41119_Niro jubilaeumsbog_blok_uk - GEA Niro

41119_Niro jubilaeumsbog_blok_uk - GEA Niro

41119_Niro jubilaeumsbog_blok_uk - GEA Niro

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

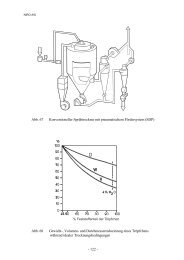

Greater environmental demands are obeyed<br />

In the course of the 1980s, a development<br />

towards increased protection of the environment<br />

and thereby better cleaning of the exhaust<br />

air from <strong>Niro</strong>’s plants is begun. Wet cleaning<br />

methods are used in the beginning, but new<br />

demands on water quality make the transition to<br />

dry cleaning practical. An independent bag filter<br />

technology is developed by <strong>Niro</strong> and becomes<br />

an important part of the delivery program.<br />

Increased competition<br />

Globalization, which starts in the early<br />

1990’s, brings increased competition,<br />

which is countered by further standardization<br />

of components and plant concepts.<br />

With increased interest in <strong>Niro</strong>’s plants,<br />

especially from the Far East and China,<br />

local manufacturing starts to further<br />

reduce costs.<br />

Reduction of dust<br />

From the 1980s, the demand by product manufacturers<br />

for reduced dust when handling<br />

powder increases. <strong>Niro</strong>’s customers want<br />

plants that manufacture less dusty products.<br />

Af Jens Thousig Møller<br />

This applies to a wide spectrum of powders,<br />

such as dyestuffs for textiles, chemicals for<br />

agriculture and wine growing, and additives<br />

to rubber in shoes and car tires etc.