1 TAME synthesis problem Tert-Amyl Methyl Ether (TAME) is an ...

1 TAME synthesis problem Tert-Amyl Methyl Ether (TAME) is an ...

1 TAME synthesis problem Tert-Amyl Methyl Ether (TAME) is an ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

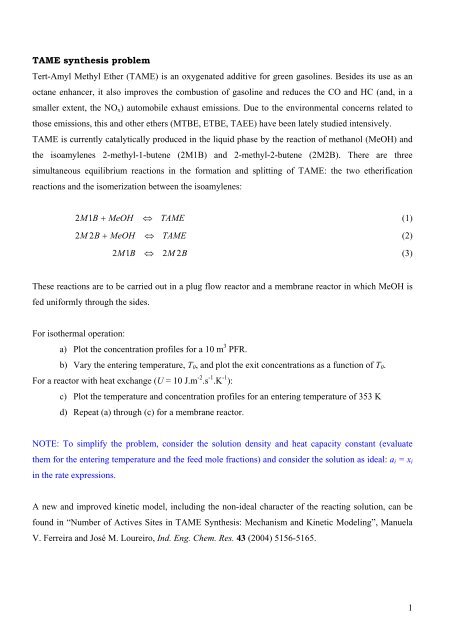

<strong>TAME</strong> <strong>synthes<strong>is</strong></strong> <strong>problem</strong><br />

<strong>Tert</strong>-<strong>Amyl</strong> <strong>Methyl</strong> <strong>Ether</strong> (<strong>TAME</strong>) <strong>is</strong> <strong>an</strong> oxygenated additive for green gasolines. Besides its use as <strong>an</strong><br />

oct<strong>an</strong>e enh<strong>an</strong>cer, it also improves the combustion of gasoline <strong>an</strong>d reduces the CO <strong>an</strong>d HC (<strong>an</strong>d, in a<br />

smaller extent, the NOx) automobile exhaust em<strong>is</strong>sions. Due to the environmental concerns related to<br />

those em<strong>is</strong>sions, th<strong>is</strong> <strong>an</strong>d other ethers (MTBE, ETBE, TAEE) have been lately studied intensively.<br />

<strong>TAME</strong> <strong>is</strong> currently catalytically produced in the liquid phase by the reaction of meth<strong>an</strong>ol (MeOH) <strong>an</strong>d<br />

the <strong>is</strong>oamylenes 2-methyl-1-butene (2M1B) <strong>an</strong>d 2-methyl-2-butene (2M2B). There are three<br />

simult<strong>an</strong>eous equilibrium reactions in the formation <strong>an</strong>d splitting of <strong>TAME</strong>: the two etherification<br />

reactions <strong>an</strong>d the <strong>is</strong>omerization between the <strong>is</strong>oamylenes:<br />

2 M1B + MeOH ⇔ <strong>TAME</strong><br />

(1)<br />

2 M 2B<br />

+ MeOH ⇔ <strong>TAME</strong><br />

(2)<br />

2M1B ⇔ 2M<br />

2B<br />

(3)<br />

These reactions are to be carried out in a plug flow reactor <strong>an</strong>d a membr<strong>an</strong>e reactor in which MeOH <strong>is</strong><br />

fed uniformly through the sides.<br />

For <strong>is</strong>othermal operation:<br />

a) Plot the concentration profiles for a 10 m 3 PFR.<br />

b) Vary the entering temperature, T0, <strong>an</strong>d plot the exit concentrations as a function of T0.<br />

For a reactor with heat exch<strong>an</strong>ge (U = 10 J.m -2 .s -1 .K -1 ):<br />

c) Plot the temperature <strong>an</strong>d concentration profiles for <strong>an</strong> entering temperature of 353 K<br />

d) Repeat (a) through (c) for a membr<strong>an</strong>e reactor.<br />

NOTE: To simplify the <strong>problem</strong>, consider the solution density <strong>an</strong>d heat capacity const<strong>an</strong>t (evaluate<br />

them for the entering temperature <strong>an</strong>d the feed mole fractions) <strong>an</strong>d consider the solution as ideal: ai = xi<br />

in the rate expressions.<br />

A new <strong>an</strong>d improved kinetic model, including the non-ideal character of the reacting solution, c<strong>an</strong> be<br />

found in “Number of Actives Sites in <strong>TAME</strong> Synthes<strong>is</strong>: Mech<strong>an</strong><strong>is</strong>m <strong>an</strong>d Kinetic Modeling”, M<strong>an</strong>uela<br />

V. Ferreira <strong>an</strong>d José M. Loureiro, Ind. Eng. Chem. Res. 43 (2004) 5156-5165.<br />

1

Additional information for solving the <strong>problem</strong><br />

• Thermodynamic equilibrium const<strong>an</strong>ts, activity based (Vilarinho Ferreira <strong>an</strong>d Loureiro, 2001)<br />

