Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Generat<strong>in</strong>g Concepts<br />

for the Whole Pad<br />

When both fasten<strong>in</strong>g method and materials were<br />

determ<strong>in</strong>ed, it was f<strong>in</strong>ally time to start generat<strong>in</strong>g<br />

concepts for the whole sanitary pad. This was done<br />

through bra<strong>in</strong>storm<strong>in</strong>g. Aspects such as how to fasten<br />

the different layers to each other, how to m<strong>in</strong>imise<br />

leakage and how to use the materials efficiently<br />

were considered. Concern<strong>in</strong>g the measurements of<br />

the sanitary pad, we decided to use measurements<br />

<strong>in</strong>spired by conventional pads as these measurements<br />

are known to be suitable.<br />

In the end, we had three methods for fasten<strong>in</strong>g the<br />

layers to each other. The first one would be to melt<br />

the beeswax on the edges of the pad and this could<br />

be accompanied by some k<strong>in</strong>d of perforation. The<br />

second method would be to produce one fibre paper,<br />

put an absorbent-shaped piece of plastic onto the wet<br />

paper and then press a second layer of fibre paper<br />

onto it. When the double paper has dried, it would<br />

be possible to remove the plastic and a space for the<br />

absorbent is created. This method will further on be<br />

referred to as the pitta concept. The third method<br />

would be to simply roll the fibre paper around the<br />

absorbent, mak<strong>in</strong>g a double layer on the bottom of<br />

the pad. This solution limits the form possibilities but<br />

decreases the risk of leakage through the barrier layer.<br />

The second and the third method require additional<br />

fasten<strong>in</strong>g of the layers <strong>in</strong> the front and the rear end of<br />

the pad. This would be possible to accomplish with<br />

the first method of us<strong>in</strong>g beeswax.<br />

In addition, we had three concepts for prevent<strong>in</strong>g<br />

leakage. The first one would be some type of fold<strong>in</strong>g<br />

around the edges of the pad. These upward fac<strong>in</strong>g<br />

folds would act as walls and stop flow from slipp<strong>in</strong>g<br />

of the pad. The walls could be shaped <strong>in</strong> various ways<br />

and be placed on only the long sides, <strong>in</strong> front and on<br />

the long sides or on all four sides. The second and<br />

third concepts were the same as conventional pads,<br />

with or without w<strong>in</strong>gs.<br />

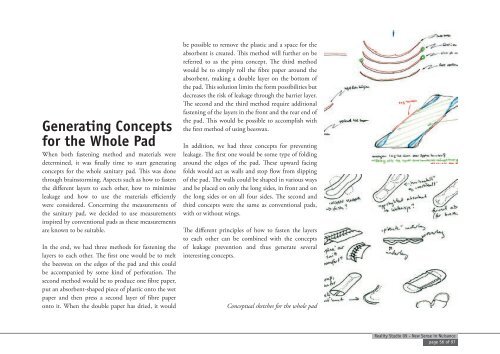

The different pr<strong>in</strong>ciples of how to fasten the layers<br />

to each other can be comb<strong>in</strong>ed with the concepts<br />

of leakage prevention and thus generate several<br />

<strong>in</strong>terest<strong>in</strong>g concepts.<br />

Conceptual sketches for the whole pad<br />

Reality Studio 09 - <strong>New</strong> <strong>Sense</strong> <strong>in</strong> <strong>Nuisance</strong><br />

page 56 of 97