Breagh Development - RWE.com

Breagh Development - RWE.com

Breagh Development - RWE.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Breagh</strong> <strong>Development</strong><br />

Phase I<br />

Environmental Statement<br />

June 2010

Standard Information Sheet<br />

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

Project name Environmental Statement for the <strong>Breagh</strong> <strong>Development</strong><br />

<strong>Development</strong> Location Block 42/13<br />

Licence No. P1230<br />

Project reference number D/4037/2008<br />

Type of project Field development<br />

Undertaker <strong>RWE</strong> Dea UK SNS Ltd.<br />

4th Floor<br />

90 High Holborn<br />

London<br />

WC1V 6LJ<br />

Licensees/owners <strong>RWE</strong> Dea UK SNS Ltd. (70%)<br />

Sterling Resources Limited (30%)<br />

Short Description The <strong>Breagh</strong> field is a gas field located in UKCS block 42/13 of the<br />

Southern North Sea (SNS). It lies 50km to the north east of the UK<br />

coast and 200km to the west of the median line between the UK<br />

and Dutch sectors. RDUK intends to develop the <strong>Breagh</strong> field by<br />

installing one Normally Unmanned Installation (NUI) over the<br />

<strong>Breagh</strong> Field, drilling 7 wells and laying c. 100km of pipeline<br />

between the <strong>Breagh</strong> Field and Teesside to transport hydrocarbons<br />

to the UK. The <strong>Breagh</strong> NUI will be based on the standard SNS<br />

design. <strong>Breagh</strong> gas will be metered on the <strong>Breagh</strong> NUI before being<br />

exported to the Teesside Gas Processing Plant for processing.<br />

Key dates NUI installation: Q3 & Q4 2011<br />

Pipeline installation: Q1 – Q3 2011 and Q2 2012<br />

First gas: Q2 2012<br />

Significant environmental None identified<br />

effects identified<br />

Statement Prepared by Genesis Oil and Gas Consultants Limited<br />

6 Albyn Place<br />

Aberdeen<br />

AB10 1YH<br />

i

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

ii<br />

[This Page is Intentionally Blank]

Non Technical Summary<br />

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

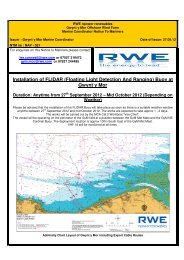

The undeveloped <strong>Breagh</strong> gas field is located in block 42/13, to the North of the UK Southern<br />

North Sea (Figure 1). It lies 50km to the north east of the UK coast and 200km to the west of<br />

the median line between the UK and Dutch sectors in approximately 61m of water.<br />

The Phase I development of the <strong>Breagh</strong> Field is expected to result in the recovery of 15.4<br />

BNm 3 of gas. The field development will start at the beginning of 2011 with a production<br />

start planned for Q2 2012. The Phase I project will yield an average yearly gas production<br />

stream of approximately 530 NMm 3 /year for the period of production from 2012-2040<br />

including onshore <strong>com</strong>pression start up in 2016. <strong>Development</strong> of the <strong>Breagh</strong> field will entail<br />

the construction of a production hub through which gas from the surrounding fields and<br />

prospects is likely to be exported The Phase 1 development will consist of:<br />

• Normally Unmanned Installation (NUI) at West <strong>Breagh</strong><br />

• Seven wells drilled<br />

• 100km 20” pipeline back to a beach crossing at Coatham Sands<br />

• 9km of onshore pipeline to, and modifications of, the Teesside Gas Processing Plant<br />

(TGPP) before delivery of gas into the National Transmission System (NTS)<br />

This Environmental Statement (ES) assesses all offshore surface and sub sea structures, the<br />

drilling of the wells and the pipeline from Mean Low Water Springs (MLWS) to the offshore<br />

installation.<br />

Figure 1: <strong>Breagh</strong> Field Location and Proposed Pipeline Route<br />

iii

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

Scope<br />

The scope of the Environmental Impact Assessment (EIA) and this resultant ES includes all<br />

offshore activities associated with the development of the <strong>Breagh</strong> field including drilling<br />

activity. The proposed scope of the development is the <strong>com</strong>pletion of the <strong>Breagh</strong> wells, the<br />

installation of the <strong>Breagh</strong> A NUI, installation of approximately 100 km of 20” production<br />

pipeline and 100 km of 3” MEG pipeline and Fibre Optic cable between the <strong>Breagh</strong> field and<br />

MLWS at Teesside, testing and <strong>com</strong>missioning of the facilities and production of gas and<br />

condensate. A separate environmental statement has been submitted for onshore planning<br />

application (Figure 2, below).<br />

Figure 2: Environmental Statement Demarcation<br />

Summary of Onshore Environmental Statement<br />

The EIA conducted for the onshore ES concludes:<br />

• The majority of the chosen pipeline route will be situated within the ‘<strong>Development</strong><br />

Limits’, coincidental to established industrial areas, therefore will minimise<br />

environmental impact;<br />

• The proposed development is feasible with little or no adverse effects on land and<br />

water quality, both during construction and operation;<br />

• A range of mitigation measures is proposed to minimise dust generation and<br />

emissions to air from construction traffic, and the adoption of these mitigation<br />

measures will ensure that there are no significant impacts as a result of emissions<br />

during construction.<br />

• No effects on features of cultural or archaeological heritage are expected during<br />

construction of the pipeline or works<br />

iv

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

• No significant impacts on protected mammals or fauna are predicted, and no<br />

significant impacts on birds are predicted.<br />

• The proposed pipeline route is predominantly located within an established<br />

industrial area therefore it is not predicted to result in any noise impacts to<br />

residential receptors.<br />

Environmental Management and Mitigation<br />

<strong>RWE</strong> Dea UK SNS Ltd. (hereafter referred to as RDUK) is the Licensed Operator for the<br />

<strong>Breagh</strong> field. RDUK is fully <strong>com</strong>mitted to conducting its activities in accordance with all<br />

applicable legislation and operates a Health, Safety & Environmental Management System<br />

(HS&EMS). The system provides the framework for managing HS&E issues within the<br />

business to ensure <strong>com</strong>pliance with <strong>com</strong>pany policy. The HS&EMS was assessed in August<br />

2008 by an accredited third party certification body, Lloyd's Register Quality Assurance<br />

(LRQA) and verified as meeting Environmental Management System (EMS) requirements set<br />

out in the OSPAR Re<strong>com</strong>mendation and Department of Environment and Climate Change<br />

(DECC) Guidance. This verification is to be repeated every 2 years and is scheduled to be re<br />

verified during August 2010 as part of the biennial cycle.<br />

The proposed development is not expected to have a significant impact on the environment.<br />

Notwithstanding this, there are a number of associated mitigation measures listed in section<br />

5 of this ES that will ensure environmental impacts are minimised wherever possible. The<br />

<strong>com</strong>mitments made within the ES will be tracked to <strong>com</strong>pletion by the RDUK Environmental<br />

Team.<br />

The HSE policy is outlined in Appendix D.<br />

<strong>Development</strong> Concept<br />

RDUK’s proposal for the development of the <strong>Breagh</strong> Field will enable the economic recovery<br />

and export of gas. The NUI will be installed over the exploration wells and the exploration<br />

wells <strong>com</strong>pleted and hooked up to manifolds on the NUI platform. From here the gas will be<br />

transported to the TGPP through a 20” production pipeline. The controls and chemicals for<br />

the <strong>Breagh</strong> development will be supplied from shore. It is proposed to provide MEG mixed<br />

with corrosion inhibitor via a separate 3” line laid adjacent to the gas export pipeline.<br />

Environmental and Socioeconomic <strong>Development</strong><br />

The flora and fauna in the area of the proposed development are typical of those found over<br />

wide areas of the Southern North Sea. During the consultation phase of the EIA, discussions<br />

were held with DECC, the Joint Nature Conservation Committee (JNCC), Natural England<br />

(NE), Marine Management Organisation (MMO), National Federation of Fisherman’s<br />

Organisation (NFFO) and Centre for Environment, Fisheries and Aquaculture Science<br />

(CEFAS), North Eastern Sea Fisheries Committee (NESFC) and no major issues were raised.<br />