3<br />

⎛ 5.<br />

0166×<br />

10 ⎞<br />

Keq = exp ⎜<br />

− 10.<br />

839 ⎟<br />

1<br />

(I.1)<br />

⎝ T<br />

⎠<br />

3<br />

⎛ 3.<br />

7264×<br />

10 ⎞<br />

Keq = exp ⎜<br />

− 9.<br />

6367 ⎟<br />

2<br />

(I.2)<br />

⎝ T<br />

⎠<br />

Keq<br />

Keq = (I.3)<br />

1<br />

3<br />

Keq2<br />

with: T in Kelvin<br />

• Kinetic const<strong>an</strong>ts for the direct reactions (Kivir<strong>an</strong>ta-Pääkkönen et al., 1998)<br />

k<br />

k<br />

k<br />

1<br />

2<br />

3<br />

3<br />

10 ⎛ 76.<br />

8×<br />

10 ⎞<br />

= 3 . 2870 × 10 exp ⎜<br />

⎜−<br />

⎟<br />

(I.4)<br />

⎝ R T ⎠<br />

3<br />

13 ⎛ 99.<br />

7 × 10 ⎞<br />

= 3 . 9682 × 10 exp ⎜<br />

⎜−<br />

⎟<br />

(I.5)<br />

⎝ R T ⎠<br />

3<br />

10 ⎛ 81.<br />

7 × 10 ⎞<br />

= 7 . 4767 × 10 exp ⎜<br />

⎜−<br />

⎟<br />

(I.6)<br />

⎝ R T ⎠<br />

with: k in mol.<br />

T in Kelvin<br />

−1<br />

kg cat .s -1<br />

R = 8.314 J.mol -1 .K -1<br />

• Adsorption const<strong>an</strong>ts for each component, activity based (calculated <strong>an</strong>d adapted from Oktar et<br />

al., 1999)<br />

3<br />

⎛ 4.<br />

6825×<br />

10 ⎞<br />

K1B = exp ⎜<br />

− 10.<br />

157 ⎟ , 1B = 2M1B (I.7)<br />

⎝ T<br />

⎠<br />

3<br />

⎛ 3.<br />

4420 × 10 ⎞<br />

K = exp ⎜<br />

− 6.<br />

5849 ⎟<br />

2B<br />

, 2B = 2M2B (I.8)<br />

⎝ T<br />

⎠<br />

3<br />

⎛1.<br />

0014 × 10 ⎞<br />

K M = exp ⎜<br />

+ 4.<br />

7496 ⎟ , M = MeOH (I.9)<br />

⎝ T<br />

⎠<br />

3<br />

⎛ 2.<br />

3934 × 10 ⎞<br />

KT = exp ⎜<br />

− 3.<br />

5736 ⎟ , T = <strong>TAME</strong><br />

⎝ T<br />

⎠<br />

with: T in Kelvin<br />

(I.10)<br />

2

1B<br />

r<br />

2B<br />

• Heat of reaction (Vilarinho Ferreira <strong>an</strong>d Loureiro, 2001)<br />

R<br />

∆ H1 = - 41.708 kJ.mol -1<br />

R<br />

∆ H 2 = - 30.981 kJ.mol -1<br />

R<br />

∆ H 3 = - 10.727 kJ.mol -1<br />

• Bulk density <strong>an</strong>d bed porosity<br />

The PFR <strong>is</strong> filled with a macroreticular strong cation ion-exch<strong>an</strong>ge resin in hydrogen form<br />

(Amberlyst 15 Wet, Rohm & Haas).<br />

The bulk density <strong>is</strong>: ρ = 770 g / L<br />

The bed porosity <strong>is</strong>: ε = 0.4<br />

b<br />

• Rate equations for the formation of each component (Vilarinho Ferreira <strong>an</strong>d Loureiro, 2001)<br />

=<br />

=<br />

k<br />

1<br />

K<br />

2<br />

( 1 + K a + K a + K a + K a ) ( 1 + K a + K a + K a + K a )<br />

k<br />

2<br />

1B<br />

K<br />

M<br />

K<br />

1B<br />

1B<br />

a<br />

M<br />

2B<br />

a<br />

1B<br />

⎛ 1<br />

⎜<br />

⎝ Keq<br />

2B<br />

1<br />

M<br />

aT<br />

a a<br />

M<br />

M<br />

1B<br />

⎞<br />

−1<br />

⎟<br />

⎠<br />

T<br />

T<br />

+<br />

1B<br />

k<br />

3<br />

1B<br />

K<br />

1B<br />

a<br />

1B<br />

2B<br />

⎛ 1<br />

⎜<br />

⎝ Keq<br />

2B<br />

3<br />

a<br />

a<br />

2B<br />

1B<br />

M<br />

⎞<br />

−1<br />

⎟<br />

⎠<br />

2<br />

( 1 + K a + K a + K a + K a ) ( 1 + K a + K a + K a + K a )<br />

1B<br />

rM r1<br />

B r2<br />

B +<br />

T<br />

M<br />

K<br />

1B<br />

2B<br />

a<br />

M<br />

2B<br />

a<br />

1B<br />

⎛ 1<br />

⎜<br />

⎝ Keq<br />

2B<br />

2<br />

M<br />

aT<br />

a a<br />

M<br />

M<br />

2B<br />

⎞<br />

−1<br />

⎟<br />

⎠<br />

T<br />

T<br />

−<br />

1B<br />

k<br />

3<br />

1B<br />

K<br />

1B<br />

a<br />

1B<br />

2B<br />

⎛ 1<br />

⎜<br />

⎝ Keq<br />

2B<br />

3<br />

a<br />

a<br />

2B<br />

1B<br />

M<br />

M<br />

⎞<br />

−1<br />

⎟<br />

⎠<br />

M<br />

T<br />

T<br />

T<br />

T<br />

(I.11)<br />

(I.12)<br />

= (I.13)<br />

r = − r<br />

(I.14)<br />

M<br />

with: r in mol.<br />

−1<br />

kg cat .s -1<br />

ai st<strong>an</strong>ds for the activity of component i in the liquid phase, <strong>an</strong>d since we are considering the<br />

