Breagh Development - RWE.com

Breagh Development - RWE.com

Breagh Development - RWE.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Breagh</strong> Environmental Statement<br />

Section 2 – Proposed <strong>Development</strong><br />

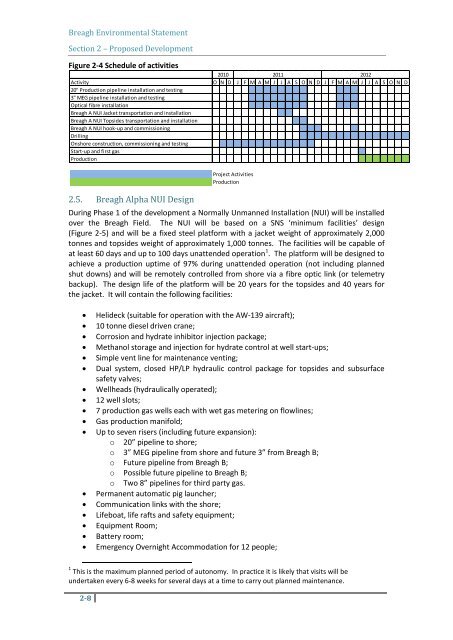

Figure 2-4 Schedule of activities<br />

2010 2011<br />

2012<br />

Activity<br />

20" Production pipeline installation and testing<br />

3" MEG pipeline installation and testing<br />

Optical fibre installation<br />

<strong>Breagh</strong> A NUI Jacket transportation and installation<br />

<strong>Breagh</strong> A NUI Topsides transportation and installation<br />

<strong>Breagh</strong> A NUI hook-up and <strong>com</strong>missioning<br />

Drilling<br />

Onshore construction, <strong>com</strong>missioning and testing<br />

Start-up and first gas<br />

Production<br />

O N D J F M A M J J A S O N D J F M A M J J A S O N D<br />

2.5. <strong>Breagh</strong> Alpha NUI Design<br />

During Phase 1 of the development a Normally Unmanned Installation (NUI) will be installed<br />

over the <strong>Breagh</strong> Field. The NUI will be based on a SNS ‘minimum facilities’ design<br />

(Figure 2-5) and will be a fixed steel platform with a jacket weight of approximately 2,000<br />

tonnes and topsides weight of approximately 1,000 tonnes. The facilities will be capable of<br />

at least 60 days and up to 100 days unattended operation 1<br />

. The platform will be designed to<br />

achieve a production uptime of 97% during unattended operation (not including planned<br />

shut downs) and will be remotely controlled from shore via a fibre optic link (or telemetry<br />

backup). The design life of the platform will be 20 years for the topsides and 40 years for<br />

the jacket. It will contain the following facilities:<br />

• Helideck (suitable for operation with the AW-139 aircraft);<br />

• 10 tonne diesel driven crane;<br />

• Corrosion and hydrate inhibitor injection package;<br />

• Methanol storage and injection for hydrate control at well start-ups;<br />

• Simple vent line for maintenance venting;<br />

• Dual system, closed HP/LP hydraulic control package for topsides and subsurface<br />

safety valves;<br />

• Wellheads (hydraulically operated);<br />

• 12 well slots;<br />

• 7 production gas wells each with wet gas metering on flowlines;<br />

• Gas production manifold;<br />

• Up to seven risers (including future expansion):<br />

o 20” pipeline to shore;<br />

o 3” MEG pipeline from shore and future 3” from <strong>Breagh</strong> B;<br />

o Future pipeline from <strong>Breagh</strong> B;<br />

o Possible future pipeline to <strong>Breagh</strong> B;<br />

o Two 8” pipelines for third party gas.<br />

• Permanent automatic pig launcher;<br />

• Communication links with the shore;<br />

• Lifeboat, life rafts and safety equipment;<br />

• Equipment Room;<br />

• Battery room;<br />

• Emergency Overnight Ac<strong>com</strong>modation for 12 people;<br />

1 This is the maximum planned period of autonomy. In practice it is likely that visits will be<br />

undertaken every 6-8 weeks for several days at a time to carry out planned maintenance.<br />

2-8<br />

Project Activities<br />

Production