Biomass as Fuel in Small Boilers (PDF 6.4 - APO Asian Productivity ...

Biomass as Fuel in Small Boilers (PDF 6.4 - APO Asian Productivity ...

Biomass as Fuel in Small Boilers (PDF 6.4 - APO Asian Productivity ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Biom<strong>as</strong>s</strong> Preparation, Storage, Hand<strong>in</strong>g, and Conversion Technologies<br />

First is the ability to burn a variety of different fuels without affect<strong>in</strong>g<br />

performance. Second is the ability to <strong>in</strong>troduce chemical reactants <strong>in</strong>to the<br />

fluidized bed to remove possible pollutants. In FBC plants burn<strong>in</strong>g coal, for<br />

example, limestone can be added to capture sulphur and prevent its rele<strong>as</strong>e to<br />

the atmosphere <strong>as</strong> sulphur dioxide. <strong>Biom<strong>as</strong>s</strong> tends to conta<strong>in</strong> less sulphur than<br />

coal, so this strategy may not be necessary <strong>in</strong> a biom<strong>as</strong>s plant.<br />

A fluidized bed boiler can burn wood with up to 55% moisture. One<br />

specialized application is <strong>in</strong> plants designed to burn chicken litter, the refuse<br />

from the <strong>in</strong>tensive farm<strong>in</strong>g of poultry.<br />

Of the five different types of combustion technologies discussed above, the<br />

FBC technology is best suited for a range of small and medium-scale boilers (say<br />

more than 2 T/hr steam generation). With technological advancements the<br />

FBC boilers give efficiency of <strong>as</strong> high <strong>as</strong> 80–82% and can be used for a wide<br />

variety of fuels.<br />

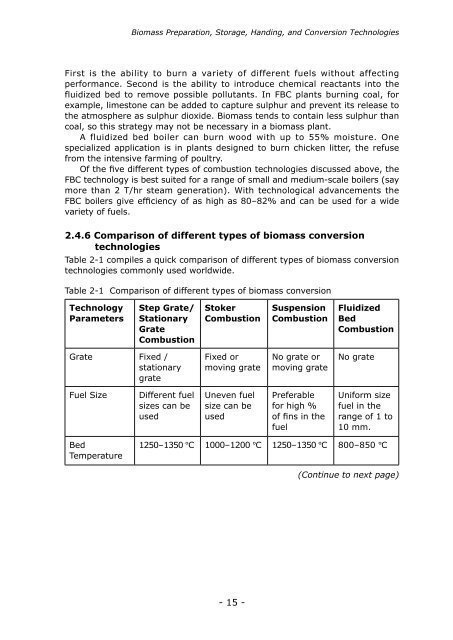

2.4.6 Comparison of different types of biom<strong>as</strong>s conversion<br />

technologies<br />

Table 2-1 compiles a quick comparison of different types of biom<strong>as</strong>s conversion<br />

technologies commonly used worldwide.<br />

Table 2-1 Comparison of different types of biom<strong>as</strong>s conversion<br />

Technology<br />

Parameters<br />

Step Grate/<br />

Stationary<br />

Grate<br />

Combustion<br />

Grate Fixed /<br />

stationary<br />

grate<br />

<strong>Fuel</strong> Size Different fuel<br />

sizes can be<br />

used<br />

Bed<br />

Temperature<br />

Stoker<br />

Combustion<br />

Fixed or<br />

mov<strong>in</strong>g grate<br />

Uneven fuel<br />

size can be<br />

used<br />

- 15 -<br />

Suspension<br />

Combustion<br />

No grate or<br />

mov<strong>in</strong>g grate<br />

Preferable<br />

for high %<br />

of f<strong>in</strong>s <strong>in</strong> the<br />

fuel<br />

Fluidized<br />

Bed<br />

Combustion<br />

No grate<br />

Uniform size<br />

fuel <strong>in</strong> the<br />

range of 1 to<br />

10 mm.<br />

1250–1350 ºC 1000–1200 ºC 1250–1350 ºC 800–850 ºC<br />

(Cont<strong>in</strong>ue to next page)