solution as ideal:<br />

a = x<br />

(I.15)<br />

i<br />

i<br />

where xi <strong>is</strong> the mole fraction of component i in the liquid phase.<br />

We c<strong>an</strong> also define the rate of each reaction:<br />

3

k<br />

K<br />

K<br />

a<br />

a<br />

1<br />

a<br />

⎞<br />

−1⎟<br />

( ) 2<br />

T<br />

1 M 1B<br />

M 1B<br />

⎜ Keq1<br />

aM<br />

a ⎟<br />

1B<br />

1 =<br />

⎝<br />

⎠<br />

(I.16)<br />

1 + K1B<br />

a1B<br />

+ K 2B<br />

a2<br />

B + K M aM<br />

+ KT<br />

aT<br />

r<br />

k<br />

K<br />

K<br />

a<br />

a<br />

⎛<br />

⎜<br />

1<br />

a<br />

⎞<br />

−1⎟<br />

( ) 2<br />

T<br />

2 M 2B<br />

M 1B<br />

⎜ Keq2<br />

aM<br />

a ⎟<br />

2B<br />

2 =<br />

⎝<br />

⎠<br />

(I.17)<br />

1 + K1B<br />

a1B<br />

+ K 2B<br />

a2<br />

B + K M aM<br />

+ KT<br />

aT<br />

r<br />

r<br />

3<br />

=<br />

1 + K<br />

1B<br />

k<br />

a<br />

3<br />

1B<br />

K<br />

1B<br />

a<br />

+ K<br />

1B<br />

2B<br />

2B<br />

⎛<br />

⎜<br />

⎛ 1 a<br />

⎜<br />

⎝ Keq3<br />

a<br />

a + K<br />

• Heat capacity of each component<br />

2B<br />

1B<br />

M<br />

⎞<br />

−1<br />

⎟<br />

⎠<br />

a +<br />

M<br />

K<br />

T<br />

a<br />

T<br />

(I.18)<br />

Cpi 2<br />

3<br />

= ai<br />

+ bi<br />

T + ci<br />

T + di<br />

T<br />

(I.19)<br />

with: Cp in kJ.mol -1 .K -1<br />

T in Kelvin<br />

component i 10 ai 10 4 bi 10 7 ci 10 10 di<br />

MeOH a<br />

2M1B b<br />

2M2B b<br />

<strong>TAME</strong> c<br />

0.077 1.62 2.06 2.87<br />

1.27 -0.609 5.08 1.69<br />

1.33 -1.48 7.51 -0.882<br />

1.73 2.29 -6.00 20.0<br />

a Zh<strong>an</strong>g <strong>an</strong>d Datta, 1995; b Kitchaiya <strong>an</strong>d Datta, 1995; c Estimated by the M<strong>is</strong>senard<br />

method (Reid et al., 1987)<br />

To simplify the <strong>problem</strong> we are going to consider the heat capacity of each component const<strong>an</strong>t<br />

<strong>an</strong>d equal to its value at the entry conditions: T = T0.<br />

The solution heat capacity will also be considered const<strong>an</strong>t <strong>an</strong>d equal to its value at the entry<br />

conditions:<br />

4<br />

∑<br />

i=<br />

1<br />

IN<br />

Cp = Cpi<br />

xi<br />

(I.20)<br />

where<br />

IN<br />

x i <strong>is</strong> the feed mole fraction of component i.<br />

4

• Density of each component (Perry <strong>an</strong>d Green, 1997)<br />

C1,<br />

i M i<br />

ρ (I.21)<br />

i<br />

= ⎡<br />

C ⎤<br />

⎢ ⎛ ⎞ 4,<br />

i<br />

⎜ T ⎟ ⎥<br />

⎢1<br />

+ 1 −<br />

⎜ ⎟ ⎥<br />

⎢<br />

⎣<br />

⎝<br />

C3,<br />

i ⎠ ⎥<br />

⎦<br />

C<br />

2,<br />

i<br />

with ρ in g.L -1<br />

T in Kelvin<br />

M in g.mol -1<br />

component i Mi C1,i C2,i C3,i C4,i<br />

MeOH<br />

2M1B<br />

2M2B<br />

<strong>TAME</strong><br />

32.042 2.288 0.2685 512.64 0.2453<br />

70.135 0.91619 0.26752 465 0.28164<br />

70.135 0.93322 0.27251 471 0.26031<br />

102.177 * * * *<br />

* as there <strong>is</strong> no data available for <strong>TAME</strong>, we will consider its density const<strong>an</strong>t <strong>an</strong>d equal to its<br />

value at 293 K: ρ = 770 g / L<br />

<strong>TAME</strong><br />

To simplify the <strong>problem</strong> we are going to consider the heat capacity of each component const<strong>an</strong>t<br />

