You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Parts & Repair<br />

Manual<br />

! WARNING<br />

LINESEAL <strong>III</strong> ® 3”– 20”<br />

LINESEAL XP ® 3”– 4”<br />

LINESEAL XPII ® 3”– 20”<br />

BURIED SERVICE BUTTERFLY VALVES<br />

WITH BONDED SEAT<br />

500 West Eldorado Street<br />

Decatur, Illinois 62522<br />

www.muellercompany.com<br />

1. Read and follow instructions carefully. Proper training and periodic review regarding the use of this equipment is essential to prevent possible serious injury<br />

and/or property damage. The instructions contained herein were developed for using this equipment on fittings of <strong>Mueller</strong> manufacturer only, and may not be<br />

applicable for any other use.<br />

2. Do not exceed the pressure ratings of any components or equipment. Exceeding the rated pressure may result in serious injury and/or property damage.<br />

3. Safety goggles and other appropriate protective gear should be used. Failure to do so could result in serious injury.<br />

4. Pressure test, check for and repair leaks in all fittings and components each time one is installed or any joint or connection is broken. Failure to find and<br />

repair a leak from any source in the fittings, by-pass lines or equipment could result in an explosion and subsequent serious injury and/or property damage.<br />

5. MUELLER ® Drilling Machines and Equipment have been carefully designed and engineered to work together as a unit. The use of equipment manufactured<br />

by someone other than MUELLER <strong>Co</strong>. may cause excessive wear or a malfunction of the MUELLER machines.<br />

All warranties, expressed or implied, for MUELLER Drilling Machines are rendered null and void if the machines are used with shell cutters or<br />

equipment manufactured by someone other than MUELLER <strong>Co</strong>.<br />

Form 11987 - Rev. 10/09 - 1M-1 <strong>Co</strong>pyright 1998 - MUELLER <strong>Co</strong>. Printed in U.S.A.

2<br />

INDEX<br />

LINESEAL <strong>III</strong> ® 3” –20”<br />

LINESEAL XP ® 3” –4”<br />

LINESEAL XPII ® 3” –20”<br />

BURIED SERVICE BUTTERFLY VALVES<br />

WITH BONDED SEAT<br />

GENERAL INFORMATION<br />

Page<br />

Recommendations for Extended Storage ...............3<br />

Troubleshooting Guide .........................................4<br />

Parts & Service Ordering Information<br />

Maintenance Instructions.......................................5<br />

BUTTERFLY VALVES<br />

3” – 20” Rubber Seated<br />

Bonded Seat and V-Type Packing ..........................6<br />

Replacing V-Type Packing .....................................7<br />

LINESEAL <strong>III</strong> Butterfly Valve Parts ............................8<br />