The development area lies within the vicinity of spawning and/or nursery grounds for Cod,<br />

Herring, Lemon Sole, Mackerel, Sprat, Sandeel, Plaice, Haddock, Nephrops and Whiting.<br />

Spawning for these species takes place over large areas of the North Sea, and as such, they<br />

are unlikely to be significantly affected by the development.<br />

v

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

Marine and Fisheries Agency 1<br />

data (Marine and Fisheries Agency, 2008) shows that the<br />

fishing effort within both the development area and the pipeline route is relatively low.<br />

Fishing effort is directed predominantly at demersal species within the development area<br />

while demersal and crustaceans are targeted along the pipeline route.<br />

The <strong>Breagh</strong> A NUI location does not lie within an important area for sea-birds. However,<br />

migrant species are known to pass through the development area and migrant and<br />

wintering wildfowl are dispersed within the vicinity of the development. The highest seabird<br />

vulnerability in block 42/13 occurs during January and February and September through to<br />

November (Very High).<br />

Low densities of cetaceans have been recorded in the area (Reid et. al., 2003). Sightings<br />

suggest that the harbour porpoise is the most frequently recorded cetacean, with low<br />

numbers occurring throughout the year. Low numbers of minke whales have been sighted<br />

in the summer months and white beaked dolphin during the winter and spring.<br />

This area of the Southern North Sea is of low to moderate <strong>com</strong>mercial fishing value in<br />

<strong>com</strong>parison to other areas of the North Sea.<br />

Otters are unlikely to be sighted within the development area given the distance of the<br />

<strong>Breagh</strong> field from shore and the low number of otter ranges along the coastline adjacent to<br />

the <strong>Breagh</strong> field.<br />

Common and grey seal breeding colonies are present on the coastline adjacent to the<br />

development. Given the feeding patterns of <strong>com</strong>mon and grey seals and the fact that the<br />

<strong>Breagh</strong> field lies 50 km from shore it is unlikely that <strong>com</strong>mon seals will be sighted at the<br />

development site while grey seals may be sighted occasionally.<br />

The Petroleum (Conservation of Habitats) Regulations 2001 and amendments 2007<br />

implement the requirements of the Habitats Directive for oil and gas developments and<br />

extend the protection of marine habitats and species beyond the 12 nautical mile zone to all<br />

oil and gas developments either partly or wholly on the UKCS. These sites are referred to as<br />

Special Areas of Conservation (SAC). At the moment there are thirteen<br />

candidate/draft/possible SACs on the UKCS. New projects/developments must demonstrate<br />

that they will not significantly disturb a European protected habitat or species in a way that<br />

will affect:<br />

• The ability of the species to survive, to breed or rear or nurture their young<br />

• The local distribution or abundance of any protected species<br />

either alone or in <strong>com</strong>bination with other plans and projects.<br />

Of the thirteen candidate/draft/possible SACs, only one is located within 40 km of the<br />

development; The Dogger Bank dSAC, which at its nearest is 34 km from the <strong>Breagh</strong><br />

development well and export pipeline. This feature contains Annex I habitat:<br />

vi<br />

• Sandbanks which are slightly covered by seawater at all times<br />

1<br />

The Marine and Fisheries Agency merged with a number of other bodies to form the Marine<br />

Management Organisation (MMO) on the 1 st April 2010.

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

Due to the proximity of this site benthic sampling has been conducted throughout the<br />

development area. The area was found to be typical of the SNS. No other Annex I seabed<br />

features were identified within the area which will be impacted upon by the development.<br />

The Saturn Reef and North Norfolk Bank pSACs are located to the South East of the <strong>Breagh</strong><br />

Field. A number of designated areas are located on the English coast within the vicinity of<br />

the development area and/or the pipeline approach to landfall including: Teesmouth and<br />

Cleveland Coast Ramsar Site and SPA; Flamborough Head SAC and SPA; Humber Flats,<br />

Marshes & Coast Phase 1 Ramsar Site and Humber Estuary SPA.<br />

The impact assessment has not identified any significant impact. The main impact upon<br />

these sites results from the presence of the pipeline installation vessels. The installation<br />

vessels will only be present for a short period of time and the waterfoul resident at<br />

Teesmouth and Cleveland Coast Ramsar Site and SPA are already subject to considerable<br />

interaction with shipping vessels in the area. Flamborough Head SAC and SPA and Humber<br />

Flats Marshes and Coast Phase 1 Ramsar Site and Humber Estuary are located at least 40 km<br />

and 95 km respectively from any part of the development respectively and are therefore<br />

unlikely to be impacted upon by the development.<br />

The development area is considered to be typical of the Southern North Sea offshore<br />

environment and there are no biological or other features identified that are thought to be<br />

particularly sensitive to the type of activities being undertaken.<br />

The full results from the EIA identified no ‘high’ risks; however a number of ‘moderate’ risks<br />

requiring additional assessment were identified. Further assessment of these, and planned<br />

mitigation measures, demonstrated no remaining moderate risks.<br />

Teesside Offshore Windfarm<br />

Northern Offshore Energy Ltd., which is part of the EDF group, was granted permission to<br />

construct and operate a 30 turbine windfarm at Redcar, Teesside. The site lies within a<br />

10km 2 trapezoidal box located 1.5km offshore from Coatham Sands, Redcar and Cleveland.<br />

The turbines will be constructed in 3 rows of 10 turbines. The spacing between the rows will<br />

be 600m with the spacing between turbines within each row approximately 300m. The tip<br />

height of the windturbines will be in the range of 110m to 132m.<br />

The windfarm will be connected to shore by three underground cables which will be laid in a<br />

single trench. The cables will <strong>com</strong>e ashore through the dunes of South Gare before linking<br />

to a sub-station in Warrenby. Figure 3 below shows the proposed windfarm and associated<br />

infrastructure within the landfall of the <strong>Breagh</strong> pipeline.<br />

vii

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

Figure 3 Teesside Offshore Windfarm, CATS Pipeline and Proposed Pipeline Route (South)<br />

viii

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

Pipelaying activities for the <strong>Breagh</strong> development will take place to the south of windfarm<br />

during Q1 to Q3 2011 and Q2 of 2012, and will take place in a controlled construction<br />

corridor. In consideration of the works undertaken as part of the Teesside Offshore<br />

Windfarm and the infrastructure present in the area, the presence of the 20” production<br />

pipeline and 3” MEG pipeline do not represent a significant cumulative impact.<br />

Summary of Environmental Effects<br />

The EIA process used a standard, structured approach for the identification of environmental<br />

hazards. This involved breaking down the development option into individual phases (e.g.<br />

subsea installation and production) and key activities. For each key activity the<br />

environmental aspect was identified and the potential effects identified and quantified.<br />

Potential effects were assessed both in terms if their likelihood (how often they occur) and<br />

their significance (their magnitude).<br />

The full results from the EIA have been assessed within the ES identified no ‘high’ risks,<br />

however a number of ‘moderate’ risks requiring additional assessment were identified.<br />

Further assessment of these, and planned mitigation measures, demonstrated no remaining<br />

moderate risks. Table 1, below, displays issues identified as requiring further assessment as<br />

detailed in Appendix B, and addressed within section 5.<br />

Table 1: Issues identified as requiring further assessment<br />

Phase / Issue Aspect / Source<br />

Surface Installation Exhaust emissions from NUI installation vessels<br />

Phase<br />

Physical presence of HLV anchors<br />

Noise associated with piling activities<br />

Accidental events<br />

Drilling Phase Atmospheric emissions from drilling operations<br />

Discharge of WBM<br />

Physical presence of the drill rig on seabed<br />

Noise associated with drilling activities<br />

Accidental events<br />

Subsea Installation Exhaust emissions from subsea installation and <strong>com</strong>missioning<br />

and Commissioning vessels<br />

Phase<br />

Discharge of hydrotest fluids<br />

Physical presence of pipelay vessel anchors<br />

Physical presence of 20” production pipeline<br />

Physical presence of trenching and associated deposits<br />

Physical presence of rockdump and mattresses<br />

Noise associated with subsea installation and <strong>com</strong>missioning vessels<br />