<strong>an</strong>d equal to its value at the entry conditions: T = T0.<br />

The solution density will also be considered const<strong>an</strong>t <strong>an</strong>d equal to its value at the entry<br />

conditions:<br />

4<br />

∑<br />

i=<br />

1<br />

IN<br />

ρ = ρ<br />

(I.22)<br />

i xi<br />

5

Starting solving the <strong>problem</strong><br />

Writing mass <strong>an</strong>d energy bal<strong>an</strong>ces<br />

In the figure <strong>is</strong> a representation of a PFR filled with a catalyst.<br />

Fig. 1:Representaion of a PFR filled with catalyst.<br />

A. Steady state mass bal<strong>an</strong>ce<br />

For the steady state mass bal<strong>an</strong>ce of component i, in the volume element of length dz, we c<strong>an</strong> write:<br />

Total Flux IN = Total Flux OUT − What <strong>is</strong> formed by Chemical Re action<br />

(A.1)<br />

z<br />

z+<br />

dz<br />

If ε <strong>is</strong> the bed porosity, the area, A, available for the catalyst particles <strong>is</strong> [(1-ε) A] <strong>an</strong>d the area available<br />

for the fluid <strong>is</strong> [ε A]. Equation (A.1) becomes:<br />

( ε ) ϕ ( ε A)<br />

ϕ − ρ r Adz<br />

A i,<br />

z = i,<br />

z+<br />

dz b i<br />

(A.2)<br />

where ϕi <strong>is</strong> the molar flux of component i, ρb <strong>is</strong> the bulk density <strong>an</strong>d ri <strong>is</strong> the rate of formation of<br />

component i.<br />

Re-writing equation (A.2):<br />

ϕ<br />

dϕ<br />

dz<br />

i,<br />

z+<br />

dz<br />

− ϕ i,<br />

z ρ b<br />

− ri<br />

= 0<br />

dz ε<br />

ρ<br />

i b<br />

− ri<br />

ε<br />

= 0<br />

IN<br />

Ci<br />

Considering a plug flow with axial d<strong>is</strong>persion, the molar flux <strong>is</strong> given by:<br />

z<br />

dz<br />

z+dz<br />

z = 0 z = L<br />

A<br />

OUT<br />

Ci<br />

(A.3)<br />

(A.4)<br />

6

dCi<br />

ϕ i = ui<br />

Ci<br />

− Dax<br />

(A.5)<br />

dz<br />

where ui <strong>is</strong> the interstitial velocity of the fluid, Ci <strong>is</strong> the concentration of component i in the fluid <strong>an</strong>d<br />

Dax <strong>is</strong> the axial d<strong>is</strong>persion coefficient.<br />

u<br />

i<br />

dC<br />

dz<br />

d<br />

2<br />

i<br />

− Dax<br />

i<br />

2 −<br />

b<br />

ri<br />

dz<br />

C<br />

ρ<br />

ε<br />

= 0<br />

Normalizing some of the variables:<br />

IN<br />

C i <strong>is</strong> the feed concentration of component i),<br />

ui<br />

C<br />

L<br />

IN<br />

total<br />

dividing by<br />

df<br />

i<br />

dX<br />

df i<br />

dX<br />

u<br />

D<br />

d<br />

2<br />

−<br />

ax<br />

2<br />

IN<br />

Ctotal<br />

i<br />

2 −<br />

b<br />

ri<br />

L<br />

i IN<br />

Ctotal<br />

L<br />

1 d<br />

Pe<br />

f<br />

dX<br />

2<br />

i b<br />

− − τ r<br />

2 IN i<br />

dX ε Ctotal<br />

f<br />

ρ<br />

ε<br />

(A.6)<br />

z<br />

Ci<br />

IN<br />

IN<br />

X = (L <strong>is</strong> the PFR length), f = ( C IN total ∑C<br />

i where<br />

L<br />

= 0<br />

, equation (A.7) becomes:<br />

ρ<br />

= 0<br />

where Pe <strong>is</strong> the dimensionless Peclet number given by<br />

ρ b<br />

Grouping the term τ r IN i<br />

ε C<br />

component i becomes:<br />

df<br />

i<br />

dX<br />

total<br />

1 d f<br />

Pe dX<br />

2<br />

i<br />

− − ℜ 2 i<br />

ax<br />

i<br />

Ctotal<br />

= i<br />

ui<br />

L<br />

, <strong>an</strong>d τ <strong>is</strong> the space-time given by<br />

D<br />

L<br />

.<br />

ui<br />

(A.7)<br />

(A.8)<br />

as a reaction term represented by ℜ i , the steady state mass bal<strong>an</strong>ce of<br />