LINESEAL XP & XPII Butterfly Valve Parts ................9<br />

MANUAL VALVE ACTUATORS<br />

MDT-2S Buried Service Actuator Parts...................10<br />

MDT-3S, 4S Buried Service Actuator Parts .............11<br />

www.muellercompany.com

<strong>Mueller</strong> ®<br />

Storage Procedure<br />

LINESEAL <strong>III</strong> ®<br />

, XP ®<br />

, and XPII ®<br />

RECOMMENDATIONS FOR EXTENDED STORAGE<br />

(6 Months or Longer):<br />

Your <strong>Mueller</strong> ® Rubber Seated Valve has been designed<br />

to provide many years of trouble-free service. A<br />

reasonable amount of care should be exercised in<br />

storing the valve to assure trouble-free service.<br />

Following are precautions which should be followed<br />

regarding storage.<br />

OUTDOOR STORAGE:<br />

1. All exposed rubber components shall be brush<br />

coated with EP2 lithium grease for potable water<br />

applications, to a thickness of 1-2 mils.<br />

2. If valves will be stored in a high humidity or<br />

corrosive environment, where bare iron or steel<br />

flanges may rust, then flanges should be coated<br />

with a rust preventative suitable for outdoor<br />

exposure such as Rust-Veto by E.F. Houghton.<br />

Clean surfaces and apply one uniform coat with a<br />

dry rag or brush.<br />

3. Valve flanges should be covered with full circle<br />

panels of 1 /4” exterior grade plywood or tempered<br />

hardboard. These covers shall be fastened to the<br />

valve flanges.<br />

4. Valve and operator assembly should be covered<br />

with black plastic sheeting having a minimum<br />

thickness of 4 mils.<br />

5. Electric equipment must be stored off the ground<br />

above possible water or snow level, in a position<br />

similar to the intended mounting position, and be<br />

covered with plastic sheeting having a minimum<br />

thickness of 4 mils.<br />

6. If the average mean temperatures fall below 60°F<br />

and/or the relative humidity exceeds 50%, all<br />

electrical control components and motor control<br />

compartments with internal heaters must have the<br />

heaters wired and operating. The wire entrance<br />

points must be sealed against moisture. Desiccant<br />

must be placed in those units that do not have<br />

internal heaters.<br />

BUTTERFLY VALVES WITH BONDED SEAT<br />

7. All conduit openings shall be sealed with metal<br />

threads pipe plugs to keep equipment free from<br />

moisture and to protect threads of conduit<br />

openings. All other openings normally sealed by<br />

the mating mounting surfaces must be covered<br />

and sealed.<br />

INDOOR STORAGE:<br />

Indoor storage will require Steps 1, 6, and 7 listed<br />

under outdoor storage.<br />

3

4<br />

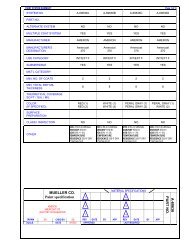

<strong>Mueller</strong> ®<br />

Troubleshooting Guide<br />

LINESEAL <strong>III</strong> ®<br />

, XP ®<br />

, and XPII ®<br />

PROBLEM<br />

Leakage between valve and<br />

actuator<br />

Bottom trunnion leaks<br />

Valve leaks when closed<br />

Chain wheel jams<br />

Valve hard to operate<br />

TROUBLESHOOTING GUIDE<br />

Packing leak<br />

CAUSES<br />

Packing or gasket leak<br />

Disc not fully closed or past<br />

fully closed<br />

Disc edge wear or damage<br />

Rubber seat wear or damage<br />

Poorly fitting chain<br />

Foreign material in valve<br />

<strong>Co</strong>rroded actuator parts<br />

Loose actuator<br />

BUTTERFLY VALVES WITH BONDED SEAT<br />

REMEDIES<br />

First, cycle the valve several<br />

times. This should adjust the<br />

packing. If this fails, clean<br />

packing bore and replace<br />

packing.<br />

First, cycle the valve several<br />

times. This should adjust the<br />

packing. If this fails, replace<br />

bottom shaft packing.<br />

Adjust actuator closed<br />

position stop.<br />

Disc must be returned to<br />

the factory for repair.<br />

Valve must be returned to<br />

the factory for repair.<br />

Replace with correct chain.<br />

Remove obstructions.<br />

Clean and grease actuator.<br />

Apply loctite or Omni-fit<br />

locking compound and<br />

tighten bolts.

