Instruction Manual - Rodney Hunt Company

Instruction Manual - Rodney Hunt Company

Instruction Manual - Rodney Hunt Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

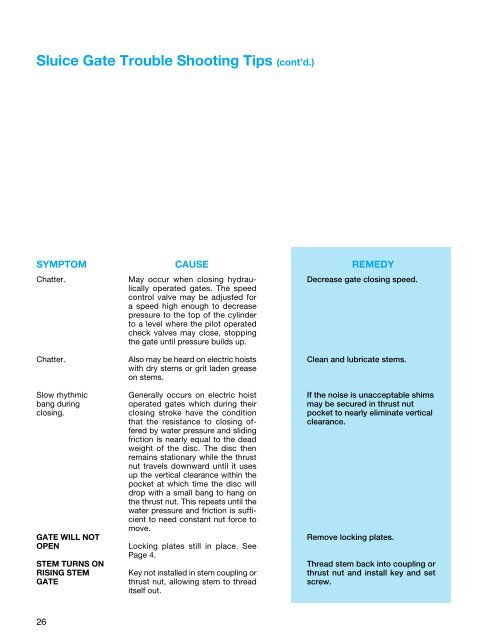

Sluice Gate Trouble Shooting Tips (cont’d.)<br />

SYMPTOM CAUSE REMEDY<br />

Chatter.<br />

Chatter.<br />

Slow rhythmic<br />

bang during<br />

closing.<br />

GATE WILL NOT<br />

OPEN<br />

STEM TURNS ON<br />

RISING STEM<br />

GATE<br />

26<br />

May occur when closing hydraulically<br />

operated gates. The speed<br />

control valve may be adjusted for<br />

a speed high enough to decrease<br />

pressure to the top of the cylinder<br />

to a level where the pilot operated<br />

check valves may close, stopping<br />

the gate until pressure builds up.<br />

Also may be heard on electric hoists<br />

with dry stems or grit laden grease<br />

on stems.<br />

Generally occurs on electric hoist<br />

operated gates which during their<br />

closing stroke have the condition<br />

that the resistance to closing offered<br />

by water pressure and sliding<br />

friction is nearly equal to the dead<br />

weight of the disc. The disc then<br />

remains stationary while the thrust<br />

nut travels downward until it uses<br />

up the vertical clearance within the<br />

pocket at which time the disc will<br />

drop with a small bang to hang on<br />

the thrust nut. This repeats until the<br />

water pressure and friction is sufficient<br />

to need constant nut force to<br />

move.<br />

Locking plates still in place. See<br />

Page 4.<br />

Key not installed in stem coupling or<br />

thrust nut, allowing stem to thread<br />

itself out.<br />

Decrease gate closing speed.<br />

Clean and lubricate stems.<br />

If the noise is unacceptable shims<br />

may be secured in thrust nut<br />

pocket to nearly eliminate vertical<br />

clearance.<br />

Remove locking plates.<br />

Thread stem back into coupling or<br />

thrust nut and install key and set<br />

screw.