= 0<br />

⎛ 1 ⎞<br />

In the limiting case of absence of d<strong>is</strong>persion ⎜ →0 ⎟ , equation (A.9) becomes:<br />

⎝ Pe ⎠<br />

df i<br />

dX<br />

− ℜi<br />

= 0<br />

(A.9)<br />

(A.10)<br />

7

B. Steady state energy bal<strong>an</strong>ce<br />

For the steady state energy bal<strong>an</strong>ce in the volume element of length dz, considering no d<strong>is</strong>persion, we<br />

c<strong>an</strong> write:<br />

heat produced by<br />

Total Flux IN + = Total Flux OUT<br />

z<br />

z+<br />

dz<br />

Chemical Re action<br />

M reactions<br />

h<br />

R<br />

h<br />

( ε A) ϕ z + ρ b ∑(<br />

∆H<br />

j rj<br />

) Adz<br />

= ( ε A)<br />

ϕ z+<br />

dz + Alat<br />

U ( T −Tw<br />

)<br />

j=<br />

1<br />

where ϕ h <strong>is</strong> the heat flux,<br />

R<br />

j<br />

heat losses through<br />

+<br />

reactor walls<br />

(B.1)<br />

(B.2)<br />

∆ H <strong>is</strong> the heat of reaction j, rj <strong>is</strong> the rate of reaction j, Alat <strong>is</strong> the lateral area<br />

of the volume element, U <strong>is</strong> the overall heat-tr<strong>an</strong>sfer coefficient, T <strong>is</strong> the reactor temperature <strong>an</strong>d Tw <strong>is</strong><br />

the reactor wall temperature.<br />

Re-writing equation (B.2):<br />

M reactions<br />

b ∑<br />

j=<br />

1<br />

R Alat<br />

( ∆H<br />

r ) + U ( T −T<br />

) = 0<br />

h h<br />

ϕ z+<br />

dz −ϕ<br />

x ε − ρ<br />

j j<br />

w<br />

(B.3)<br />

dz<br />

A dz<br />

The heat flux c<strong>an</strong> be given by:<br />

h<br />

ϕ = ρ CpT<br />

(B.4)<br />

u i<br />

where ρ <strong>is</strong> the solution density <strong>an</strong>d Cp <strong>is</strong> the solution heat capacity.<br />

If R0 <strong>is</strong> the reactor radius, the lateral area of the volume element of length dz <strong>is</strong>:<br />

= 2π R dz<br />

(B.5)<br />

A lat 0<br />

<strong>an</strong>d its sectional area <strong>is</strong>:<br />

A = π R<br />

(B.6)<br />

2<br />

0<br />

leading to:<br />

Alat 2<br />

= (B.7)<br />

Adz<br />

R<br />

0<br />

Substituting into equation (B.3):<br />

8

− b ∑<br />

j=<br />

1<br />

R 2<br />

( ∆H<br />

r ) + U ( T −T<br />

) = 0<br />

M reactions<br />

dT<br />

ε ui ρ Cp ρ<br />

j j<br />

w<br />

(B.8)<br />

dz<br />

R<br />

Normalizing the space variable:<br />

rearr<strong>an</strong>ging equation (B.8):<br />

M reactions<br />

b<br />

− ∑ ρ Cp j=<br />

1<br />

0<br />

z<br />

X = , remembering the space-time definition<br />

⎛ ⎞<br />

⎜τ<br />

= L ⎟ <strong>an</strong>d<br />

L<br />

⎝ ui<br />

⎠<br />

R 2U<br />

τ<br />

( ∆H<br />

r ) + ( T −T<br />

) = 0<br />

dT ρ τ<br />

ε j j<br />

w<br />

(B.9)<br />

dX<br />

ρ Cp R<br />

The term<br />

2U<br />

τ<br />

ρ Cp R<br />

0<br />

0<br />

<strong>is</strong> dimensionless <strong>an</strong>d <strong>is</strong> referred as NTU (number of heat tr<strong>an</strong>sfer units).<br />

Finally, the steady state energy bal<strong>an</strong>ce becomes:<br />

M reactions<br />

b<br />

− ∑ ρ Cp j=<br />

1<br />

R ( ∆H<br />

r ) + NTU ( T −T<br />

) = 0<br />

dT ρ τ<br />

ε j j<br />

w<br />

(B.10)<br />

dX<br />

C. Boundary Conditions<br />

In the absence of d<strong>is</strong>persion, we only need one boundary condition:<br />

IN ⎧ Ci<br />

⎪ fi<br />

=<br />

X = 0 ⇒<br />

IN<br />

⎨ C<br />

(C.1)<br />

total<br />

⎪<br />

⎩ T = T0<br />

where T0 <strong>is</strong> the initial reactor temperature.<br />

9

Algorithm to solve the <strong>problem</strong><br />

We have a non-linear system of Ordinary Differential Equations (ODE) to solve:<br />