Accidental events<br />

Production Phase Physical presence of the NUI<br />

Accidental events<br />

Wider <strong>Development</strong> Noise<br />

Concerns<br />

Protected species<br />

Transboundary impacts<br />

Cumulative impacts<br />

ix

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

Main Conclusions<br />

The proposed development will not result in any significant long-term environmental,<br />

cumulative or transboundary effects. The identified discharges and emissions will be<br />

minimised by the mitigation measures in place and are likely to be dispersed rapidly in the<br />

immediate environment.<br />

x

Glossary<br />

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

Acute Of Short duration<br />

Annulus The ring shaped cavity between 2 concentric tubes, e.g. inner and outer<br />

strings of casing, or between casing, or drill pipe, and the well borehole.<br />

Appraisal well A well drilled to confirm the size or quality of a hydrocarbon discovery.<br />

Before development, a discovery is likely to require at least 2 or 3 of such<br />

wells.<br />

Barite A very heavy substance used as a main <strong>com</strong>ponent of drilling mud to<br />

increase its density and counter balance down-hole pressures.<br />

Bathymetry The measurement of ocean depth and the study of floor topography.<br />

Benthic Relating to organisms that are attached to, or resting on, the bottom<br />

sediments.<br />

Bioaccumulate The increasing concentration of <strong>com</strong>pounds within fauna such as limpets,<br />

oysters and other shellfish.<br />

Biocide A chemical toxic or lethal to living organisms.<br />

Biogenic Produced by the action of living organisms<br />

Biomagnify Increase in toxicity within a species<br />

Block Sub-division of sea for the purpose of licensing to a <strong>com</strong>pany or group of<br />

<strong>com</strong>panies for exploration and production rights. A UK block is<br />

approximately 200 – 250km 2 .<br />

Casing Steel lining used to prevent caving of the sides of a well, to exclude<br />

unwanted fluids and to provide a means to control well pressures and oil<br />

and gas production.<br />

Cetacean Aquatic animals <strong>com</strong>prising porpoises, dolphins and whales.<br />

Choke An aperture restricting flow in a well or flowline.<br />

Christmas Tree An assembly of isolation valves, chokes and gauges installed at the top of<br />

a well to control the flow of oil and gas once a well has been <strong>com</strong>pleted.<br />

Condensate Light hydrocarbon fractions produced with natural gas which condense<br />

into liquid at normal temperatures and pressures associated with surface<br />

production equipment.<br />

Cuttings pile Pile of primarily rock chips deposited on the seabed as a result of drilling<br />

activities.<br />

Demersal Living at or near the bottom of the sea.<br />

Dinoflagellates Plankton with two flagellae.<br />

Down hole Down a well. The expression covers any equipment, measurement, etc. In<br />

a well or designed for use in one.<br />

Dynamic Positioning Use of thrusters to maintain a vessels’ position without the use of<br />

anchors.<br />

Environmental aspect An activity that causes an environmental effect.<br />

Environmental effect Any change to the environment or its use.<br />

Flagellae A long projection from a unicellular or multicellular body that aids the<br />

movement of the organism.<br />

Flowline Pipe through which produced fluids travel<br />

Greenhouse gas Gas that contributes to the greenhouse effect. Includes gases such as<br />

carbon dioxide and methane.<br />

Greenhouse effect The greenhouse effect results in a rise in temperature due to infrared<br />

radiation trapped by carbon dioxide and water vapour in the Earth’s<br />

atmosphere.<br />

Infauna Benthic organisms that live within the sediment.<br />

xi

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

Injection well Well into which gas or water is pumped to maintain reservoir pressure.<br />

ISO 14001 International management system standard.<br />

Macrofauna Larger bethic organisms.<br />

Manifold A piping arrangement which allows one stream of liquid or gas to be<br />

divided into two or more streams, or which allows several streams to be<br />

collected into one.<br />

Meiofauna Benthic organisms sized between 50µm and 1mm.<br />

Microfauna Benthic organisms sized less than 50µm.<br />

Oxygen scavenger Chemical used to remove oxygen.<br />

Pelagic Organisms inhabiting the water column of the sea.<br />

Phytoplankton Free floating microscopic plants.<br />

Pig Piece of equipment inserted into a pipeline and carried along by the flow<br />

of oil and gas to clean or monitor the internal condition of the pipeline.<br />

Ramsar The Convention of Wetlands of International Importance especially as<br />

Waterfowl Habitat.<br />

Riser A pipe which connects a rig or platform to a subsea wellhead or pipeline<br />

during drilling or production operations.<br />

Tie-in The action of connecting one pipeline to another or to another piece of<br />

equipment.<br />

Sidetrack Creation of a new section of the wellbore for the purpose of detouring<br />

around an obstruction in the main wellbore or to access a new part of the<br />

reservoir from an existing wellbore.<br />

Special Area of<br />

Conservation<br />

xii<br />

Areas considered to be important for certain habitats and non-bird species<br />

of interest in a European context. One of the main mechanisms by which<br />

the EC Habitats and Species Directive 1992 will be implemented.<br />

Special Protection Area Sites designated by the UK Government to protect certain rare or<br />

vulnerable species and regularly occurring migratory species of birds.<br />

Sublittoral Below the level of low tide.<br />

Thermocline Pronounced temperature incline.<br />

Well <strong>com</strong>pletion The process by which a finished well is either sealed off or prepared for<br />

production by fitting a wellhead.<br />

Zooplankton Free floating microscopic animals.<br />

Acronyms<br />

ALARP As Low as Reasonably Practicable<br />

API The standard unit adopted for measuring the density of a liquid,<br />

(especially hydrocarbons) expressed in degrees.<br />

Bbl Barrels<br />

bcf Billion Cubic Feet<br />

BERR Department for Business Enterprise and Regulatory Reform<br />

BOP Blow Out Preventor<br />

BP British Petroleum<br />

Bpd Barrels Per Day<br />

Bscm Billion Standard Cubic Metres<br />

C Carbon<br />

°C Degrees Celsius<br />

CATS Central Area Transmissions System<br />

CCLS Combined Control and Safety System

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

CEFAS Centre for Environment Fisheries and Aquaculture Science<br />

CGR Condensate Gas Ratio<br />

CHARM Chemical Hazard and Risk Management<br />

CITHP Closed In Tubing Head Pressure<br />

CMACS Centre for Marine and Coastal Studies<br />

Cm/s Centimetre per second<br />

CO2<br />

Carbon Dioxide<br />

COPA Crude Oil Pipeline Agreement<br />

COWRIE Collaborative Offshore Wind Research Into The Environment<br />

CPA Closest Possible Approach<br />

CRA Corrosion Resistant Alloy<br />

cSAC Candidate Special Area of Conservation<br />

dB Decibels<br />

DECC Department of Energy and Climate Change<br />

DEME Dredging, Environmental and Marine Engineering<br />

dSAC Draft Special Area of Conservation<br />

DP Dynamic Positioning<br />

DSV Dive Support Vessel<br />

DTI Department of Trade and Industry<br />

E East<br />

EAC Ecological Assessment Criteria<br />

EC European Commission<br />

EDF EDF Energy (Northern Offshore Wind) Ltd<br />

EEC European Economic Community<br />

EEMS Environmental Emissions Monitoring System<br />

EIA Environmental Impact Assessment<br />

EMS Environmental Management System<br />

ENV Environmental station<br />

ES Environmental Statement<br />

ETS Emissions Trading Scheme<br />

EU European Union<br />

°F Degrees Fahrenheit<br />

FO Fibre Optic<br />

FRS Fisheries Research Services<br />

ft Feet<br />

FWHP Flowing Well Head Pressure<br />

FWHT Flowing Well Head Temperature<br />

GBS Gravity Based Structure<br />

GDT Gas down to<br />

HAB Harmful Algal Blooms<br />

HIPPS High Integrity Pressure Protection System<br />

HLV Heavy Lift Vessel<br />

HP High Pressure<br />

hr Hour<br />

HSE Health Safety & Environmental (Management System)<br />

HQ Hazard Quotient<br />

H2S Hydrogen Sulphide<br />

ICES International Council for the Exploration of the Sea<br />

INCA Industry Nature Conservation Association<br />

IPPC Integrated Pollution Prevention and Control<br />

ISO International Standards Organisation<br />

IUCN International Union for the Conservation of Nature<br />

JNCC Joint Nature Conservation Committee<br />

xiii

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

Juv Juvenile<br />

km Kilometres<br />

KP Kilometre Point<br />

kw Kilowatt<br />

l Litre<br />

LAT Lowest Astronomical Tide<br />

LTOBM Low Toxic Oil Based Mud<br />

LP Low Pressure<br />

LSA Low Specific Activity<br />

Ltd Limited<br />

LWMS Low Water Mean Spring [Tide]<br />

m metres<br />

MAOP Maximum Allowable Operating Pressure<br />

MARPOL International Convention for the Prevention of Marine Pollution from<br />

Ships<br />

MEG Monoethylene Glycol<br />

MeOH Methanol<br />

MESH Mapping European Seabed Habitats<br />

MLWS Mean Low Water Springs (Tide)<br />

mm Millimetre<br />

MMO Marine Mammal Observer<br />

m/s Metres per second<br />

MMscf Million Standard Cubic Feet<br />

MMscf/d Million Standard Cubic Feet per Day<br />

MoD Ministry of Defence<br />

Msm 3 Million Standard Metres Cubed<br />

MW Megawatt<br />

N Nitrogen<br />

NFFO National Federation of Fishermen’s Organisations<br />

ng Nanograms<br />

Nm Nautical Mile<br />

NMm 3 Normal Metres Cubed<br />

NNW North Northwest<br />

NTS National Transmission System<br />

NUI Normally Unmanned Installation<br />

OBM Oil Based Mud<br />

OCNS Offshore Chemical Notification Scheme<br />

OD Outside Diameter<br />

OPPC Oil Pollution Prevention and Control<br />

OSIRIS Osiris Hydrographic & Geophysical Projects Ltd<br />

OSPAR Convention for the Protection of the Marine Environment in the North<br />

East Atlantic<br />

OVI Oil Vulnerability Index<br />

PAH Polycyclic Aromatic Hydrocarbon<br />

PCB Polychlorobiphenyls<br />

PLONOR Poses Little Or No Risk to the environment<br />

PON Petroleum Operations Notice<br />

PPC Pollution Prevention and Control<br />

ppm Parts Per Million<br />

psi Pounds per Square Inch<br />

Psia Pounds per Square Inch Absolute<br />

pSAC Possible Special Area of Conservation<br />

PVT Pressure Volume Transducer<br />

xiv

RAMSAR RAMSAR Convention on Wetlands<br />

ROV Remote operated Vehicle<br />

RQ Risk Quotient<br />

SAC Special Area of Conservation<br />

S Seconds<br />

SCANS Small Cetacean Abundance in the North Sea<br />

scf/hr Standard Cubic Feet per Hour<br />

SEA Strategic Environmental Assessment<br />

SG Specific Gravity<br />

SIMOPS Simultaneous Drilling and Production<br />

SIWHP Shut In Well Head Pressure<br />

Sm 3 /d Standard Meters Cubed per day<br />

SNS Southern North Sea<br />

SPA Special Protection Area<br />

Spp Species<br />

SOPEP Ship Oil Pollution Emergency Plan<br />

t Tonnes<br />

t/d Tonnes per day<br />

TGPP Teesside Gas Processing Plant<br />

THC Total Hydrocarbon Content<br />

TOC Total Organic Carbon<br />

TOM Total Organic Matter<br />

TVD True Vertical Depth<br />

TVDSS True Vertical Depth Subsea<br />

µg micrograms<br />

UK United Kingdom<br />

UKCS United Kingdom Continental Shelf<br />

UKOOA United Kingdom Offshore Operators Association<br />

UPS Uninterrupted Power Supply<br />

UTM Universal transverse Mercator<br />

V Vaults<br />

VHF Very High Frequency<br />

VOC Volatile Organic Compound<br />

WBM Water Based Mud<br />

WHSIP Well Head Shut In Pressure<br />

WUP Water up to<br />

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

xv

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

Table of Contents<br />

Standard Information Sheet .............................................................................................. i<br />

Non Technical Summary .................................................................................................. iii<br />

Scope ..................................................................................................................................... iv<br />

Summary of Onshore Environmental Statement .................................................................. iv<br />

Environmental Management and Mitigation ........................................................................ v<br />

<strong>Development</strong> Concept ............................................................................................................ v<br />

Environmental and Socioeconomic <strong>Development</strong> ................................................................. v<br />

Teesside Offshore Windfarm ................................................................................................ vii<br />

Environmental Effects ........................................................................................................... ix<br />

Main Conclusions.................................................................................................................... x<br />

Glossary.......................................................................................................................... xi<br />

Acronyms ...................................................................................................................... xii<br />

Introduction ................................................................................................................. 1-1<br />

Aim of the Project ............................................................................................................... 1-2<br />

Purpose of the Environmental Statement .......................................................................... 1-2<br />

Requirement for an Environmental Statement .................................................................. 1-2<br />

Scope of the Environmental Statement ............................................................................. 1-3<br />

Legislative Overview ........................................................................................................... 1-3<br />

Environmental Management .............................................................................................. 1-6<br />

Areas of Uncertainty ........................................................................................................... 1-6<br />

Consultation Process .......................................................................................................... 1-7<br />

Proposed <strong>Development</strong> ................................................................................................. 2-1<br />

Introduction ........................................................................................................................ 2-1<br />

Nature of the Reservoir ...................................................................................................... 2-2<br />

<strong>Development</strong> Options ........................................................................................................ 2-4<br />

Schedule of Activities ......................................................................................................... 2-7<br />

<strong>Breagh</strong> Alpha NUI Design .................................................................................................... 2-8<br />

Subsea Design ................................................................................................................... 2-13<br />

Drilling............................................................................................................................... 2-20<br />

Production ........................................................................................................................ 2-29<br />

Environmental Performance ............................................................................................ 2-31<br />

xvi

<strong>Breagh</strong> Environmental Statement<br />

Non Technical Summary<br />

Permitting ......................................................................................................................... 2-32<br />

De<strong>com</strong>missioning ............................................................................................................. 2-34<br />

Teesside Gas Processing Plant .......................................................................................... 2-37<br />

Baseline Environment ................................................................................................... 3-1<br />

Physical Environment ......................................................................................................... 3-3<br />

Biological Environment ..................................................................................................... 3-16<br />

Socio-Economic Environment ........................................................................................... 3-49<br />

Overview ........................................................................................................................... 3-60<br />

Environmental Assessment Methodology ...................................................................... 4-1<br />

Likelihood ........................................................................................................................... 4-1<br />

Consequence ...................................................................................................................... 4-1<br />

Combining Likelihood and Consequence to Establish Risk ................................................ 4-2<br />

Assessment of Potential Impacts and Control Measures ................................................. 5-1<br />

Surface Installation Phase .................................................................................................. 5-2<br />

Drilling................................................................................................................................. 5-5<br />

Subsea Installation and Commissioning ........................................................................... 5-10<br />

Production ........................................................................................................................ 5-17<br />

Wider <strong>Development</strong> Concerns ......................................................................................... 5-18<br />

Conclusions .................................................................................................................. 6-1<br />

Environmental Effects ........................................................................................................ 6-1<br />

Minimising the Environmental Impact ............................................................................... 6-1<br />

Overall Conclusion .............................................................................................................. 6-3<br />

References .................................................................................................................... 7-1<br />

Appendix A Register of Environmental Legislation ......................................................... A-1<br />

Appendix B Environmental Assessment ........................................................................ B-1<br />

Appendix C Chemical Register ....................................................................................... C-1<br />

Appendix D Environmental Management System .......................................................... D-1<br />

Appendix E Survey Data ................................................................................................ E-1<br />

Appendix F Oil Spill Modelling ....................................................................................... F-1<br />

Appendix G Drawings ................................................................................................... G-1<br />

xvii

1. Introduction<br />

<strong>Breagh</strong> Environmental Statement<br />

Section 1 - Introduction<br />

The <strong>Breagh</strong> gas field is located in Block 42/13 of the northern reaches of the UK Southern<br />

North Sea (SNS) (Figure 1-1). It lies 50 km to the north east of the UK coast and 200 km to<br />

the west of the median line between the UK and Dutch sectors in approximately 62 m of<br />

water. Block 42/13 is owned by <strong>RWE</strong> Dea SNS Limited (RDUK) (70%) and Sterling Resources<br />

(UK) Limited (30%).<br />

Figure 1 - 1 <strong>Breagh</strong> Field<br />

The <strong>Breagh</strong> field development concept <strong>com</strong>prises the installation of up to two Normally<br />

Unattended Installations. A first NUI, <strong>Breagh</strong> A, will be installed on the west side of the field<br />

(West <strong>Breagh</strong>) in Phase 1. In Phase 2 a second NUI, <strong>Breagh</strong> B, will be installed on the east<br />

side of the field.<br />

The scope of this ES is limited to Phase 1 activities. The activities associated with Phase 2<br />

will depend on the success of Phase 1 and will be the subject of a future submission.<br />

1-1

<strong>Breagh</strong> Environmental Statement<br />

Section 1 - Introduction<br />

1.1. Aim of the Project<br />

The purpose of the project is to develop the <strong>Breagh</strong> field in order to deliver hydrocarbons to<br />

the UK and to install a gas export route from Block 42/13 to the Teesside Gas Processing<br />

Plant (TGPP) for future developments.<br />

1.2. Purpose of the Environmental Statement<br />

The purpose of this Environmental Statement (ES) is to report on the Environmental Impact<br />

Assessment (EIA) process undertaken to meet both statutory and RDUK’s project<br />

requirements.<br />

The ES was prepared in accordance with the Offshore Petroleum Production and Pipelines<br />

(Assessment of Environmental Effects) (Amendment) Regulations 2007.<br />

The ES reports on the conclusions from the EIA, which investigated and evaluated routine<br />

and non-routine environmental impacts associated with the development, specifically:<br />

atmospheric emissions, physical presence of installation vessels, impacts of drilling and<br />

testing the new wells and installation of the export pipeline. The presence of permanent<br />

new subsea infrastructure and the fate of potential hydrocarbon spills from all stages of the<br />

project were also included.<br />

1.3. Requirement for an Environmental Statement<br />

The ES documents the results from the Environmental Impact Assessment (EIA) of the<br />

proposed project. The EIA was carried out to ensure that the environmental impacts<br />

associated with the project were identified and their significance assessed, and that<br />

appropriate mitigation and control measures are implemented.<br />

The Offshore Petroleum Production and Pipelines (Assessment of Environmental Effects)<br />

Amendment) Regulations 2007 requires: 1) evaluation of projects likely to have a significant<br />

effect on the offshore environment; and 2) formal public consultation on the resulting ES.<br />

The ES is also required to take into account European Directives, in particular the EU<br />

Habitats Directive 92/43/EEC (enacted in the UK by The Offshore Petroleum Activities<br />

(Conservation of Habitats) Regulations 2001, SI 2001 No. 1754 and the EU Birds Directive<br />

79/409/EEC.<br />

RDUK has an HSEQ-EMS in place which ensures that:<br />

1. There is an effective management organisation in place to plan operations to<br />

minimise the impact to the environment by identifying and managing the relevant<br />

risks.<br />

2. Environmental issues are considered from the outset when planning operations, to<br />

reduce waste, the consumption of resources and prevent damage to wildlife<br />

habitats.<br />

1-2

1.4. Scope of the Environmental Statement<br />

<strong>Breagh</strong> Environmental Statement<br />

Section 1 - Introduction<br />

The scope of the EIA and this resultant ES includes all activities associated with the Phase 1<br />

of the offshore development of the <strong>Breagh</strong> Field up to the landfall at the Mean Low Water<br />

Springs (MLWS) line.<br />

The proposed scope of the offshore Phase 1 development is to:<br />

• Install the <strong>Breagh</strong> A NUI;<br />

• Drill 7 target wells (including re-drilling in two existing wells at the platform<br />

location);<br />

• Install approximately 100 km of 20” export pipeline, 3” MEG line and fibre optic<br />

cable between <strong>Breagh</strong> A and the landfall at Teesside;<br />

• Test and <strong>com</strong>mission all the facilities;<br />

• Produce gas and condensate.<br />

The landfall and terminal impacts are considered under a separate submission as required<br />

under the Town and Country Planning Act (Figure 1-2).<br />

Figure 1-2 Environmental Statement Demarcation<br />

1.5. Legislative Overview<br />

This section provides a brief overview of the current legislation. A full summary of applicable<br />

legislation is included in Appendix A of the ES.<br />

Current offshore environmental control has evolved over the past thirty years and is<br />

continuing to evolve in response to increasing awareness of the potential environmental<br />

impact. Strands of both primary and secondary legislation, voluntary agreement, and<br />

conditions in consents granted under the petroleum licensing regime and international<br />

conventions have also contributed.<br />

1-3

<strong>Breagh</strong> Environmental Statement<br />

Section 1 - Introduction<br />

The main controls for new projects are EIAs, which have been a legal requirement for<br />

offshore developments since 1998. Current requirements are set out in the Offshore<br />

Petroleum Production and Pipelines (Assessment of Environmental Effects (Amendment)<br />

Regulations 2007 and ac<strong>com</strong>panying Guidance Notes for Industry) (DECC, 2009).<br />

The Offshore Petroleum Production and Pipelines (Assessment of Environmental Effects)<br />

(Amendment) Regulations 2007, hereafter referred to as ES Regulations, require an ES to be<br />

submitted and prepared for:<br />

• <strong>Development</strong>s which will produce 500 tonnes or more per day of oil or 500,000<br />

cubic meters or more per day of gas;<br />

• Pipelines of 800 mm diameter and 40 km or more in length.<br />

In addition to this an ES may be required for developments which are:<br />

• Less than 40 km from the UK coast line;<br />

• Within, or less than 10 km from, an SPA or SAC;<br />

• Where designated archaeological features are present and may be damaged or<br />

disturbed;<br />

• Areas which are subject to high seasonal environmental sensitivities and/or within<br />

herring or sandeel spawning grounds or important fisheries;<br />

• Operations which may significantly impact other users of the sea;<br />

• Within 10 km of international boundaries where other member states may request<br />

to participate in the procedure.<br />

Following the submission of the ES a period of formal public consultation is required under<br />

both the ES Regulations and European Directive 2003/35/EC (Public Participation Directive).<br />

The EIA needs to consider the impact on the surrounding environment including any<br />

protected areas or sites currently undergoing the process of being designated as protected.<br />

These areas have been developed as a consequence of European Directives, in particular the<br />

EU Habitats Directive 92/43/EEC and the EU Birds Directive 79/409/EEC which have been<br />

enacted in the UK by the following legislation:<br />

• Conservation (Natural Habitats, &c.) Regulations 1994 (as amended 1997 and 2000);<br />

• Conservation (Natural Habitats, &c.) Amendment (Scotland) Regulations 2007;<br />

• Conservation (Natural Habitats, &c.) (Amendment) Regulations 2007;<br />

• Offshore Petroleum Activities (Conservation of Habitats) Regulations 2001 and 2007<br />

amendment;<br />

• The Offshore Marine Conservation (Natural Habitats &c.) Regulations 2007;<br />

• The Offshore Marine Conservation (Natural Habitats, &c.) (Amendment) Regulations<br />

2009;<br />

• The Conservation of Habitats and Species Regulations 2010.<br />

Until 1999 these Directives applied only to UK territorial waters (as defined in COPA 1997)<br />

when their scope was extended to include the offshore with the Offshore Regulations being<br />

subsequently prepared to <strong>com</strong>ply with the changes. As a result new offshore projects or<br />

developments must demonstrate that they are not “likely to have a significant impact on the<br />

integrity of the conservation objectives for the protected site” or “significantly disturb<br />

European protected species” either alone or in <strong>com</strong>bination with other plans and projects.<br />

