Biomass as Fuel in Small Boilers (PDF 6.4 - APO Asian Productivity ...

Biomass as Fuel in Small Boilers (PDF 6.4 - APO Asian Productivity ...

Biomass as Fuel in Small Boilers (PDF 6.4 - APO Asian Productivity ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

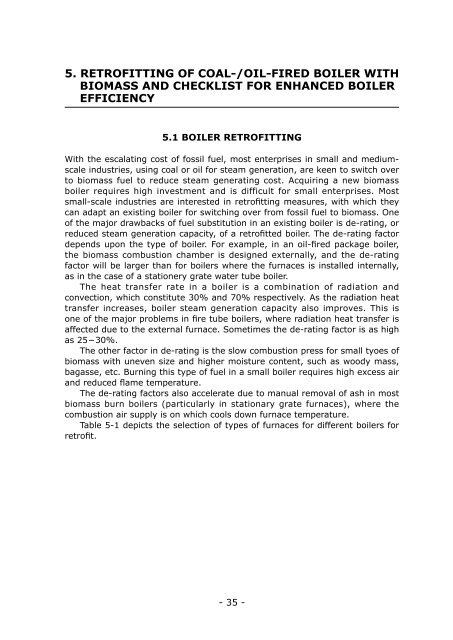

5. RETROFITTING OF COAL-/OIL-FIRED BOILER WITH<br />

BIOMASS AND CHECKLIST FOR ENHANCED BOILER<br />

EFFICIENCY<br />

5.1 BOILER RETROFITTING<br />

With the escalat<strong>in</strong>g cost of fossil fuel, most enterprises <strong>in</strong> small and mediumscale<br />

<strong>in</strong>dustries, us<strong>in</strong>g coal or oil for steam generation, are keen to switch over<br />

to biom<strong>as</strong>s fuel to reduce steam generat<strong>in</strong>g cost. Acquir<strong>in</strong>g a new biom<strong>as</strong>s<br />

boiler requires high <strong>in</strong>vestment and is difficult for small enterprises. Most<br />

small-scale <strong>in</strong>dustries are <strong>in</strong>terested <strong>in</strong> retrofitt<strong>in</strong>g me<strong>as</strong>ures, with which they<br />

can adapt an exist<strong>in</strong>g boiler for switch<strong>in</strong>g over from fossil fuel to biom<strong>as</strong>s. One<br />

of the major drawbacks of fuel substitution <strong>in</strong> an exist<strong>in</strong>g boiler is de-rat<strong>in</strong>g, or<br />

reduced steam generation capacity, of a retrofitted boiler. The de-rat<strong>in</strong>g factor<br />

depends upon the type of boiler. For example, <strong>in</strong> an oil-fired package boiler,<br />

the biom<strong>as</strong>s combustion chamber is designed externally, and the de-rat<strong>in</strong>g<br />

factor will be larger than for boilers where the furnaces is <strong>in</strong>stalled <strong>in</strong>ternally,<br />

<strong>as</strong> <strong>in</strong> the c<strong>as</strong>e of a stationery grate water tube boiler.<br />

The heat transfer rate <strong>in</strong> a boiler is a comb<strong>in</strong>ation of radiation and<br />

convection, which constitute 30% and 70% respectively. As the radiation heat<br />

transfer <strong>in</strong>cre<strong>as</strong>es, boiler steam generation capacity also improves. This is<br />

one of the major problems <strong>in</strong> fire tube boilers, where radiation heat transfer is<br />

affected due to the external furnace. Sometimes the de-rat<strong>in</strong>g factor is <strong>as</strong> high<br />

<strong>as</strong> 25-30%.<br />

The other factor <strong>in</strong> de-rat<strong>in</strong>g is the slow combustion press for small tyoes of<br />

biom<strong>as</strong>s with uneven size and higher moisture content, such <strong>as</strong> woody m<strong>as</strong>s,<br />

bag<strong>as</strong>se, etc. Burn<strong>in</strong>g this type of fuel <strong>in</strong> a small boiler requires high excess air<br />

and reduced flame temperature.<br />

The de-rat<strong>in</strong>g factors also accelerate due to manual removal of <strong>as</strong>h <strong>in</strong> most<br />

biom<strong>as</strong>s burn boilers (particularly <strong>in</strong> stationary grate furnaces), where the<br />

combustion air supply is on which cools down furnace temperature.<br />

Table 5-1 depicts the selection of types of furnaces for different boilers for<br />

retrofit.<br />

- 35 -