<strong>Mueller</strong> ®<br />

LINESEAL <strong>III</strong> ®<br />

, XP ®<br />

, and XPII ®<br />

Maintenance Instructions and Parts & Service<br />

ANNUAL MAINTENANCE INSTRUCTIONS<br />

BONDED SEAT BUTTERFLY VALVES FOR<br />

STANDARD SERVICE:<br />

1. Cycle valve to verify operation and no<br />

interference in line.<br />

2. Close valve and check for leakage. If leakage is<br />

detected, check operator stops to verify that disc is<br />

fully closed. If leakage persists, remove valve to<br />

inspect seat. A damaged seat requires valve to be<br />

returned to the factory for repair.<br />

3. Check flange connections for leakage. Tighten<br />

bolts accordingly.<br />

4. Check top trunnion area for shaft leakage. If<br />

leakage is detected, replace valve packing.<br />

Note: 10” and larger valves have top and<br />

bottom packing.<br />

Note: Lubrication is not required.<br />

BONDED SEAT BUTTERFLY VALVES FOR BURIED<br />

SERVICE:<br />

1. Cycle valve to verify operation and no interference<br />

in line. Listen for leakage in closed position.<br />

NOTE: Lubrication is not required.<br />

MDT ACTUATOR FOR STANDARD SERVICE:<br />

1. Verify that actuator is still bolted securely to the<br />

valve trunnion or bonnet. If movement is<br />

detected, remove actuator cover and tighten<br />

mounting bolts.<br />

2. If operation is difficult or gear box is noisy, remove<br />

actuator cover to inspect link and lever mechanism<br />

and lubricant. Clean actuator and replace grease<br />

if it has separated or worn away.<br />

3. Check pointer on top of actuator to see if it<br />

properly indicated valve position.<br />

MDT ACTUATOR FOR BURIED SERVICE:<br />

No scheduled maintenance required.<br />

BUTTERFLY VALVES WITH BONDED SEAT<br />

<strong>Mueller</strong> products are designed for long life. No<br />

spare parts are recommended or required for<br />

normal operations; however, should a part ever<br />

be found worn or broken, you can order<br />

replacement parts.<br />

HOW TO ORDER PARTS:<br />

To obtain further information or to order parts for<br />

the 24" - 48" MUELLER ® LINESEAL <strong>III</strong> ® or 24" - 48"<br />

MUELLER ® LINESEAL XPII ® Butterfly Valve, contact<br />

a local <strong>Mueller</strong> representative or customer service<br />

for butterfly valves:<br />

Henry Pratt <strong>Co</strong>mpany<br />

401 S. Highland Avenue<br />

Aurora, IL 60506-5563<br />

Attention: Parts Manager<br />

Phone: (630) 844-4000 extension 4029<br />

Fax: (630) 844-4191<br />

E-mail: bfvparts@muellervalves.com<br />

TO ORDER SERVICE:<br />

Henry Pratt <strong>Co</strong>mpany<br />

401 S. Highland Avenue<br />

Aurora, IL 60506-5563<br />

Attention: Field Service Manager<br />

Phone: (630) 844-4000 extension 4163<br />

Fax: (630) 844-4160<br />

E-mail: bfvservice@muellervalves.com<br />

For the most prompt assistance, please be ready<br />

to provide the following information before<br />

speaking with a customer service representative:<br />

1. Valve size and type<br />

2. Serial number<br />

3. Order number<br />

This information can be found on the valve<br />

nameplate or on the submittal drawings.<br />

5

6<br />

<strong>Mueller</strong> ®<br />

LINESEAL <strong>III</strong> ®<br />

, XP ®<br />

, and XPII ®<br />

Bonded Seat and V-Type Packing<br />

3”– 20” RUBBER SEAT BUTTERFLY VALVE<br />

BONDED SEAT DESIGN**<br />

Your <strong>Mueller</strong> Rubber Seat Butterfly Valve has been<br />

designed to provide many years of useful service and,<br />

while rugged in construction, a reasonable amount<br />

of care should be exercised in handling and<br />

installation to ensure the realization of its normally<br />

long service life.<br />

This valve is supplied with Nylon bearings which<br />

should never be greased or oiled and which require<br />

no further attention.<br />

The rubber seat is firmly bonded to the valve body in<br />

the factory and cannot be replaced in the field. In the<br />

