Biomass as Fuel in Small Boilers (PDF 6.4 - APO Asian Productivity ...

Biomass as Fuel in Small Boilers (PDF 6.4 - APO Asian Productivity ...

Biomass as Fuel in Small Boilers (PDF 6.4 - APO Asian Productivity ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Biom<strong>as</strong>s</strong> <strong>as</strong> <strong>Fuel</strong> <strong>in</strong> <strong>Small</strong> <strong>Boilers</strong><br />

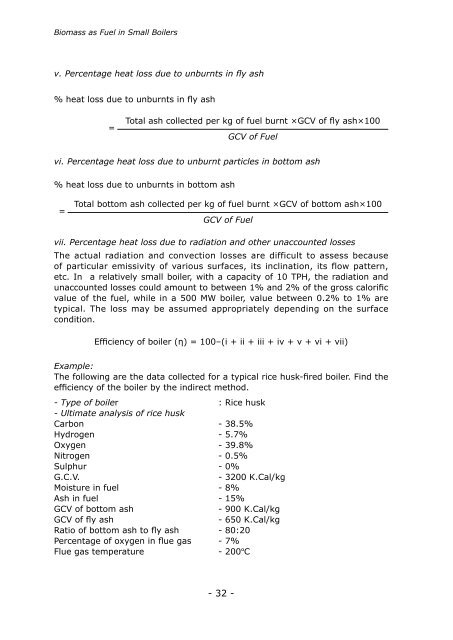

v. Percentage heat loss due to unburnts <strong>in</strong> fly <strong>as</strong>h<br />

% heat loss due to unburnts <strong>in</strong> fly <strong>as</strong>h<br />

vi. Percentage heat loss due to unburnt particles <strong>in</strong> bottom <strong>as</strong>h<br />

% heat loss due to unburnts <strong>in</strong> bottom <strong>as</strong>h<br />

= Total bottom <strong>as</strong>h collected per kg of fuel burnt ×GCV of bottom <strong>as</strong>h×100<br />

= Total <strong>as</strong>h collected per kg of fuel burnt ×GCV of fly <strong>as</strong>h×100<br />

GCV of <strong>Fuel</strong><br />

vii. Percentage heat loss due to radiation and other unaccounted losses<br />

The actual radiation and convection losses are difficult to <strong>as</strong>sess because<br />

of particular emissivity of various surfaces, its <strong>in</strong>cl<strong>in</strong>ation, its flow pattern,<br />

etc. In a relatively small boiler, with a capacity of 10 TPH, the radiation and<br />

unaccounted losses could amount to between 1% and 2% of the gross calorific<br />

value of the fuel, while <strong>in</strong> a 500 MW boiler, value between 0.2% to 1% are<br />

typical. The loss may be <strong>as</strong>sumed appropriately depend<strong>in</strong>g on the surface<br />

condition.<br />

Efficiency of boiler (η) = 100–(i + ii + iii + iv + v + vi + vii)<br />

Example:<br />

The follow<strong>in</strong>g are the data collected for a typical rice husk-fired boiler. F<strong>in</strong>d the<br />

efficiency of the boiler by the <strong>in</strong>direct method.<br />

- Type of boiler : Rice husk<br />

- Ultimate analysis of rice husk<br />

Carbon - 38.5%<br />

Hydrogen - 5.7%<br />

Oxygen - 39.8%<br />

Nitrogen - 0.5%<br />

Sulphur - 0%<br />

G.C.V. - 3200 K.Cal/kg<br />

Moisture <strong>in</strong> fuel - 8%<br />

Ash <strong>in</strong> fuel - 15%<br />

GCV of bottom <strong>as</strong>h - 900 K.Cal/kg<br />

GCV of fly <strong>as</strong>h - 650 K.Cal/kg<br />

Ratio of bottom <strong>as</strong>h to fly <strong>as</strong>h - 80:20<br />

Percentage of oxygen <strong>in</strong> flue g<strong>as</strong> - 7%<br />

Flue g<strong>as</strong> temperature - 200 ºC<br />

- 32 -<br />

GCV of <strong>Fuel</strong>