1-4

<strong>Breagh</strong> Environmental Statement<br />

Section 1 - Introduction<br />

The disturbance of European protected species has been further defined by the 2009<br />

Regulations where it is an offence to:<br />

“Injure or kill an animal”<br />

“deliberately disturb wild animals of any such species in such a way as to be likely to<br />

significantly to affect—<br />

- the ability of animals of that species to survive, breed, or rear or nurture their<br />

young; or<br />

- The local distribution or abundance of that species…<br />

…disturbance of animals includes in particular any disturbance which is likely –<br />

to impair their ability-<br />

- to survive, to breed or reproduce, or to rear or nurture their young;<br />

- in the case of animals of a hibernating or migratory species, to hibernate or<br />

migrate; or<br />

- to affect significantly the local distribution or abundance of the species to which<br />

they belong.”<br />

In June 2000, OSPAR made a decision requiring a mandatory system for the control of<br />

chemicals (OSPAR Decision 2000/2 on a Harmonised Mandatory Control System for the Use<br />

and Reduction of the Discharge of Offshore Chemicals). This decision operates in conjunction<br />

with two OSPAR Re<strong>com</strong>mendations; OSPAR Re<strong>com</strong>mendation 2000/4 on a Harmonised Pre-<br />

Screening Scheme for Offshore Chemicals; and OSPAR Re<strong>com</strong>mendation 2000/5 on a<br />

Harmonised Offshore Chemical Notification Format (HOCNF).<br />

Under the broader umbrella of the Integrated Pollution Prevention and Control (IPPC) Act,<br />

the UK Government’s offshore oil and gas regulator, the Department of Energy and Climate<br />

Change (DECC), implemented OSPAR Decision 2000/2 on the control of chemical use<br />

offshore, through the Offshore Chemicals Regulations (2002).<br />

The offshore industry is also operating the European Union Emissions Trading Scheme (EU<br />

ETS) enacted in the UK via the Greenhouse Gas Emissions Trading Scheme Regulations 2005<br />

(Statutory Instrument 2005 No. 925) and the Greenhouse Gas Emissions Trading Scheme<br />

(Amendment) Regulations 2007 (Statutory Instrument 2007 No. 465). This scheme is one of<br />

a raft of measures introduced to reduce emissions of greenhouse gases and sets challenging<br />

targets for UK industry.<br />

In line with OSPAR Re<strong>com</strong>mendation (2001/1) the UK (DECC) has introduced regulatory<br />

requirements to reduced the permitted average monthly oil in produced water discharge<br />

concentration to 30mg/l.<br />

OSPAR Re<strong>com</strong>mendation 2001/1 also required a 15% reduction in the discharge of oil in<br />

produced water from 2006 measured against a 2000 baseline; controlled by the issue of<br />

permits to each installation. The permits replaced the granting of exemptions under the<br />

Prevention of Oil Pollution Act 1971 and are issued under the Offshore Petroleum Activities<br />

(Oil Pollution Prevention and Control) Regulations 2005.<br />

1-5

<strong>Breagh</strong> Environmental Statement<br />

Section 1 - Introduction<br />

1.6. Environmental Management<br />

All projects undertaken by RDUK follow the RDUK Health, Safety and Environmental<br />

Management System (HS&EMS). The system provides the framework for managing HS&E<br />

issues within the business to ensure <strong>com</strong>pliance with <strong>com</strong>pany policy (provided in Appendix<br />

D) and legislation. Additionally it ensures clear assignment of responsibilities, efficient and<br />

cost-effective planning and operations, effective management of HS&E risks and continuous<br />

improvement. The RDUK HS&EMS applies at all levels within the RDUK organisation,<br />

including all subsidiary <strong>com</strong>panies.<br />

The HS&EMS is based on the requirements of the Company HS&E Policy Statement. It has<br />

been developed in accordance with current UK environmental legislation and health &<br />

safety legislation, including The Health & Safety at Work etc. Act (HSWA) and various<br />

Regulations made under HSWA.<br />

The content and structure of the HS&EMS have also been based on:<br />

• principles in the Health and Safety Executive publication HS(G)65 ‘Successful Health<br />

and Safety Management’;<br />

• OHSAS 18001 ‘Occupational Health & Safety Management Systems – Specification’;<br />

• BS EN ISO 14001 standard for Environmental Management Systems.<br />

The HS&EMS is not certified for <strong>com</strong>pliance with ISO14001 or OHSAS18001 standards. The<br />

HS&EMS was, however, assessed in 2008 by an accredited third party certification body<br />

(LRQA) and verified as meeting EMS requirements set out in the OSPAR Re<strong>com</strong>mendation<br />

and DECC Guidance. The EMS is scheduled to be re-assessed in August 2010 as part of the<br />

two year cycle.<br />

More details on the HS&EMS are included in Appendix D along with a copy of the <strong>com</strong>pany<br />

environmental policy.<br />

1.7. Areas of Uncertainty<br />

1. The exact co-ordinates of the well locations of the <strong>Breagh</strong> field are still to be<br />

finalised, these will be provided in the subsequent PON15B application;<br />

2. Production profiles (based on models) have a degree of uncertainty associated with<br />

them. The profiles contained within the ES are based on the P10 (high) case;<br />

3. At the time of writing, the contract for pipelaying was still out to tender. As such it<br />

is possible that a DP pipelay vessel or anchored lay barge may be used to lay the 20”<br />

production pipeline. In addition the temporary dump sites for sediments excavated<br />

from the pipeline trenches will not be known until the contract is awarded and a<br />

method statement defined.<br />

The assumptions detailed in Table 1-1 were made for the purposes of conducting the EIA<br />

and preparing this ES.<br />

1-6

<strong>Breagh</strong> Environmental Statement<br />

Section 1 - Introduction<br />

Table 1-1 Uncertainties and Assumptions<br />

Subject Assumption<br />

Trenching<br />

Backhoe and suction hopper trencher width of impact is 30 m including<br />

sediment redeposit<br />

NUI Feet Feet of NUI are 51 m 2 each<br />

Pipelay barge<br />

anchors<br />

Anchors have to be reset every 2.5km (40 times along route)<br />

Rockdumping 1 tonne of rock dump impacts on 1 m 2 of seabed<br />

HLV Consumes 55 tonnes of diesel per day<br />

20" production<br />

pipeline<br />

Assumed width of impact on seabed is 0.5 m<br />

Piling Assumed maximum diameter of NUI piles is 2.4 m<br />

1.8. Consultation Process<br />

During the process to assess the environmental impact of the development a number of<br />

organisations were consulted (Table 1-2). The process of consultation will continue<br />