event a new rubber seat is required, the valve body<br />

must be returned to the factory. (<strong>Co</strong>ntact Customer<br />

Service for authorization and instructions.)<br />

BUTTERFLY VALVES WITH BONDED SEAT<br />

V-TYPE VALVE SHAFT PACKING<br />

Your <strong>Mueller</strong> Rubber Seat Butterfly Valve is equipped<br />

with a valve shaft packing gland located at the point<br />

where the shaft extends through the valve body.<br />

This packing gland is non-adjustable. It consists of a<br />

set of V-type packing rings with the top and bottom<br />

adapter ring held in place by the operator furnished<br />

on the valve.<br />

This wear compensating V-type packing has a long<br />

service life, but should replacement be required, the<br />

table below will assist you. It is important to obtain<br />

replacement packing that conforms to the nominal<br />

depth of the packing set as listed below. A deviation<br />

will result in pressure that might prevent the packing<br />

from functioning properly. Refer to the following for<br />

the replacement procedure.<br />

Nominal<br />

Packing Packing Depth of<br />

Valve Size Shaft Size Size Location Packing Set * No. of Rings<br />

3”<br />

4”<br />

5”<br />

1 /2”<br />

5 /8”<br />

3 /4”<br />

6” 1”<br />

8” 1 1 /8”<br />

10” 1 3 /8”<br />

12” 1 1 /2”<br />

14” 1 3 /4”<br />

16” 2”<br />

18” 2 1 /4”<br />

20” 2 1 /2”<br />

*In addition, top and bottom adapter rings are required.<br />

**Linseal XP Valves 3” and 4” only.<br />

1 /4” Top Only<br />

1 /4” Top Only<br />

1 /4” Top Only<br />

1 /4” Top Only<br />

1 /4” Top Only<br />

1 /4” Top and Bottom<br />

1 /4” Top and Bottom<br />

1 /4” Top and Bottom<br />

1 /4” Top and Bottom<br />

1 /4” Top and Bottom<br />

1 /4” Top and Bottom<br />

41 /64” 3<br />

41 /64” 3<br />

41 /64” 3<br />

41 /64” 3<br />

41 /64” 3<br />

41 /64” 3<br />

41 /64” 3<br />

41 /64” 3<br />

41 /64” 3<br />

41 /64” 3<br />

41 /64” 3<br />

Material-<br />

Top and Bottom Adapter: <strong>Co</strong>tton Duck impregnated with Neoprene and Vulcanized or Phenolic. V-Rings:<br />

Homogenous Neoprene Ring

<strong>Mueller</strong> ®<br />

Replacing V-Type Packing<br />

REPLACING V-TYPE PACKING RUBBER SEAT<br />

BUTTERFLY VALVES<br />

Before commencing any work on the valve, with the<br />

disc open, close the nearest upstream and<br />

downstream valves (in that order), then be sure the<br />

valve disc is in the CLOSED POSITION. This removes<br />

line pressure from the disc and positions it so that it is<br />

unlikely to move when the operator is removed.<br />

1. Remove old packing. A bent steel hook rod or a<br />

3” drywall screw will assist in this operation.<br />

2. Apply EP2 lithium grease to the packing during<br />

the assembly process which will aid in installation<br />

and sealing of packing. Exercise extreme care in<br />

placing ring in packing bore so as not to damage<br />

the ring. The two sealing lips on the V-packing<br />

should be pointed toward the valve disc (see<br />

sketch below).<br />

3. Reassemble operator to valve.<br />

LINESEAL <strong>III</strong> ®<br />

, XP ®<br />

, and XPII ®<br />

BUTTERFLY VALVES WITH BONDED SEAT<br />

VALVE SHAFT<br />

TOP ADAPTER<br />

TOP TRUNNION<br />

PACKING RINGS<br />

BOTTOM ADAPTER<br />

7

8<br />

<strong>Mueller</strong> ®<br />

LINESEAL <strong>III</strong> ®<br />

, XP ®<br />

, and XPII ®<br />

Replacement Parts for Lineseal <strong>III</strong><br />

Item No.<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12**<br />

Description<br />

Body<br />

Disc*<br />

Shaft<br />

Squeeze Pin<br />

Bearing<br />

Packing<br />

Key<br />

<strong>Co</strong>ver (10”-20” Valves)<br />

Lockwasher<br />

Cap screw<br />

Seat<br />

Exp. Plug (3”-8” Valves)<br />

10” THRU 20”<br />

LINESEAL <strong>III</strong><br />

VALVES<br />

Parts - for <strong>Mueller</strong> Lineseal <strong>III</strong> Butterfly Valves, 3" - 20" Sizes,<br />

150 PSI working pressure<br />

*3”-6” discs are cast stainless steel ASTM A-351 Grade CF8M.<br />

**This plug is for 3”-8” sizes only<br />

BUTTERFLY VALVES WITH BONDED SEAT<br />

3” AND 8”<br />

LINESEAL <strong>III</strong> VALVES<br />

Material<br />

Cast Iron ASTM A-126 Class B<br />

Cast Iron ASTM A-126 Class B with 316 Edge<br />

Stainless Steel 18-8 Type 304 ASTM A-276<br />

Stainless Steel 18-8 Type 304 ASTM A-276<br />

Nylatron GS<br />

Chevron V-Type<br />

Carbon Steel C-1045<br />

Cast Iron ASTM A-48 Class 40<br />

Stainless Steel Type 304<br />

Stainless Steel Type 304<br />

Buna N<br />

Stainless Steel 18-8 Type 304 ASTM A-276

<strong>Mueller</strong> ®<br />

LINESEAL <strong>III</strong> ®<br />

, XP ®<br />

, and XPII ®<br />

Replacement Parts for Lineseal XP and XPII<br />

Item No.<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

13<br />

Description<br />

Body<br />

Disc*<br />

Shaft<br />

Squeeze Pin<br />

Bearing*<br />

Packing<br />

Key<br />

<strong>Co</strong>ver (10”-20” Valves)<br />

Lockwasher<br />

Cap screw<br />

Seat<br />

Plug (6” and 8” Valves)<br />

10” thru 20”<br />

LINESEAL XPII<br />

3” and 4” XP<br />

VALVES<br />

Parts - for <strong>Mueller</strong> Lineseal XP 3” and 4” sizes and XPII<br />

Butterfly Valves, 3" - 20" Sizes, 250 PSI working pressure<br />

*3”-6” discs are cast stainless steel ASTM A-351 Grade CF8M.<br />

BUTTERFLY VALVES WITH BONDED SEAT<br />

3” thru 8”<br />

LINESEAL XPII VALVES<br />

Material<br />

Ductile Iron ASTM A-536 (65-45-12)<br />

Ductile Iron ASTM A-536 (65-45-12)<br />

Stainless Steel ASTM A-564 Type 630 COND. H-1150<br />

Stainless Steel ASTM A-564 Type 630 COND. H-1150<br />

Teflon with Stainless Steel Backing<br />

Chevron V-Type<br />

Carbon Steel C-1045<br />

Cast Iron ASTM A-48 Class 40<br />

Stainless Steel Type 304<br />

Stainless Steel Type 304<br />

Buna N<br />

Cast Iron Bearings are Nylatron GS<br />

9

10<br />

<strong>Mueller</strong> ®<br />

LINESEAL <strong>III</strong> ®<br />

, XP ®<br />

, and XPII ®<br />

Buried Service Actuator – MDT-2S Parts<br />

Item No.<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

19<br />

20<br />

21<br />

22<br />

A<br />

A<br />

Description<br />

Housing<br />

Expansion Plug<br />

Insert<br />

O-Ring<br />

O-Ring<br />

Cap Screw<br />

Shim<br />

Bearing<br />

Slider Nut<br />

Slider Tube<br />

Slider Block<br />

Lever<br />

Shaft<br />

Groove Pin<br />

<strong>Co</strong>ver<br />

Cap Screw<br />

Gasket<br />

O-Ring<br />

Spring Pin<br />

Nut<br />

12<br />

6<br />

16<br />

14<br />

9<br />

15<br />

10<br />

8<br />

7<br />

13<br />

19<br />

Material<br />

Cast Iron ASTM A-126 Class B<br />