⎧ 1B<br />

⎪ − ℜ1B<br />

= 0<br />

⎪<br />

2B<br />

⎪ − ℜ2<br />

B = 0<br />

⎪<br />

⎪ M<br />

⎨ − ℜ M = 0<br />

⎪<br />

⎪<br />

dfT<br />

− ℜT<br />

= 0<br />

⎪ dX<br />

3<br />

⎪ dT b<br />

⎪ − ∑<br />

⎩ dX Cp j=<br />

dX<br />

df<br />

dX<br />

df<br />

dX<br />

df<br />

ρ τ<br />

ε<br />

ρ<br />

1<br />

R ( ∆H<br />

r ) + NTU ( T −T<br />

)<br />

j<br />

j<br />

w<br />

= 0<br />

The program we developed uses subroutine DDASSL (Bren<strong>an</strong> et al., 1989) to solve th<strong>is</strong> system. Th<strong>is</strong><br />

code solves a system of differential/algebraic equations of the form delta(t, y, yprime)=0, with<br />

delta(i) = yprime(i) – y(i), using the backward differentiation formulas of orders one trough five. t <strong>is</strong><br />

the current value of the independent variable (in our case t = X), y <strong>is</strong> the array that contains the solution<br />

components at t (in our case we have: y(i) = f(i), i=1,4 <strong>an</strong>d y(5) = T) <strong>an</strong>d yprime <strong>is</strong> the array that<br />

contains the derivatives of the solution components at t.<br />

The program solves the system from t to tout <strong>an</strong>d it <strong>is</strong> easy to continue the solution to get results at<br />

additional tout. In our case, we are going to get results at different values of X, between 0 <strong>an</strong>d 1.<br />

Th<strong>is</strong> <strong>problem</strong> <strong>is</strong> rather complex because most of the other variables depend on yi: the kinetic, adsorption<br />

<strong>an</strong>d thermodynamic equilibrium “const<strong>an</strong>ts” depend on T (y5), the reaction rate <strong>an</strong>d the components rate<br />

of formation depend on yi (fi (i=1,4) <strong>an</strong>d T), as the activity coefficients.<br />

In Figure 2 <strong>is</strong> the algorithm to solve our <strong>problem</strong>.<br />

(1)<br />

10

Read data from file<br />

T0, Tw IN<br />

C i<br />

Q (operation flow)<br />

Input const<strong>an</strong>ts values<br />

ε, ρb, U, R 0,<br />

V (reactor volume)<br />

∆ H<br />

R<br />

j<br />

Calculate const<strong>an</strong>ts<br />

ε V<br />

τ =<br />

Q<br />

C C<br />

IN<br />

total = ∑<br />

i<br />

IN<br />

i<br />

IN<br />

0 Ci<br />

f i = IN<br />

Ctotal<br />

Initialize the variables<br />

t = X = 0<br />

yi (i=1,4) = f<br />

y5 = T 0<br />

0<br />

i<br />

Solve system of ODEs<br />

Call<br />

subroutine DASSL<br />

New values<br />

of<br />

yi<br />

Cp<br />

ρ<br />

NTU<br />

tout = X =<br />

X + ∆X<br />

No<br />

tout = X = 1 ?<br />

Fig. 2: Algorithm to solve the <strong>problem</strong>.<br />

Yes<br />

STOP<br />

11

Some results<br />

For both cases, <strong>is</strong>othermal <strong>an</strong>d non-<strong>is</strong>othermal, the feed concentrations were the same:<br />

C<br />

C<br />

C<br />

C<br />

IN<br />

2M<br />

1B<br />

IN<br />

2M<br />

2B<br />

IN<br />

MeOH<br />

IN<br />

<strong>TAME</strong><br />

=<br />

=<br />

=<br />

= 0<br />

3.<br />

33<br />

3.<br />

33<br />

6.<br />

66<br />

mol / L<br />

mol / L<br />

mol / L<br />

These concentrations lead to a feed mole ratio MeOH/<strong>is</strong>oamylenes, RM/IA, of 1.0.<br />

a) Figures R.1, R.2 <strong>an</strong>d R.3 represent the concentration profiles for a 10 m 3 <strong>is</strong>othermal PFR, operating<br />

at 323 K, 343 K <strong>an</strong>d 363 K, <strong>an</strong>d a flow of 40 L/min.<br />

C (mol/L)<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Isothermal: T = 323 K<br />

RM/IA = 1, Q = 40 L/min<br />

0 0.2 0.4 0.6 0.8 1<br />

X<br />

2M1B 2M2B MeOH <strong>TAME</strong><br />

Fig. R.1: Concentration profiles for a 10 m 3 <strong>is</strong>othermal PFR operating at 323 K.<br />

12

C (mol/L)<br />

Fig. R.2: Concentration profiles for a 10 m 3 <strong>is</strong>othermal PFR operating at 343 K.<br />

C (mol/L)<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Isothermal: T = 343 K<br />

RM/IA = 1, Q = 40 L/min<br />

0 0.2 0.4 0.6 0.8 1<br />

X<br />

2M1B 2M2B MeOH <strong>TAME</strong><br />

Isothermal: T = 363 K<br />

RM/IA = 1, Q = 40 L/min<br />

0 0.2 0.4 0.6 0.8 1<br />

X<br />

2M1B 2M2B MeOH <strong>TAME</strong><br />

Fig. R.3: Concentration profiles for a 10 m 3 <strong>is</strong>othermal PFR operating at 363 K<br />

