Brochure Minerals & Mining (PDF, 25.2MB) - Thyssenkrupp

Brochure Minerals & Mining (PDF, 25.2MB) - Thyssenkrupp

Brochure Minerals & Mining (PDF, 25.2MB) - Thyssenkrupp

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ThyssenKrupp is a full-line supplier of machinery and equipment<br />

for bulk material handling. For decades we have been<br />

planning and delivering advanced turnkey systems that help<br />

reduce both costs and environmental impact. We supply<br />

complete solutions for transporting and handling raw materials<br />

in stockyards, bulk material distribution centers, port<br />

terminals and processing plants in the coal and ore industries.<br />

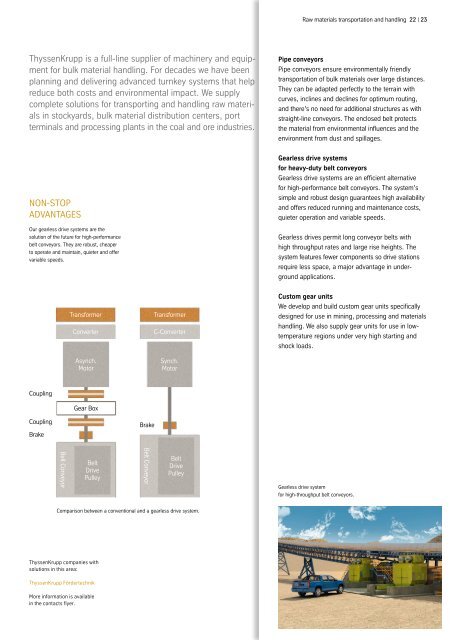

NON-STOP<br />

ADVANTAGES<br />

Our gearless drive systems are the<br />

solution of the future for high-performance<br />

belt conveyors. They are robust, cheaper<br />

to operate and maintain, quieter and offer<br />

variable speeds.<br />

Coupling<br />

Coupling<br />

Brake<br />

Belt Conveyor<br />

Transformer<br />

Converter<br />

Asynch.<br />

Motor<br />

Gear Box<br />

Belt<br />

Drive<br />

Pulley<br />

ThyssenKrupp companies with<br />

solutions in this area:<br />

ThyssenKrupp Fördertechnik<br />

More information is available<br />

in the contacts flyer.<br />

Brake<br />

Belt Conveyor<br />

Transformer<br />

C-Converter<br />

Synch.<br />

Motor<br />

Belt<br />

Drive<br />

Pulley<br />

Comparison between a conventional and a gearless drive system.<br />

Raw materials transportation and handling 22 | 23<br />

Pipe Stockyard conveyors and port handling systems<br />

Pipe for conveyors bulk materials ensure environmentally friendly<br />

transportation We are an experienced of bulk materials and reliable over large partner distances. when<br />

They it comes can be to adapted designing perfectly and building to the terrain complete with<br />

curves, systems: inclines Handling and declines equipment for optimum for loading routing, and<br />

and unloading there’s no ships need and for additional trains; stockyard structures equipment as with<br />

straight-line for stacking conveyors. and reclaiming The enclosed raw materials; belt protects and<br />

the linked material by from belt conveyors environmental and influences intelligent and control the<br />

environment systems. Our from stockyard dust and technologies spillages. are used<br />

in the homogenization, blending, distribution and<br />

Gearless stockpiling drive of systems raw materials.<br />

for heavy-duty belt conveyors<br />

Gearless Bucket-wheel drive systems stacker/reclaimers<br />

are an efficient alternative<br />

for Combined high-performance bucket-wheel belt conveyors. stacker/reclaimers The system’s allow<br />

simple stacking and robust and reclaiming design guarantees of large amounts high availability of bulk<br />

and material offers reduced in stockyards. running The and machines maintenance are fully costs,<br />

quieter automatable, operation with and corresponding variable speeds. monitoring<br />

equipment, unmanned operation and manage -<br />

Gearless ment of drives raw material permit long levels conveyor in the stockyard belts with are<br />

high possible, throughput saving rates money and large and time. rise heights. The<br />

system features fewer components so drive stations<br />

require With less their space, slewing a major and luffing advantage capabilities, in under- the<br />

ground machines applications. can stack or reclaim individual sections<br />

of the pile. The material is fed to further handling<br />

Custom facilities gear in units a very even flow, making it possible to<br />

We optimize develop and the fill build cross-section custom gear of units downstream specifically belt<br />

designed systems. for use in mining, processing and materials<br />

handling. We also supply gear units for use in lowtemperature<br />

Ship loaders regions with under fully very enclosed high starting conveyors and<br />

shock Eco loads. ship loaders from ThyssenKrupp transfer bulk<br />

materials from terminal to ship’s hold through<br />

completely enclosed conveyor systems. The booms<br />

are designed in the form of a large tube, inside<br />

which are the conveyors and service walkways.<br />

The enclosed design prevents contamination of<br />

port loading zones.<br />

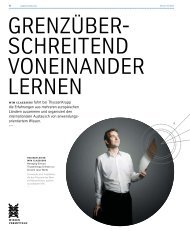

Gearless drive system<br />

for high-throughput belt conveyors.