Brochure Minerals & Mining (PDF, 25.2MB) - Thyssenkrupp

Brochure Minerals & Mining (PDF, 25.2MB) - Thyssenkrupp

Brochure Minerals & Mining (PDF, 25.2MB) - Thyssenkrupp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Conveying and classifying equipment<br />

In addition to crushing equipment we can supply<br />

conveying and classifying equipment to build a<br />

complete plant. On request, electrical and automation<br />

systems can be supplied in a package with<br />

mechanical, hydraulic and steel work.<br />

Grinding and processing equipment<br />

Grinding equipment from ThyssenKrupp Polysius is<br />

used in the minerals & mining industry throughout<br />

the world. The reasons for this are low operating<br />

costs, robust design and outstanding availability,<br />

even when grinding extremely abrasive materials.<br />

Our wide range of different mill types offers the<br />

right system for every job.<br />

POLYCOM ® high-pressure grinding rolls have proven<br />

extremely successful in mineral grinding. 60% of<br />

all high-pressure grinding rolls used in the minerals<br />

& mining industry are made by ThyssenKrupp,<br />

making us the global market leader. POLYCOM ® is<br />

suitable for grinding copper ore, gold ore, iron ore,<br />

diamond ore and platinum ore.<br />

For other applications we supply roller mills as well<br />

as autogenous and ball mills for wet and dry<br />

grinding. Our solutions for the pyroprocessing of<br />

diverse materials combine proven processing and<br />

equipment know-how. The range includes rotary<br />

kilns, preheaters, multiple hearth furnaces and<br />

high-temperature shaft kilns, as well as lime shaft<br />

kilns.<br />

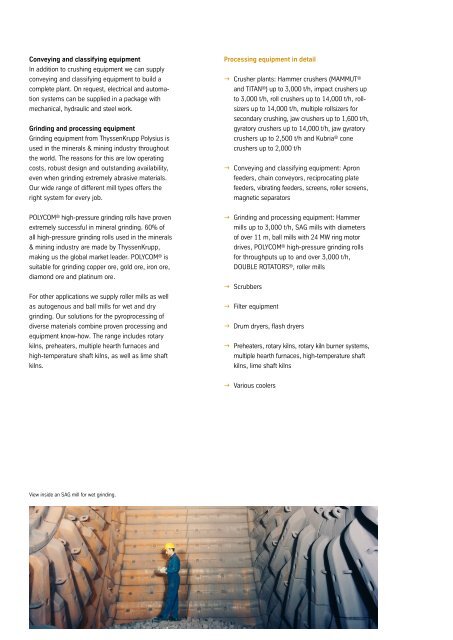

View inside an SAG mill for wet grinding.<br />

Processing equipment in detail<br />

g Crusher plants: Hammer crushers (MAMMUT ®<br />

and TITAN ® ) up to 3,000 t/h, impact crushers up<br />

to 3,000 t/h, roll crushers up to 14,000 t/h, rollsizers<br />

up to 14,000 t/h, multiple rollsizers for<br />

secondary crushing, jaw crushers up to 1,600 t/h,<br />

gyratory crushers up to 14,000 t/h, jaw gyratory<br />

crushers up to 2,500 t/h and Kubria ® cone<br />

crushers up to 2,000 t/h<br />

g Conveying and classifying equipment: Apron<br />

feeders, chain conveyors, reciprocating plate<br />

feeders, vibrating feeders, screens, roller screens,<br />

magnetic separators<br />

g Grinding and processing equipment: Hammer<br />

mills up to 3,000 t/h, SAG mills with diameters<br />

of over 11 m, ball mills with 24 MW ring motor<br />

drives, POLYCOM ® high-pressure grinding rolls<br />

for throughputs up to and over 3,000 t/h,<br />

DOUBLE ROTATORS ® , roller mills<br />

g Scrubbers<br />

g Filter equipment<br />

g Drum dryers, flash dryers<br />

g Preheaters, rotary kilns, rotary kiln burner systems,<br />

multiple hearth furnaces, high-temperature shaft<br />

kilns, lime shaft kilns<br />

g Various coolers