As the temperature increases, the reactions are faster, favoring <strong>TAME</strong> production, but the chemical<br />

equilibrium <strong>is</strong> moved to the opposite direction: for <strong>an</strong> operating temperature of 363 K, the equilibrium<br />

concentration of <strong>TAME</strong> <strong>is</strong> reached faster th<strong>an</strong> for 343 K, but its value <strong>is</strong> lower.<br />

13

) Figure R.4 represents the exit concentrations as a function of the entering temperature, T0, for a 10<br />

m 3 <strong>is</strong>othermal PFR operating with a flow of 40 L/min.<br />

C OUT (mol/L)<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Isothermal operation<br />

RM/IA = 1.0, Q = 40 L/min<br />

323 333 343 353 363<br />

T0 (K)<br />

2M1B 2M2B MeOH <strong>TAME</strong><br />

Fig. R.4: Exit concentrations as function of T0, for a 10 m 3 <strong>is</strong>othermal PFR<br />

Figure R.4 shows that there <strong>is</strong> <strong>an</strong> optimum operating temperature around 333 K that leads to a<br />

maximum exit concentration for <strong>TAME</strong>. It <strong>is</strong> due to the fact that we have a system with competition<br />

between kinetics <strong>an</strong>d equilibrium, as we are going to see for the non-<strong>is</strong>othermal PFR<br />

c) We chose a reactor diameter of 1 m (for a volume of 10 m 3 it leads to a reactor length of 12.7 m<br />

approximately) <strong>an</strong>d for the wall temperature, we decided to use room temperature: 298 K. The entering<br />

temperature <strong>is</strong> 353 K.<br />

It <strong>is</strong> import<strong>an</strong>t to notice that the catalyst used in <strong>TAME</strong> production <strong>is</strong> a macroreticular strong cation ionexch<strong>an</strong>ge<br />

resin in hydrogen form (Amberlyst 15 Wet, Rohm & Haas) that has a maximum operating<br />

temperature of 393 K.<br />

Figure R.5 represents the concentration (a) <strong>an</strong>d temperature (b) profiles for <strong>an</strong> operating flow of 200<br />

L/min.<br />

14

(a)<br />

(b)<br />

C (mol/L)<br />

T (K)<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

390<br />

380<br />

370<br />

360<br />

350<br />

Non-Isothernal: To = 353 K, Tw = 298 K<br />

RM/IA = 1.0, Q = 200 L/min<br />

0 0.2 0.4 0.6 0.8 1<br />

X<br />

2M1B 2M2B MeOH <strong>TAME</strong><br />

0 0.2 0.4 0.6 0.8 1<br />

X<br />

Fig. R.5: Non-<strong>is</strong>othermal PFR: (a) concentration profiles; (b) temperature profile.<br />

Figure R.5(a) shows the competition between the three reactions: first, 2M1B <strong>an</strong>d 2M2B react with<br />

MeOH to produce <strong>TAME</strong> <strong>an</strong>d the react<strong>an</strong>ts concentrations decrease <strong>an</strong>d <strong>TAME</strong> concentration<br />

increases; but then, although MeOH <strong>an</strong>d <strong>TAME</strong> concentrations are almost const<strong>an</strong>t, 2M1B <strong>is</strong> still<br />

decreasing <strong>an</strong>d 2M2B starts to increase: the third reaction, the <strong>is</strong>omerization, <strong>is</strong> now more evident.<br />

The temperature profile (Fig. R.5(b)) shows that the reactor seams to be almost adiabatic (no heat losses<br />

through the reactor walls) since the reactor temperature <strong>is</strong> always increasing. Th<strong>is</strong> close to adiabatic<br />

behavior was expected since the reactor diameter <strong>is</strong> rather large: 1 m. But the temperature reaches a<br />

value that <strong>is</strong> very close to the catalyst limit: remember that its maximum operating temperature <strong>is</strong> 393 K<br />

<strong>an</strong>d the reactor <strong>is</strong> reaching 385 K.<br />

15

To see what <strong>is</strong> the maximum temperature that the reactor reaches, we c<strong>an</strong> make it adiabatic setting the<br />

overall heat-tr<strong>an</strong>sfer coefficient equal to zero: U = 0. In Figure R.6 are the results for the adiabatic<br />

reactor.<br />

(a)<br />

C (mol/L)<br />

(b)<br />

T (K)<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

390<br />

380<br />

370<br />

360<br />

350<br />

Adiabatic operation: To = 353 K<br />

RM/IA = 1.0, Q = 200 L/min<br />

0 0.2 0.4 0.6 0.8 1<br />

X<br />

2M1B 2M2B MeOH <strong>TAME</strong><br />

0 0.2 0.4 0.6 0.8 1<br />

X<br />

Fig. R.6: Adiabatic PFR: (a) concentration profiles; (b) temperature profile.<br />

