STEEL GUIDE - BlueScope Distribution

STEEL GUIDE - BlueScope Distribution

STEEL GUIDE - BlueScope Distribution

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

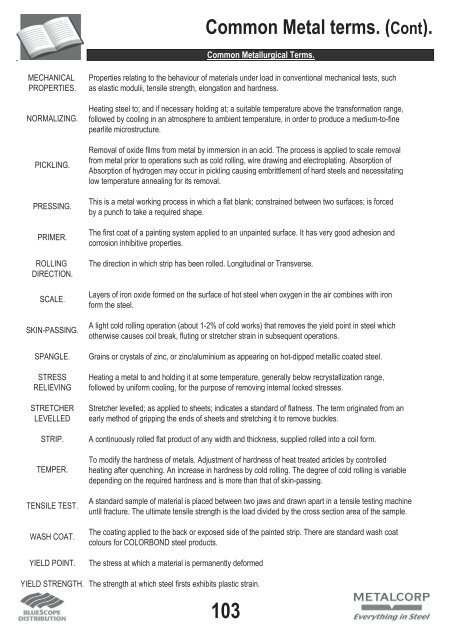

Common Metal terms. (Cont).<br />

MECHANICAL Properties relating to the behaviour of materials under load in conventional mechanical tests, such<br />

PROPERTIES. as elastic modulii, tensile strength, elongation and hardness.<br />

NORMALIZING.<br />

PICKLING.<br />

PRESSING.<br />

PRIMER.<br />

Heating steel to; and if necessary holding at; a suitable temperature above the transformation range,<br />

followed by cooling in an atmosphere to ambient temperature, in order to produce a medium-to-fine<br />

pearlite microstructure.<br />

Removal of oxide films from metal by immersion in an acid. The process is applied to scale removal<br />

from metal prior to operations such as cold rolling, wire drawing and electroplating. Absorption of<br />

Absorption of hydrogen may occur in pickling causing embrittlement of hard steels and necessitating<br />

low temperature annealing for its removal.<br />

This is a metal working process in which a flat blank; constrained between two surfaces; is forced<br />

by a punch to take a required shape.<br />

The first coat of a painting system applied to an unpainted surface. It has very good adhesion and<br />

corrosion inhibitive properties.<br />

ROLLING The direction in which strip has been rolled. Longitudinal or Transverse.<br />

DIRECTION.<br />

SCALE.<br />

SKIN-PASSING.<br />

Layers of iron oxide formed on the surface of hot steel when oxygen in the air combines with iron<br />

form the steel.<br />

A light cold rolling operation (about 1-2% of cold works) that removes the yield point in steel which<br />

otherwise causes coil break, fluting or stretcher strain in subsequent operations.<br />

SPANGLE. Grains or crystals of zinc, or zinc/aluminium as appearing on hot-dipped metallic coated steel.<br />

STRESS Heating a metal to and holding it at some temperature, generally below recrystallization range,<br />

RELIEVING followed by uniform cooling, for the purpose of removing internal locked stresses.<br />

STRETCHER Stretcher levelled; as applied to sheets; indicates a standard of flatness. The term originated from an<br />

LEVELLED early method of gripping the ends of sheets and stretching it to remove buckles.<br />

STRIP. A continuously rolled flat product of any width and thickness, supplied rolled into a coil form.<br />

TEMPER.<br />

TENSILE TEST.<br />

WASH COAT.<br />

To modify the hardness of metals. Adjustment of hardness of heat treated articles by controlled<br />

heating after quenching. An increase in hardness by cold rolling. The degree of cold rolling is variable<br />

depending on the required hardness and is more than that of skin-passing.<br />

A standard sample of material is placed between two jaws and drawn apart in a tensile testing machine<br />

until fracture. The ultimate tensile strength is the load divided by the cross section area of the sample.<br />

The coating applied to the back or exposed side of the painted strip. There are standard wash coat<br />

colours for COLORBOND steel products.<br />

YIELD POINT. The stress at which a material is permanently deformed<br />

YIELD STRENGTH. The strength at which steel firsts exhibits plastic strain.<br />

Common Metallurgical Terms.<br />

103