Stainless Steel Type 304<br />

Noryl Grade GFN3-780<br />

Buna N<br />

Buna N<br />

Alloy Steel<br />

Hardened Steel<br />

Sintered Iron<br />

Ductile Iron ASTM A-536 Grade 80-60-03<br />

Carbon Steel<br />

Suitered Iron ASTM B-439 GR3<br />

Ductile Iron ASTM A-536 Grade (65-45-12)<br />

Carbon Steel (Stress Proof)<br />

Alloy Steel<br />

Cast Iron ASTM A-126 Class B<br />

Stainless Steel Type 304<br />

Blended Fiber, Cured Nitrite Binder<br />

Buna N<br />

Stainless Steel Type 420<br />

Cast Iron ASTM A-126 Class B<br />

8<br />

BUTTERFLY VALVES WITH BONDED SEAT<br />

20<br />

21<br />

4<br />

3<br />

5<br />

1<br />

11<br />

14<br />

7<br />

2<br />

22

18<br />

10<br />

23<br />

<strong>Mueller</strong> ®<br />

LINESEAL <strong>III</strong> ®<br />

, XP ®<br />

, and XPII ®<br />

Buried Service Actuator – MDT-3S & MDT-4S Parts<br />

A<br />

A<br />

Item No.<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

26<br />

15<br />

Description<br />

Housing<br />

Expansion Plug<br />

Insert<br />

O-Ring<br />

O-Ring<br />

Cap Screw<br />

Lever<br />

Bearing<br />

Link<br />

Set Screw<br />

Retaining Ring<br />

Slider Tube<br />

Eccentric Bearing<br />

<strong>Co</strong>ver<br />

Cap Screw<br />

Shim<br />

Thrust Washer<br />

Thrust <strong>Co</strong>llar<br />

Drive Pin<br />

Slider Nut<br />

Bearing<br />

Bearing<br />

Shaft<br />

Gasket<br />

O-Ring<br />

Nut<br />

Pin<br />

Flange Bearing<br />

27<br />

7<br />

6<br />

MDT-3S<br />

ONLY<br />

25 26<br />

16<br />

17<br />

13<br />

12<br />

20<br />

8<br />

11<br />

9<br />

28<br />

14<br />

15<br />

24<br />

BUTTERFLY VALVES WITH BONDED SEAT<br />

SECTION A-A<br />

27 17 22<br />

Material<br />

Cast Iron ASTM A-126 Class B<br />

Stainless Steel Type 304<br />

Noryl Grade GFN3-780<br />

Buna N<br />

Buna N<br />

Alloy Steel (Zinc Plated)<br />

Ductile Iron ASTM A-536 Grade (65-45-12)<br />

Sintered Bronze<br />

Carbon Steel<br />

Alloy Steel<br />

Carbon Steel<br />

Carbon Steel<br />

Sintered Iron<br />

Cast Iron ASTM A-126 Class B<br />

Stainless Steel Type 304<br />

Carbon Steel<br />

Sintered Bronze (MTD-4S)/Iron (MDT-3S)<br />

Carbon Steel<br />

Alloy Steel<br />

Ductile Iron ASTM A-536 (65-45-12)<br />

Nylon (MDT-4S only)<br />

Sintered Bronze<br />

Carbon Steel<br />

Blended Fiber, Cured Nitrite Binder<br />

Buna N<br />

Cast Iron ASTM A-48 Class 40 (MTD-4S)/ASTM A-126 Class B (MDT-3S)<br />

Stainless Steel Type 304<br />

Sintered Iron<br />

2<br />

19<br />

13<br />

12<br />

8<br />

11<br />

9<br />

4<br />

3<br />

5<br />

1<br />

19<br />

21<br />

MDT-3S<br />

ONLY<br />

MDT-4S<br />

ONLY<br />

11