Biomass as Fuel in Small Boilers (PDF 6.4 - APO Asian Productivity ...

Biomass as Fuel in Small Boilers (PDF 6.4 - APO Asian Productivity ...

Biomass as Fuel in Small Boilers (PDF 6.4 - APO Asian Productivity ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Biom<strong>as</strong>s</strong>-b<strong>as</strong>ed Fluidized Bed Combustion (FBS) <strong>Boilers</strong><br />

3.5 BOILER BLOW-DOWN<br />

When water is boiled and steam is generated, dissolved solids that were<br />

conta<strong>in</strong>ed <strong>in</strong> the water rema<strong>in</strong> <strong>in</strong> the boiler. After a period of time their<br />

solubility <strong>in</strong> water is exceeded and they are deposited from the solution.<br />

Above certa<strong>in</strong> levels of concentration, these solids encourage foam<strong>in</strong>g and<br />

cause carryover of water <strong>in</strong>to steam. The deposit also leads to scale formation<br />

<strong>in</strong> boiler tubes and reduces efficiency, localized heat<strong>in</strong>g, and tube failure.<br />

It is therefore necessary to control the level of concentration of the solids and<br />

this can be achieved by the process known <strong>as</strong> blow-down, <strong>in</strong> which a certa<strong>in</strong><br />

amount of water from the boiler is blown off. The maximum amount of total<br />

dissolved solids (TDS) concentration permissible <strong>in</strong> various types of boilers is<br />

shown <strong>in</strong> Table 3-3.<br />

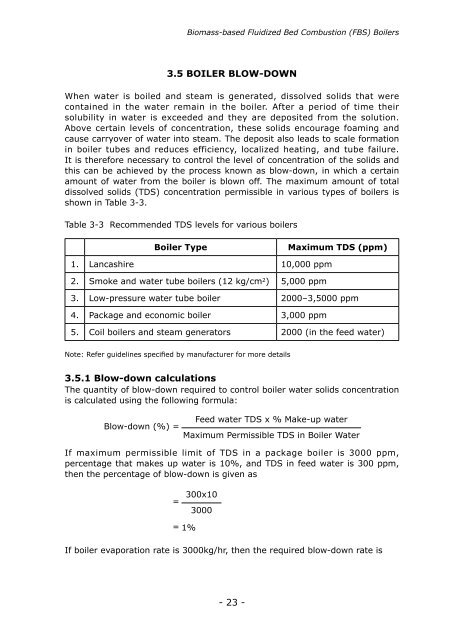

Table 3-3 Recommended TDS levels for various boilers<br />

Boiler Type Maximum TDS (ppm)<br />

1. Lanc<strong>as</strong>hire 10,000 ppm<br />

2. Smoke and water tube boilers (12 kg/cm 2 ) 5,000 ppm<br />

3. Low-pressure water tube boiler 2000–3,5000 ppm<br />

4. Package and economic boiler 3,000 ppm<br />

5. Coil boilers and steam generators 2000 (<strong>in</strong> the feed water)<br />

Note: Refer guidel<strong>in</strong>es specified by manufacturer for more details<br />

3.5.1 Blow-down calculations<br />

The quantity of blow-down required to control boiler water solids concentration<br />

is calculated us<strong>in</strong>g the follow<strong>in</strong>g formula:<br />

Blow-down (%) =<br />

If maximum permissible limit of TDS <strong>in</strong> a package boiler is 3000 ppm,<br />

percentage that makes up water is 10%, and TDS <strong>in</strong> feed water is 300 ppm,<br />

then the percentage of blow-down is given <strong>as</strong><br />

=<br />

= 1%<br />

Feed water TDS x % Make-up water<br />

Maximum Permissible TDS <strong>in</strong> Boiler Water<br />

300x10<br />

3000<br />

If boiler evaporation rate is 3000kg/hr, then the required blow-down rate is<br />

- 23 -