technical and economic study of drying and granulation of ... - Helcom

technical and economic study of drying and granulation of ... - Helcom

technical and economic study of drying and granulation of ... - Helcom

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

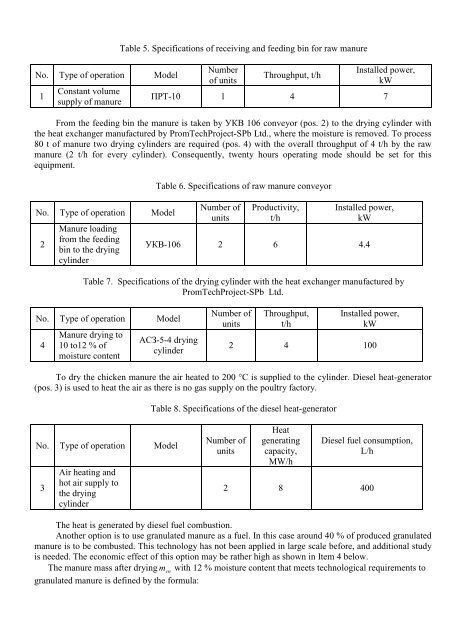

No. Type <strong>of</strong> operation Model<br />

1<br />

Constant volume<br />

supply <strong>of</strong> manure<br />

Table 5. Specifications <strong>of</strong> receiving <strong>and</strong> feeding bin for raw manure<br />

Number<br />

<strong>of</strong> units<br />

Throughput, t/h<br />

Installed power,<br />

kW<br />

ПРТ-10 1 4 7<br />

From the feeding bin the manure is taken by УКВ 106 conveyor (pos. 2) to the <strong>drying</strong> cylinder with<br />

the heat exchanger manufactured by PromTechProject-SPb Ltd., where the moisture is removed. To process<br />

80 t <strong>of</strong> manure two <strong>drying</strong> cylinders are required (pos. 4) with the overall throughput <strong>of</strong> 4 t/h by the raw<br />

manure (2 t/h for every cylinder). Consequently, twenty hours operating mode should be set for this<br />

equipment.<br />

No. Type <strong>of</strong> operation Model<br />

2<br />

Manure loading<br />

from the feeding<br />

bin to the <strong>drying</strong><br />

cylinder<br />

Table 6. Specifications <strong>of</strong> raw manure conveyor<br />

Number <strong>of</strong><br />

units<br />

Productivity,<br />

t/h<br />

Installed power,<br />

kW<br />

УКВ-106 2 6 4.4<br />

Table 7. Specifications <strong>of</strong> the <strong>drying</strong> cylinder with the heat exchanger manufactured by<br />

PromTechProject-SPb Ltd.<br />

No. Type <strong>of</strong> operation Model<br />

4<br />

Manure <strong>drying</strong> to<br />

10 to12 % <strong>of</strong><br />

moisture content<br />

АСЗ-5-4 <strong>drying</strong><br />

cylinder<br />

Number <strong>of</strong><br />

units<br />

Throughput,<br />

t/h<br />

Installed power,<br />

kW<br />

2 4 100<br />

To dry the chicken manure the air heated to 200 °C is supplied to the cylinder. Diesel heat-generator<br />

(pos. 3) is used to heat the air as there is no gas supply on the poultry factory.<br />

No. Type <strong>of</strong> operation Model<br />

3<br />

Air heating <strong>and</strong><br />

hot air supply to<br />

the <strong>drying</strong><br />

cylinder<br />

Table 8. Specifications <strong>of</strong> the diesel heat-generator<br />

Number <strong>of</strong><br />

units<br />

Heat<br />

generating<br />

capacity,<br />

MW/h<br />

Diesel fuel consumption,<br />

L/h<br />

2 8 400<br />

The heat is generated by diesel fuel combustion.<br />

Another option is to use granulated manure as a fuel. In this case around 40 % <strong>of</strong> produced granulated<br />

manure is to be combusted. This technology has not been applied in large scale before, <strong>and</strong> additional <strong>study</strong><br />

is needed. The <strong>economic</strong> effect <strong>of</strong> this option may be rather high as shown in Item 4 below.<br />

The manure mass after <strong>drying</strong> m cn with 12 % moisture content that meets technological requirements to<br />

granulated manure is defined by the formula: