Cutting cylinder oil costs without a break in service - Wärtsilä

Cutting cylinder oil costs without a break in service - Wärtsilä

Cutting cylinder oil costs without a break in service - Wärtsilä

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Photo: Nordcapital<br />

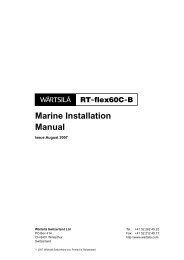

Pressure<br />

sensor<br />

Shut-off<br />

valve for<br />

lubricat<strong>in</strong>g <strong>oil</strong><br />

Cyl<strong>in</strong>der<br />

<strong>oil</strong> <strong>in</strong>let<br />

To system <strong>oil</strong><br />

dra<strong>in</strong> tank<br />

Relief valve<br />

for servo <strong>oil</strong><br />

Shut-off valve<br />

for servo <strong>oil</strong><br />

Fig. 3 – The RPLS lubricat<strong>in</strong>g module with lubricator connections and<br />

associated electronics for eight lubricators.<br />

WÄRTSILÄ TECHNICAL JOURNAL 02.2007<br />

Cyl<strong>in</strong>der <strong>oil</strong><br />

outlet to<br />

lubricators<br />

Vent<strong>in</strong>g plug for<br />

<strong>cyl<strong>in</strong>der</strong> <strong>oil</strong><br />

Vent<strong>in</strong>g plug<br />

for servo <strong>oil</strong><br />

4/2-way<br />

solenoid valve<br />

Diaphragm<br />

accumulator<br />

Fig. 4 – One of the n<strong>in</strong>e conta<strong>in</strong>er ships managed by E.R. Schiffahrt, which have<br />

been completely retrofitted with the Pulse Lubricat<strong>in</strong>g System. The ships are<br />

powered by <strong>Wärtsilä</strong> RTA96C low-speed diesel eng<strong>in</strong>es.<br />

shut-off valve. For RT-flex eng<strong>in</strong>es, servo<br />

<strong>oil</strong> is drawn from the eng<strong>in</strong>e servo <strong>oil</strong><br />

system through a pressure reduc<strong>in</strong>g valve<br />

by which the <strong>oil</strong> pressure is reduced from<br />

200 bar to 50 bar. The reduced pressure<br />

is monitored by pressure transmitters<br />

directly connected to the alarm system; the<br />

pipes are SOLAS compliant. The reduced<br />

pressure can be adjusted and its level is<br />

shown on an analogue pressure gauge.<br />

The lubricat<strong>in</strong>g module for each<br />

<strong>cyl<strong>in</strong>der</strong> consists of a dosage pump, a<br />

4/2-way solenoid valve, monitor<strong>in</strong>g<br />

electronics, pressure sensor, and diaphragm<br />

accumulator on a base plate. The timed<br />

lubricat<strong>in</strong>g module feeds a predefi ned<br />

metered quantity of <strong>cyl<strong>in</strong>der</strong> <strong>oil</strong> at high<br />

speed to the lubricators at the precise<br />

tim<strong>in</strong>g ascerta<strong>in</strong>ed by the eng<strong>in</strong>e control<br />

system. Part of the control <strong>oil</strong> fl ow from<br />

the servo <strong>oil</strong> l<strong>in</strong>e is routed to the 4/2-way<br />

solenoid valve. At the same time, the loaddependent<br />

<strong>cyl<strong>in</strong>der</strong> lubricat<strong>in</strong>g <strong>oil</strong> needs<br />

of the respective <strong>cyl<strong>in</strong>der</strong>s are ascerta<strong>in</strong>ed<br />

by the eng<strong>in</strong>e control system, which sends<br />

a correspond<strong>in</strong>g signal to the monitor<strong>in</strong>g<br />

electronics of the lubricat<strong>in</strong>g module. The<br />

ALM-20 (Advanced Lubricat<strong>in</strong>g Module)<br />

checks that the dosage pump is work<strong>in</strong>g<br />

correctly. The ALM-20 communicates<br />

with the master control unit through a<br />

redundant bus system, sends the signal to<br />

the 4/2-way solenoid valve, and processes<br />

the data from the pressure transmitter.<br />

The redesigned lubricator delivers the<br />

<strong>cyl<strong>in</strong>der</strong> <strong>oil</strong> radially as compact <strong>oil</strong> pulse<br />

feeds exactly <strong>in</strong>to the piston r<strong>in</strong>g package,<br />

from where it is equally distributed around<br />

the circumference of the <strong>cyl<strong>in</strong>der</strong> l<strong>in</strong>er.<br />

The lubricators (up to eight) are arranged<br />

around the l<strong>in</strong>er <strong>in</strong> one row to ensure an<br />

excellent distribution of the <strong>cyl<strong>in</strong>der</strong> <strong>oil</strong> on<br />

the <strong>cyl<strong>in</strong>der</strong> l<strong>in</strong>er. The vertical distribution<br />

is governed by the lubricat<strong>in</strong>g <strong>oil</strong> <strong>in</strong>jection<br />

tim<strong>in</strong>g as a function of the crank angle.<br />

A generously dimensioned 40micron<br />

<strong>cyl<strong>in</strong>der</strong> lubricat<strong>in</strong>g <strong>oil</strong> fi lter is<br />

arranged before the lubricat<strong>in</strong>g modules.<br />

It effectively removes any particles of<br />

dirt, thereby ensur<strong>in</strong>g reliable operation<br />

of the lubricat<strong>in</strong>g modules. A 12 litre<br />

buffer tank is provided with a scaled<br />

sight glass that enables <strong>cyl<strong>in</strong>der</strong> <strong>oil</strong><br />

consumption measurements of up to<br />

five litres. The buffer tank also allows<br />

the filter to be changed while the eng<strong>in</strong>e<br />

is runn<strong>in</strong>g. When the filter is dirty,<br />

the <strong>in</strong>tegrated sensor gives a signal on<br />

the excessive differential pressure. p<br />

<strong>in</strong>detail 53