Brochure Minerals & Mining (PDF, 25.2MB) - Thyssenkrupp

Brochure Minerals & Mining (PDF, 25.2MB) - Thyssenkrupp

Brochure Minerals & Mining (PDF, 25.2MB) - Thyssenkrupp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THINKING BIG<br />

Given the dimensions involved in the<br />

minerals & mining industry, our slewing<br />

bearings offer key advantages. We are<br />

one of the few companies worldwide<br />

capable of producing one-piece slewing<br />

bearings in diameters up to 8,000 mm.<br />

ThyssenKrupp companies with<br />

solutions in this area:<br />

ThyssenKrupp Steel Europe<br />

Rothe Erde<br />

More information is available<br />

in the contacts flyer.<br />

ThyssenKrupp manufactures high-quality components for the minerals & mining<br />

industry. Our products are tested under the toughest conditions and constantly<br />

improved by our engineers to ensure their efficiency, safety and reliability.<br />

Slewing bearings and rings<br />

ThyssenKrupp is world market leader for slewing<br />

bearings. Our products can be found in excavators,<br />

bucket wheel loaders, stackers/spreaders and<br />

ship loaders/unloaders. Their compact design with<br />

integrated sealing system permits an excellent<br />

performance-to-weight ratio. At the same time,<br />

our slewing bearings are easy to install and service<br />

and offer cost-efficient solutions for bearings in<br />

com panion structures.<br />

We supply seamless rolled rings for a range of<br />

applications, from simple as-rolled parts to processed,<br />

ready-to-install components.<br />

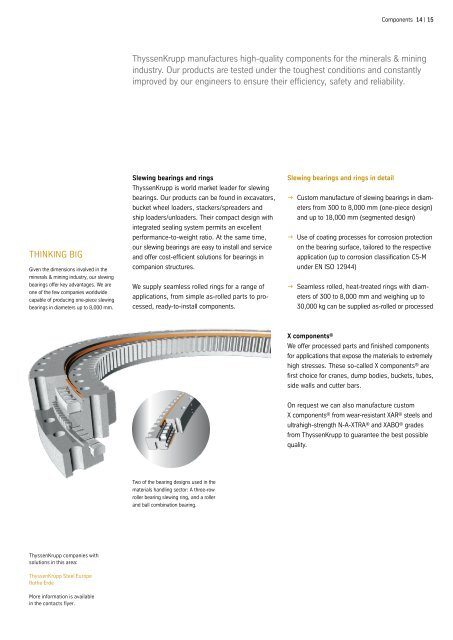

Two of the bearing designs used in the<br />

materials handling sector: A three-row<br />

roller bearing slewing ring, and a roller<br />

and ball combination bearing.<br />

Slewing bearings and rings in detail<br />

Components 14 | 15<br />

g Custom manufacture of slewing bearings in dia meters<br />

from 300 to 8,000 mm (one-piece design)<br />

and up to 18,000 mm (segmented design)<br />

g Use of coating processes for corrosion protection<br />

on the bearing surface, tailored to the respective<br />

application (up to corrosion classification C5-M<br />

under EN ISO 12944)<br />

g Seamless rolled, heat-treated rings with dia meters<br />

of 300 to 8,000 mm and weighing up to<br />

30,000 kg can be supplied as-rolled or processed<br />

X components ®<br />

We offer processed parts and finished components<br />

for applications that expose the materials to extremely<br />

high stresses. These so-called X components ® are<br />

first choice for cranes, dump bodies, buckets, tubes,<br />

side walls and cutter bars.<br />

On request we can also manufacture custom<br />

X components ® from wear-resistant XAR ® steels and<br />

ultrahigh-strength N-A-XTRA ® and XABO ® grades<br />

from ThyssenKrupp to guarantee the best possible<br />

quality.