The maximum temperature reached by the reactor <strong>is</strong> 388 K. Comparing Figures R.5 <strong>an</strong>d R.6 it <strong>is</strong> easy to<br />

see that the non-<strong>is</strong>othermal 1m diameter PFR c<strong>an</strong> be considered adiabatic: the concentration <strong>an</strong>d<br />

temperature profiles are almost the same.<br />

To improve the reactor production, i.e., to reach higher exit concentrations of <strong>TAME</strong>, we c<strong>an</strong> use a<br />

multi-tubular reactor. Lets think of a reactor composed of 4000 tubes (each one considered as a PFR)<br />

16

with a diameter of 1’’ each. To have a total reactor volume of 10 m 3 , each tube has a length of 5 m. In<br />

order to compare the results of the multi-tubular reactor with the ones obtained with the 1 m diameter<br />

PFR (Fig. R.5), we have to choose similar operating conditions: to have a total operating flow of 200<br />

L/min, the equivalent flow in each tube <strong>is</strong> 0.05 L/min; since the reactor <strong>is</strong> now really cooled, we will<br />

choose the “best” temperature for the cooling fluid (333 K, as seen with the <strong>is</strong>othermal behavior runs).<br />

Figure R.7 shows the results for one of th<strong>is</strong> tubes operating in the above conditions.<br />

(a)<br />

C (mol/L)<br />

(b)<br />

T (K)<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

360<br />

358<br />

356<br />

354<br />

352<br />

350<br />

Non-Isothermal Multi-tubular reactor<br />

To = 353 K, Tw = 333 K, Qtotal = 200 L/min<br />

0 0.2 0.4 0.6 0.8 1<br />

X<br />

2M1B 2M2B MeOH <strong>TAME</strong><br />

0 0.2 0.4 0.6 0.8 1<br />

X<br />

Fig. R.7: Multi-tubular reactor: (a) concentration profiles; (b) temperature profile.<br />

The maximum temperature reached <strong>is</strong> 358 K - in th<strong>is</strong> case there are no <strong>problem</strong>s with the catalyst - <strong>an</strong>d<br />

the exit concentration of <strong>TAME</strong> <strong>is</strong> higher: 2.603 mol/L against 1.862 mol/L for the PFR in Figure R.5,<br />

which represents <strong>an</strong> increase of 28.5 %.<br />

17

References<br />

Bren<strong>an</strong>, K., Campbell, S. <strong>an</strong>d L. Petzold, “Numerical Solution of Initial-Value Problems in<br />

Differencial-Algebraic Equations, Elsevier, N.Y. (1989).<br />

Kitchaiya, P. <strong>an</strong>d R. Datta, “<strong>Ether</strong>s from Eth<strong>an</strong>ol. 2. Reaction Equilibria of Simult<strong>an</strong>eous tert-amyl<br />

Ethyl <strong>Ether</strong> Synthes<strong>is</strong> <strong>an</strong>d Isoamylene Isomerization”, Ind. Eng. Chem. Res. 34 (1995) 1092-1101.<br />

Kivir<strong>an</strong>ta-Pääkkönen, P.K., Struckm<strong>an</strong>, L.K. <strong>an</strong>d A.O.I. Krause, “Compar<strong>is</strong>on of the Various Kinetic<br />

Models of <strong>TAME</strong> Formation by Simulation <strong>an</strong>d Parameter Estimation”, Chem. Eng. Technol. 21 (1998)<br />

321-326.<br />

Oktar, N., Mürtezaoglu, K., Dogu, T. <strong>an</strong>d Gülsen Dogu, “Dynamic Analys<strong>is</strong> of Adsorption Equilibrium<br />

<strong>an</strong>d Rate Parameters of React<strong>an</strong>ts <strong>an</strong>d Products in MTBE, ETBE <strong>an</strong>d <strong>TAME</strong> Production”, C<strong>an</strong>.J.<br />

Chem. Eng. 77 (1999) 406-412.<br />

Perry, R.H. <strong>an</strong>d D<strong>an</strong> W. Green, “Perry’s Chemical Engineers’ H<strong>an</strong>dbook”, 7 th edition, McGraw-Hill<br />

(1997).<br />

Reid, R.C., Prausnitz, J.M. <strong>an</strong>d Thomas K. Sherwood, “The Properties of Gases <strong>an</strong>d Liquids”, 3 rd<br />

edition, McGraw-Hill (1977).<br />

Reid, R.C., Prausnitz, J.M. <strong>an</strong>d B.E. Poling, “The Properties of Gases <strong>an</strong>d Liquids”, 4 th edition,<br />

McGraw-Hill (1987).<br />

Vilarinho Ferreira, M.M. <strong>an</strong>d J.M. Loureiro, “Synthes<strong>is</strong> of <strong>TAME</strong>: Kinetics in Batch Reactor <strong>an</strong>d<br />

Thermodynamic Study”, presented on the “3 rd Europe<strong>an</strong> Congress of Chemical Engineering, ECCE3”,<br />

Nuremberg, Germ<strong>an</strong>y (June 2001).<br />

Zh<strong>an</strong>g, T. <strong>an</strong>d R. Datta, “Integral Analys<strong>is</strong> of <strong>Methyl</strong> tert-Butyl <strong>Ether</strong> Synthes<strong>is</strong> Kinetics”, Ind. Eng.<br />

Chem. Res. 34 (1995) 730-740.<br />

18