Breagh Development - RWE.com

Breagh Development - RWE.com

Breagh Development - RWE.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Breagh</strong> Environmental Statement<br />

Section 2 – Proposed <strong>Development</strong><br />

The HLV will moor at the installation site using up to 8 anchors which will be managed by up<br />

to two anchor handling vessels. The template will be lifted from the barge and lowered into<br />

position over the pre drilled wells and the two docking piles installed. After the docking piles<br />

have been installed the template will be recovered to the surface.<br />

The jacket will then be lifted from the barge and lowered into position over the pre-drilled<br />

wells guided by the docking piles. Each leg of the jacket will be secured to the seabed. A<br />

platform foundation assessment has been undertaken to identify the most suitable method<br />

(Senergy Ltd, 2008). Four methods were considered; pile driven, drilled and grouted piles,<br />

gravity based structure (GBS) and suction piles. Of these methods suction piles are not<br />

considered feasible due to the presence of chalk as water ingress through fractures in the<br />

chalk make it difficult to generate enough suction in the pile to penetrate it through the hard<br />

chalk. Difficulties associated with drilled and grouted piles and GBS lead to driven piles<br />

being the preferred option with up to 8 piles being required as a worst case option. A site<br />

specific geotechnical survey and test programme has been undertaken by Fugro in April<br />

2010 to establish the seabed strength.<br />

The HLV will <strong>com</strong>mence piling activities which are expected to last up to a maximum of 10<br />

days. Piling activities will be initiated using the soft start method to minimise impact upon<br />

cetaceans in the area. An Marine Mammal Observer (MMO) will be present during piling<br />

activities. Once the piles are driven to a sufficient depth to secure the jacket to the seabed<br />

the piles will be grouted to the jacket sleeves. The size of the piles which will be required to<br />

secure the <strong>Breagh</strong> A NUI to the seabed have not been defined but are not likely to be<br />

greater than 2.44 m in diameter.<br />

Upon <strong>com</strong>pletion of piling the HLV will lift the topsides into position on the jacket and the<br />

topsides welded to the top of the jacket legs. In total, installation activities will be<br />

approximately 44 days. Table 2-5 details installation vessel requirements assuming no<br />

weather delays.<br />

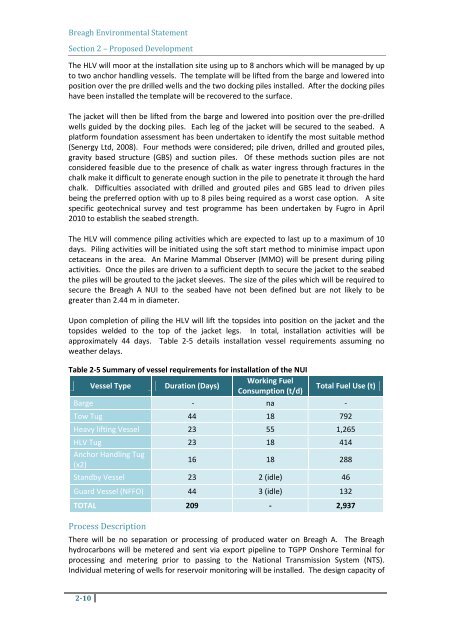

Table 2-5 Summary of vessel requirements for installation of the NUI<br />

Vessel Type Duration (Days)<br />

Working Fuel<br />

Consumption (t/d)<br />

Total Fuel Use (t)<br />

Barge - na -<br />

Tow Tug 44 18 792<br />

Heavy lifting Vessel 23 55 1,265<br />

HLV Tug 23 18 414<br />

Anchor Handling Tug<br />

(x2)<br />

16 18 288<br />

Standby Vessel 23 2 (idle) 46<br />

Guard Vessel (NFFO) 44 3 (idle) 132<br />

TOTAL 209 - 2,937<br />

Process Description<br />

There will be no separation or processing of produced water on <strong>Breagh</strong> A. The <strong>Breagh</strong><br />

hydrocarbons will be metered and sent via export pipeline to TGPP Onshore Terminal for<br />

processing and metering prior to passing to the National Transmission System (NTS).<br />

Individual metering of wells for reservoir monitoring will be installed. The design capacity of<br />

2-10