throughout the project.<br />

Table 1- 2 Consultation Process<br />

Consultees and<br />

Dates<br />

DECC & JNCC<br />

March 2010<br />

Natural England<br />

April 2010<br />

NFFO<br />

March 2010<br />

Issue/Concerns<br />

DECC identified the need for RDUK to consult with<br />

Natural England with respect to the environmental<br />

surveys undertaken for the nearshore (shoreline<br />

out to 12 Nm) section of the pipeline route to<br />

shore. RDUK subsequently provided survey<br />

information to Natural England for review.<br />

RDUK sent an information pack to NE in March<br />

2010 containing all environmental survey<br />

information collected to date. NE requested that:<br />

• Options assessment was detailed and cross<br />

referenced to survey data where<br />

appropriate;<br />

• Methods to minimise impacts on sensitive<br />

species identified are provided;<br />

• Offshore pipeline construction and<br />

onshore construction works are linked to<br />

minimise disturbance to designated<br />

species and sub-features at the beach<br />

landing area.<br />

RDUK held a meeting with NFFO in March 2010 to<br />

discuss the project. NFFO feedback was as follows.<br />

NFFO identified the main fishing types within the<br />

project area and the pipeline route to shore. It was<br />

recognised that there will need to be a clearly<br />

defined work corridor within which there is<br />

sufficient space during all construction activities.<br />

Good liaison with fisheries throughout<br />

Where Addressed<br />

in the ES<br />

3<br />

2, 3<br />

3, 5<br />

1-7

<strong>Breagh</strong> Environmental Statement<br />

Section 1 - Introduction<br />

Marine<br />

Management<br />

Organisation<br />

(Formerly the<br />

Marine Fisheries<br />

Agency)<br />

March 2010<br />

North Eastern<br />

Sea Fisheries<br />

Committee<br />

March 2010<br />

JNCC<br />

January 2009<br />

CEFAS January<br />

2009<br />

1-8<br />

construction will be necessary. Agreed to use<br />

guard vessels to patrol the working corridor and<br />

ensure smaller fishing vessels deploying static gear<br />

observe the designated work corridor. NFFO<br />

preference is for trenched and buried pipelines.<br />

Q3/Q4 2010 RDUK and NFFO shall start working on<br />

a collaboration/co-operation plan for liaison with<br />

local fisherman during pipeline construction<br />

activities in 2011.<br />

RDUK contacted three groups within the MMO<br />

• North Shields District Inspector;<br />

• Grimsby District Inspector;<br />

• Marine Consents (North Shields).<br />

RDUK sent a short project briefing and a summary<br />

of the meeting with NFFO for review and <strong>com</strong>ment<br />

to the MMO. Response was as follows:<br />

The MMO agreed with the actions identified during<br />

the NFFO consultation. The MMO expressed a<br />

desire for smaller fishing businesses which may not<br />

be members of the NFFO to be included in the<br />

consultation/collaboration plan.<br />

The NESFC requested that:<br />

• Near shore fishing activities were<br />

accurately identified;<br />

• Consult DECC and DEFRA data regarding<br />

near shore fishing activities;<br />

• Consider undertaking beam trawls as part<br />

of the near shore survey.<br />

Baseline survey to be undertaken and any potential<br />

impacts addressed.<br />

CEFAS did not <strong>com</strong>ment on the proposed<br />

development but requested that a copy of the ES<br />

be distributed to the OCNS team.<br />

3, 5<br />

3, 5<br />

3

2. Proposed <strong>Development</strong><br />

2.1. Introduction<br />

<strong>Breagh</strong> Environmental Statement<br />

Section 2 – Proposed <strong>Development</strong><br />

The <strong>Breagh</strong> gas field is located in Block 42/13 of the Southern North Sea UKCS. RDUK plan<br />

to develop the <strong>Breagh</strong> field and export the gas to shore by the installation of an export<br />

pipeline to the existing Teesside Gas Processing Plant (TGPP). It is proposed to develop the<br />

field by the installation of two offshore platforms, both of which would be Normally<br />

Unmanned Installations (NUI). The project is split into two phases, outlined below. The<br />

offshore elements of Phase 1 (from the offshore NUI location up to the shoreline at the<br />

Mean Low Water Springs (MLWS) are subject to this ES.<br />

Phase 1:<br />

• Installation of a NUI on the west side of the field (<strong>Breagh</strong> A);<br />

• Installation of the export pipeline from <strong>Breagh</strong> A to TGPP and a 3” MEG pipeline and<br />

fibre optic cable from TGPP to <strong>Breagh</strong> A;<br />

• Drilling and connection of seven target wells (12 slot template);<br />

• Commissioning of the infrastructure;<br />

• Production from the wells.<br />

The exact scope and nature of the Phase 2 development will depend on the production<br />

results of Phase 1, ongoing <strong>Breagh</strong> Field appraisal, the surrounding area exploration success<br />

and possible third party business. However, it is currently envisaged to include the<br />

following:<br />

Phase 2:<br />

• Installation of a NUI on the east side of the field (<strong>Breagh</strong> B);<br />

• Drilling and tieback of additional wells;<br />

• Commissioning of the infrastructure;<br />

• Production from the wells.<br />

An overview of the <strong>Breagh</strong> <strong>Development</strong> concept is shown in Figure 2-1.<br />

Figure 2-1 Overview of the <strong>Breagh</strong> development<br />

Onshore Landfall<br />

Offshore<br />

TGPP<br />

Processing<br />

Phase 1<br />

Phase 1 Phase 2<br />

<strong>Breagh</strong> A<br />

NUI<br />

(West)<br />

Phase 2<br />

<strong>Breagh</strong> B<br />

NUI<br />

(East)<br />

2-1

<strong>Breagh</strong> Environmental Statement<br />

Section 2 – Proposed <strong>Development</strong><br />

It is anticipated that gas flow for the Phase I development will peak at 1,588 Msm 3 per year<br />

(annual average). The recoverable reserves for the Phase I development are estimated at<br />

15.4 Bscm. It is expected that no sand will be produced with the gas, however it is<br />

anticipated that condensate and water will be produced with the water content peaking in<br />

2013 before falling for the remainder of the field life.<br />

In summary, the development programme considered within this ES <strong>com</strong>prises:<br />

• Installation of the <strong>Breagh</strong> A NUI;<br />

• Installation of approximately 100km of 20” pipeline, 3” MEG line and fibre optic (FO)<br />

cable between the <strong>Breagh</strong> A NUI and Mean Low Water Springs (MLWS) at Teesside;<br />

• Drilling of 7 production wells;<br />

• Commissioning of the wells and facilities;<br />

• Production of gas and condensate.<br />

This ES addresses those activities regulated by the Department for Energy and Climate<br />

Change under The Offshore Petroleum Production and Pipe-lines (Assessment of<br />

Environmental Effects) Regulations 1999 and the Offshore Petroleum Production and Pipelines<br />

(assessment of Environmental Effects (Amendment) Regulations 2007, that is namely<br />

those associated with the offshore aspects of the <strong>Breagh</strong> development up to MLWS.<br />

2.2. Nature of the Reservoir<br />

The <strong>Breagh</strong> Gas Field is located in the UKCS Southern North Sea gas basin (Block 42/13)<br />

some 50 km from the North East coast of England. The field was discovered by exploration<br />

well 42/13-2 drilled in 60 m of water by Mobil in 1997. The well tested gas from sandstones<br />

of Visean age (Lower Carboniferous) below the Base Permian Unconformity between 7,300<br />

and 7,650 ft TVD. Table 2-1 shows the <strong>Breagh</strong> discovery and appraisal well history.<br />

Table 2-1 Well history in the <strong>Breagh</strong> field<br />

Well Operator Spud Date Well Type Status<br />

42/13-1 BP 29 Jun 1968 Exploration P&A<br />

42/13-2 Mobil 12 Jul 1997 Exploration P&A (discovery well)<br />

42/13-3 Sterling 28 Sep 2007 Appraisal Suspended<br />

42/13-4 Sterling 18 Aug 2008 Exploration/ Appraisal Suspended<br />

42/13-5 Sterling 12 Nov 2008 Appraisal Abandoned<br />

42/13-5z Sterling 24 Dec 2008 Appraisal Suspended<br />

Note: P&A – Plugged and Abandoned<br />

The <strong>Breagh</strong> gas reservoir, shown in Figure 2-2, is a carboniferous reservoir. The structure is a<br />

four way dip enclosure mapped at Base Zechstein. The gas is reservoired within stacked<br />

fluvial channel sands in two discrete intervals. These sands are interpreted to be the<br />

deposits of large scale braided fluvial channels anastomosing from north to south within a<br />

channel belt many kilometres in width. Recoverable reserves from the Phase I development<br />

are estimated at 15.4 Bscm. Table 2-2 gives the reservoir conditions and fluid properties.<br />

Table 2-3 shows the <strong>com</strong>position of the <strong>Breagh</strong> gas.<br />

