Vibration Analysis of Tread Brake Block in the ... - university press

Vibration Analysis of Tread Brake Block in the ... - university press

Vibration Analysis of Tread Brake Block in the ... - university press

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INTERNATIONAL JOURNAL OF SYSTEMS APPLICATIONS, ENGINEERING & DEVELOPMENT<br />

Issue 1, Volume 5, 2011<br />

from someth<strong>in</strong>g abnormal vibration <strong>in</strong> <strong>the</strong> rang<strong>in</strong>g <strong>of</strong> <strong>the</strong> vehicle<br />

speed at 140 [km/h] (i.e. about 808 [rpm]) and 70 [km/h] (i.e.<br />

about 404 [rpm]) consider<strong>in</strong>g <strong>the</strong> 920 [mm] wheel diameter.<br />

Therefore, we exam<strong>in</strong>ed <strong>the</strong> frequency analysis on <strong>the</strong> axle and<br />

<strong>the</strong> brake block us<strong>in</strong>g <strong>the</strong> 3-axis accelerometers and<br />

displacement measure sensor.<br />

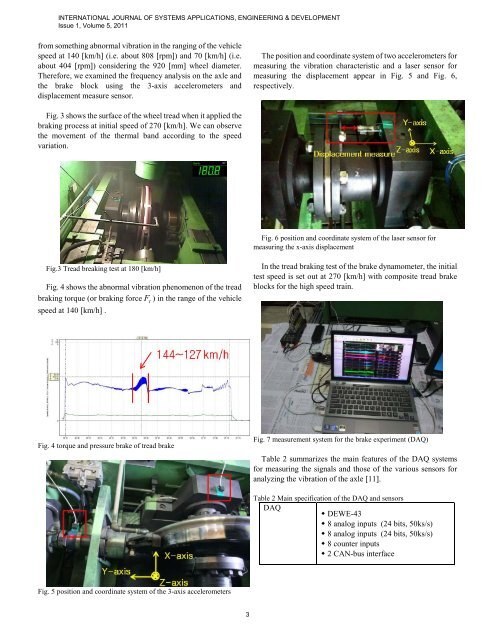

Fig. 3 shows <strong>the</strong> surface <strong>of</strong> <strong>the</strong> wheel tread when it applied <strong>the</strong><br />

brak<strong>in</strong>g process at <strong>in</strong>itial speed <strong>of</strong> 270 [km/h]. We can observe<br />

<strong>the</strong> movement <strong>of</strong> <strong>the</strong> <strong>the</strong>rmal band accord<strong>in</strong>g to <strong>the</strong> speed<br />

variation.<br />

Fig.3 <strong>Tread</strong> break<strong>in</strong>g test at 180 [km/h]<br />

Fig. 4 shows <strong>the</strong> abnormal vibration phenomenon <strong>of</strong> <strong>the</strong> tread<br />

brak<strong>in</strong>g torque (or brak<strong>in</strong>g force F t ) <strong>in</strong> <strong>the</strong> range <strong>of</strong> <strong>the</strong> vehicle<br />

speed at 140 [km/h] .<br />

Fig. 4 torque and <strong>press</strong>ure brake <strong>of</strong> tread brake<br />

Fig. 5 position and coord<strong>in</strong>ate system <strong>of</strong> <strong>the</strong> 3-axis accelerometers<br />

3<br />

The position and coord<strong>in</strong>ate system <strong>of</strong> two accelerometers for<br />

measur<strong>in</strong>g <strong>the</strong> vibration characteristic and a laser sensor for<br />

measur<strong>in</strong>g <strong>the</strong> displacement appear <strong>in</strong> Fig. 5 and Fig. 6,<br />

respectively.<br />

Fig. 6 position and coord<strong>in</strong>ate system <strong>of</strong> <strong>the</strong> laser sensor for<br />

measur<strong>in</strong>g <strong>the</strong> x-axis displacement<br />

In <strong>the</strong> tread brak<strong>in</strong>g test <strong>of</strong> <strong>the</strong> brake dynamometer, <strong>the</strong> <strong>in</strong>itial<br />

test speed is set out at 270 [km/h] with composite tread brake<br />

blocks for <strong>the</strong> high speed tra<strong>in</strong>.<br />

Fig. 7 measurement system for <strong>the</strong> brake experiment (DAQ)<br />

Table 2 summarizes <strong>the</strong> ma<strong>in</strong> features <strong>of</strong> <strong>the</strong> DAQ systems<br />

for measur<strong>in</strong>g <strong>the</strong> signals and those <strong>of</strong> <strong>the</strong> various sensors for<br />

analyz<strong>in</strong>g <strong>the</strong> vibration <strong>of</strong> <strong>the</strong> axle [11].<br />

Table 2 Ma<strong>in</strong> specification <strong>of</strong> <strong>the</strong> DAQ and sensors<br />

DAQ<br />

DEWE-43<br />

8 analog <strong>in</strong>puts (24 bits, 50ks/s)<br />

8 analog <strong>in</strong>puts (24 bits, 50ks/s)<br />

8 counter <strong>in</strong>puts<br />

2 CAN-bus <strong>in</strong>terface