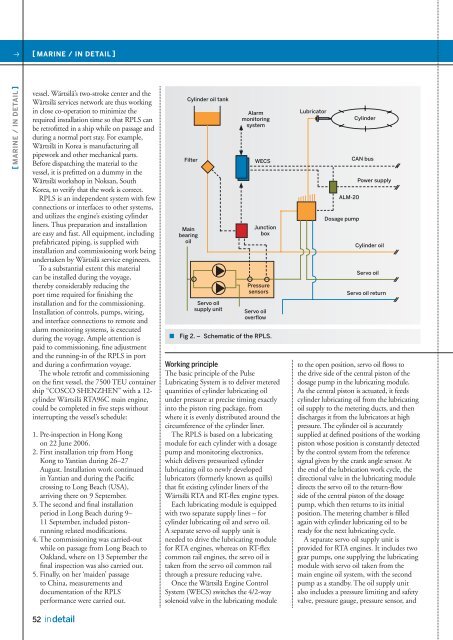

Cyl<strong>in</strong>der <strong>oil</strong> tank<br />

Alarm<br />

monitor<strong>in</strong>g<br />

system<br />

Filter WECS<br />

Ma<strong>in</strong><br />

bear<strong>in</strong>g<br />

<strong>oil</strong><br />

Servo <strong>oil</strong><br />

supply unit<br />

Junction<br />

box<br />

Pressure<br />

sensors<br />

Servo <strong>oil</strong><br />

overfl ow<br />

Fig 2. – Schematic of the RPLS.<br />

Work<strong>in</strong>g pr<strong>in</strong>ciple<br />

The basic pr<strong>in</strong>ciple of the Pulse<br />

Lubricat<strong>in</strong>g System is to deliver metered<br />

quantities of <strong>cyl<strong>in</strong>der</strong> lubricat<strong>in</strong>g <strong>oil</strong><br />

under pressure at precise tim<strong>in</strong>g exactly<br />

<strong>in</strong>to the piston r<strong>in</strong>g package, from<br />

where it is evenly distributed around the<br />

circumference of the <strong>cyl<strong>in</strong>der</strong> l<strong>in</strong>er.<br />

The RPLS is based on a lubricat<strong>in</strong>g<br />

module for each <strong>cyl<strong>in</strong>der</strong> with a dosage<br />

pump and monitor<strong>in</strong>g electronics,<br />

which delivers pressurized <strong>cyl<strong>in</strong>der</strong><br />

lubricat<strong>in</strong>g <strong>oil</strong> to newly developed<br />

lubricators (formerly known as quills)<br />

that fit exist<strong>in</strong>g <strong>cyl<strong>in</strong>der</strong> l<strong>in</strong>ers of the<br />

<strong>Wärtsilä</strong> RTA and RT-flex eng<strong>in</strong>e types.<br />

Each lubricat<strong>in</strong>g module is equipped<br />

with two separate supply l<strong>in</strong>es – for<br />

<strong>cyl<strong>in</strong>der</strong> lubricat<strong>in</strong>g <strong>oil</strong> and servo <strong>oil</strong>.<br />

A separate servo <strong>oil</strong> supply unit is<br />

needed to drive the lubricat<strong>in</strong>g module<br />

for RTA eng<strong>in</strong>es, whereas on RT-fl ex<br />

common rail eng<strong>in</strong>es, the servo <strong>oil</strong> is<br />

taken from the servo <strong>oil</strong> common rail<br />

through a pressure reduc<strong>in</strong>g valve.<br />

Once the <strong>Wärtsilä</strong> Eng<strong>in</strong>e Control<br />

System (WECS) switches the 4/2-way<br />

solenoid valve <strong>in</strong> the lubricat<strong>in</strong>g module<br />

Lubricator<br />

ALM-20<br />

Dosage pump<br />

Cyl<strong>in</strong>der<br />

CAN bus<br />

Power supply<br />

Cyl<strong>in</strong>der <strong>oil</strong><br />

Servo <strong>oil</strong><br />

Servo <strong>oil</strong> return<br />

to the open position, servo <strong>oil</strong> fl ows to<br />

the drive side of the central piston of the<br />

dosage pump <strong>in</strong> the lubricat<strong>in</strong>g module.<br />

As the central piston is actuated, it feeds<br />

<strong>cyl<strong>in</strong>der</strong> lubricat<strong>in</strong>g <strong>oil</strong> from the lubricat<strong>in</strong>g<br />

<strong>oil</strong> supply to the meter<strong>in</strong>g ducts, and then<br />

discharges it from the lubricators at high<br />

pressure. The <strong>cyl<strong>in</strong>der</strong> <strong>oil</strong> is accurately<br />

supplied at def<strong>in</strong>ed positions of the work<strong>in</strong>g<br />

piston whose position is constantly detected<br />

by the control system from the reference<br />

signal given by the crank angle sensor. At<br />

the end of the lubrication work cycle, the<br />

directional valve <strong>in</strong> the lubricat<strong>in</strong>g module<br />

directs the servo <strong>oil</strong> to the return-fl ow<br />

side of the central piston of the dosage<br />

pump, which then returns to its <strong>in</strong>itial<br />

position. The meter<strong>in</strong>g chamber is fi lled<br />

aga<strong>in</strong> with <strong>cyl<strong>in</strong>der</strong> lubricat<strong>in</strong>g <strong>oil</strong> to be<br />

ready for the next lubricat<strong>in</strong>g cycle.<br />

A separate servo <strong>oil</strong> supply unit is<br />

provided for RTA eng<strong>in</strong>es. It <strong>in</strong>cludes two<br />

gear pumps, one supply<strong>in</strong>g the lubricat<strong>in</strong>g<br />

module with servo <strong>oil</strong> taken from the<br />

ma<strong>in</strong> eng<strong>in</strong>e <strong>oil</strong> system, with the second<br />

pump as a standby. The <strong>oil</strong> supply unit<br />

also <strong>in</strong>cludes a pressure limit<strong>in</strong>g and safety<br />

valve, pressure gauge, pressure sensor, and