2-2

Figure 2-2 <strong>Breagh</strong> reservoir depth map<br />

Table 2-2 Initial Reservoir conditions and fluid properties<br />

<strong>Breagh</strong> Environmental Statement<br />

Section 2 – Proposed <strong>Development</strong><br />

Reservoir Property Measurement<br />

Reservoir Fluid Type Gas<br />

Reservoir Pressure @ 7250’ TVDSS 3750 psia<br />

Reservoir Temperature @ 7920’ TVDSS F (88 o C)<br />

Condensate to Gas Ratio 2-2.5 bbl/MMscf<br />

Max CITHP c. 3162 psia<br />

Max FWHT F (≤ 55 o C)<br />

Reservoir Water saturation 30%<br />

Gas SG 0.62<br />

Design Temperature (well <strong>com</strong>pletion) 176°F (80°C)<br />

Design Temperature (platform piping,<br />

risers and pipeline)<br />

149°F (65°C)<br />

2-3

<strong>Breagh</strong> Environmental Statement<br />

Section 2 – Proposed <strong>Development</strong><br />

Table 2-3 Gas Compositional Analysis (Separator Gases from PVT Analysis)<br />

2-4<br />

Gas Compositional Analysis mol %<br />

Well 42/13-2 Well 42/13-3<br />

C1 91.27 92.31<br />

C2 2.10 2.12<br />

C3 0.46 0.49<br />

iC4 0.08 0.07<br />

nC4 0.13 0.12<br />

iC5 0.08 0.04<br />

nC5 0.06 0.04<br />

C6 0.08 0.06<br />

C7 0.17 0.03<br />

C8 0 0.03<br />

C9 0 0.02<br />

C10 0 0.02<br />

C11+ 0 0.04<br />

H2 0 0<br />

CO2 3.08 2.37<br />

N2 2.54 2.23<br />

H2S < 1 ppm < 3 ppm<br />

2.3. <strong>Development</strong> Options<br />

Prior to RDUK be<strong>com</strong>ing operator of the <strong>Breagh</strong> field in mid 2009, the previous operator,<br />

Sterling Resources (UK) Limited, undertook a preliminary evaluation of export routes from<br />

the <strong>Breagh</strong> field. The options under consideration at that time included pipeline routes to<br />

the following locations:<br />

• ConocoPhillips (CMS, Murdoch), approximately 120 km;<br />

• Perenco (Tyne/Trent), approximately 80 km;<br />

• BP Cleeton, approximately 60 km;<br />

• Centrica (Rough), approximately 85 km; and<br />

• Teesside Gas Processing Plant (TGPP), approximately 100 km offshore section and 10<br />

km onshore to the existing facility.<br />

These export options are schematically represented in Figure 2-3 below.

Figure 2-3 <strong>Breagh</strong> Export Route Options<br />

<strong>Breagh</strong> Environmental Statement<br />

Section 2 – Proposed <strong>Development</strong><br />

Initial requests for host infrastructure service were sent out covering all options in the area<br />

in May 2008 (by Sterling Resources). In the case of ConocoPhillips (CMS), Perenco<br />

(Tyne/Trent) and Centrica (Rough) the response indicated that either capacity was not<br />

available or that capacity would have to be bid for against other fields.<br />

BP made an indicative offer of capacity at Dimlington terminal with access via Cleeton<br />

platform or via a hot-tap into the Cleeton-Dimlington pipeline (nominally at 1 km from the<br />

Cleeton facility). Teesside Gas Processing Plant (TGPP) offered capacity in their terminal that<br />

was being made available by the end of 2008 following the end of an existing contract.<br />

Subsequent to the initial exercise in 2008, RDUK in its role as Operator of the <strong>Breagh</strong><br />

development instigated a <strong>com</strong>petitive bidding process in September 2009 to identify the<br />

optimal export route for the <strong>Breagh</strong> Field. With consideration of the responses to the 2008<br />

process of approaching hosts, a revised Statement of Requirements was issued to three<br />

prospective hosts in September 2009 with a request for responses by the end of October<br />

2009. This process recognised the potential for additional equity gas from the Greater<br />

<strong>Breagh</strong> Area and third party business.<br />

The three routes under evaluation were:<br />

• Teesside Gas Processing Plant (TGPP);<br />

• Central Area Transmission System (CATS) terminal in Teesside (adjacent to the<br />

TGPP), who were not approached in the 2008 process; and<br />

• Southern North Sea Pipeline System (Dimlington).<br />

2-5

<strong>Breagh</strong> Environmental Statement<br />

Section 2 – Proposed <strong>Development</strong><br />

RDUK received processing offers from TGPP and Dimlington. The CATS (working through the<br />

substitute <strong>com</strong>mercial operator – BG) did not respond to the request.<br />

The main uncertainties associated with the Cleeton/Dimlington options related to (i)<br />

throughput capacity, i.e. modifications required to the Dimlington facility in order to achieve<br />

the production rates from <strong>Breagh</strong>, (ii) hydrate/corrosion inhibitor issues, i.e. delivery of<br />

these production chemicals in the volumes required to the <strong>Breagh</strong> facility, and (iii) offshore<br />

pipeline pressure protection (it was considered possible that a HIPPS would be required to<br />

protect the Southern North Sea Pipeline System from the high reservoir pressure at <strong>Breagh</strong>).<br />

In <strong>com</strong>parison, the options for dealing with these issues were relatively well defined within<br />

the TGPP option. Additionally, TGPP was able to offer up to 400 mmscfd throughput<br />

capacity versus a maximum rate of 200 mmscfd at Dimlington.<br />

The technical uncertainties associated with the Dimlington option coupled with the lower<br />

throughput rates meant that TGPP became a favoured option for both technical and<br />

economic reasons, particularly with one of the key aspects of the bidding process being the<br />

potential for additional equity gas from the Great <strong>Breagh</strong> Area and third party business.<br />

As such, export to TGPP via landfall at Teesside was the selected option.<br />

Subsequent to the selection of the TGPP export route, various sub-options were examined<br />

to identify the preferred route, pipeline installation method and type of NUI. A breakdown<br />

of each of these sub-options with a brief justification for selection or rejection is given<br />

below.<br />

2-6

<strong>Breagh</strong> Environmental Statement<br />

Section 2 – Proposed <strong>Development</strong><br />

Preferred Route<br />

South of the CATS pipeline No requirement for crossing the CATS pipeline and associated<br />

<strong>com</strong>plications.<br />

Minimise length of pipeline.<br />

Minimise impact on windfarm.<br />

North of the CATS pipeline Avoid static fishing grounds.<br />

Avoid rocky out crop south of the CATS pipeline.<br />

Avoid harder substrate which impedes trenching.<br />

20” Export Pipeline Installation<br />

Trench and bury the<br />

pipeline along the entire<br />

route<br />

Coat the line with concrete<br />

to add stability and lay on<br />

the seabed (with trenching<br />

along the final 12 km to<br />

shore) with a fishing<br />

friendly design.<br />

Adds stability to the pipeline and reduces the required<br />

concrete thickness. Would increase the installation duration<br />

and number of vessels required.<br />

Increase area of seabed disturbed during the installation.<br />

Removes the requirement for trenching the majority of the<br />

line.<br />

Minimises the number of vessels required for the installation.<br />

Minimises the impact on the seabed during the installation.<br />

Type of NUI<br />

Sea Harvester design The <strong>Breagh</strong> topsides would be larger and heavier than any currently<br />

installed to date. Similarly it would be in water depths greater than<br />

that of any currently installed to date - all of which would add<br />

<strong>com</strong>plications to the design. Due to the heavy topsides a heavy<br />

lifting vessel would be required for the installation.<br />

Standard design Likely to be heavier than the Sea Harvester design. Fully proven<br />

design for similar applications in the North Sea. Due to the heavy<br />

topsides a heavy lifting vessel would be required for the<br />

installation.<br />

Self-installing design No requirement for the heavy lifting vessel and requires minimal<br />

hook-up.<br />

The following options were selected for the development of the <strong>Breagh</strong> field:<br />

• Preferred Route: The route south of the CATs pipeline is preferred as it eliminates<br />

the need to cross the CATs pipeline and reduces the overall length of the pipeline;<br />

• Pipeline Installation: Surface lay pipeline (20”) to minimise the duration of the<br />

installation period and the impact on the seabed. The 20” pipeline will be trenched<br />

and buried from 12 km offshore to the landfall. Trench and bury the 3” MEG<br />

pipeline and fibre optic cable along their entire length;<br />

• Type of NUI: Standard design NUIs to ensure that there is sufficient space available<br />

for the required operations.<br />

2.4. Schedule of Activities<br />

Installation activities are scheduled between Q4 2010 and Q1 2012 with the first gas in Q2<br />

2012. The schedule of activities is shown in Figure 2-4.<br />

2-7